Abstract

Chemical diffusion and reaction are generally involved in the formation of materials. These two processes are coupled together and play a role in the structure evolution of materials. Although the individual role of diffusion and reaction has been investigated, it is still unclear how these two factors work together to determine the materials structure and what is the mechanism behind. Firstly we used different approaches to regulate the diffusion and reaction rates in the synthesis of silver particles [1-3]. The role of diffusion and reaction in shaping particles was generalized. At a diffusion limitation, small silver particles were obtained and big polyhedral particles were formed at a reaction limitation. In the middle range of diffusion and reaction, dendritic structures were largely produced, which is independent on the preparation methods. In the following, the control on diffusion and reaction has been extended to synthesize other materials and the similar results were obtained [4-6], which further confirms the general role of diffusion and reaction in shaping materials. The Damkoehler number was employed to quantify the relative change of diffusion and reaction[7]. It was found that the morphology of materials is dependent on the relative strength of diffusion and reaction. Since the diffusion and reaction determine the chemical distribution around the growth front of materials, the local chemical gradient was proposed to be the mechanism of diffusion and reaction controlling materials structures, which was verified by measuring the local chemical distribution by laser interference as well as by conducting phase field simulation.

References

[1] Chemical Engineering Science 2018, 192, 254-263.

[2] Chemical Engineering Science 2015, 138, 457-464.

[3] Ind. Eng. Chem. Res. 2016, 55, 8319-8326.

[4] CrystEngComm 2017, 19, 72-79.

[5] Crystal Growth & Design 2013, 13, 1820-1825.

[6] Advanced Energy Materials, 2019, doi.org/10.1002/aenm.201900019.

[7] Crystal Growth & Design 2016, 16, 2850-2859.

Numerical modeling plays a leading part for virtual manufacturing in industries. When numerical technologies are utilized in the general industrial systems, high-accuracy, simple operation and calculation efficiency are always required. The requirements are the same even in powder industries. In the author's group, innovative models such as coupled discrete element method (DEM) with volume-of-fluid (VOF), signed distance functions (SDF) and coarse graining DEM have been developed for the simulations of granular flows in industrial powder systems. The SDF makes it possible to create an arbitrary shape domain by simple operation. The SDF has been applied to various powder systems such as mixers, die filling and conveyers so far. Besides, calculation domain for simulations of industrial multi-phase flows including solid particles can be created easily by combining the SDF with immersed boundary method (IBM). The coarse graining DEM is a scaling law model and can simulate large-scale systems by smaller number of computational particles than actual ones. Efficiency of the coarse graining DEM has been examined through several industrial systems such as a spouted bed and a fluidized bed. The DEM-VOF method can simulate gas-solid-liquid flows in an arbitrary shape domain because the SDF and the IBM has been introduced as wall boundary model. The DEM-VOF has been applied to a complex gas-solid-liquid flow system such as a twin screw kneader. Adequacy of these models has been proven through verification and validation tests. Hence, in the future, usage and/or combination of these models will be useful for virtual manufacturing.

This study is financially supported by JSPS KAKENHI grants (17KK0110, 17H02825 and 17H03451).

The inhaled drugs are generated as aerosol in dry powder inhalers (DPIs) and then delivered into respiratory tract. The deposition in the target sites mainly depends on a number of factors related to anatomical structure variation, particle characteristics and inhalation conditions (inhaled angle and breathing pattern e.g.). This project aims to numerically and experimentally investigate the effects of inhalation parameters on fine particle deposition in the US pharmacopeia throat (USP), idealized mouth-throat (IMT) and realistic mouth-throat (RMT) models with a commercial inhaler (Handihaler®). In the numerical model, the flow-field equations are solved by computational fluid dynamics (CFD). The monodispersed and Rosin-Rammler distributed particles in the size range of 1-20 μm are tracked with discrete phase method (DPM). Corresponding physical experiments under the same inhalation conditions are designed to quantitatively and qualitatively characterize particle deposition in realistic mouth-throat as well as validate the numerical results. The results indicate that particle deposition fraction and spatial distribution are highly sensitive to the geometrical variation and respiratory conditions such as the inhalation airflow rate, particle size and inhalation angle. Moreover, the effect of geometrical variation on the particle deposition pattern is more dominant. In the RMT model, inhalation angle creates quite obvious effect on the aerosol delivery, especially for particles depositing in oral cavity. This study could be used to develop an in vitro method which aims to better predict in vivo lung deposition mechanisms of pharmaceutical aerosol.

Keywords: computational fluid dynamics, particle deposition, dry powder inhalers, mouth-throat geometry.

There are continuum and discrete approaches to describe granular flows. A continuum approach relies on local average quantities which can be derived through an averaging method based on a discrete approach. But the selection of averaging domain and the validity of local quantities for constitutive relations are not well established, particularly for transient particle-fluid flows. This presentation is about our recent study in this direction for non-cohesive and cohesive particles. Here, it is demonstrated that converged local quantities can be achieved on an averaging domain with proper spatial and temporal sizes. Furthermore, the relation between solid pressure and solid volume fraction is established, agreeing qualitatively to all the existing monotonic ones in the literature. But it is quantitatively different, showing a bifurcation at a high solid volume fraction, which is essentially linked to the variation of short and enduring contacts among particles with flow state and solid volume fraction. This bifurcation must be properly recognized in developing constitutive relations for granular materials. It is also demonstrated that there are different temporal scales in the fluidized bed and different averaged quantities can be obtained, showing the transient heterogeneous structures.

Coupled method the discrete elements method (DEM) with the computational fluid dynamics (CFD) is widely used for numerical simulation of gas-solid two phase flows, such as fluidized beds. In the DEM-CFD method, the modeling of the arbitrary shaped boundaries and stable algorithm are essential for simulating engineering processes, as industrial systems often have complex shaped wall boundaries. To model arbitrary shaped boundaries, the SDF-IBM wall boundary modelling, where the signed distance function (SDF) are coupled with immersed boundary method (IBM), has been developed. The efficiency and accuracy of the SDF-IBM boundary modeling have been proved through verification and validation tests. On the other hand, when drag forces acting on solid particles becomes extremely high, numerical simulation cannot be performed stably. In order to solve the instability problem, the aim of this study is development of an implicit algorithm for stable calculation for the drag force term. In verification test in the fixed bed, it is revealed that the implicit algorithm solves the numerical instability problem in the drag force. Subsequently, a new robust implicit algorithm which combined the implicit algorithm to SDF-IBM wall boundary modeling is developed and the validation tests are performed in a fluidized bed with inserted tubes. Consequently, a robust implicit algorithm for DEM-CFD method is developed and adequacy of this algorithm is proved through validation tests.

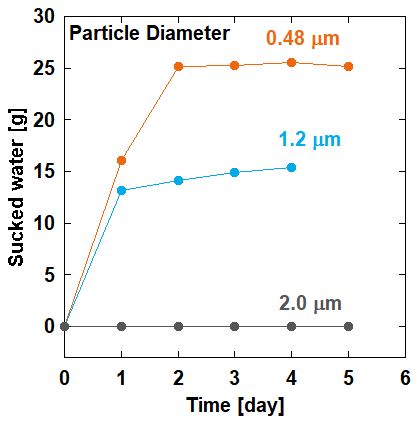

From our previous research, it was found that the sediment of well-dispersed slurry could act as a continuous osmotic pump and kept sucking water for long time. This means that the sediment of well dispersed slurry is expected to be a pump for irrigation and greening desert. In order to achieve this, it is important to increase the amount of sucking water flux, thus, the effects of slurry conditions on the water sucking behavior for the sediment of well dispersed slurry must be clarified. Therefore, in this study, we investigated the effects of slurry conditions such as particle size, particle concentration, slurry height, type of additives, on the water sucking flux of the sediment. In addition, the osmotic pressure generated by the sediment for various slurries were measured. It was shown that the sediment of the smaller particles could generate the larger osmotic pressure and show the higher water sucking flux, since the overlap of the electric double layer became remarkable for the slurry of smaller particles.

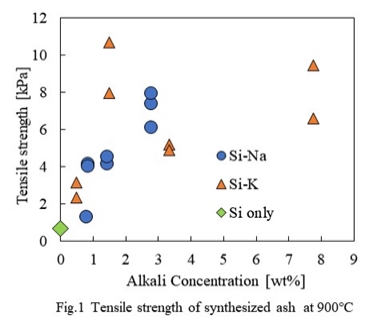

Ash adhesion and deposition phenomena on the surface of super heater and furnace wall has hindered the stable operation of coal, biomass and waste combustion and power generation plants. These phenomena also reduced the efficiency of power generation and heat transfer. Based on the measurement of tensile strength and shrinking behavior of various ash powder bed collected from the coal-fired power plant and waste incinerator at high temperature ranging from 773 to 1173 K, we estimated that a very few amount of liquid or slag phase formation of main component SiO2 with alkali metal, such as Na and K, contributed to the increase of adhesion force between ash particles. However, since many other chemical compounds were included in real combustion ash, it is difficult to discuss the quantitative influence of alkali component in ash on the adhesion behavior at high temperature. In this study, in order to clarify the influence of alkaline components on adhesion behavior, some kinds of synthesized model combustion ash particles with different alkali metal content were synthesized from pure silica particles. The tensile strength and shrinking behavior of each synthesized ash particle bed at high temperature was carried out and analyzed by thermodynamic calculation. Fig.1 shows tensile strength at 900°C of synthesized ashes with different contain of Na and K. By the few amounts of Na and K content (lower than several few %) in synthesized model ash, the adhesion force increased more than several 10 times compared with pure silica particles. Furthermore, alumina nanoparticles, which was useful to reduce adhesion force by the addition with real ash particles in our previous paper, were similarly added to synthesized model ash, and then the effect of adhesion behavior at high temperature were investigated.

As mediators for cell communication, exosomes are an emerging carrier for drug delivery. Cell communication is a dynamic process, will affected dramatically by the cell conditions, however, the present studies only focus on the normal condition. Inspired by this, we compared the cancer cell uptake of five different stressed and normal cancer cell originated exosomes, found that low-pH stressed cell secret exosomes have the highest uptake efficiency (2.9 times of normal exosomes). Lipidomics data and molecular-dynamics simulations indicated that the unique lipid composition played the key role for cancer cell membrane affinity which further affected cancer cell uptake efficiency. The homologous targeting was evidenced by the gastric cancer cell (MGC803) originated exosomes were only uptaken by cancer cells (MGC803, HGC27 and MKN45), the gastric epithelial cell (GES1) exosomes were only uptaken by GES1, the tumor targeting was further verified by the in vivo imaging of biodistribution. Using the low-pH stressed cancer cell exosomes, we loaded the hydrophobic doxorubicin (Dox) in the lipid membrane and a hydrophilic photosensitizer, Al (III) phthalocyanine chloride tetrasulfonic acid (AlPcS4) in the lumen to construct a combined anticancer therapy platform. The reactive oxygen species generated by AlPcS4 after irradiation destructed the exosomes for rapid released of Dox, at the same time, induced apoptosis with released Dox in a synergistic manner. The superior anticancer therapeutic effects were achieved both in vitro and in vivo. The successful utilizing of low-pH stressed cell exosomes for gastric cancer therapy in this study indicated that the efficient exosomes may have great potential for various anticancer drug delivery.

Epoxy-based resin filled with SiO2 nanoparticles is one of useful composites applied as adhesives for electronic devices, as it provides reliable insulation resistance and improved mechanical properties. On processing SiO2/epoxy composites, a compound with lower viscosity which is favorable for shaping and those curable to a material with improved elastic modulus is required. However, since the disaggregation of SiO2 nanoparticles is essential for the former and network formation is necessary for the latter, the realization of both properties was a kind of contradiction and difficult to achieve. To overcome this issue, herein we report a processing route to fabricate epoxy-based composites co-filled with SiO2 nanoparticles and cellulose nanofibers (CNFs). First, the surface of SiO2 nanoparticles were modified to improve the compatibility with epoxy-based resin. Briefly, the adsorption of functional dispersant, polyethyleneimine partially complexed with oleic acid (PEI-OA), on SiO2 nanoparticles and further epoxy grafting from the free amine groups of PEI-OA was conducted simultaneously in toluene with bead milling. The disaggregated and surface modified SiO2 nanoparticles were collected by centrifugation and redispersed in ethyl acetate. Then, CNFs and epoxy based resins (a mixture of bisphenol-F type phenoxy resin and bisphenol-A type epoxy resin) was mixed with the epoxy-grafted SiO2 dispersion. While CNFs strongly aggregated in the solution of ethyl acetate/epoxy-based resin, CNFs found to disperse and flowable suspension was obtained when the epoxy grafted SiO2 nanoparticles were co-dispersed (>1 mg-CNF/g-SiO2). Furthermore, the cured epoxy-based resin filled with SiO2 nanoparticles (15 phr) and CNFs (1.0 mg-CNF/g-SiO2) showed improved storage elastic modulus above Tg compared to those without CNFs. We suspect that SiO2 nanoparticles having a surface compatible with epoxy resin adsorbed on CNFs and stabilized them in the resin/solvent solution. The existence of small amount of dispersed CNFs were effective to improve the mechanical properties of epoxy-based composites.