This paper offers how to realize quick refolding of high concentration protein via microchannel flow membrane dialysis. E. coli. are suitable host cells for mass production of proteins due to their fast proliferation and translation rate. On the other hand, proteins produced by E. coli. are often expressed as insoluble inclusion body, which have no activity. In that case, the “refolding” process to recover the original protein structure and activity is required. A quick refolding of high-concentration protein is important issue for industrial process but generally quite difficult. Dilution method can quickly refold protein but the concentration becomes low, while dialysis method can refold high concentration protein but requires long time. Considering the rate determining step of the dialysis is the slow permeation of denaturant through dialysis membrane, here, we propose the design to realize both of quick and high-concentration protein refolding by using microchannel flow dialysis.

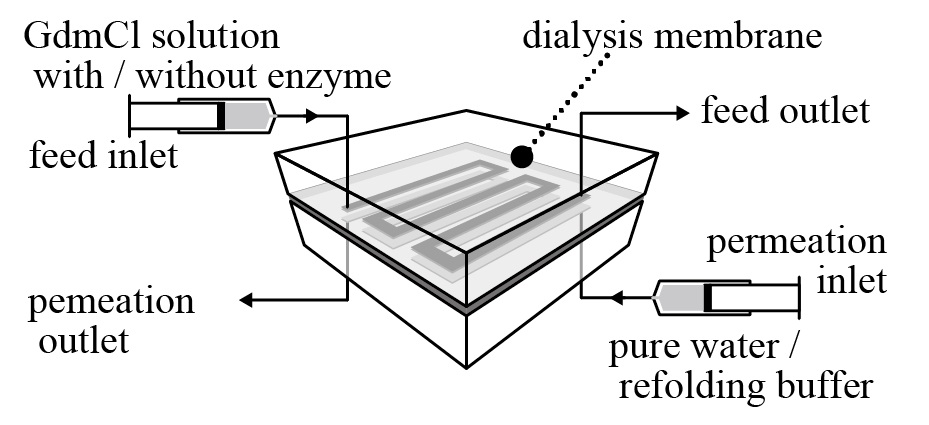

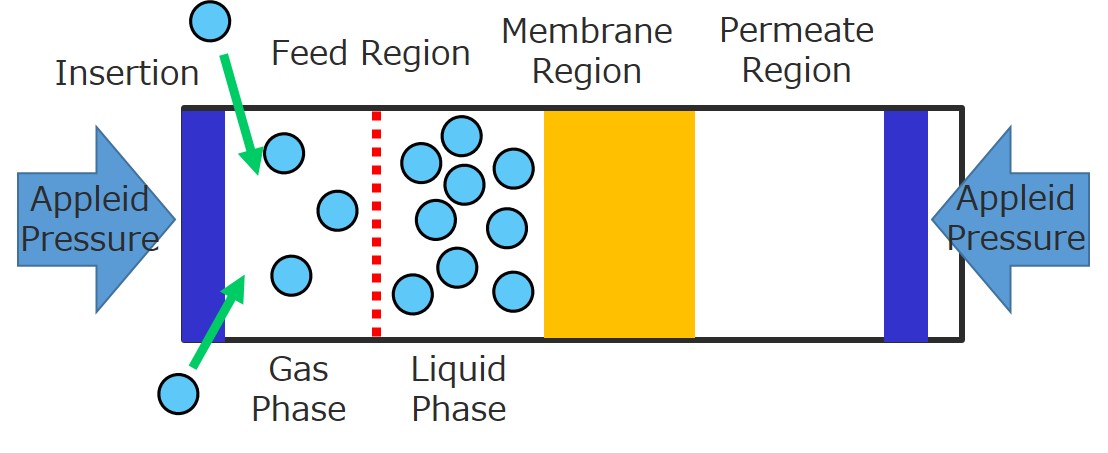

Dialysis membrane was sandwiched with two microchannels; feed channel and permeation channel. Carbonic Anhydrase (CA) (as model enzyme) denatured by denaturant (guanidinium chloride (GdmCl)) was fed into feed channel. On the other hand, refolding buffer was fed into permeation channel. The denaturant was quickly removed from feed channel to permeation channel through dialysis membrane due to high specific membrane surface area in microchannel flow. As a result, CA can be refolded in only twenty minutes, which are much shorter than the time for conventional dialysis method, and just a bit longer than the time required for refolding of CA. Furthermore, the microchannel flow process realizes almost 100% protein recovery and active recovery for CA with concentration as high as conventional dialysis method within the quick process. The demerit of the microchannel flow is low flow rate but it can be easily solved by numbering up and increasing flow rate with longer channel flow.

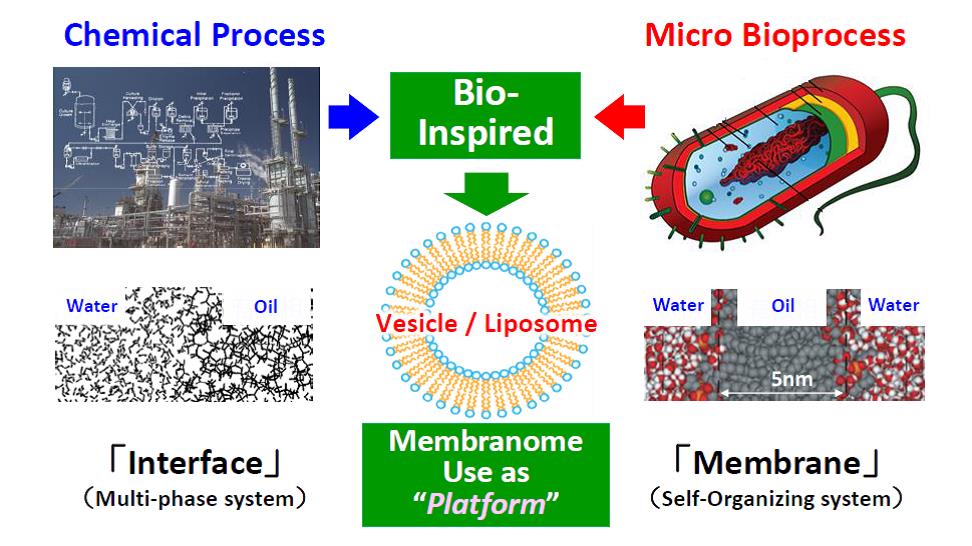

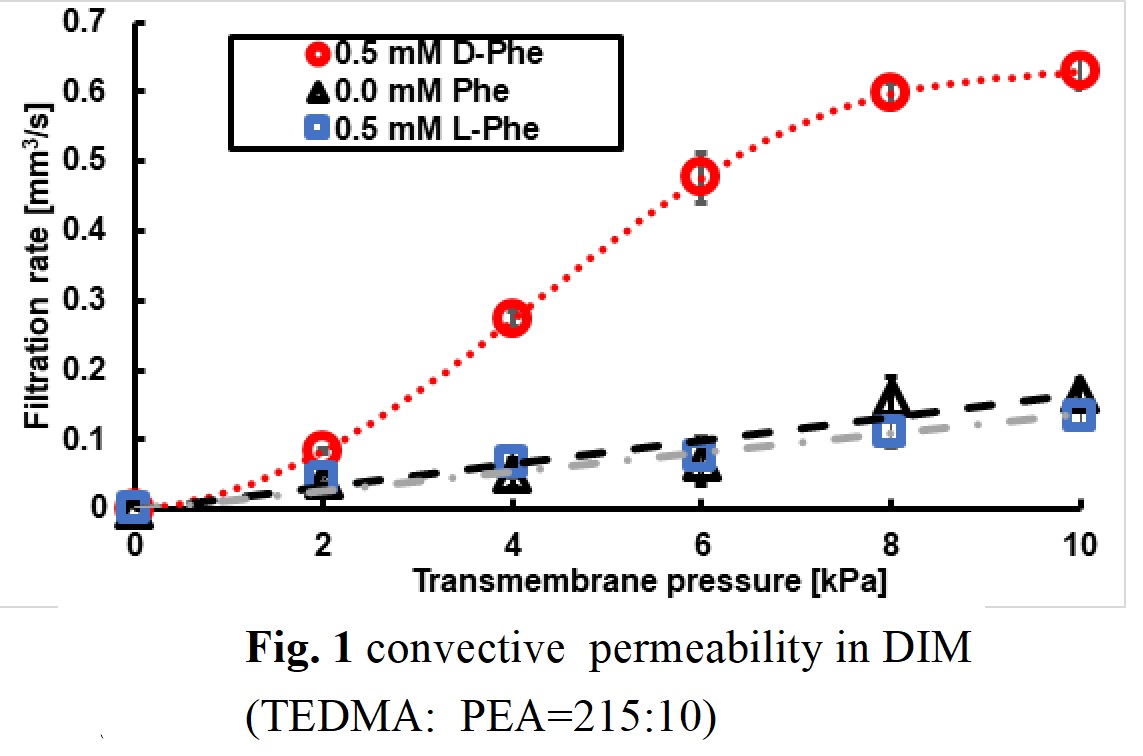

A “Biomembrane” is a highly-organized self-assembly of biomolecules (i.e. lipid, protein etc.) and a key interface for the survival of biological cell. The “Membranome” can be defined as the properties of vesicle (or liposome), which arise from the bilayer molecular assembly of amphiphiles, focusing on “emergent properties” which are not present in the individual components, and is gradually recognized as an important research methodology to investigate the potential functions of vesicles (or liposome) and to apply them for the bioprocess design. “Self-Organizing System”, such as liposome or vesicle, possesses several benefits in the recognition of (bio)molecules, where it can recognize them with (i) electrostatic, (ii) hydrophobic interaction, and (iii) stabilization effect of hydrogen bonds at its surface. A key of next chemical engineering is the use of “Self-Organizing System”, where “enthalpy-driven” nature of chemical process would be converted to “entropy-driven” one. We call this strategy as “Bio-Inspired Chemical Engineering”. In this study, the basic and applied aspect of the self-organizing system were reviewed, especially focusing on chiral separation and chiral conversion process.

Reference:

P. Walde et al., Chem. Commun., 50, 10177-10197 (2014). T. Ishigami et al., ACS Appl. Mater. Interf., 7, 21065-21072 (2015). T. Ishigami et al., Langmuir, 32, 6011-6019 (2016). M. Hirose et al., Langmuir, 31, 12968-12974 (2015). F. Iwasaki et al., ACS Omega, 2, 91-97 (2017). F. Iwasaki et al., ACS Omega, 2, 1447-1453 (2017).

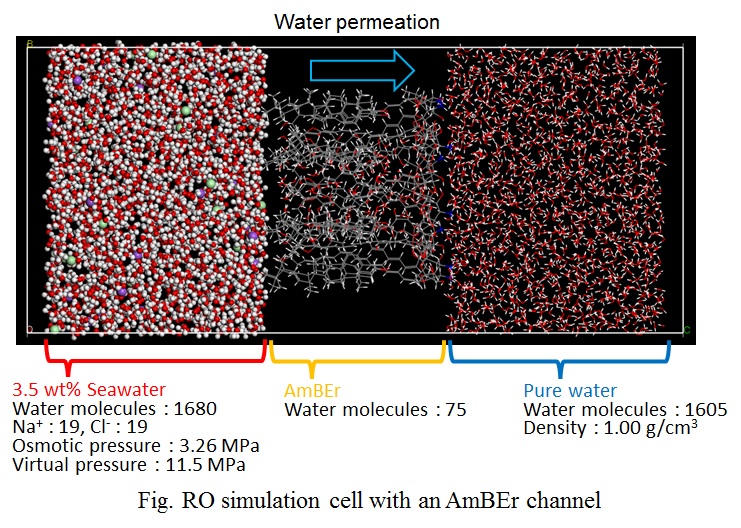

Polyamide and cellulose triacetate are known to be materials for reverse osmosis (RO) membranes, which are used in desalination of seawater. In order to deal with increasing water demands all over the world, a development of higher performance RO membrane and membrane processes are required. A drastic change in RO membrane materials would lead to one of the solutions to improve RO membrane performance. Amphotericin B-Ergosterol (AmBEr) is a biomimetic channel, and water and specific ions can be selectively transported through the channel [1]. RO membranes in which AmBEr channels can be embedded suitably are expected to be utilized high performance RO membranes. In order to design high water permeable channels, it is indispensable to understand microscopic channel structures and water transport mechanisms in a molecular scale.

In this study, a quasi-non-equilibrium MD simulation technique with applied (RO mode) or osmotic (forward osmosis, FO mode) pressure difference of several MPa was conducted to estimate water permeability through an AmBEr channel (Fig.). We had successfully carried out direct simulation of forward osmosis (FO) water permeation in artificial water channels [2]. In RO simulation, the virtual pressure was applied by increasing density of seawater side in RO simulations. Simulated FO and RO water permeability for an AmBEr channel were equal to or greater than the water permeability in Aquaporin [3] and carbon nanotube [4] water channels. No permeation of Na+ and Cl- ions were observed during the simulation time of several nanoseconds. The results suggested the excellent performance of AmBEr channel as an artificial biomimetic membrane material.

[1] H. Wu et al., J. Memb. Sci., 545, 229 (2018), [2] H. Wu et al., Desalination, 424, 85 (2017), [3] M. Kumar et al., Proc. Natl. Acad. Sci., 104, 20719 (2007), [4] B. Corry, J. Phys. Chem. B, 112, 1427 (2008)

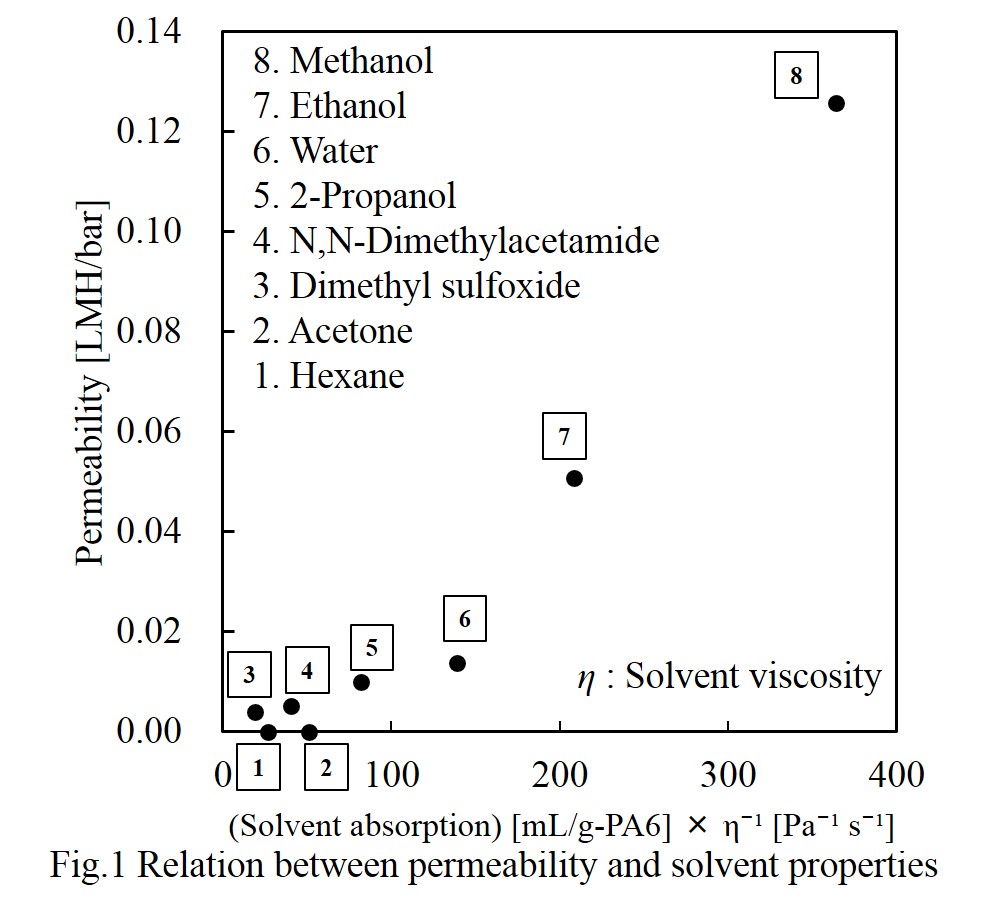

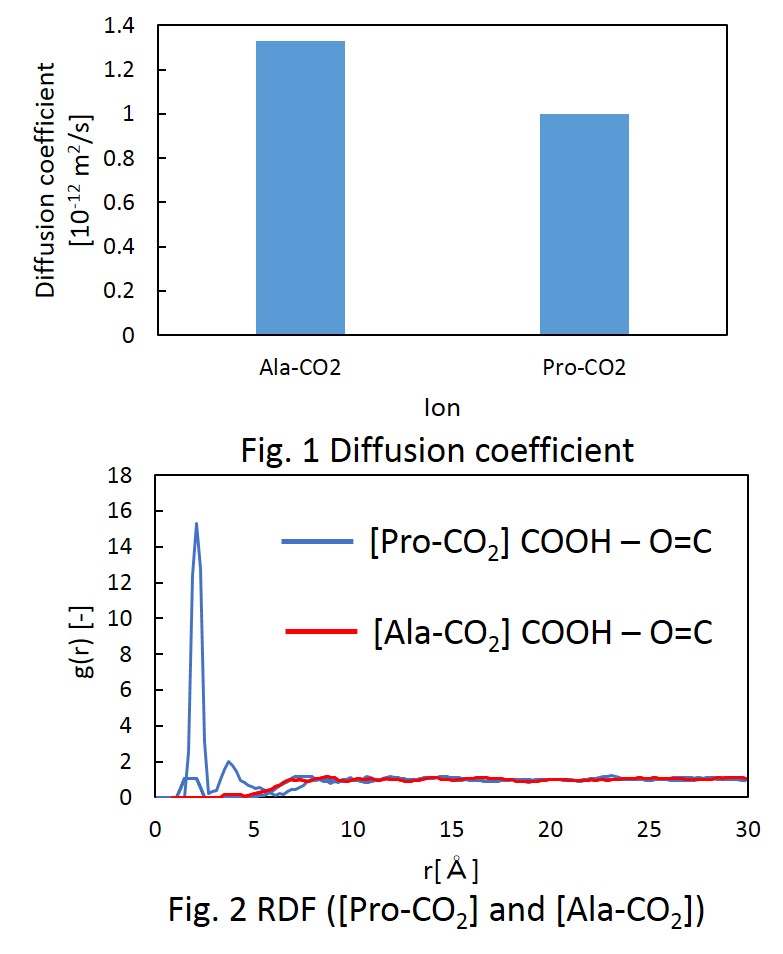

Nanofiltration has been applied to various separation systems, in particular, for the separation of aqueous or organic solvents. For a development of more efficient membrane process, better understanding of separation mechanism of solvent including multicomponent species is of fundamental. Molecular modeling becomes a powerful tool for prediction of membrane performance and design of membrane materials for particular separation systems. Our group has reported a novel simulation scheme of molecular dynamics for the permeation of feed solution through nano porous membranes. Molecular dynamics of multi component species in the feed, however, is still difficult to be simulated because a feed concentration of multicomponent such as ions cannot keep at a constant in our simulation techniques as well as other conventional non-equilibrium molecular dynamics scheme. In this paper, to model multicomponent solutions through nanofiltration or reverse osmosis membranes, we will present a novel molecular dynamics technique that can control the feed concentration including multicomponent species at constant. This simulation technique is completely new and first methodology that could model multicomponent solution systems in membrane separation from atomistic level, as long as our knowledge. We will report that this simulation technique works well and can produce the permeation of multicomponent feed solution. The flux and ions selectivity were calculated and compared to the theoretical values to examine the validity of our proposed scheme.

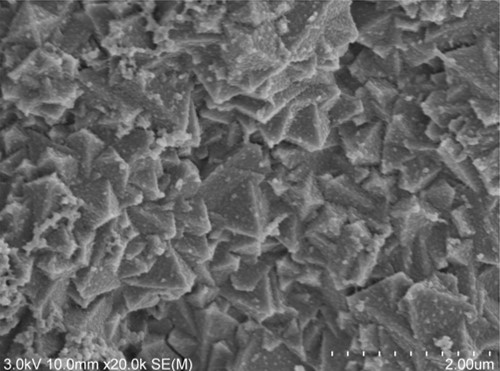

We have synthesized 80-cm-long mordenite membranes on mullite supports by secondary growth method. Mordenite has a moderate Si/Al ratio of 3–10 and regular pore size of 0.65 × 0.7 nm. These advantages allow mordenite membranes to be a potential candidate for separating water from acetic acid solutions with excellent acidic-resistant property and hydrophilicity. The enhancement of flux as well as high reproducibility is critical for industrial application of mordenite membranes. To improve the flux of membrane, we rapidly prepare mordenite membranes on macroporous mullite supports in a fluoride-containing precursor gel. The molar composition of synthesis solution is 1SiO2: 0.08Al2O3: 0.25Na2O: 0.2NaF: 40H2O. The hydrothermal treatment is carried out at 170 °C for 5 h. After synthesis, the as-synthesized membranes are characterized by XRD, SEM and pervaporation (PV) test. The surface SEM image of the membrane prepared under optimal conditions shows compact and highly intergrown zeolite layers composed with ellipsoidal polycrystalline grains. The membrane thickness is approximately 8 μm. High-flux mordenite membranes exhibit a long-term acid stability for a 90 wt% HAc/H2O mixture at 75 °C, the flux and separation factor ultimately keep stable at approximately 1.03 kg m-2 h-1 and 4500 for 10 d. Furthermore, mordenite membranes are successfully scaled-up from 10 cm to an industrial scale of 80 cm with transverse crystallization. These high performance 80-cm-long mordenite membranes with good roeprducibility show a promising industrial application for dehydration of water-acetic acid mixtures.

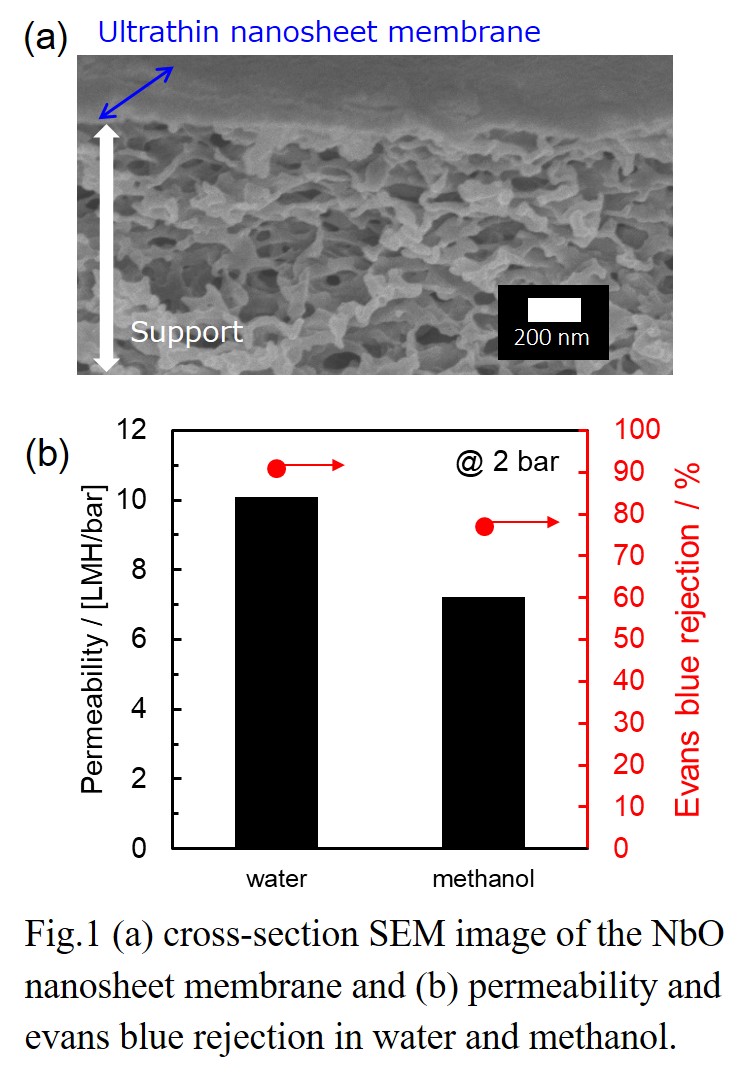

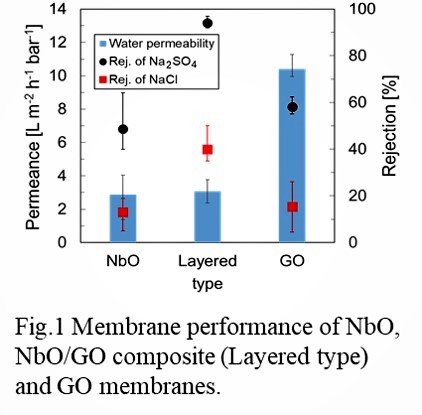

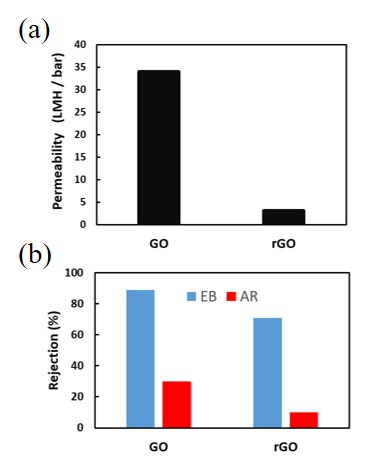

Two-dimensional (2D) nanosheet membranes are expected to function as size-selective molecular separation membranes, based on their unique atomic thickness with micrometer lateral dimensions. Stacked nanosheet membranes are formed by assembling single molecular sheets into thin membranes, and contain 2D nanochannels between the stacked sheets that allow water or solvents to pass through whilst rejecting unwanted solutes [1]. Therefore, they represent promising materials for potentially high-functional membranes for liquid separation such as water treatment and organic solvent filtration. The structural stability of nanosheet membranes during filtration is also a critical issue for their application.

In this study, we fabricated nanosheet membranes using single 2D nanosheets of niobium oxide (NbO) on a porous cellulose nitrate or anodic alumina support by a simple vacuum filtration. The thickness of NbO membranes were controlled by adjusting the volume of nanosheet colloidal solution used during the vacuum filtration. The stacked NbO nanosheet membranes had a dense structure and were highly stable during separation tests, because of the chemical cross-linking between nanosheets. The method allowed the formation of nanochannels in the NbO membranes. The NbO membranes showed high rejection performances against anionic dyes and salts in water [2,3]. Furthermore, membrane structure and separation performances in alcohols were also investigated. There was little difference in the interlayer spacing of the stacked structure between water and alcohols, suggesting the stable layered structure in alcohol solvents. The NbO membranes demonstrated relatively high rejection performances such as 85% rejection for Evans blue (EB, Mw: 960.8) in methanol. The channel structure and separation mechanism for NbO membranes in water and alcohols will be discussed.

[1] G. Liu, et al., Angew. Chem. Int. Ed.55, 2–16 (2016), [2] K. Nakagawa et al., Chem. Commun. 53, 7929-7932 (2017), [3] K. Nakagawa et al., Sep. Purif. Technol, 219, 222-229 (2019)

High purity propylene is an octane-enhancing chemical and also feedstock to industrially important chemicals. Purification of propylene from propane mixture is technologically and financially challenging because of their close boiling points. ZIF-8 membrane has the potential to separate propylene from propane effectively due to the gate opening effects, although the theoretical ZIF-8 aperture size (0.34 nm) is smaller than the kinetic diameters of propylene (0.4 nm) and propane (0.43 nm). In this work, defect free ZIF-8 membranes were successfully developed from the secondary growth seeding technique with sodium formate as deprotonating agent that facilitated continuous, well-intergrown ZIF-8 membrane on α-Al2O3 support. The defects formed by the crack formation in the membrane was steadily and effectively removed by the uniquely discovered self-healing property that the sodium formate extended. The ZIF-8 membranes demonstrated their excellent molecular sieve separation capability for equal molar propylene/propane mixture with the highest separation factor of 115 and average propylene permeance of 50.40×10-10 mol/m2 s Pa.

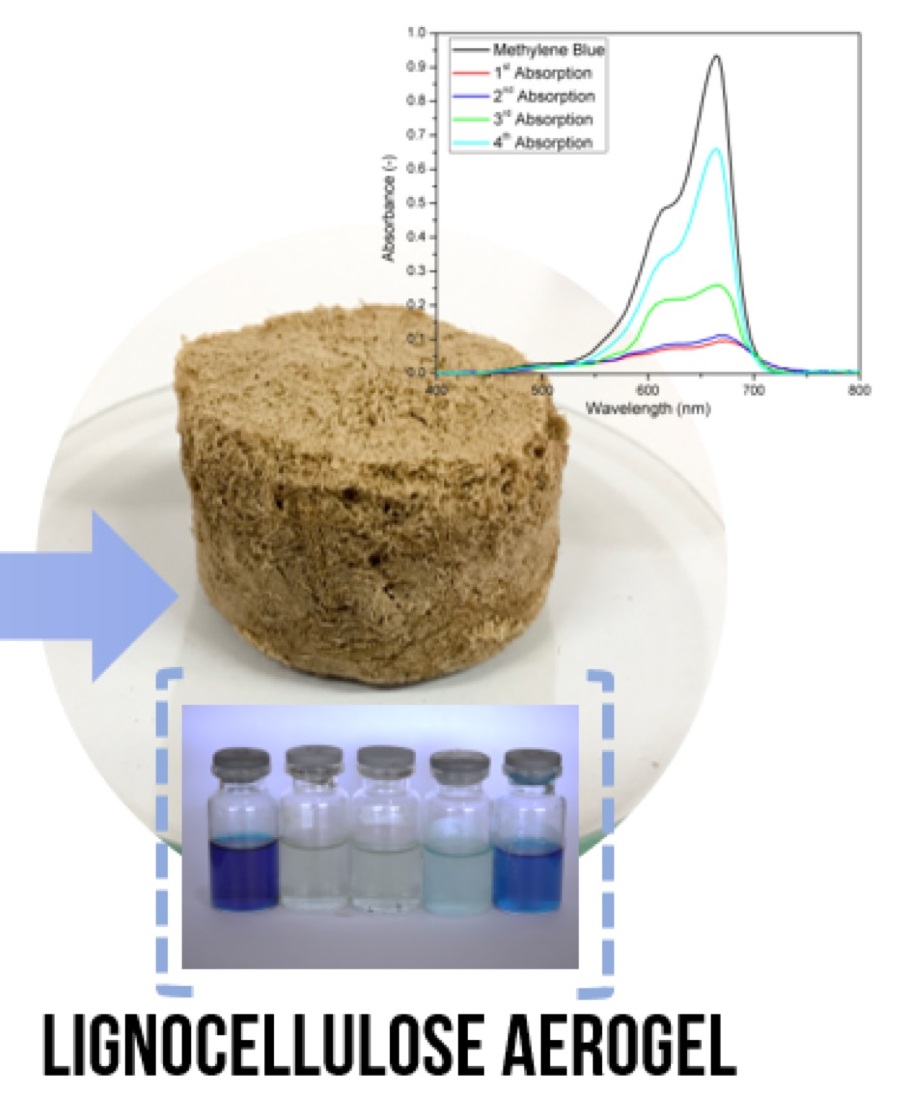

In this talk, I will report the development of novel omniphobic membranes and operation modes for various process applications with membrane contactors (MCs). An omniphobic membrane was fabricated for membrane distillation (MD) by effectively depositing ZnO nanoparticles on a hydrophilic glass fiber (GF) membrane to create hierarchical re-entrant structures, followed by surface fluorination and the addition of a polymer coating to lower the surface energy of the membrane. The omniphobic membranes possessed a particulate membrane morphology and an extremely high fluorine concentration on the surface. The omniphobicity of the fabricated membrane was indicated by the contact angles for water and ethanol, which were as high as 152.8±1.1 ° and 110.3±1.9 °, respectively. In particular, it will focus on the development of tuned hydrophobic, hydrophilic and asymmetric wettability membranes. Membrane contactors are membrane systems that can find application in different fields of industrial interest, covering, for example, gas-liquid operations, liquid-liquid extractions and vapor-liquid distillation. In past decade, the use of membrane absorption to capture carbon (membrane absorption, MA), to prepare emulsions (membrane emulsification, ME), to recover resources from sea (membrane crystallization, MCr) to carry out distillation processes for water scarcity issue (membrane distillation, MD) has been subject of many research activities worldwide. Focus of this talk will be placed on the applications of the developed novel aerogel membranes for MA and MD processes to resolve the carbon abundance and water scarcity issues, respectively, for achieving an ultimate goal toward a sustainable planet.

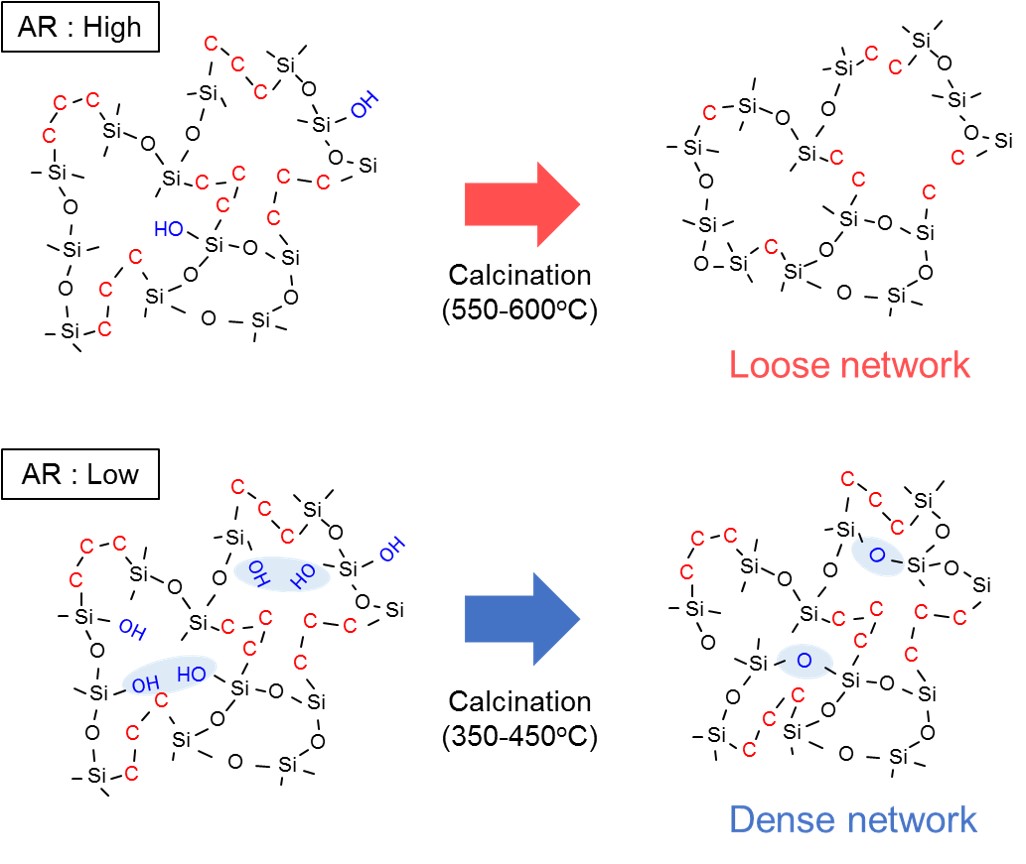

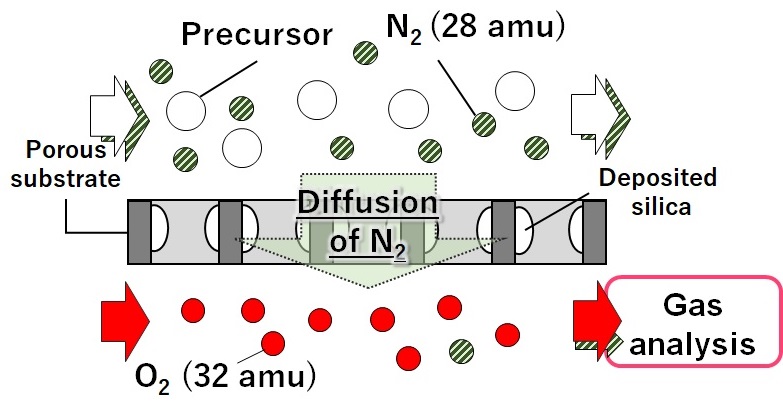

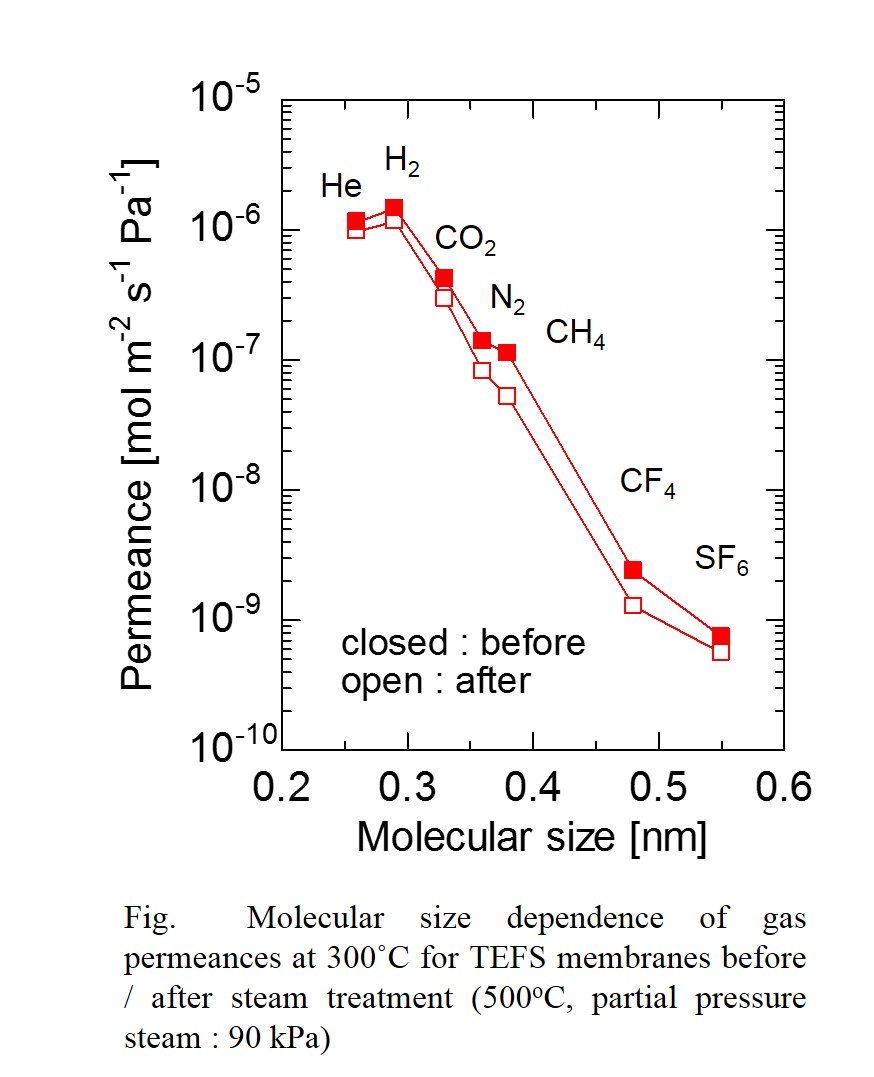

Silica membranes have been developing as hydrogen permselective membranes. A counter diffusion chemical vapor deposition (CVD) method is the preparation method for the silica membranes. One of the problems for the application of hydrogen permselective membranes is hydrothermal stability. In this study, effects of organic groups in the silica structure on hydrothermal stability was investigated.

γ-alumina (φ10 mm, L30 mm, Noritake Co..) was used for a porous substrate. γ-alumina layer or silica sol-gel layer was coated on the porous substrate. Aluminum sol 5S (Kawaken Fine Chem. Co) with polyvinylalcohol (PVA) was used for the coating of the γ-alumina layer. The parent sol of Tetraethoxysilane (TEOS):EtOH: H2O:HNO3=1:0.1:4:5 was employed for the silica coating. The coated substrates were calcined at 600 °C. CVD was carried out by using HTMOS (Hexyltrimethoxysilane) or TMOS (Tetramethoxysilane) as a silica source at 450 or 600 °C for 15 min. Single gas permeation tests were carried out by using H2 and SF6 at 270 °C.

The hydrothermal stability under steam was examined for the TMOS derived membrane deposited at 550 °C and for the HTMOS derived membrane deposited at 450 °C. The time courses of H2 permeance through the both membranes were shown the figure. The H2 permeance through the TMOS derived membrane decreased gradually, and the permeance was reduced by 37% under the steam treatment for 12h. On the other hand, the reduction rate of the H2 permeance through the HTMOS derived membrane on the silica coated substrates after 23h of the steam treatment was only 10%. In order to confirm the effects of coating of the substrates, the results through the membrane deposited on the coating of the γ-alumina layer were also shown as open plots in the same figure. The H2 permeance looks the similar indicating that there were little effects on the HTMOS derived membranes.

Membrane separation technology has been paid attention for one of the energy saving technologies. A silica membrane is categorized as one of the typical inorganic membranes, and the silica membranes show high hydrogen permselective performance comparing with the other inorganic membranes, such as zeolite and carbon membranes. On the other hand, it is generally known that permselective performance of silica membranes are affected strongly under hydrothermal conditions.

In this study, influence of steam on permeation performance of the DMDPS-derived silica membrane was evaluated to develop the silica membranes having relatively high hydrothermal durability. The silica membrane was prepared by counter-diffusion chemical vapor deposition method on a porous alumina support purchased from Nikkato co., Japan. After membrane preparation, permeation performance was measured using single component H2, N2 and SF6, respectively. Heat-treatment of the membrane was conducted at 573 K for 50 h. During heat-treatment, H2, N2 and SF6 permeances showed approximately constant value. To evaluate effect of heat-treatment, durability test was conducted under 0.1 ~ 1.0 mol% steam co-existed conditions at 573 K by using heat-treated and non-treated silica membranes. Comparing influence of steam on permeation performances of these membranes, permeance decreasing ratio of heat-treated membrane showed lower value than that of non-treated membrane in any steam concentrations. In addition, in-situ diffuse reflectance FT-IR spectra of heat-treated and non-treated silica powder was obtained. The heat-treated silica had less amount of adsorbed water molecules than the non-treated silica because the silanol group was decreased owing to heat treatment. From these results, it is considered that hydrothermal durability of the silica membrane is determined by the silanol group density.

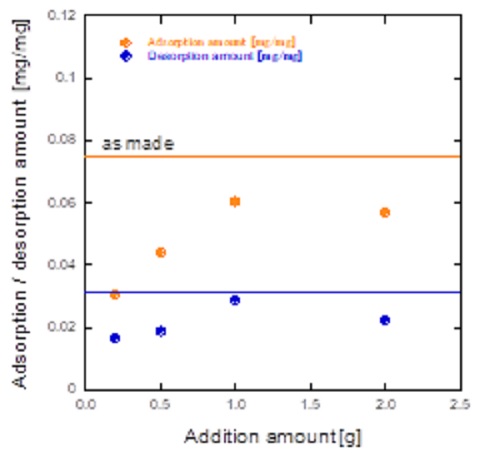

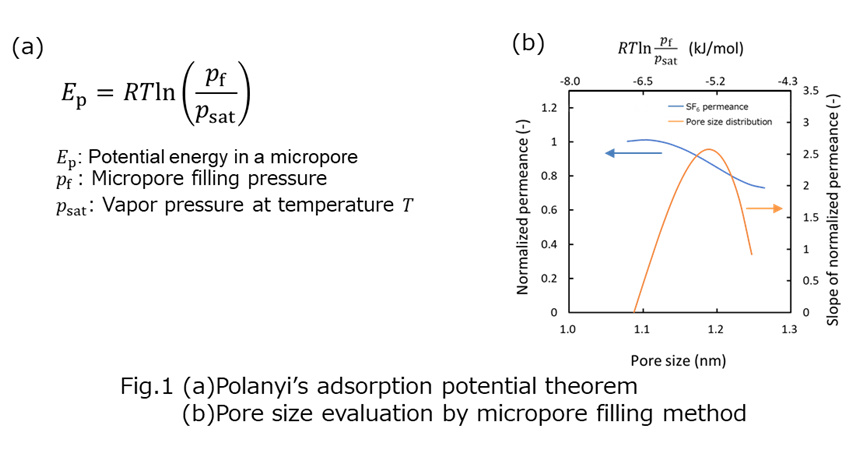

In generally, permeation phenomenon in microporous membrane can be divided in three steps, adsorption, diffusion, and desorption. Though investigation of these factors in membrane is quite important to understand permeation mechanism, these factors are hardly evaluated in direct.

We previously reported non-destructive adsorption measurement for zeolite membrane.1 In this study, we estimated diffusion property of hydrocarbon in silicalite-1 membrane from gas permeation measurement.

Silicalite-1, pure silica zeolite with MFI-topology, membrane was synthesized by a seed-assisted crystallization method on an outer surface of porous tubular a-alumina support (Noritake, i.d. = 7 mm, o.d. = 10 mm, average pore size = 150 nm).

Diffusion and desorption behavior was evaluated as follows. At first, permeation flux of helium through silicalite-1 membrane was detected. After that hydrocarbon vapor were fed to a membrane with flowing helium. When micropore of zeolite membrane was saturated by adsorbed hydrocarbon, the helium flux drastically decreased. Finally, hydrocarbon feeding was stopped, and then micropore would open by desorption of hydrocarbon. Thus, we can estimate the diffusion and desorption behavior of hydrocarbon from the rate of helium flux increase by pore opening. In addition, diffusion coefficient of hydrocarbon in mocropore could be calculated by using Fick's second law.

(1) M. Seshimo, K. Matsumoto, M. Mastukata, Evaluation of micropore volume of zeolite membrane under non-destructive condition by nitrogen adsorption method, 16th International Conference of Inorganic Membrane, P2.11, July, 2016.

Acknowledgment

This work was partially supported by JST CREST (Japan Science and Technology agency, Create REvolutionary technological seeds for Science and Technology innovation program), Grant Number JPMJCR1324, Japan.

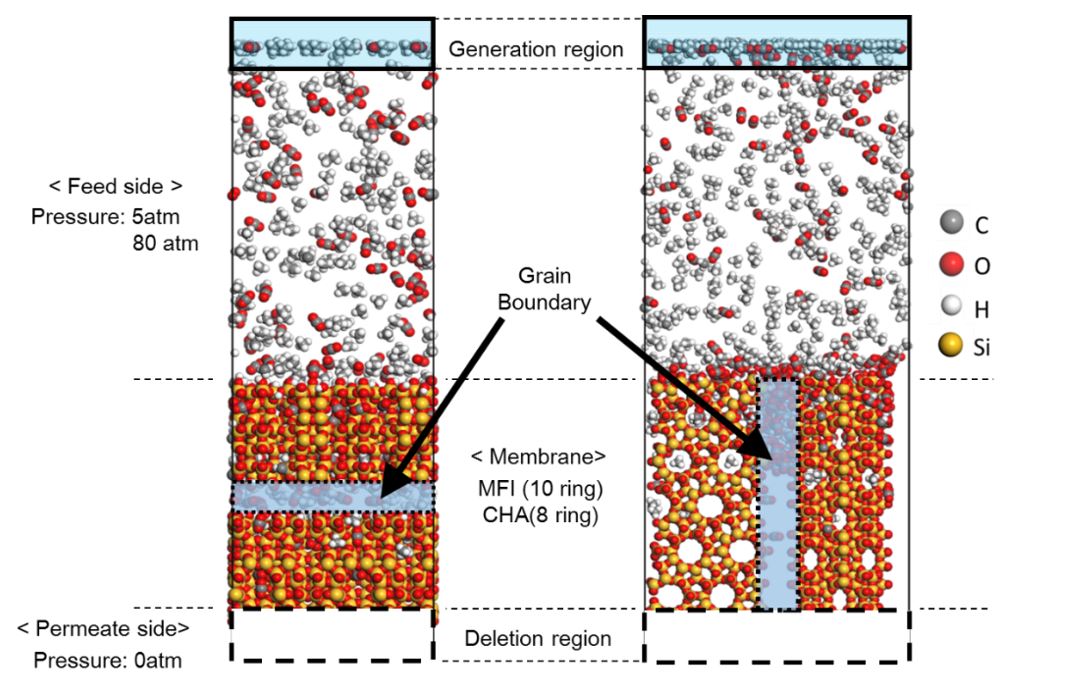

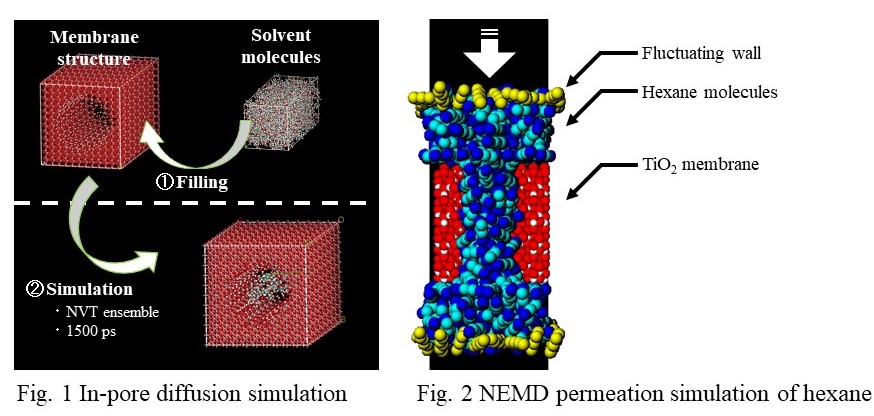

Zeolite membranes have unique properties such as molecular sieving and thermal stability. Therefore, the practical use of zeolite membranes for a purification process of natural gas has been investigated. Grain boundaries in inorganic membranes are known to degrade membrane performance, however, the detailed information of effect on selectivity still difficult to predict prior to the permeation test. Non-equilibrium molecular dynamics (NEMD) method is one of the theoretical prediction method of separation characteristics in inorganic membranes. The NEMD simulation is an atomistic-scale modeling, thus this can easily apply to the prediction of permeability and selectivity in multicomponent gas systems. The effect of trace components for membrane performance can be also investigated using NEMD.

In this study, we investigate the separation properties of CHA and MFI type zeolite membranes by NEMD for CO2/CH4 systems, and elucidate the mechanism of the effect of grain boundary on selectivity for ternary separation systems. Two different types of zeolite membranes having different pore sizes of MFI and CHA are considered to investigate the effect of pore size on selectivity. Two different models used in NEMD are shown in the figure. In the left side model in figure, grain boundary exists insides the zeolite crystal. In the right side model in figure, grain boundary runs lengthwise of zeolite crystal. In Generation region in the feed side gas molecules appear at every certain period. In Deletion region in the permeate side a permeated gas molecule is removed from the system. Our NEMD results indicates that the presence of grain boundary could increase the selectivity, which means that a control of grain boundary is a key factor to enhance the selectivity. In the conference, we will discuss the details of the effect of grain boundaries as well as pore size on this interesting phenomena regarding the selectivity.

Palladium membranes made of pure palladium, palladium-silver, palladium-copper, etc. are promising in terms of high selectivity to hydrogen. Because palladium is limited in resources and costly, various attempts have been made to reduce necessary amount of palladium preparing not only membranes supported by porous materials but also foil-shaped thin self-supported membranes. Hoverer, self-supported membranes are difficult to seal with frames of modules because welding is not easy for thin foils. To utilize self-supported membranes in practice to process large amount of hydrogen, technology to compose modules is necessary.

In this study, therefore, membrane modules for self-supported palladium membranes have been developed. A prototype module had eight sheets of palladium-silver foils 0.02 mm thick and 30 mm × 60 mm wide including sealing area. The foil-shaped membranes and spacers were alternatively accumulated and combined by thermal diffusion. The combined structure was set inside a stainless-steel container and welded between one of the spacers and the container. The module had three ports for feed, permeate and retentate gases. The module size was 34 mm × 44 mm × 64 mm excluding three ports.

Hydrogen permeation performance of the module was investigated using 1-MPa pure hydrogen as a feed gas at 623 K. As a result, 6 L(at 293 K, 1 atm)/min hydrogen was obtained from the permeate port. Durability was proved at least for 467 hours. This kind of modules are expected to enlarge the applicability of palladium membranes.

Membrane gas separation have the potential to reduce energy consumption in chemical industry. Currently polymeric membranes are widely used. However, their applications are limited because of their low selectivity. Carbon molecular sieve (CMS) membranes have higher permselectivity than commercially available polymeric membranes and lower fabrication cost than silica and zeolite membranes. The CMS membrane are expected to expand the range of application of membrane gas separation. One of problems to be considered for application is the effect of impurity. In this study, we have investigated the effect of coexisting component on gas permeation and separation through CMS membranes. Mixed gas permeation experiments have been carried out for binary mixtures of hydrogen (H2)-nitrogen(N2) and tertiary mixtures of H2, N2 and water vapor. Two CMS membranes prepared from a polyimide have been used.

Permeance to H2 at a constant partial pressure did not change with increasing N2 partial pressure for both membranes. Permeance to N2 at a constant N2 partial pressure did not changed with increasing H2 partial pressure for one membrane. However, N2 permeance increased with increasing H2 pressure for another membrane. Consequently selectivity of H2 over N2 decreased with H2 partial pressure for the latter membrane.

Coexisting water vapor decreased both H2 and N2 permeance for both membranes. However, H2/N2 selectivity decreased for one membrane and it increased for another membrane. Water vapor had a complex effect on a H2/N2 mixed gas permeation for CMS membranes.

New class of tough gel membranes containing a large amount of ionic liquids (ILs) in an inorganic/organic double-network, termed inorganic/organic double network ion gel (DN ion gel) was fabricated. The inorganic/organic double-network could be easily synthesized in the same IL pot, which allowed the preparation of freely shapeable DN ion gel, including a film shape. The DN gels showed excellent mechanical strength (more than 25 MPa of compressive fracture stress) without any leakage of ILs under compression. From tensile stress loading/unloading test, it was confirmed that the excellent mechanical strength of the DN ion gel was owing to the inorganic network which acted as a sacrificial bond to dissipate the loaded energy and the organic network which played a role of hidden length to sustain large deformation.

The gas permeation under pressurized condition was examined by using the tough ion gel membrane containing more than 80 wt% of an IL. As expected, the ion gel film was not destroyed under high trans-membrane pressure differences up to 700 kPa. Regarding the CO2 separation performance, the CO2/N2 selectivity was almost same as that of the supported ionic liquid membranes. The DN ion gel membrane with optimized network composition and 80 wt% ionic liquid sustained about 1200 barrer of CO2 permeability and 25 of CO2/N2 selectivity for more than 300 h at 50 oC under humid condition. In addition, it was confirmed that the CO2 permeability as well as CO2/N2 selectivity of the ion gel membrane containing more than 90 wt% of an IL was almost same as that of the supported ionic liquid membrane. The superior gas permeability of the ion gel membranes stem from the fact that there is almost no diffusion resistance in the ion gel owing to its low polymer content.

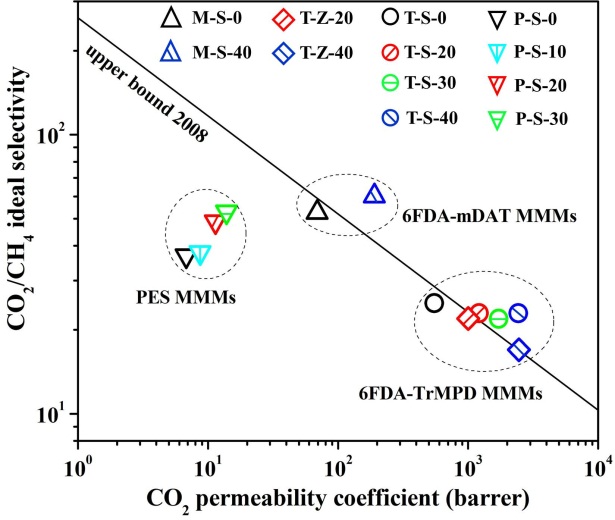

Membrane separation technology has been investigated and applied into purify natural gas, especially removing CO2 from CH4 to reduce the pipeline corrosion and increase heating value. Polymer membrane has easy processability, high reproducibility but reaches a limit in a trade-off between permeability and selectivity (Robeson upper bound line). Inorganic membrane owns excellent separation property and mechanical stability, while its high-cost membrane fabrication demands improvement. Blending inorganic particles into the polymer matrix to prepare mixed matrix membranes (MMMs) could be considered as an appropriate method due to it could combine both advantages of polymer membrane and inorganic membrane.

In this study, nanoporous SAPO-34 zeolite (~0.38 nm) and ZIF-8 particles (~0.42 nm) were severally added into polyimide (6FDA-TrMPD and 6FDA-mDAT) and polyethersulfone (PES) to prepare MMMs for CO2/CH4 separation. The filler, polymer and N-methyl pyrrolidone (solvent) were mixed to form a homogeneous solution with filler content in polymer about 0 wt.% ~ 40 wt.%. The solution was cast on a glass plate and the formed MMMs were peeled off after drying. The single gas permeation through the membranes was tested by vacuum method at 1 atm and 35 °C.

According to the figure, 6FDA-TrMPD/SAPO-34 MMMs (T-S-0~40) and 6FDA-TrMPD/ZIF-8 MMMs (T-Z-20~40) possessed the highest CO2 permeability. The 6FDA-mDAT/SAPO-34 MMMs (M-S-0~40) provided the best CO2/CH4 ideal selectivity. Addition of SAPO-34 could both increase the gas permeability and selectivity of PES/SAPO-34 MMMs (P-S-0~30) and 6FDA-mDAT MMMs. In term of 6FDA-TrMPD MMMs, all the SAPO-34 and ZIF-8 could only enhance the gas permeability at a slight loss of selectivity. Nevertheless, the separation performance of 6FDA-TrMPD MMMs containing 30%~40% SAPO-34 (T-S-30 and T-S-40) still exceeded the Robeson upper bound line (2008) of the polymer membrane, which was the same as the 6FDA-mDAT MMM with 40% SAPO-34 zeolite (M-S-40).

In recent years, microfiltration is used in wastewater and drinking water treatments, and food and pharmaceutical industries. In the process of using microorganisms, the feed solution is a complex mixture comprising bacterial flocks and microbial metabolite. Therefore, it is essential to clarify the mechanism of flux decline behaviors in microfiltration of microorganism and its metabolite. The key objective of this study is to examine the effect of polysaccharide-protein interaction on membrane fouling caused by microbial metabolite since the microbial metabolite is composed mainly of polysaccharides and proteins. Microfiltration experiments were performed in a dead-end filtration mode using various types of solutions at pH of 4.5 and 6.5 under constant pressure condition. Sodium alginate (SA) with the molecular weight (MW) of 129 kDa was used as model polysaccharide, and lysozyme with the MW of 14.3 kDa, the isoelectric point (pI) of 11.0 and bovine serum albumin (BSA) with the MW of 67 kDa, the pI of 5.1 were used as model protein in this study. The flux decline behaviors were observed in the case of mixture of polysaccharide and protein, and in particular, the filtration rate of solution containing SA and BSA was influenced by the solution pH. The BSA molecule is negatively charged at pH 6.5 and positively charged at pH 4.5, while at both pH values, the lysozyme molecule has a net positive charge, and SA molecule has a negative charge. It is obvious that the effect of the surface charge of protein on the filtration resistance should be considered.

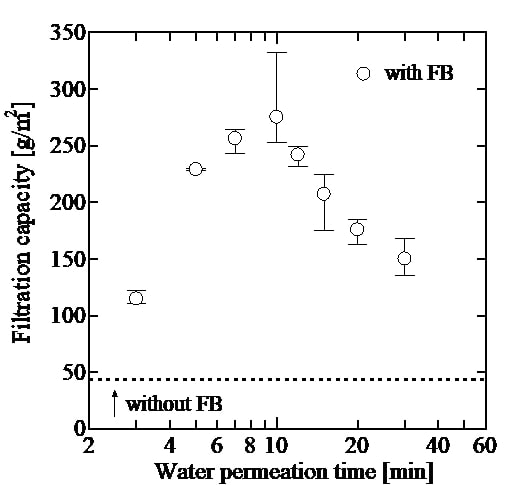

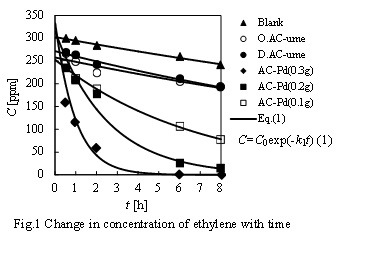

Algal bio-fuel as alternative to fossil fuel has been attracting lots of attention due to the global warming and depleting natural fuel resources. However, the cost of bio-fuel production is relatively high. Especially, harvesting and dewatering of microalgae suspension are reported to account for 20 - 30 % of the total cost, because suspended solid (SS) concentration of microalgae culture is low with 0.02 - 0.06 wt%. Therefore, efficient dewatering process is required. This study examined the performance of dewatering of microalgae suspension by cake filtration using filter cloth.

Two hundred milliliter of microalgae suspension with 0.02 wt%-SS was filtered at constant pressure (70 kPa) using filter cloths (24.4 cm2 of effective area) made from polypropylene, which have different pore size 0.8 - 14 μm. Average permeate flux was increased from 5.9 to 2600 L/(m2 h) with the increase in pore size, while SS rejection was decreased from 94 to 53 %. The filtration behavior was analyzed by existing filtration models. As a result, when filter cloths with smaller pore size than algal cell size (about 8 μm) were used, filtration mode was finally settled into cake filtration. On the other hand, for the filtration using filter cloth with 14 μm of pore size, filtration mode was not settled into cake filtration. Then, in order to conduct cake filtration using filter cloth with 14 μm of pore size for expecting high permeate flux, pre-concentrated suspension (0.1 wt%-SS) was filtered with the intention of forming a cake layer quickly by the deposition of many algal cells on the filter surface. Consequently, microalgae suspension was successfully concentrated up to 18 wt%-SS with 360 L/(m2 h) of average permeate flux and 99 % of SS rejection. These results suggest the potential of microalgae dewatering by cake filtration with high flux and rejection.

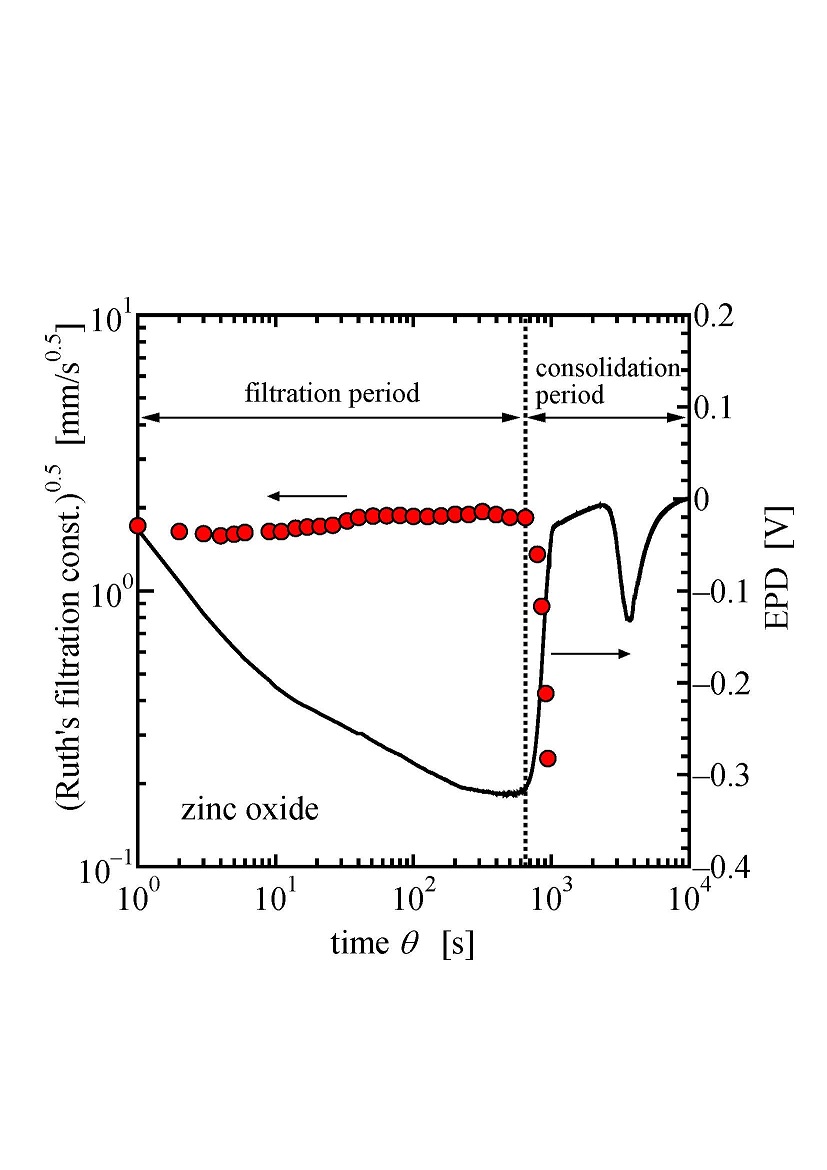

Expression is the separation of liquid from a solid/liquid system by compression due to the movement of the retaining walls of the filter chamber. In the expression of slurry material, the application of mechanical pressure to the retaining walls causes a sudden increase of hydraulic pressure uniformly throughout the slurry. Initially, the process of expression proceeds based on the principle of filtration, where the thickness of filter cake increases over time. Filtration terminates when the whole slurry forms a layer of filter cake, and the consolidation of the cake follows. Exact identification of the time when the chamber is filled with the cake is essential for an effective expression operation. The electrokinetic response of expressed material provides us with some information on the status of the filter chamber. In this work, we have measured the time course of electric potential difference (EPD) between the retaining walls to elucidate the electrokinetic aspects of mechanical dewatering. The experimental apparatus used in this study consists essentially of a piston press with a cylinder and a piston. Filter media are placed at the cylinder bottom and the very end of the piston. EPD between the filter media was monitored during the experiment. As can be seen from the figure, the absolute value of EPD increases with the progress of the filtration period, followed by the decrease during the consolidation period. It was observed that the time when the absolute value of EPD began to decline coincides with the time when the filtration period ended. We have derived a theoretical equation of streaming potential for a flow path of the expressed material and combined it with filtration and consolidation theories to calculate the theoretical time course of EPD of expressed material. It has been found that EPD reflects liquid pressure variation throughout the solid/liquid mixture.

The application of membrane filtration processes has been increased because of global shortage of water. Membrane fouling is considered as a major factor limiting the use of the membrane filtration process and is the irreversible alternation in the membrane caused by specific physical and chemical interactions between membrane and various components present in the process stream. The fouling configuration can be classified into three simple mechanisms: pore narrowing by adsorption, pore blocking/plugging and cake/gel layer formation. In many actual processes the species causing the dominant fouling effects is not always known because of the complexity of the feed stream. Identifying the foulant and understanding fouling phenomena are required for adopting countermeasures for the fouling. Electrostatic and hydrophobic interactions are recognized as the major interactions causing fouling. The zeta potential of the foulant or the membrane, that is, the electrical potential at the surface of shear between the solid and the liquid, can be useful for the prediction of the electrostatic interaction. Adsorption is a major cause of membrane fouling in microfiltration of macromolecule containing solutions. The change ratio of zeta potential by protein adsorption is directly proportional to the surface coverage regardless of pH. In pore blocking or cake formation caused by fine particles the location of pressure drop in the system depends on the fouling configuration. The zeta potential reflected the local pressure drop part, where the gap between particle and pore in pore blocking filtration and the gap between particles in cake filtration. These observations shows the zeta potential will useful for monitoring the fouling configuration during the filtration operation.

Traditional pharmaceuticals have been made from chemical processes. Today, a significant fraction of valuable pharmaceuticals, such as hormones, insulin, growth factors, interferon, enzymes, drug intermediates, etc. are replaced by biotechnology processes. One of the building blocks is to make protein out of recombinant processes where extracellular or intracellular protein can be “engineered” and secreted from host biological cells which have been inserted with vectors carrying human genes. The host cells, e.g. the mammalian cells, bacteria and yeast can secret high amounts of recombinant protein in a bioreactor or fermenter. For extracellular protein, the first step in harvesting protein is to separate the protein from the cells. On the other hand for intracellular protein, the bacteria cells have to be lysed first before releasing the protein in form of inclusion body, for which separation follows. Disk stack and tubular centrifuges operating between 4,000–15,000 times gravity are popular choices to make separation of cells, cell debris, and proteins from the broth. We will discuss the various scenarios of centrifugal separation of protein in clarification, separation, classification and purification by washing during protein harvest. This is an extremely important step that affects yield and downstream processes, e.g., purification by chromatography. We will also discuss testing, modelling and prediction of protein separation in protein harvesting. Further, new technologies on separation of flocculated bio-solids and other popular biotech separation processes by centrifugation will also be discussed.

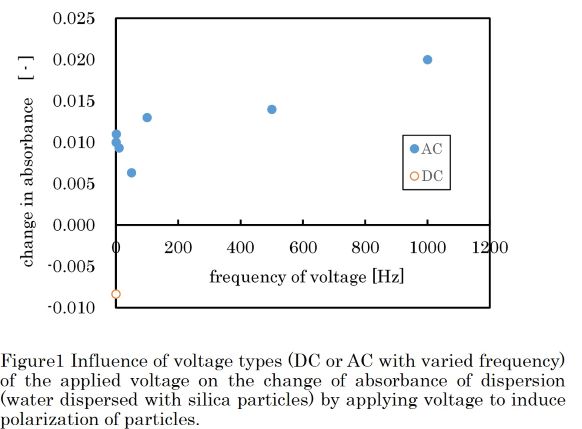

A deformable gel-packed chromatographic column was used to separate as-synthesized graphite oxide with different sizes. The synthesized gel (56 micrometer) was deformed by pressure of the fluid flow and the gaps in the gels showed a range of sizes. A suspension of graphene oxide (0.1 g/L, 10 mL) was injected, and graphene oxide in the elution had a size at 0.56 micrometer and 0.14 micrometer, whereas in half upper and bottom domain of the gel layer graphene oxide had a size at 33 micrometer and 2.9 micrometer, respectively, demonstrating that graphene oxide suspension was separated by size through gel layer. On behalf of graphene oxide, suspension of silica particle produced by dry process was also injected to the elastic gel -layer to separate silica particles due to their size and morphology.

To elute the filtered colloidal particle among the gel, the elastic gel layer was compacted and extended by the change of the applied pressure of water. At that time due to the dynamic change of the gel layer, the filtered particles was gradually eluted by the expansion of the gel's gaps as well as the convection of the fluid flow. The recovery percentage of the silica particles filtered was increased with increasing the repeated time of compaction and extension of the elastic gel layer.

The capture of solute into freezing part is difficult by the vigorous agitation of the freezing interface during the fast freezing of solution. We have been studying the applicability of ultrasonic irradiation (frequency: 20 kHz) to the agitating method, and found that the freeze concentration efficiency of solutes is improved greatly by this irradiation. In this paper, the effect of the frequency of ultrasonic irradiation on the freeze concentration characteristics for multiple solutes is examined.

Using three kind of solutions containing only one solute (Histidine, Vitamin C, and saccharose (these can widely be found in the food materials), 0.03 mol/L), we examined the freeze concentration characteristics with ultrasonic irradiation. The frequencies of ultrasonic irradiation were 20 kHz and 200 kHz, which were adjusted to the same output (11.8 W). From the experimental results, decreasing dissolved oxygen concentration (DO) can increase the concentration efficiency of all solutes in the case of 20 kHz ultrasonic frequency. On the other hand, in the case of 200 kHz ultrasonic frequency, increasing DO may increase the concentration efficiency. The DO dependence of the concentration efficiency differs depending on the frequency of ultrasonic irradiation and solute type.

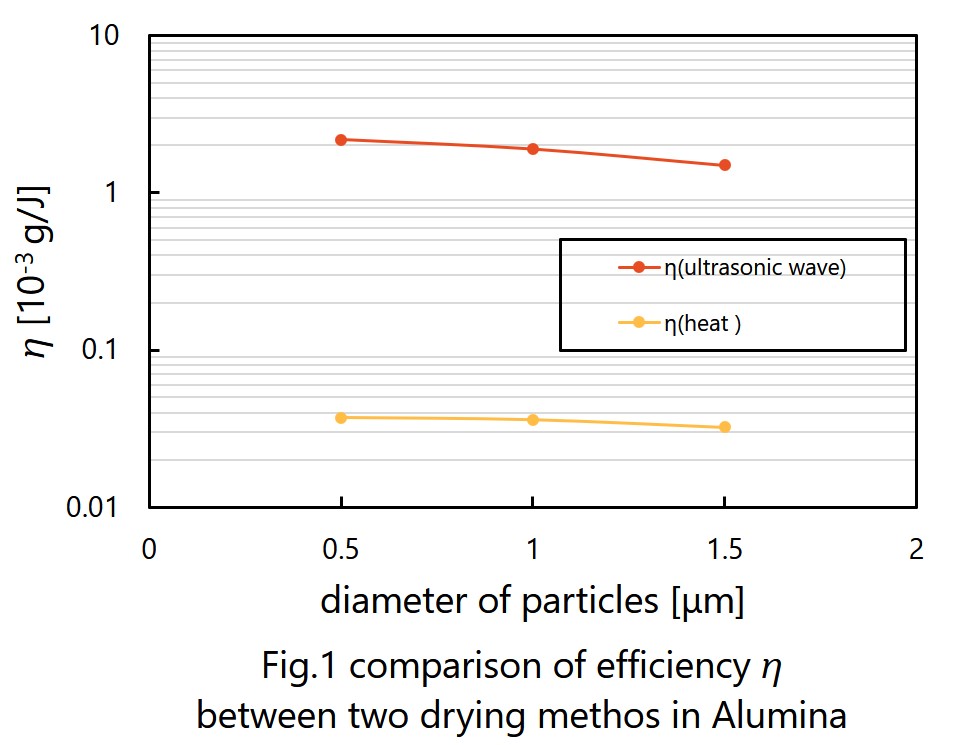

Ultrasonic wave is applied in many situations, for example cleaning glasses, sensors, dispersion. In cleaning glasses, the frequency of ultrasonic is about 100 kHz. When the frequency of sonication increases to about 2 MHz and vibrates water, water becomes mist and flies away. This phenomenon is ultrasonic atomization. In this research, we applied this atomization to drying particles that is useful in chemical processes. This drying method is called ultrasonic drying.

It is expected that ultrasonic drying will be faster and consume less energy than drying by heat. We had three experiments to prove them. First was testing whether ultrasonic can dry wet particles. I tried to dry fly ash by ultrasonic and observed how humidity of fly ash changed. Next is measuring the rate of ultrasonic drying. We prepared three kinds of particles, alumina, silica and fly ash. I moreover prepared three different diameter of alumina and two different diameter of silica to see whether the rate of ultrasonic drying depends on the diameter of particles. Last is comparing efficiencies of ultrasonic drying and traditional drying. We measured the loss of weight of materials by drying and the consumption of electronic energy. Efficiency of drying, as shown in Fig. 1, is defined by the weight loss divided by the electric energy consumption.

The result of first experiment was that mist appeared from the surface of particles, so we were sure that ultrasonic can dry materials. Second experiment suggests that the rate of ultrasonic drying has positive dependence on diameter of particles. This experiment, however, cannot show difference in dying rate among different particles. Efficiency of ultrasonic drying gotten in last experiment is approximately 100 times better than one of drying by heat. Considering by those outcomes, ultrasonic drying will replace some current drying methods in a few decades.

Consumer products largely originate from fossil resources which will be depleted sooner or later and contribute to CO2 emissions and climate change. Alternatives are sought with low carbon emissions and these are inexhaustible resources like plant derived biomass. Our motivation is to optimize the extraction process of lignin. The only water pre-treatment process and combination with organic solvent Soxhletation was carried out in the first stage to reduce impurities. Soda process and diluted acid process were chosen for extraction methods and microwave-assisted as the main instrument for heating up solution.

The results showed that pre-treatment process by using water following with isopropanol-hexane was given the best result. Water helped to extract sugar, alcohol, and some water soluble impurities. When isopropanol extracted the rest of polar impurities that water could not be done, Hexane was extracted non-polar impurities such as lipid. It could have extracted about 5.3 % weight loss of impurities without changed the lignin structure significantly due to TGA and FTIR results. This study aims to extract lignin in moderate temperature, pressure, and power in as little concentration and time as we could achieve. The process was done with soda process for 2 wt% NaOH concentration at 130 oC with 30-min extraction process as the best result rather than diluted acid process. The amount of lignin obtained about from this process was relatively higher both in 99.7% yield and 94.6% purity compared to other studies result. This type of lignin has similar characteristic to commercial dealkaline lignin.

This study aimed the treatment of the aqueous solution contaminated by antibiotics with duckweed, Lemna minor, which was reported to uptake organic compounds in the aqueous solution, and the removal of the antibiotics in the aqueous solution with duckweed under various conditions was measured to study the mechanism of antibiotics removal from contaminated solution. Firstly, it was confirmed that the molar concentrations of ciprofloxacin and sulfamethoxazole, which were selected as model antibiotics to be treated because of most popular antibiotics causing aquatic environmental pollution, could be reduced due to the mechanisms of hydrolysis, photo-degradation and uptake by duckweed. Ciprofloxacin was more degradable due to hydrolysis and photo-degradation in the aqueous solution than sulfamethoxazole, and the degrees of the molar concentration reduction due to uptake by duckweed were comparable for both antibiotics. In the cases of the treatment of ciprofloxacin of the initial molar concentration at 1×10-5mol/L, the reduction of the molar concentration due to the hydrolysis and photo-degradation shared 0.6 relative to the total reduction of the molar concentration, and the ratio of reduction due to uptake relative to the total reduction was 0.4. On the other hand, the molar concentration reduction of sulfamethoxazole due to the uptake relative to the total concentration reduction was 0.95, and the contribution of the hydrolysis and photo-degradation to the total reduction of ciprofloxacin concentration was so small. When the initial molar concentrations of both antibiotics increased up to 5×10-5mol/L, the contributions of these three factors to the antibiotics reduction were similar to the cases with the initial concentration as 1×10-5mol/L. Accordingly the uptakes of both antibiotics by duckweed were so influential to reduce the molar concentrations in the aqueous solution, especially for sulfamethoxazole, and this treatment method might have a potential to remediate the aquatic environment polluted by antibiotics.

The response surface methodology was applied to study and to optimize the surfactant-enhanced extraction of tea tree oil (TTO), i.e. the essential oil of Melaleuca alternifolia, by hydrodistillation method. Both Tween 20 and Tween 80 were used as surfactants added in the hydrodistillation vat with an aim to enhance the extraction yield of TTO. In principle, this study evaluated the relevance of several independent parameters, including the concentration of surfactant, extraction time, and liquid/solid ratio, against TTO yield with a design of experiment (DOE) based on response surface methodology. Central composite design (CCD) was used to optimize the processing condition of TTO extraction. The chemical compositions of tea tree oil were analyzed and quantized by GC-FID and were referred with the international standard "ISO 4730". Additionally, TTO obtained from optimal condition was examined on the stability of its microemulsion formulations as well as the antibacterial property, compared with the commercial TTO. The microemulsion stability was mainly determined by the particle size measurement with dynamic light scattering (DLS), whereas the antibacterial assay was carried out by agar disk diffusion method with Escherichia coli and Staphylococus aureus.

Keywords: Melaleuca alternifolia; Extraction; Design of experiment (DOE); Optimization

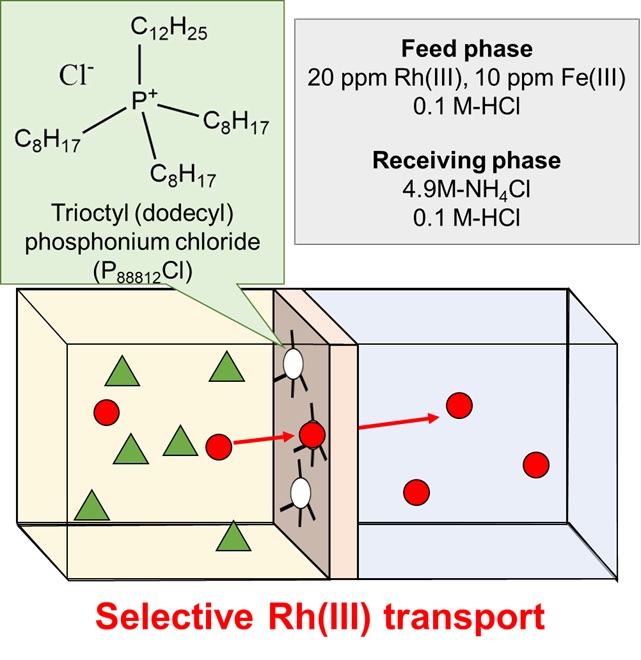

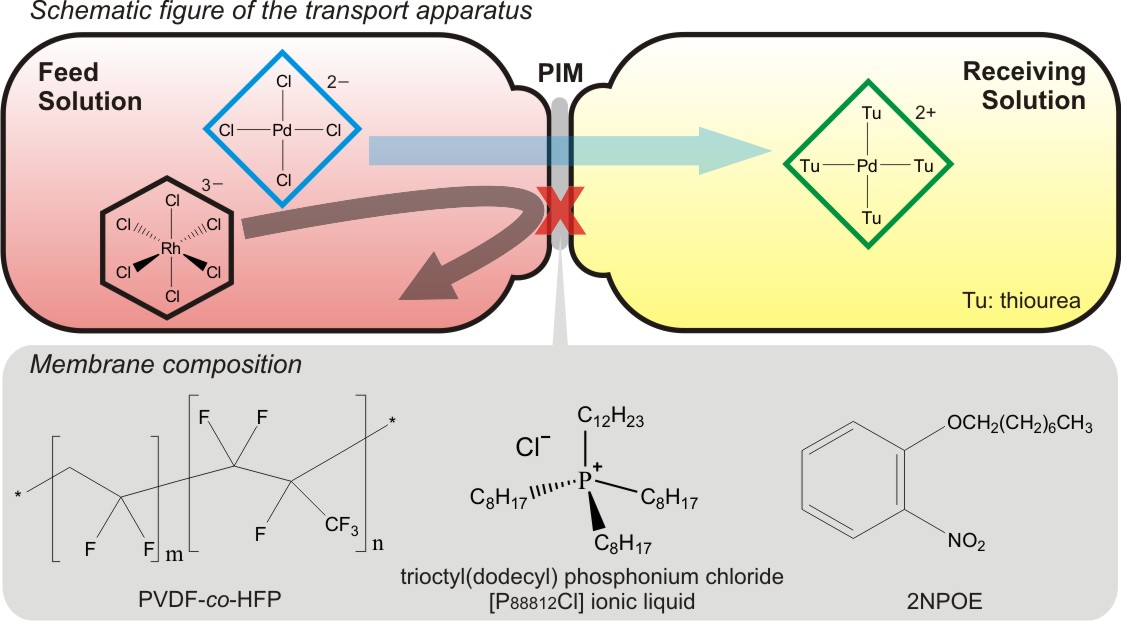

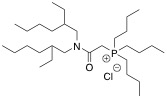

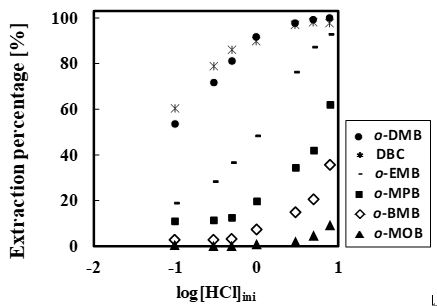

Solvent extraction (SX) is generally used for separation and purification of platinum group metal (PGM) in hydrometallurgical processes. The development of a successful SX process depends on the choice of appropriate extractants. Therefore, we have been studying the extraction behavior of PGM with newly synthesized extractants in addition to the structural properties of PGM complex anions extracted in the organic phase.

We have developed a new palladium extractant, thiodiglycolamide (TDGA), which can rapidly extract Pd(II) from HCl solution with a good selectivity and has a high oxidation resistance, compared with an industrial palladium extractant, di-n-hexyl sulfide (DHS). Currently, TDGA has been commercially available and already put to practical use in a PGM separation plant.

To date, there have been no effective practical extractants for rhodium in acidic chloride media, because the dominant rhodium species in relatively concentrated HCl solutions ([RhClx(H2O)6–x]3–x (x ≥ 4)) are poorly extracted into an organic phase. We have found that amide-containing tertiary amine (ACTA) compounds show a higher efficiency for the Rh(III) extraction from HCl solution than the conventional tertiary amine extractant, tri-n-octyl amine. The protonated ACTA molecules extract the mono-aquated dianion [RhCl5(H2O)]2– through the formation of an outer-sphere assembly, which was characterized by slope analysis, FT-IR, EXAFS, SANS, computational modeling, etc.

Prices of strategic metals and rare earth elements (REEs) have been rising over the past decade due to the global shortages in supply and increasing demands. These metals are essential components of advanced and emerging technologies associated with transport, environment, energy, defense, electronics, information and aerospace. With the utility of REEs projected to increase in the next decade, it is important to find alternative sources to conventional mining to cope with the demand. There are a few studies conducted on the potential of coal fly ashes as secondary resource of REE. Coal fly ash are waste products from coal burning in a coal power generation plants.

This research is aimed at extracting rare earth elements from coal fly ash by hydrochloric acid leaching. The purpose of this study is to explore the amenability of coal fly ash to metallurgical processing for the extraction of rare earth elements. Three process parameters were investigated in this study, namely, hydrochloric acid concentration, leaching time, and the leaching method. Results of the experiment showed that the recovery of rare earth elements increased with increasing hydrochloric acid concentration. Direct leaching method achieved higher recovery values for REEs compared to sequential leaching. Maximum recovery value for REEs was obtained at 1 h leaching time.

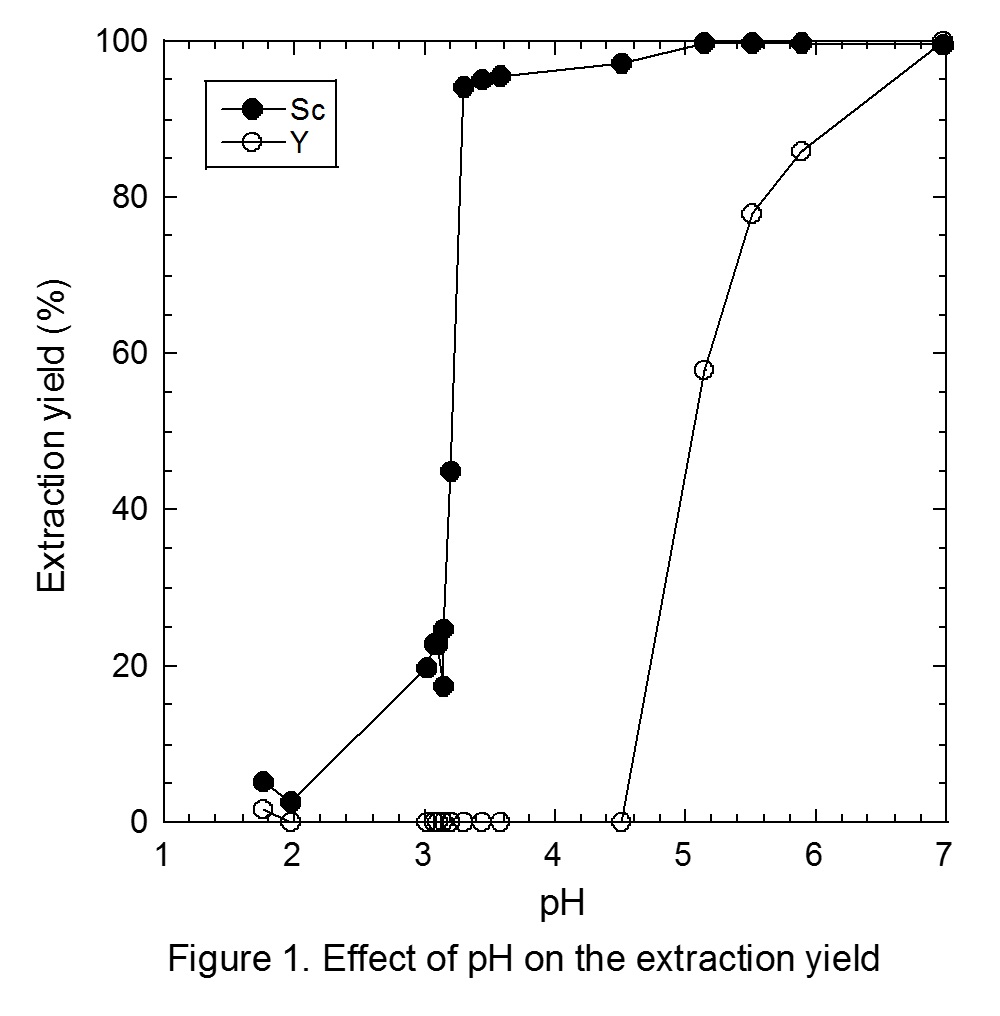

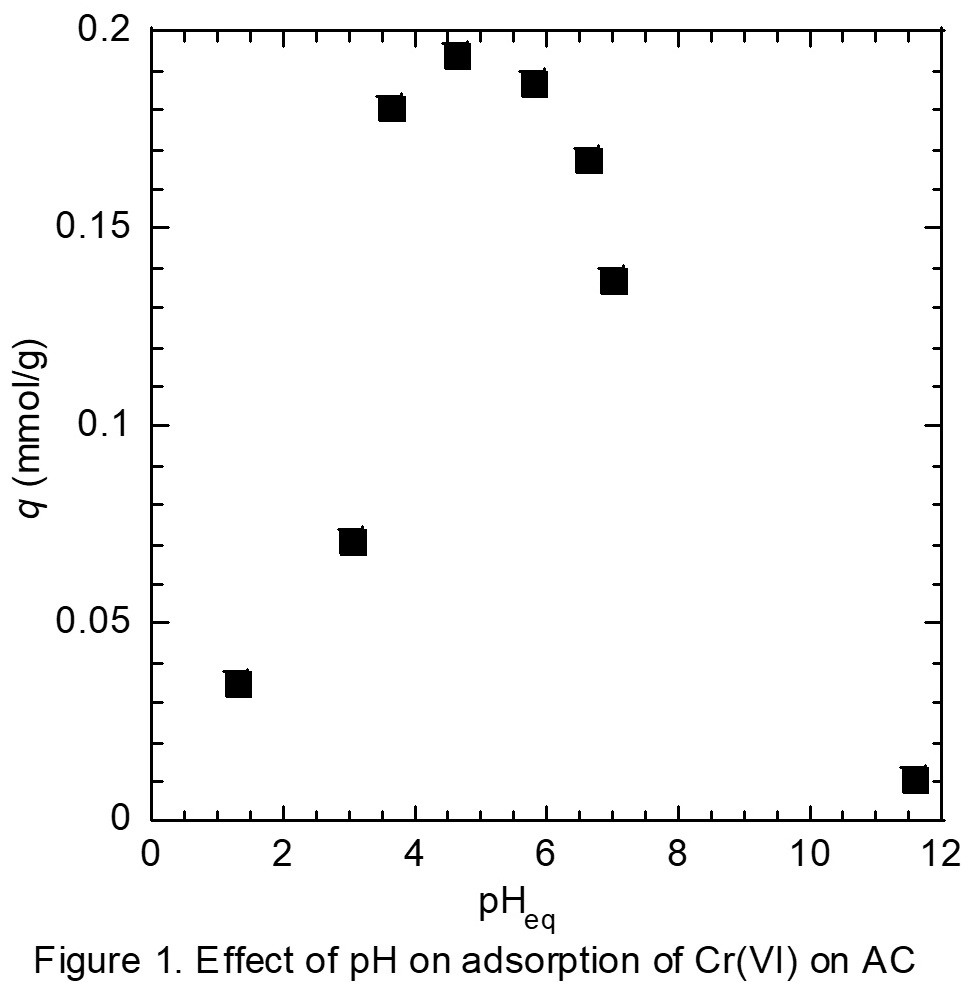

Scandium (Sc) is rare and expensive metal in high demand, providing excellent characteristics for various industrial applications. Since Sc is commonly found in crustal together with Y owing to its small ionic radius, the separation of Sc from yttrium (Y) and other rare earths is required. In the present work, separation and recovery of Sc in an aqueous chloride media was investigated by solvent extraction with carboxylic acid, Versatic acid 10.

The aqueous chloride solutions of rare earths were prepared by dissolving their oxides in 1 or 2 mol/L HCl solution. Organic solution was prepared by diluting Versatic acid 10 in IP Solvent 2835. Extraction of Sc and Y was carried out by shaking the organic and aqueous solutions at volume ratio of 1 : 1 at 25oC for more than 6 h. Concentrations of the metals in the aqueous solutions were determined by ICP-AES and those in the organic solutions were calculated based on material balance.

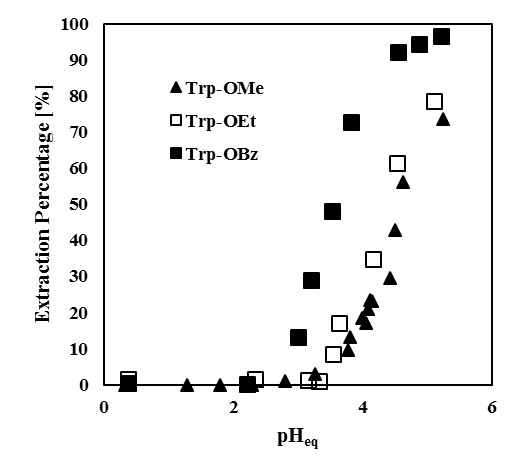

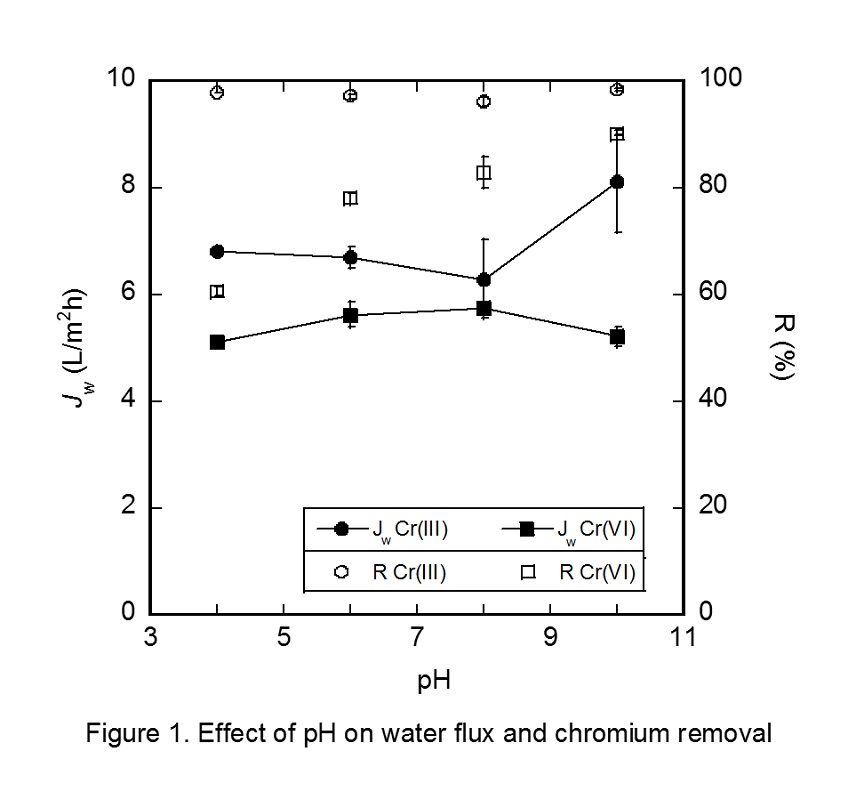

Figure 1 shows the effect of pH on the extraction yields of Sc and Y from the binary solution. Extraction of Sc proceeds from pH 3, and is increased with pH, while the extraction of Y proceeds from pH 4.5. Separation of Sc and Y is therefore easily achieved with Versatic acid 10. The conventional slope analysis of Sc with Versatic acid 10 revealed that the extraction is based on the cation exchange mechanism and the stoichiometry of Sc and the dimeric extractant of Versatic Acid 10 was 1 : 3.

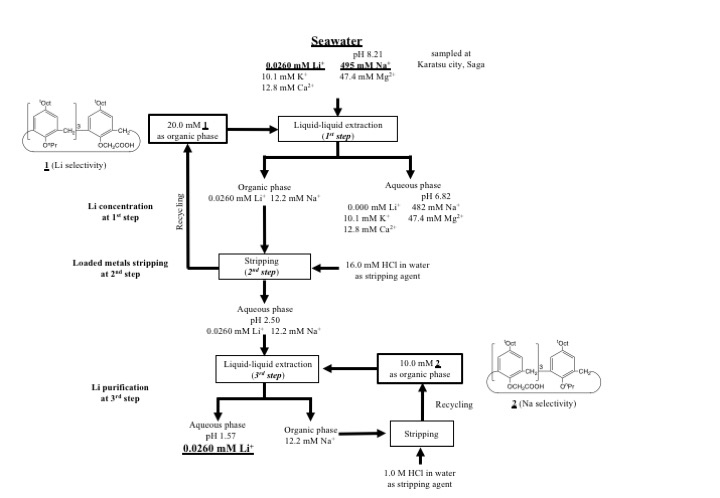

Two derivatives of p-t-octylcalix[4]arene were prepared to investigate extraction behavior of alkali metal ions. Tripropyl-monoacetic acid derivative (1) exhibited lithium selectivity among alkali metal ions, while Triacetic acid-monopropyl one (2) showed sodium selectivity. Then, they were employed for individual and stepwise recovery of alkali metal ions using microreactor system. Finally, they were employed for Li recovery from the seawater. Compound 1 was applied for Li recovery to concentrate Li ion at the 1st step and to strip the loaded metal ions, and compound 2 was employed to remove sodium ion for Li purification. Lithium ion was successfully completely recovered form seawater with two derivatives using microreactor system. Flow sheet for Li recovery with two derivatives using microreactor system is shown in Figure.

The polymer inclusion membranes (PIMs) composed by polymer and carrier without plasticizer have been used in this study. The extractant used in this study is containing in long alkyl chains and double bond. The great benefits of PIMs are to be used a small amount of extractant and less organic solvent and also are less leak of the extractant out of the membranes.

In the near future, it is expected that a large amount of wastes of used solar panels containing In(III), Ga(III) and Zn(II) is discharged. In this research, we were interested in alkyl-derivatives of sarcosine as an extractant to selectively separate In(III) and Ga(III) from Zn(II). Accordingly, a comparison of the metals(In(III), Ga(III) and Zn(II)) extraction was performed using four kind of extractants (two types of carboxylic acid and two types of sarcosine) and three polymers. Among them, We found the membrane containing poly(vinylidenefluoride-cohexafluoropropylene) (PVDF-HFP) as a polymer skeleton and N-oleoylsarcosine as a carrier. This membrane exhibited highly selective to In(III) and Ga(III) in hydrochloric acid solution. Finally we found that the PIM containing N-oleoyl sarcosine could perform the selectively separate In(III) and Ga(III) from Zn(II) from hydrochloric acid. In addition, we succeed in containing 60 % w/w N-oleoylsarcosine in the membrane.

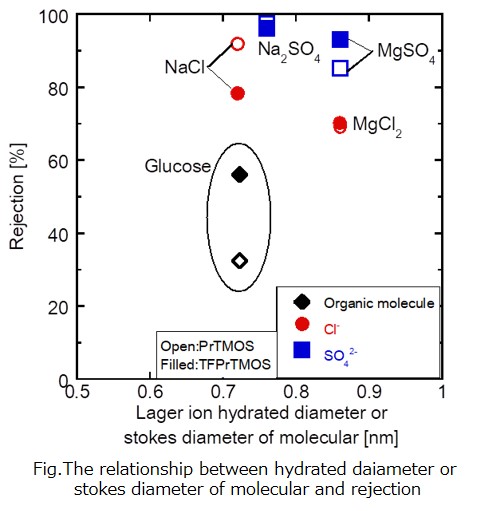

We successfully developed a novel nanofiltration membrane that enables the separation of Mg2+ and Ca2+ from effluents in the electrodialysis process in salt productions. For that purpose, we first fabricated the polyamide layers using piperazine and trimesoyl chloride onto microfiltration membranes as supports, and then immobilized poly(2-methacryloyloxyethyl)trimethylaminium chloride) (polyMTMA) covalently on the surfaces and the pore walls of the polyamide layers by the plasma graft polymerization method. The polyMTMA grafted on the substrates made the membranes surface positively-charged, and at the same time reduced the pore sizes. Throughout the systematic nanofiltration experiments using various single salts with concentrations of 1.9 x 103 ppm, a membrane with a grafting amount of 0.24 mg cm-2 showed the following rejection performances that positively-charged nanofiltration membranes typically exhibit; the observed rejections (Robs) for NaCl, CaCl2, MgCl2, Na2SO4, CaSO4, MgSO4 were 0.20, 0.64, 0.65, 0.21, 0.35, 0.44, respectively. We also carried out Mg2+ separation tests from Na+-rich solutions by using aqueous solutions containing NaCl and MgCl2 with the ratios of 9:1, 14:1, and 19:1 as feed. The results indicated that around half of Mg2+ ions were retained with the permeation of more than 80% of Na+ ions.

Acknowledgement: Part of this study was financially supported by a grant from the Salt Science Research Foundation, Japan.

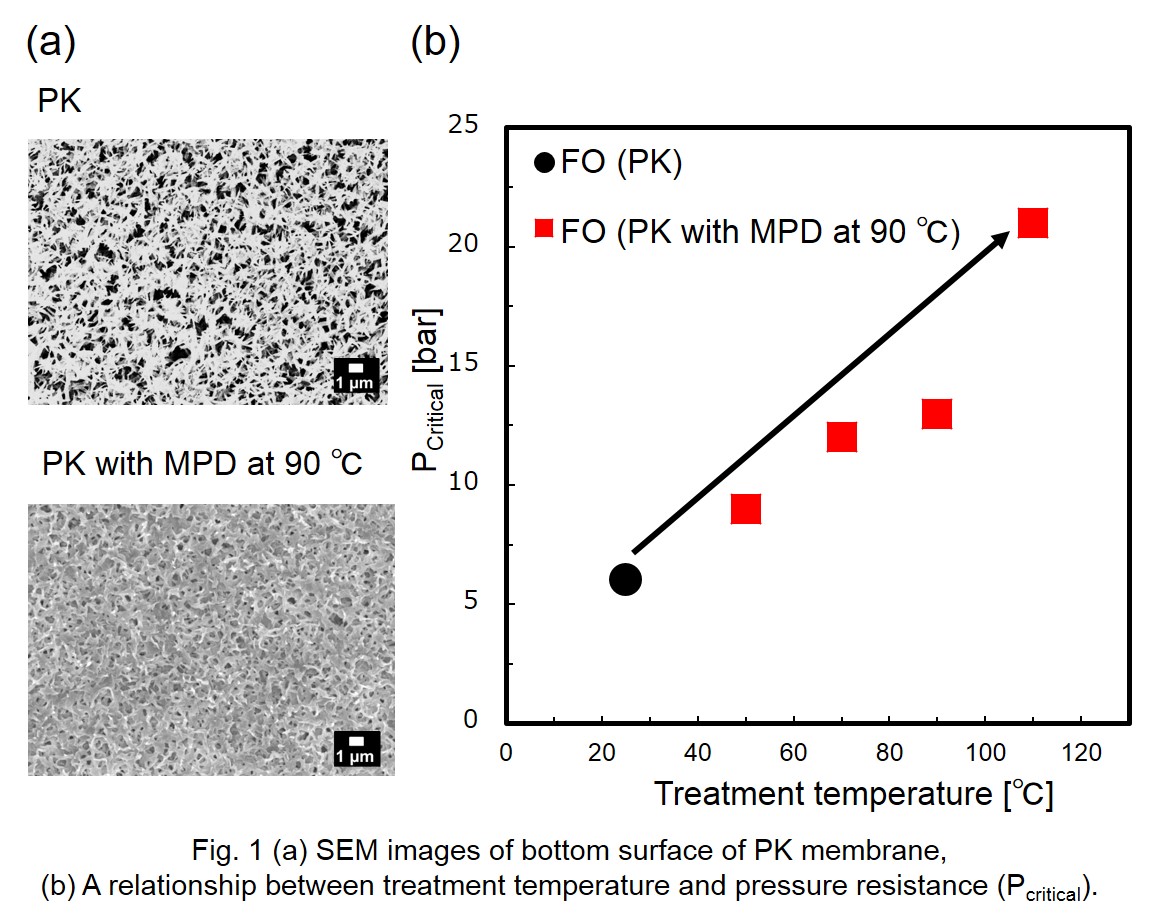

Oil/water separation has attracted more attention in both of academia and industry due to the increased amount of oily wastewater from the industrial process and frequent oil spill accidents, causing fatal damage to ecosystem and people's health. How to treat the oily wastewater has become a big challenge all over the world. In this work, an innovative aliphatic polyketone (PK) membrane surrounded by hydrophilic silica nanoparticles with hierarchical micro/nanoscale structure was developed by a APTES-assistance deposition process. With the APTES help to make the PK membrane positive charged, the negative charged silica was uniformed deposited on the membrane surface. The resultant silica-d-PK membrane displays superhydrophilicity, ultralow oil-adhesion underwater superoleophobicity, and distinctive self-cleaning ability, as well as excellent solvent resistance. More important, the membrane shows ultrafast and anti-oil-fouling separation performances for different oil-in-water emulsions. Therefore, it is very promising for large-scale applications.

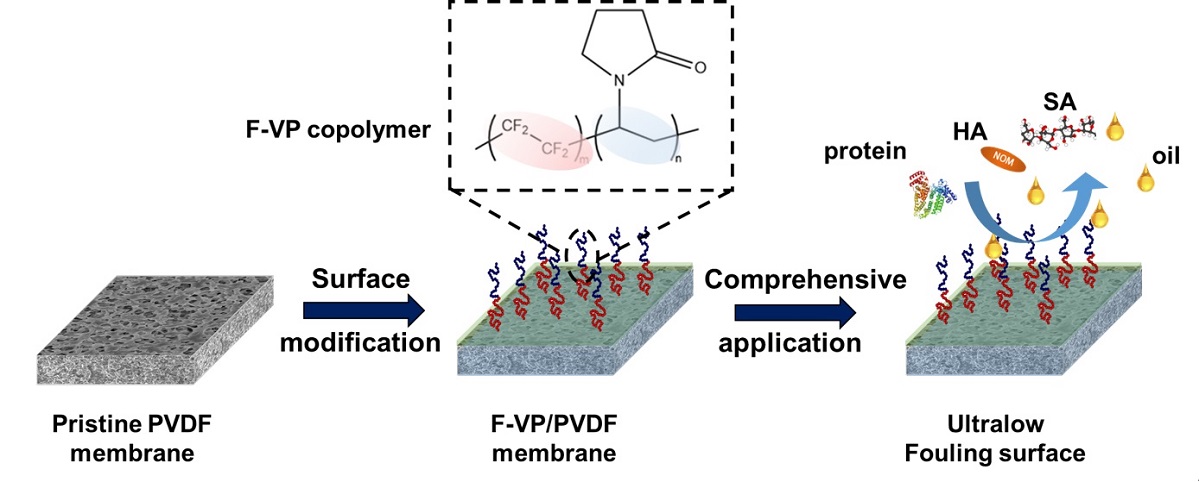

Fouling problem caused by oil and other pollutants is one of the most severe challenges for membranes used for the purification of comprehensive oil-in-water emulsions. Poly(tetraflouride-r-vinylpyrrolidone) (F-VP) with low-adhesive superleophobicity is a class of novel material for fouling-repellent membrane modification to achieve highly-efficient separation of complex oily wastewater. In this work, the construction an ultrathin F-VP layer with a controllable thickness of 2 μm supported by polyvinylidene difluoride (PVDF) substrate was achieved, via an extremely simple, scalable and one-step surface modification process. Benefiting from the ultrathin fouling-resistant skin layer, the resultant F-VP/PVDF membrane exhibited a superior comprehensive fouling-resistant and fouling releasing property, while maintained a highly mass-transfer efficiency without significant flux sacrificing. The intrinsically non-fouling nature of F-VP modification layer endowed the F-VP/PVDF membrane with superoleophobic property to various oils, superhydrophilic/under oil superhydrophilic properties, and excellent antifouling property for comprehensive oil-in-water emulsions. It is capable of efficiently separating the oil-in-water emulsions with a high water permeability of 4612 L m-1 h-1 bar-1, high emulsion permeability (10000 ppm soybean oil-in-water emulsion) of 461 L m-1 h-1 bar-1 with high rejection ratio of >99.9%, and an outstanding stable fouling-resistant and fouling-releasing property of ~93% flux recovery, over 5-time continuous cyclic tests. Overall, this work provides an insight into a facile preparation of advanced composite membrane with ultralow fouling-propensity property, which shows a great potential in treating practically challenging emulsified wastewater.

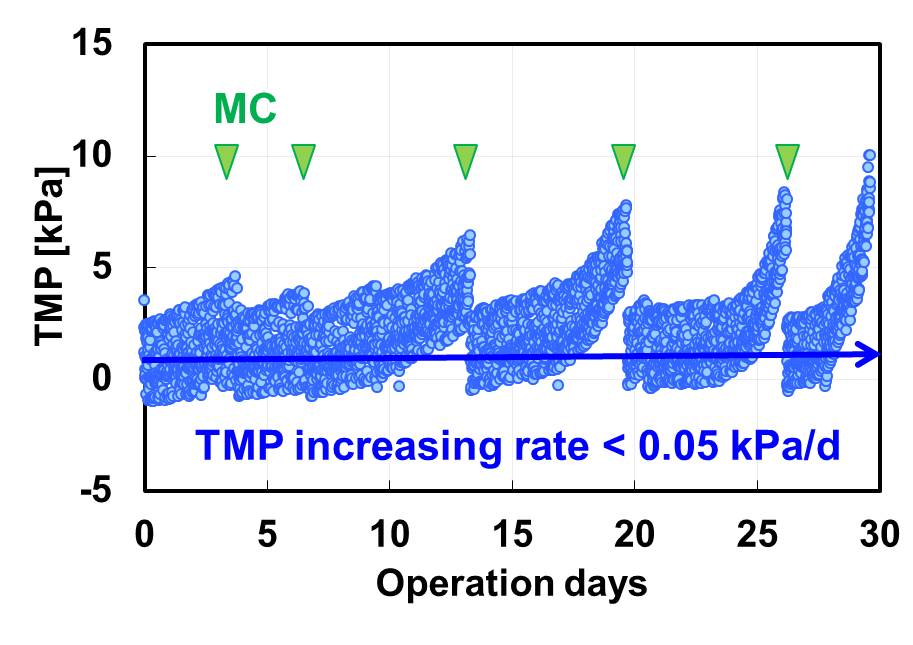

Membrane bioreactor (MBR) technology has many advantages from the views of high product water quality, small footprint and high possibility of treated water reuse. The critical challenges of MBR are membrane fouling and high energy consumption. Membrane air scouring is the main cause of high energy consumption in MBR. In fact, overall energy consumption can be reduced by operating at high flux or low air flow, on the other hand, serious membrane fouling will occur under high suction pressure. We investigated the fouling mechanism and main foulant type in high flux operation (42 LMH) comparing with low flux (25 LMH). The total amount of protein and polysaccharide clogged in the membrane at high flux operation was 2 times higher than that at low flux operation. Those clogging foulants in membrane pores were considered to be responsible for serious fouling at high flux operation. In order to mitigate those foulants, low concentration chemical cleaning, so-called maintenance cleaning (MC) was applied.

Additionally, we focused scouring efficiency to remove foulant from the membrane at low air flow operation. In order to increase scouring efficiency, new MBR structure that has 3 times higher scouring efficiency than the current MBR structure was developed. Scouring efficiency was improved by increase of the probability of contact of air and membrane in the new MBR.

A verification test using new membrane module at high flux and low air flow was conducted for a month with periodic MC every 3-7 days (Figure). The base membrane TMP (Trans Membrane Pressure) increasing rate was maintained at less than 0.05 kPa/d. The aeration energy consumption per product water was reduced 80% in high flux and low air flow operation.

Aromatics have numerous applications in the chemical and petrochemical industries (Odedairo and Al-Khattaf 2011). Transalkylation which includes transfer of alkyl group from one molecule to another is one of the prominent catalytic processes for the conversion of aromatics, especially for the production of industrially important products like xylenes, ethylbenzene, cumene, and cymene (Brown and Nelson 1953). The products of transalkylation reactions have commercial importance as they are derived from low-valued by-products like diethyl or diisopropyl benzenes, toluene, and benzene. An attempt was made to transalkylate low-valued toluene to industrially important product of great commercial value. A series of zeolite (LaB, CeB, and PrB) containing rare earth metals lanthanum (La), cerium (Ce), and praseodymium (Pr) were used for transalkylation reaction. The modified beta zeolites were characterized by EDS, XRD, BET, FTIR, and TPD. The effect of various process parameters like metal loading (2–10 wt%), catalyst loading (1.44–8.63 w/w%), temperature (448–573 K),reactant ratio 1–15, and space time (3.2–9.29 kg h/kmol)on the conversion of reactant and selectivity of product was studied. Catalytic performance of praseodymium-modified beta zeolite shows highest cumene conversion (86.4 wt%)and cymene selectivity (65.7 wt%) compared to other zeolites. The maximum cumene conversion and cymene selectivity were obtained at 523 K, toluene-to-cumene ratio of 9:1, and a space time of 9.29 kg h/kmol. Kinetic modelling of the reaction was done to estimate the reaction kinetic constants and adsorption constants. The activation energy of the transalkylation was found to be 61.44 kJ/mol.

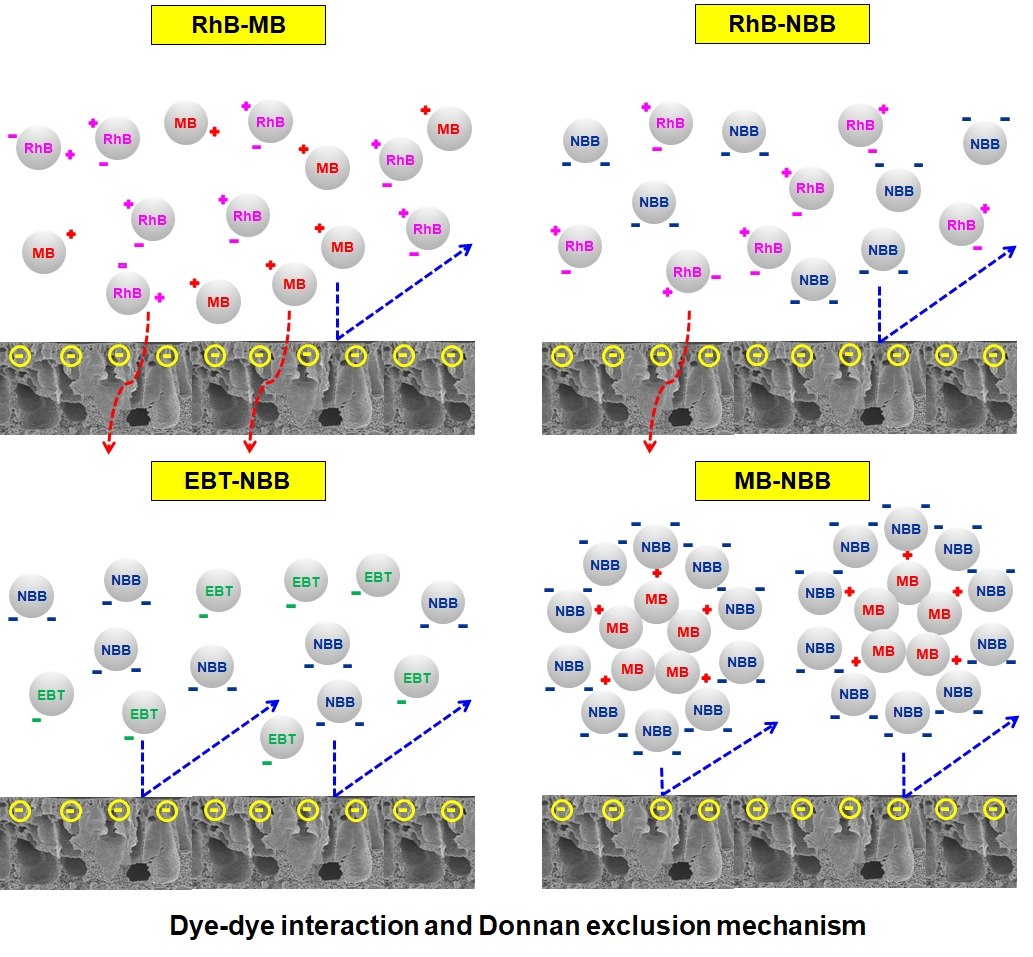

The objective of our research was to investigate the impact of dye-dye interaction on the separation performance of dual dye systems through an ultrafiltration (UF) membrane. Four representative charged dyes were chosen for single experiments, including rhodamine B (RhB) - a zwitterionic dye, methylene blue (MB) - a cationic dye, and eriochrome black T (EBT) and naphthol blue black (NBB) - anionic dyes. Four binary dye mixtures (RhB-MB, RhB-NBB, EBT-NBB and MB-NBB) were then studied in mixture experiments. A microporous poly(vinylidene fluoride) (PVDF) UF membrane was prepared via phase inversion method for the dye separation. The Donnan exclusion effect was proven as the predominant dye removal mechanism. The PVDF membrane surface was negatively charged in almost all experimental dye solutions (pH > 4.5). Therefore, zwitterionic RhB had nearly no rejection (1.1%), cationic MB exhibited low rejection (45.6%), whereas anionic EBT and NBB achieved high removal rates (83.5% and 89.1%, respectively). In dye mixtures, the mixed zwitterionic or same-charged dye solutions (RhB-MB, RhB-NBB and EBT-NBB) showed rejection efficiencies similar to their components' single dye solutions and filtrate permeance values in the range of the constituents' single dye solutions. On the contrary, in the case of the mixed opposite-charged dye solution (MB-NBB), intermolecular interaction induced the formation of micron-scale dye aggregates which provided stronger negative surface charge and were readily repulsed by the membrane. Hence, the MB-NBB mixture attained almost complete dye removal (98.0%) along with an enhanced permeation rate (111.1 L m-2 h-1 MPa-1). The excellent performance stability for all the dye feeds was demonstrated during three-cycle filtration tests. The separation mechanism proposed in this work can be applied to real dye wastewater systems of multi-components. The filtration performance may be predicted once the molecular interactions are known, and the surface zeta potentials of the solutes and membrane are identified.

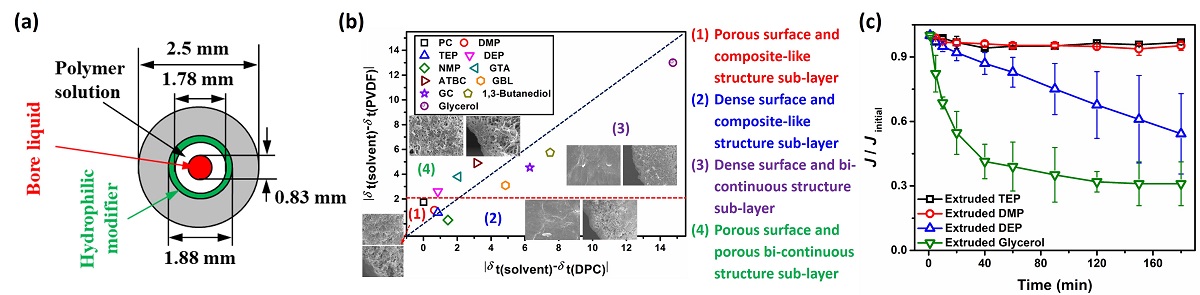

In this work, we demonstrated for the first time that by extruding solvents at the outermost layers of the extruded polymer solutions in the thermally induced liquid-liquid phase separation by using a triple orifice spinneret, both the surface and sub-layer structures of hollow fiber membranes were effectively tailored. Hence, four essential characteristics of the membranes, permeability, rejection, permeation stability and mechanical strength were balanced here simultaneously.

The ternary interactions among the extruded solvents, diluent and polymer played a substantial role in tailoring the surface pore size and permeation stability of TIPS-prepared membranes. At the interfaces between extruded solvents and polymer solutions, apart from the segregations of diluent or polymer that control the surface pores size, composite-like structure (spherules connected by the bicontinuous network) at the sub-layer substantially affected the membrane permeation stability. Regarding the importance of the ternary interaction in tailoring the surface pore size and the permeation stability of the prepared membrane in TIPS process, turn on a spotlight for selecting appropriate extruded solvents to obtain hollow fiber membranes with high water permeability, permeation stability, controlled pore size, and satisfying mechanical strength.

Jatiluhur dam is one of the biggest dams in Indonesia which serves water for various activities of millions of West Java population such as for fisheries, agricultures, recreations and also as a source of clean water and drinking water. The water comes from Citarum River which passing through different areas thus dissolves various impurities during their travel along the river body. One of the impurities that usually occur in surface water is natural organic matter (NOM) that extracted either from the soil or decaying of plants or animals contacted with the water body. NOM may harmful to human since during water treatment it will produce DBPs (Disinfection by Products) which are carcinogenic compounds.

This study is aimed to investigate the characteristics of NOM at Jatiluhur dam water and their removal efficiency using membrane. The water was obtained at 0.2 and 5 m depth and taken at two different seasons; rainy and dry season. Meanwhile, one commercial ultrafiltration membrane and two commercial nanofiltration membranes were investigated at various pressure and pH for NOM removal. The research found that the characteristics of NOM found on Jatiluhur dam were dominated by hydrophobic compounds either at rainy or dry season. The best permeability was obtained by using ultrafiltration membrane at pH 6 and 6 bar operated pressure. Whilst, higher rejection is obtained by nanofiltration membrane by around 73% of the NOM was rejected at pH 6 and 4 bar operated pressure.

Keywords: Membrane, NOM, Jatiluhur Dam, Drinking Water, Hydrophobicity

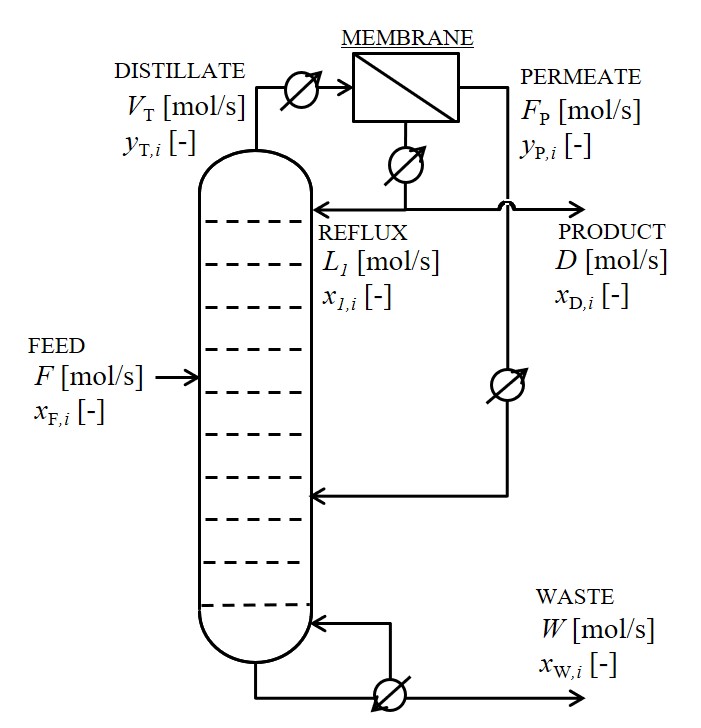

Energy conservation of distillation processes is still an important issue in process industries. Though the heat pump has been said to be a promising tool for energy saving, it has not been applied to many processes. One of the drawbacks that obstructs the installation is the high equipment cost of the custom-ordered compressor. In this paper, we propose to introduce a general-purpose heat pump system (G-HP) to the distillation processes. G-HP is superior to a custom-ordered heat pump in the cost and the maintainability, that is very important feature for the long term operation.

The G-HP proposed in this research uses water as the working fluid in the heat pump. The coefficient of performance (COP) decreases with the increase of the temperature difference between the heat source and the heat sink. Thus, it is preferable to select the heating and cooling stages that has small temperature difference. On the other hand, the efficiency of distillation is highest when the heat is supplied to the reboiler (highest temperature position) and removed from at the condenser (lowest temperature position). It means that the proper selection of the heating and cooling places is important.

In this study, by taking the simplicity of the process structure into account, the vapor to the condenser is selected as the heat source. The required compress ratio depends on the selection of the heat supply stage and affects COP. We executed the simulations of the cases having various VLE curves and product specifications, and derived the best location of the heating stage and the condition suitable for the introduction of G-HP. The effectiveness of the structures having double heat pumps that supplies heat to the middle of the column and the reboiler, and those having double feed streams is also discussed.

Since methanol is an attractive fuel and chemical for various applications, its demand will continue to increase in energy year. Most methanol is currently produced from fuel such as natural gas through steam reforming. A methanol–water mixture is produced from the carbon monoxide or carbon dioxide and hydrogen in the presence of a catalyst and distilled to acquire pure methanol.

Self-heat recuperation was recently developed as an energy-saving process design, in which overall-process internal energy caused by condition changes is recirculated within the process without the need for heat addition, leading to a reduction in the energy requirements of several chemical processes.

In this study, the feasibility of applying self-heat recuperation technology to the industrial methanol synthesis process which possesses both temperature and pressure changes, a reactor and separators was investigated from energy-saving and process design points of view, based on actual plant data. Based on simulation results, it was concluded that the use of self-heat recuperation technology is an attractive alternative for sustainable future development of the methanol synthesis process.

Mass transfer was both experimentally and theoretically investigated based on shell model for a packed distillation column equipped with wire-mesh structured packing. The experimental column consists of three packed beds stacked in series and total bed height is 5,320 mm. In order to observe local variation of HETP, thermocouples were embedded at an equal interval on the column centerline. Each thermocouple can be considered to measure the temperature of internal reflux liquid owing to its large heat capacity. Distillation test was conducted at normal pressure under total reflux condition with three kinds of binary systems. Local variation of HETP in each bed region was determined by comparing the observed temperatures with the calculated ones due to the process simulator package. After obtaining the corresponding overall HTU from the experimentally obtained HETP, the vapor-phase and liquid-phase film coefficients were calculated by solving a simultaneous equation deduced between two vertical locations. However since the stripping factor remains almost unchanged in the top and bottom regions, it was considerably difficult to obtain an appropriate simultaneous equation without approximation. On the other hand, it has been found that those film resistances can be easily determined by assuming that the tie-line and VLE equilibrium curve should have an orthogonal relation at an arbitrary theoretical stage.

As a result, this orthogonal model successfully gave comprehensive correlation of vapor-phase and liquid-phase HTUs with the corresponding F-factor and superficial liquid load.

Although this investigation is still in the process of analysis, the orthogonal model has a possibility to lead to further progress in distillation mass transfer from a view point of transport science.

The development of the industrial systems for the year 2050 has been well defined in the recent Research Agenda with many strategic sectors, such as water, energy, food, health, etc. The drive towards greater sustainability has prompted process industries to search for opportunities to decrease their production costs, energy consumption, equipment size, and environment impact as well as improve the raw material yields, remote control, and process flexibility. Distillation process as a dominant player among all separation technologies are typically energy and cost intensive. One of the major challenges in distillation process industry is thus to improve the energy efficiency of existing and/or new processes through economic and ecological strategies. Integration, intensification and hybrid approach of distillation have become the main trend to achieve green and sustainable chemical process. Process integration and intensification is defined as a set of innovative principles applied to the design of processes and equipment to satisfy those concerns about energy and ecology impact of the process. The energy efficiency of a distillation process could be maximum by optimizing the design and operational parameters. However, as distillation processes become more complex in structure and operation through integration, intensification and hybrid, to find their optimal design and operation conditions drawing out its full potential is also becoming more challenging. This presentation will review briefly applications and trend of integration, intensification, and hybrid of distillation processes with their optimization. The potential and reliability of these technologies are addressed briefly, which will enable distillation process to achieve higher efficiency and high capacity. The recent developments in current research are summarized to highlight the importance as well as the effects, challenges, and future prospects of distillation process integration, intensification, and hybridization.

Orthogonal model of interphase mass transfer in a packed column distillation process

Kunio Kataoka, Goro Nishimura, Hideo Noda and Hiroshi Yamaji

Kansai Chemical Engineering Co., Ltd

2-9-7 Minami-nanamatsu-cho, Amagasaki, Hyogo 660-0053., Japan

Mass transfer model was investigated for a distillation column which consisted of three packed beds of wire-mesh structured packing stacked in series. Thirteen thermocouples for local liquid temperature observation were embedded at an equal interval on the centerline of the packed beds. The distillation experiment was conducted with a binary solution of methanol and ethanol under total-reflux conditions. The F-factor was varied as the control parameter by changing the heat duty of the reboiler. The shell balance model was based on a cylindrical control volume having a local HETP as the shell height. The process simulation analysis was done by using a simulator package in the same condition as the experiment. Local variation of HETP, HTU, and volumetric overall mass transfer coefficient were analyzed by comparing the experimental data with the process simulation results,

In order to analyze interphase mass transfer based on the two-film theory, an orthogonal relation between the tie-line and the vapor-liquid equilibrium curve was assumed, so that the vapor and liquid compositions can be evaluated at the vapor-liquid contacting interface. This orthogonal assumption definitely determined vapor-phase and liquid-phase volumetric film coefficients of mass transfer. By means of dimensional analysis, the vapor-phase and liquid-phase mass transfer coefficients defined in the form of j-factor data were well correlated with the corresponding Reynolds number.

In the middle bed where the accuracy of local HETP observation is the best, a set of correlation functions were obtained by least square.

By virtue of the orthogonal assumption. the Reynolds number dependency of the mass transfer model in the form of j-factor was improved, especially in the liquid-phase j-factor correlation.

These days, many chemical engineers pay much attention to apply heat pump system for improving the energy efficiency of industrial separation processes. In distillation process, heat pump system can save energy significantly by upgrading the low-temperature waste heat to high temperature and utilizing it instead of steam for supplying heat to the reboiler. In this study, a blower based heat pump system was proposed to improve the energy efficiency of separation and purification processes in chemical industry. This paper showed the advantages and disadvantages of a blower based heat pump system and figured out when it can be applied. Blower based heat pump system is mainly used when there is only a small temperature difference between the hot and cold streams, where small pressure ratio and consequently smaller blower duty are needed. Several important industrial cases have been investigated to demonstrate the proposed configuration. By applying blower based heat pump systems, the latent heat can be circulated during the process, leading to a substantial improvement in energy efficiency. Notably, the operating costs can be reduced by up to 78%, 64% and 82% for the C3 splitter, C4 splitter and refrigerant separation processes, respectively.

Acknowledgement

This project is supported by the R&D Center for Reduction of Non-CO2 Greenhouse Gases (201700240008) funded by the Ministry of Environment as a ‘Global Top Environment R&D Program' and Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (2018R1A2B6001566) and by Priority Research Centers Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (2014R1A6A1031189).

In order to improve the economics of the ETBE production, binary and ternary VLE data for ETBE(1)+Ethanol(2)+TBA(3) system are measured and correlated using NRTL-RK model. According to the obtained thermodynamic model, pressure dependence of the azeotropic point between ETBE(1)+Ethanol(2) system is evaluated using the Residue Curve Map. The separation feasible flow sheets are derived from the Residue curve maps and modeled using Aspen Plus. The process economics and performance are evaluated with those of the existing Uhde Process.

Since fossil fuel combustion systems will still be used to meet the energy demand of the future, capture of CO2 represents a global environmental challenge. Simultaneously, removal of hazardous chemicals is a critical issue from environmental standpoints. Therefore, environmental regulations for industries from acceptable levels of human exposure become continuously more stringent to cope with the emission of CO2 gas as well as to protect humans from toxic chemicals. For practical applications, the developed sorbents should be structured into pellets or beads, satisfying the stability, working capacity, shape, etc.

Herein, MgO was prepared by various synthesis methods of nano-sized mesoporous MgO to optimize the platform material for MgO composite for sulfur removal and CO2 sorption. To improve the removal and decomposition efficiency of sulfur compounds, various MgO composites were developed: MgO-SiO2, MgO-Fe3O4, carbon-coated MgO, etc. The developed MgO composite showed higher performance than commercial activated carbon in sulfur removal. Then we exploit new synthesis methods for the development of porous MgO composite beads. The as-prepared spherical beads featured diameters of hundreds of micrometres, hierarchical porosity, and high surface areas. With respect to pre-combustion CO2 capture, the sorption working capacity of the salt-promoted MgO composite beads is comparable to that of powder MgO, with remarkable cyclic stability. However, at more real regeneration condition using CO2 flow, stable operation was achieved after several cycles, where the working capacity was 1.3 and 1.6 times higher than that of the corresponding powder and pressed-pellet sorbents.

Finally, in the presentation, a platform simulation model of a dual fluidized-bed system for CO2 capture and sorption enhanced reaction, which consists of a fast fluidized-bed carbonator and a bubbling fluidized-bed regenerator, will be also introduced.

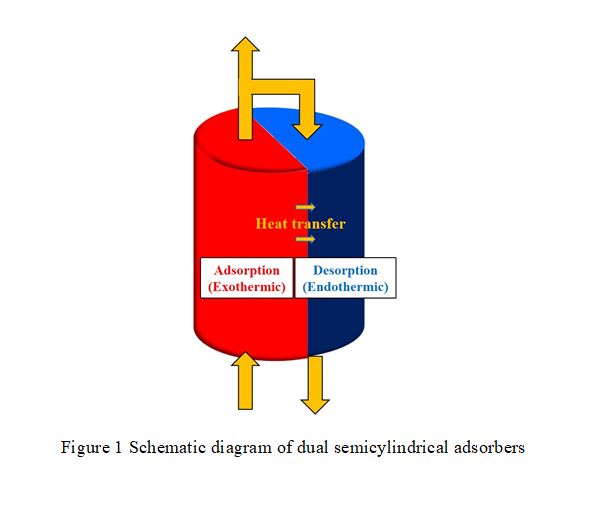

This simulation study utilizes zeolite 5A to separate oxygen from air in order to compare the performance of semicylindrical adsorber with that of traditional cylindrical adsorber for pressure swing adsorption (PSA). The semicylindrical adsorbers are designed to contact and exchange heat to each other by lateral surface area. Therefore, semicylindrical adsorber can have better heat compensation during adsorption and desorption, which increases the oxygen purity in Skarstrom cycle.