Forensic engineering is the utilization of engineering skills or techniques to the investigation of material components that do not perform as intended during service. It usually deals with accidents, disasters and product failure of all kinds with an intention to provide solution. Quite often forensic materials engineers while dealing with it are focusing on two aspects; whether or not the appropriate engineering or quality standards have been followed during production process and whether the failure results from use or abuse.

Metal failure analysis are well established today simply because most have been used in service for many years, those of families of other materials especially failures of polymeric and elastomeric products are poorly published as these are recently introduced as engineering materials. Whatever the situation, material cannot be prevented from failure but root-cause analysis would help to prevent from known causes.

This presentation highlights the principal approach for the analysis of failed polymeric components. In the approach we mainly focus on three aspects, such as

* the parallels between failures in different materials - For engineering polymeric materials adequate properties database are not available to check whether or not a particular material is fit to be used under a specified set of circumstances. Therefore, comprehensive searches are being made to look for the track record of parallel product failures that already have been determined and causes established.

* IDprevious examples of similar failures - It provides a context for a previous investigation that can not only help resolve ambiguities but also aid designers in selecting materials with knowing the environment in which products have to perform reliably.

* alternative interpretations by other investigators - The role of alternative failure analysis may not be similar or may not provide detail information. Therefore assumptions on interactive effect may require to make for root cause analysis.

Particularly, in presentation, emphasis will be given to understanding polymeric materials component failures and the principles of failure analysis to discuss the unified approach of integrating the failure mechanism within the products which fail as case studies. Some challenges in current approaches are also presented.

From the process industry such as petroleum refining and petrochemicals to vehicles, heat exchangers are used to efficiently exchange thermal energy between the two fluids. Depending on the fluids during operation, clogging or deposits cause a decrease in the heat transfer efficiency, a decrease in the flow rate of the working fluid, and an increase in the differential pressure. As a result, the operating capacity is reduced. In this case, the heat exchanger needs to be cleaned. In this paper, a case study is presented that describes the possibility of the occurrence of corrosion of the aluminum alloy plate fin type heat exchanger by methanol solution used as a cleaning agent. The corrosion characteristics of the aluminum construction material were evaluation in the laboratory and countermeasures against corrosion then were implemented on the plant.

Global carbon dioxide (CO2) concentration in the atmosphere is continuously increasing due to excessive greenhouse gas emissions, worsening global warming, and climate change. The conventional method to capture CO2 from stationary industrial sources is liquid amine absorption, but its regeneration process is energy-intensive and poses risks of solvent losses. One feasible alternative solution is the use of solid adsorbents prepared by immobilizing amines onto porous substrates with high surface area. We investigated the use of natural bentonite and activated carbon coated with aminated pectin as adsorbents for CO2 capture using a pure CO2 source. The pectin was aminated by initiating the opening of the polysaccharide chains and introducing tetraethylenetetramine as the aminating agent before coating onto the porous substrates. The coating solution was analyzed using nuclear magnetic resonance and Fourier transform infrared spectroscopy to confirm the amination of pectin. The surface morphology of the adsorbents was characterized using scanning electron microscopy to reveal attachment of the modified pectin onto the substrates. The crystallinity of the coated substrates was also studied using X-ray diffraction. The effect of coating aminated pectin on the CO2 adsorption capacity of natural bentonite and activated carbon at 5% breakthrough was determined and discussed.

DME (Dimethyl Ether) is the future environmental friendly fuel. Some parts of equipment for transporting the DME are using rubber as a hoses or seals. This research is about the using of natural rubber for those applications. The influential part in the manufacture of natural rubber products are fillers. The use of filler depends on what the product will be made. DME nature have high permeability and easy to absorb into a rubber and plastic. In such of that, the rubber or plastic could be damaged and not durable. In order to determine the type of degradation, the number of samples were immersed in liquid DME. The ratio of the loading of carbon black/silica filler in natural rubber was varied. DME causes two types of degradation, namely absorption and extraction . The addition of filler composition can reduce the absorption and extraction, which can cause a reduction in the percentage decrease in the value of the change in mass and a decrease in tensile strength. On the other hand, the addition of filler composition will increase the changes of hardness. The higher filler loading, will increase the crosslink density and lower Scorch time. The presence of silica further is to enhance the crosslink density as well as to lower Scorch time. Therefore, the presence of silica affects on the decreasing of the swelling level and shrinking. In general, the presence of silica filler in the mixture will be slightly lowering the tensile strength, but not affecting the elongation at break. The presence of silica before and after soaking with DME will increase hardness.

Constructing mass production method of graphene is essential for practical usage of this remarkable material. Direct exfoliation of graphite in liquid is the promising approach for production of high quality graphene. However, this technique has three huge obstacles to be solved; limitation of solvent, low yield and low exfoliation degree. Here, we found that soluble graphite produced by mechanochemical reaction with salts overcomes above three drawbacks. The soluble graphite was exfoliated into 100% monolayer graphene with more than 10 % yield in five min. of sonication. Surprisingly, the modified graphite was easily exfoliated in low-boiling point solvent such as acetone, alcohol and water without an aid of surfactant. Molecular simulation revealed that the salt is adsorbed to the active carbon at the graphite edge. In the case of weak acid salts, the original bonding nature between alkali atom ion and the base molecule is kept after the reaction. Thus, the alkali metals are easily dissociated in polar solvent, leading to negative charging of graphene. This phenomenon enables the exfoliation of graphite in low boiling point solvents. The approach proposed here opens up a practical usage of the attractive 2D materials.

In recent years, renewable energy has been attracting as alternative energy to replace the thermal power and nuclear power due to the power situation. Wind power generation has been attracting attention from power generation efficiency and equipment cost. But, there are problems about the installation of the generations, such as site area and noise, and few suitable sites that satisfy those conditions in Japan. However, since Japan has the world's sixth largest Exclusive Economic Zone, development of offshore wind power generation is being expected.

Blades of onshore wind power generation are damaged by sand erosion. It is believed that rain erosion damage will be occurred on the blades of offshore wind power generations. Rrosion on the damage, using a water jet erosion method test apparatus, studies have been conducted about the erosion damage of metal material due to droplet impact. Fiber reinforced plastic is mainly used on blades of wind power generations. In many cases, for the improvement of erosion resistance, the resin coating layer has been performed on the blades of wind power generations.

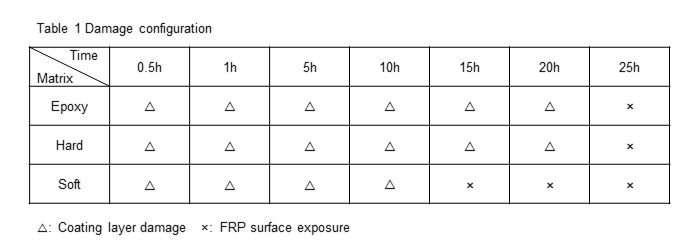

In this study, therefore, test pieces with resin coating layer were made and erosion resistance of resin coating layer was investigated by performing a rain erosion experiment. After the experiment, damaged surfaces were observed and erosion resistance of coating layer was discussed. The results obtained in this study are shown in Table 1. Erosion resistance of the test piece, which is combined with hard matrix and the hard coating layer, is higher than the test piece combined with soft matrix and the hard coating layer.

Accidents due to material degradation have occurred several times on FRP-made hydrochloric acid storage tanks. In order to prevent such accidents, we have developed a sensor that detects chemical degradation of polymeric materials using an optical fiber. This sensor has been modified to be installed at the nozzle attached on the tank for field application. In this study, problems were clarified that that occur when this sensor is applied to the actual plant, and after that, it was improved and field data was taken.

An amine cured epoxy resin including a pH indicator, such as BPB, shows discoloration when hydrochloric acid penetrates into the resin. The principle of detecting this color change by a spectroscope via an optical fiber was used for the sensor. This was loaded into a PVC blind flange and installed on a 35% hydrochloric acid storage tank in field chemical plants. By changing the embedding depth of the optical fiber, it is possible to return the time to detection, and at different depths. There was no problem in acquiring data at the time of installation, but even if it passed the water leak test, the leakage of the hydrochloric acid gas from the site where took out the optical fiber was found. To solve this problem, it was necessary to use a leakproof o-ring.

These days sewage system has many problems like high electric power consumption and aging of sewerage facilities. Development of new energy-saving wastewater treatment technology is an urgent issue for sewage works. New developed sewage treatment plant applied an “Energy Saving Wastewater Treatment Technology Using No-aeration System” method with hollow cylinder shape mineral-filled polyolefin carriers, this method a combined technology of a biological treatment and a filtration. The biological treatment uses carriers containing microorganisms and a trickling filter dissolving oxygen, and the filtration uses suspended carriers in the former and the after process. After one-year test operation, a slightly amount of degraded carriers would cause problem to the system. Thus it is necessary to analyze the degradation behavior and develop a lifetime evaluation method of these carriers inside this sewage treatment plant. In order to evaluate the performance of these carriers in this sewage environment, we conducted accelerated immersion tests under acid conditions using organic acid (acetic acid) or inorganic acid (sulfuric acid) with high concentrations and high temperature. After the samples reaching saturation, the mass change and FT-IR tests were used to analysis the changing during the degradation. The roughness of the sample surface was measured by contact angle test. Moreover, tensile tests of the cylinder shape samples and dumbbell shape samples were conducted to investigate the mechanical properties of these carriers under real sewage system condition and the ideal condition.