Abstract

Chemical diffusion and reaction are generally involved in the formation of materials. These two processes are coupled together and play a role in the structure evolution of materials. Although the individual role of diffusion and reaction has been investigated, it is still unclear how these two factors work together to determine the materials structure and what is the mechanism behind. Firstly we used different approaches to regulate the diffusion and reaction rates in the synthesis of silver particles [1-3]. The role of diffusion and reaction in shaping particles was generalized. At a diffusion limitation, small silver particles were obtained and big polyhedral particles were formed at a reaction limitation. In the middle range of diffusion and reaction, dendritic structures were largely produced, which is independent on the preparation methods. In the following, the control on diffusion and reaction has been extended to synthesize other materials and the similar results were obtained [4-6], which further confirms the general role of diffusion and reaction in shaping materials. The Damkoehler number was employed to quantify the relative change of diffusion and reaction[7]. It was found that the morphology of materials is dependent on the relative strength of diffusion and reaction. Since the diffusion and reaction determine the chemical distribution around the growth front of materials, the local chemical gradient was proposed to be the mechanism of diffusion and reaction controlling materials structures, which was verified by measuring the local chemical distribution by laser interference as well as by conducting phase field simulation.

References

[1] Chemical Engineering Science 2018, 192, 254-263.

[2] Chemical Engineering Science 2015, 138, 457-464.

[3] Ind. Eng. Chem. Res. 2016, 55, 8319-8326.

[4] CrystEngComm 2017, 19, 72-79.

[5] Crystal Growth & Design 2013, 13, 1820-1825.

[6] Advanced Energy Materials, 2019, doi.org/10.1002/aenm.201900019.

[7] Crystal Growth & Design 2016, 16, 2850-2859.

Numerical modeling plays a leading part for virtual manufacturing in industries. When numerical technologies are utilized in the general industrial systems, high-accuracy, simple operation and calculation efficiency are always required. The requirements are the same even in powder industries. In the author's group, innovative models such as coupled discrete element method (DEM) with volume-of-fluid (VOF), signed distance functions (SDF) and coarse graining DEM have been developed for the simulations of granular flows in industrial powder systems. The SDF makes it possible to create an arbitrary shape domain by simple operation. The SDF has been applied to various powder systems such as mixers, die filling and conveyers so far. Besides, calculation domain for simulations of industrial multi-phase flows including solid particles can be created easily by combining the SDF with immersed boundary method (IBM). The coarse graining DEM is a scaling law model and can simulate large-scale systems by smaller number of computational particles than actual ones. Efficiency of the coarse graining DEM has been examined through several industrial systems such as a spouted bed and a fluidized bed. The DEM-VOF method can simulate gas-solid-liquid flows in an arbitrary shape domain because the SDF and the IBM has been introduced as wall boundary model. The DEM-VOF has been applied to a complex gas-solid-liquid flow system such as a twin screw kneader. Adequacy of these models has been proven through verification and validation tests. Hence, in the future, usage and/or combination of these models will be useful for virtual manufacturing.

This study is financially supported by JSPS KAKENHI grants (17KK0110, 17H02825 and 17H03451).

The inhaled drugs are generated as aerosol in dry powder inhalers (DPIs) and then delivered into respiratory tract. The deposition in the target sites mainly depends on a number of factors related to anatomical structure variation, particle characteristics and inhalation conditions (inhaled angle and breathing pattern e.g.). This project aims to numerically and experimentally investigate the effects of inhalation parameters on fine particle deposition in the US pharmacopeia throat (USP), idealized mouth-throat (IMT) and realistic mouth-throat (RMT) models with a commercial inhaler (Handihaler®). In the numerical model, the flow-field equations are solved by computational fluid dynamics (CFD). The monodispersed and Rosin-Rammler distributed particles in the size range of 1-20 μm are tracked with discrete phase method (DPM). Corresponding physical experiments under the same inhalation conditions are designed to quantitatively and qualitatively characterize particle deposition in realistic mouth-throat as well as validate the numerical results. The results indicate that particle deposition fraction and spatial distribution are highly sensitive to the geometrical variation and respiratory conditions such as the inhalation airflow rate, particle size and inhalation angle. Moreover, the effect of geometrical variation on the particle deposition pattern is more dominant. In the RMT model, inhalation angle creates quite obvious effect on the aerosol delivery, especially for particles depositing in oral cavity. This study could be used to develop an in vitro method which aims to better predict in vivo lung deposition mechanisms of pharmaceutical aerosol.

Keywords: computational fluid dynamics, particle deposition, dry powder inhalers, mouth-throat geometry.

Ironmaking blast furnace industry involves many complex thermochemical processes including, for example, multiphase flows, heat and mass transfers and chemical reactions. It is essential to understand, visualize and optimize the in-furnace phenomena for competitiveness and sustainability under increasing economic and environmental demanding conditions. Mathematical modelling, facilitated by physical modelling, provides a cost-effective way of achieving this goal. In particular, multiscale modelling is widely used in academia and industry for their proven effectiveness. This paper will review our recent CFD- and DEM-based process models and discuss their roles in the development of new technology for sustainable ironmaking. Some recent examples are used: 3D modelling of blast furnace with raceway, 3D modelling of pulverised coal injection, and 3D modelling of cokemaking. It is demonstrated that mathematical modelling indeed plays a significant role in process understanding and optimisation, vital to sustainable modern ironmaking.

Hydrogen production by coal gasification in supercritical water is a promising way of coal utilization due to its clean, efficient and low-carbon characteristics. How to further lower the temperature for complete conversion of carbon in supercritical water is a hot topic. Extensive theoretical and experimental investigations were conducted in State Key Laboratory of Multiphase Flow in Power Engineering since 1997.

(1) The rate-determining steps for the supercritical water gasification of coal particles were obtained at different spatial scales. Experimental device such as supercritical water visual platform that combining Raman spectrometer was established to reveal the microscopic kinetic mechanisms. Density functional theory (DFT) and reactive empirical force fields (ReaxFF) were combined to investigate the rate-determining steps and its reaction enhancement strategy. The directional gasification characteristics can be obtained by coordination regulation and control method of temperature and pressure for chemical/transport properties of supercritical water.

(2) A fluidized reactor operating in supercritical water condition was invented. A series of theories of multiphase flow, heat/mass transfer, and chemical reaction gasification in supercritical water fluidized bed reactor were established. By the approach of the coordinated matching of mass flow and energy flow, the primary reactions were enhanced while the side reactions were suppressed.

(3) A demonstration plant was constructed to verify the above-mentioned theories. The carbon content in coal is completely gasified below 670 °C. The C, H, O content in typical coals can be converted to H2 and CO2, while other impurities are flushed off in clean, non-toxic and inert ashes. The demonstration plant operation has lasted continuously and stably for more than ten thousand hours, which lays a foundation for large scale industrialization and widespread application, so as to provide a new way for the solution of energy shortage problems, haze controlling and the realization of a clean and efficient utilization of coal.

Non-oxidative dehydroaromatization can convert methane into important aromatic products, such as benzene toluene and naphthalene, and produce large amounts of hydrogen simultaneously. A pilot-scale methane dehydroaromatization—H2 regeneration fluidized bed system (MDARS) has been developed. The catalyst circulates between two fluidized beds which are methane dehydroaromatization reactor and catalyst H2 regeneration reactor. The fluidization and energy transportation including mechanism of catalytic reactions are modelled in the Eulerian-Lagrangian Multi-Phase Particle-in-Cell (MP-PIC) methodology, also called Computational Particle Fluid Dynamics (CPFD). MP-PIC model uses a stochastic particle method and an Eulerian method for the fluid phase to solve equations for dense particle flow.

The mechanisms of methane dehydroaromatization reaction and catalyst deactivation reaction were investigated by fixed bed reactor and agreed with the experiment data. The whole system with two reactors and one cyclone was simulated in one model so that the interaction between two fluidized beds and catalyst deactivation can be investigated. The simulation results indicated that the catalytic activity remain stable, and the optimal regeneration-reaction ratio is 8 which consistent with the experiment results. The influence of catalyst particle size and catalyst loading were also investigated. The results showed that the small catalyst particle size can increase the methane conversion and products formation rate. The suitable catalyst loading is between 20~30 gram in consideration of the conversion and formation rate per catalyst mass. More operating conditions can be varied over a wide range to optimize and scale-up the methane dehydroaromatization—H2 regeneration fluidized bed system.

The downer reactor, in which gas and solids move downward in a co-current way, has attracted many attentions in the past two decades due to its unique features such as shorter residence time, narrower residence time distribution, less solids back-mixing and lower pressure drop since gravity acts in the same direction with the flow direction of gas and solids when compared to the flow behaviors in riser. How to increase the solids holds-up in a downer is still an important issue. In this talk, solids volumetric flux (Vs), which is expected to replace the solids mass flux (Gs) as the key factor influencing solids holdup in circulating fluidized beds, was proposed to investigate the solids holdup variation and predict the extreme operation conditions in the downers. It is considered that using Vs to replace Gs to define high-density operation in the downer could be more suitable in this study To increase the solids-up in the downer, the flow behaviors in a series of novel gas-solids co-current downflow conical fluidized bed which is expected to realize a high-density solids holdup along a downer-type pyrolyzer to strengthen the heat transfer efficiency, were systematically investigated by means of a numerical approach. In addition, A Eulerian–Eulerian model incorporating the kinetic theory of granular flow was adopted to simulate the gas-solids flow behaviors in a dense downer below a conventional downer, which could be used for the further pyrolysis of coal and/or decomposition of tar on the generated char before the char and tar are completely separated in a triple-bed combined circulating fluidized bed (TBCFB) system.

(Acknowledgments:This work is supported by the JSPS KAKENHI Grant-in-Aid for Scientific Research B (Kiban B, 17H03451), Japan and the National Natural Science Foundation of China (U1710101)

Biomass is a carbon-neutral fuel and has the potential to replace coal in ironmaking blast furnaces (BFs) under the carbon-constrained environmental policy conditions. However, the flow and thermochemical in-furnace phenomena related to biomass combustion are not clear at industrial scale BF conditions yet. In this study, a three-dimensional (3D) industrial scale computational fluid dynamics (CFD) model is developed for describing the flow and thermo-chemical behaviours related to charcoal injection into the lower part of a BF under the real BF conditions. The computational domain includes lance, blowpipe, tuyere, raceway and the surrounding coke bed regions. The model features characteristics of the industrial scale BF and charcoal materials, including the real dimensions, operating conditions, bird's nest within the raceway, coke bed around the raceway, non-spherical particle shape of charcoal particles, modified sub-models of charcoal chemical reactions. The simulation results show that the charcoal combustion process can be classified into 5 stages based on the evolutions of the gas species, burnout, fuel gas and gas temperature along the particle plume. The behaviour of different charcoal particle size groups varies considerably within the raceway. The combustion profiles of the charcoal and two typical PCI coals are then compared. It is indicated the burnout profiles comparable qualitatively, confirming the potential of charcoal utilization in PCI technology, whereas the temperature and gas species profiles are different from typical PCI operation quantitatively, indicating the charcoal injection and its control strategy should be redesigned in BF practice, for example, the use of finer mean particle size. This industrial scale model is useful for understanding the combustion behaviour of pulverized charcoal and optimising biomass injection operations.

There are continuum and discrete approaches to describe granular flows. A continuum approach relies on local average quantities which can be derived through an averaging method based on a discrete approach. But the selection of averaging domain and the validity of local quantities for constitutive relations are not well established, particularly for transient particle-fluid flows. This presentation is about our recent study in this direction for non-cohesive and cohesive particles. Here, it is demonstrated that converged local quantities can be achieved on an averaging domain with proper spatial and temporal sizes. Furthermore, the relation between solid pressure and solid volume fraction is established, agreeing qualitatively to all the existing monotonic ones in the literature. But it is quantitatively different, showing a bifurcation at a high solid volume fraction, which is essentially linked to the variation of short and enduring contacts among particles with flow state and solid volume fraction. This bifurcation must be properly recognized in developing constitutive relations for granular materials. It is also demonstrated that there are different temporal scales in the fluidized bed and different averaged quantities can be obtained, showing the transient heterogeneous structures.

Coupled method the discrete elements method (DEM) with the computational fluid dynamics (CFD) is widely used for numerical simulation of gas-solid two phase flows, such as fluidized beds. In the DEM-CFD method, the modeling of the arbitrary shaped boundaries and stable algorithm are essential for simulating engineering processes, as industrial systems often have complex shaped wall boundaries. To model arbitrary shaped boundaries, the SDF-IBM wall boundary modelling, where the signed distance function (SDF) are coupled with immersed boundary method (IBM), has been developed. The efficiency and accuracy of the SDF-IBM boundary modeling have been proved through verification and validation tests. On the other hand, when drag forces acting on solid particles becomes extremely high, numerical simulation cannot be performed stably. In order to solve the instability problem, the aim of this study is development of an implicit algorithm for stable calculation for the drag force term. In verification test in the fixed bed, it is revealed that the implicit algorithm solves the numerical instability problem in the drag force. Subsequently, a new robust implicit algorithm which combined the implicit algorithm to SDF-IBM wall boundary modeling is developed and the validation tests are performed in a fluidized bed with inserted tubes. Consequently, a robust implicit algorithm for DEM-CFD method is developed and adequacy of this algorithm is proved through validation tests.

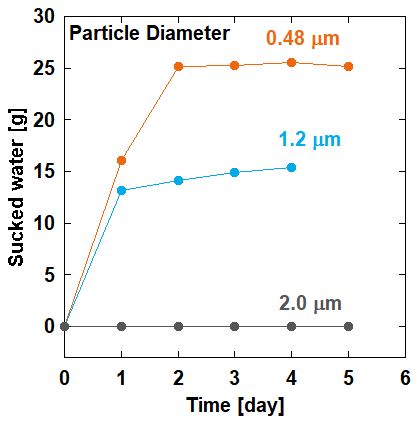

From our previous research, it was found that the sediment of well-dispersed slurry could act as a continuous osmotic pump and kept sucking water for long time. This means that the sediment of well dispersed slurry is expected to be a pump for irrigation and greening desert. In order to achieve this, it is important to increase the amount of sucking water flux, thus, the effects of slurry conditions on the water sucking behavior for the sediment of well dispersed slurry must be clarified. Therefore, in this study, we investigated the effects of slurry conditions such as particle size, particle concentration, slurry height, type of additives, on the water sucking flux of the sediment. In addition, the osmotic pressure generated by the sediment for various slurries were measured. It was shown that the sediment of the smaller particles could generate the larger osmotic pressure and show the higher water sucking flux, since the overlap of the electric double layer became remarkable for the slurry of smaller particles.

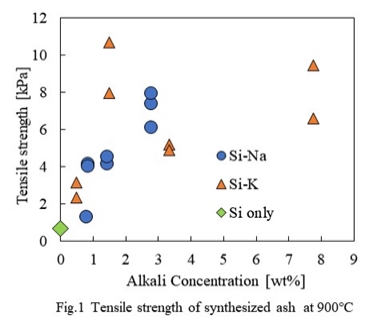

Ash adhesion and deposition phenomena on the surface of super heater and furnace wall has hindered the stable operation of coal, biomass and waste combustion and power generation plants. These phenomena also reduced the efficiency of power generation and heat transfer. Based on the measurement of tensile strength and shrinking behavior of various ash powder bed collected from the coal-fired power plant and waste incinerator at high temperature ranging from 773 to 1173 K, we estimated that a very few amount of liquid or slag phase formation of main component SiO2 with alkali metal, such as Na and K, contributed to the increase of adhesion force between ash particles. However, since many other chemical compounds were included in real combustion ash, it is difficult to discuss the quantitative influence of alkali component in ash on the adhesion behavior at high temperature. In this study, in order to clarify the influence of alkaline components on adhesion behavior, some kinds of synthesized model combustion ash particles with different alkali metal content were synthesized from pure silica particles. The tensile strength and shrinking behavior of each synthesized ash particle bed at high temperature was carried out and analyzed by thermodynamic calculation. Fig.1 shows tensile strength at 900°C of synthesized ashes with different contain of Na and K. By the few amounts of Na and K content (lower than several few %) in synthesized model ash, the adhesion force increased more than several 10 times compared with pure silica particles. Furthermore, alumina nanoparticles, which was useful to reduce adhesion force by the addition with real ash particles in our previous paper, were similarly added to synthesized model ash, and then the effect of adhesion behavior at high temperature were investigated.

As mediators for cell communication, exosomes are an emerging carrier for drug delivery. Cell communication is a dynamic process, will affected dramatically by the cell conditions, however, the present studies only focus on the normal condition. Inspired by this, we compared the cancer cell uptake of five different stressed and normal cancer cell originated exosomes, found that low-pH stressed cell secret exosomes have the highest uptake efficiency (2.9 times of normal exosomes). Lipidomics data and molecular-dynamics simulations indicated that the unique lipid composition played the key role for cancer cell membrane affinity which further affected cancer cell uptake efficiency. The homologous targeting was evidenced by the gastric cancer cell (MGC803) originated exosomes were only uptaken by cancer cells (MGC803, HGC27 and MKN45), the gastric epithelial cell (GES1) exosomes were only uptaken by GES1, the tumor targeting was further verified by the in vivo imaging of biodistribution. Using the low-pH stressed cancer cell exosomes, we loaded the hydrophobic doxorubicin (Dox) in the lipid membrane and a hydrophilic photosensitizer, Al (III) phthalocyanine chloride tetrasulfonic acid (AlPcS4) in the lumen to construct a combined anticancer therapy platform. The reactive oxygen species generated by AlPcS4 after irradiation destructed the exosomes for rapid released of Dox, at the same time, induced apoptosis with released Dox in a synergistic manner. The superior anticancer therapeutic effects were achieved both in vitro and in vivo. The successful utilizing of low-pH stressed cell exosomes for gastric cancer therapy in this study indicated that the efficient exosomes may have great potential for various anticancer drug delivery.

Epoxy-based resin filled with SiO2 nanoparticles is one of useful composites applied as adhesives for electronic devices, as it provides reliable insulation resistance and improved mechanical properties. On processing SiO2/epoxy composites, a compound with lower viscosity which is favorable for shaping and those curable to a material with improved elastic modulus is required. However, since the disaggregation of SiO2 nanoparticles is essential for the former and network formation is necessary for the latter, the realization of both properties was a kind of contradiction and difficult to achieve. To overcome this issue, herein we report a processing route to fabricate epoxy-based composites co-filled with SiO2 nanoparticles and cellulose nanofibers (CNFs). First, the surface of SiO2 nanoparticles were modified to improve the compatibility with epoxy-based resin. Briefly, the adsorption of functional dispersant, polyethyleneimine partially complexed with oleic acid (PEI-OA), on SiO2 nanoparticles and further epoxy grafting from the free amine groups of PEI-OA was conducted simultaneously in toluene with bead milling. The disaggregated and surface modified SiO2 nanoparticles were collected by centrifugation and redispersed in ethyl acetate. Then, CNFs and epoxy based resins (a mixture of bisphenol-F type phenoxy resin and bisphenol-A type epoxy resin) was mixed with the epoxy-grafted SiO2 dispersion. While CNFs strongly aggregated in the solution of ethyl acetate/epoxy-based resin, CNFs found to disperse and flowable suspension was obtained when the epoxy grafted SiO2 nanoparticles were co-dispersed (>1 mg-CNF/g-SiO2). Furthermore, the cured epoxy-based resin filled with SiO2 nanoparticles (15 phr) and CNFs (1.0 mg-CNF/g-SiO2) showed improved storage elastic modulus above Tg compared to those without CNFs. We suspect that SiO2 nanoparticles having a surface compatible with epoxy resin adsorbed on CNFs and stabilized them in the resin/solvent solution. The existence of small amount of dispersed CNFs were effective to improve the mechanical properties of epoxy-based composites.

Hollow multi-shelled structures (HoMSs) with hollow interior and multiple shells have been recognized as one type of promising material for applications in in energy conversion and storage, sensors, catalysis, electromagnetic absorption and drug delivery, etc. However, compared to their single- shelled counterparts, the synthesis of HoMSs is much more challenging due to the increased complexity of the structure.

Our group proposed a general and widely usable sequential templating approach (STA) to prepare HoMSs by utilizing carbonaceous spheres as templates to adsorb metal ions and heating them to remove the template and generate multiple shells. Numerous HoMSs of single metal oxides (such as α-Fe2O3, ZnO, Co3O4, SnO2, TiO2, Mn2O3 and V2O5), metal sulfides (Ni3S2, NiS, NiS2), binary metal oxides ((CO2/3Mn1/3)(Co5/6Mn1/6)2O4) and also heterogeneous mixed metal oxides (ZnO@ZnO/ZnFe2O4@ ZnO/ZnFe2O4) have been successfully prepared using STA. The concentration and radial distribution of metal ions can be adjusted by changing the corresponding experimental conditions, such as the metal salt concentration, the solvent, the adsorption temperature and duration, the heating temperature and rate, and so forth, thus controlling the geometric parameters of HoMSs.

The breakthrough of synthetic methodologies for HoMSs also provides opportunities to acquire unique physical or chemical properties and performance in specific applications by manipulating their geometric structures, such as shell numbers, shell thickness, inter-shell space as well as shell composition and morphology. Many successful examples have been well demonstrated in the specific fields, including dye-sensitized solar cells, lithium ion batteries, sodium-ion battery, alkaline rechargeable battery,[14,16, 19] photo detector, gas sensors, etc.

Pickering emulsion is a special emulsion stabilized by nanoparticles instead of surfactant, it has been studied since 1903. Pickering emulsion has many advantages, for example: it is more stable than normal emulsion; its properties can be modulated by nanoparticles. However, conventionally SiO2 or polystyrene (PST) nanoparticle was used for preparing Pickering emulsion because uniform SiO2 and PST nanoparticles are easily prepared. The bio-application study of Pickering emulsion was limited due to the preparation difficulty of uniform biodegradable nanoparticles.

In this study, we prepared uniform alginate/chitosan and poly(lactide-glycolide) (PLGA) biodegradable nanoparticles by membrane emulsification technique and other technique, and used them to prepare Pickering emulsion for Insulin oral delivery and advanced engineered vaccine.

Firstly, we prepared alginate nanoparticle by rapid membrane emulsification technique, then we obtained alginate/chitosan nanoparticle by layer-by-layer process. Then, we prepared Pickering double emulsion (W/O/W) with insulin solution as inner water phase, PLGA/ethyl acetate (EA)/Arlacel 83 as oil phase, and nanoparticle aqueous phase as outer water phase. Then, after removing EA, we can obtain microcapsule with nanoparticle on its surface, it is called colloidosome. This colloidosome showed pH-sensitivity, it was stable at pH 1.2 (stomach), but released insulin quickly at pH 6.8 (Intestine), due to the pH-sensitivity of alginate/chitosan nanoparticle. Finally, the blood glucose level can be decreased apparently after oral administration.

Secondly, we prepared Pickering emulsion (O/W) by using squalene as oil phase, and PLGA nanoparticle aqueous phase as outer phase. Then we assembled antigen in the gap among nanoparticles to form engineered vaccine. We found that this vaccine mimic pathogen behavior, it showed force-dependent deformation, and antigen can move at oil/water interface. As a result, compared with conventional emulsion, it exerted potent immune protections against influenza virus challenge, and enhanced therapeutic anti-tumor efficiency, when we loaded H1N1 or MUC1 antigen on this Pickering emulsion, respectively.

Polyacrylic acid–modified titanium peroxide nanoparticles (PAA-TiOx NPs) locally injected into tumors exhibit radiosensitizing activity in vivo, enhancing the therapeutic effect of X-ray irradiation. However, the underlying mechanism remains unclear except for the involvement of hydrogen peroxide (H2O2), which is continuously from the PAA-TiOx NPs. Thus, this study investigated the details of H2O2 release from PAA-TiOx NPs and the effect on radiosensitivity of cultured tumor cells in vitro using a clonogenic assay in comparison with H2O2 solution as a control. PAA-TiOx NPs were internalized by treated cells within 10 min and released H2O2 for at least 7 h. Interestingly, further experiments revealed a significant increase in the intracellular H2O2 concentration corresponding with PAA-TiOx NP internalization. Additional X-ray irradiation killed tumor cells that had internalized PAA-TiOx NPs more effectively than tumor cells treated only with H2O2. PAA-TiOx NPs represent a novel radiosensitizing system for generating H2O2 in tumor cells.

Owing to the extreme complexity in vivo, the performance of elaborately designed anticancer formulation in the final clinical trials is often compromised from the previous experimental results. Such a inconsistency apparently reduces the druggability of the research objects and increases the risk of new drug development. Therefore, it is urgent to change traditional ideas of research and development for anticancer formulation.

In order to solve this problem, we have integrated the structure, function and program of biological systems into the design, and developed new preparation processes to construct a series of biomimetic anticancer formulations. For example, we developed in situ drug loading technology based on the unique hollow-porous structure of cage proteins. The high expression of corresponding receptors on the surface of tumor cells further enabled us to achieve targeted drug delivery. Meanwhile, a new hydrothermal process was developed to precisely regulate the bacterial structure for the accommodation of tumor antigen. Through natural infection, a large amount of antigen could be delivered to the dendritic cells, leading to a potent immune response. In addition, we also developed a new membrane emulsification process to coat the nanoparticles with cell membranes, thereby endowing them with excellent in vivo fate, such as long circulation and tumor penetration. Such a camouflage approach could significantly improve the performance for cancer imaging, diagnosis and chemotherapy.

As aforementioned, biomimetic formulation followed the intrinsic transport route in vivo, and precisely delivered drug, antigen or probe to the target site as expected. We believe these candidates will lead to the slightest adverse reaction, obtain the optimal application effects, reduce the risk of research and development, and promote the clinical conversion.

Controlling dispersion stability and assembled structures of nanoparticles in solvents during processing nanoparticle-based composite materials is one of the most important key factors toward designing the material properties. Although various surface designs have been reported up to date to achieve the improvement of nanoparticle dispersion stability, most system suffers from limited conditions to have enhanced dispersion stability (i.e. limitation in dispersible solvents and nanoparticle species). Herein, we report a new class of polymer dispersants which can be applied to various combinations of particles and solvent species. The proposed dispersant design involves the partial complex formation of polyethyleneimine (PEI) with functional anionic surfactant, which branches into polyethylene glycol based hydrophilic chain and alkyl based hydrophobic chain near the head group. The designed PEI-complex found to effectively adsorb on various species of particles including metal oxides, metal nitrides, metals, and carbon related materials. The particles fully covered with the designed dispersant were able to be dispersed into various series of solvents such as methanol, methyl ethyl ketone, ethyl acetate and toluene. Due to the high versatility of the designed dispersants, nanoparticles were able to be stabilized though relatively complicated process, such as ligand exchanging process of oleylamine stabilized Ag nanoparticles and simultaneous surface modifications of gas phase synthesized SiO2 nanoparticles during bead milling treatments. As well as the dispersion properties of PEI-complex-stabilized nanoparticles, some of our achievements toward aligning the surface modified nanoparticles on template particles/nanofibers and micro-structural control of composite materials will be introduced.

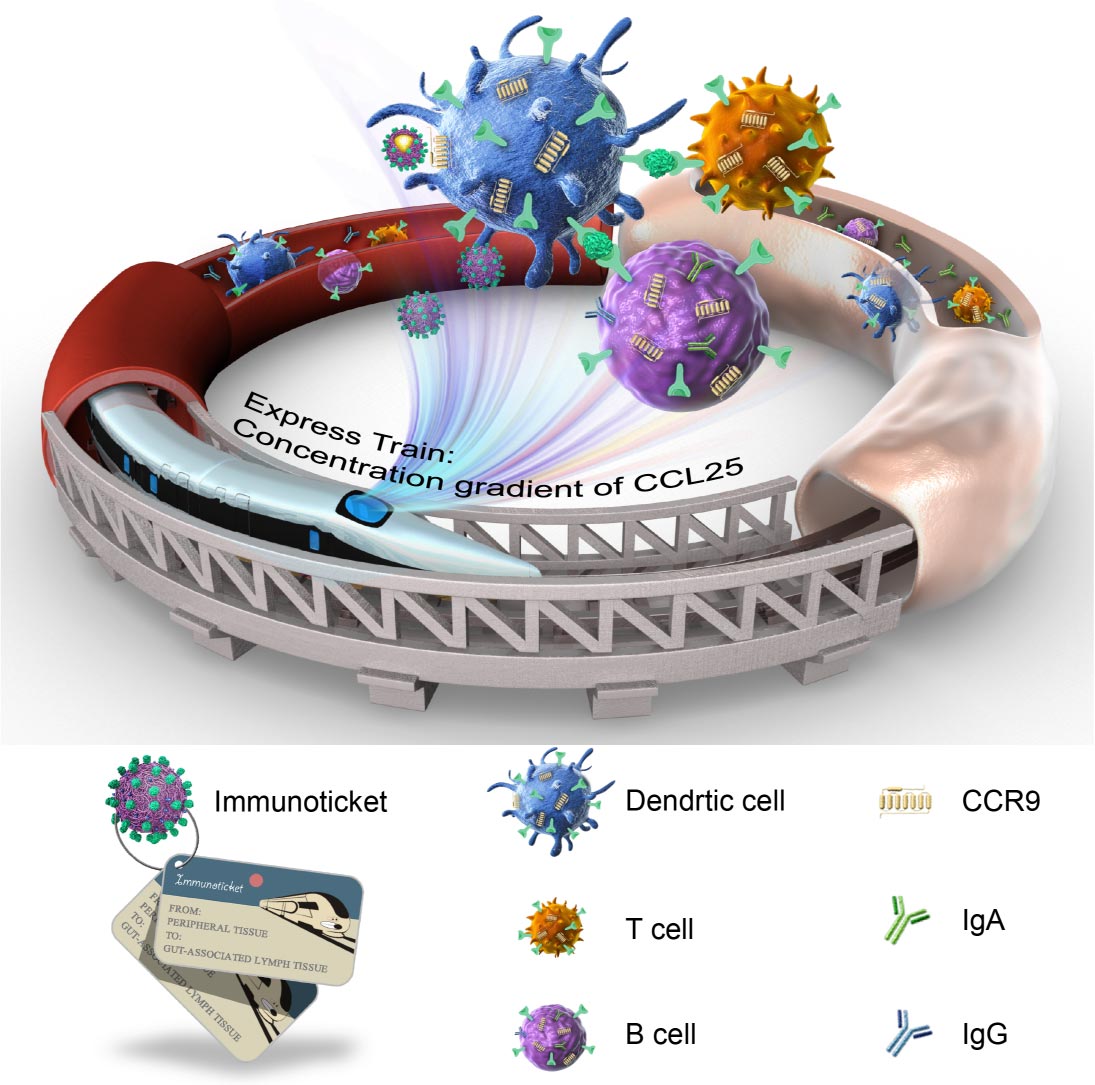

As peripheral lymphocytes are typically excluded from the gastrointestinal lymph tissues, current parenteral vaccinations failed to simultaneously induce systemic and mucosal responses. To break the natural barrier, we developed and heralded “immunoticket” capsules. Via internal phase separation, the capsules were formed with positive charged shells and oily core (oil-in-polymer particles) to spatiotemporally deliver antigens and all-trans retinoic acid (RA). After intramuscular vaccinations, these capsules functioned as immunoticket to cultivate the peripheral DCs with chemokine receptor 9 (CCR9). By hitchhiking on the concentration gradient of chemokine (C-C motif) ligand 25 (CCL25), the primed DCs would home to the gut associated lymphoid tissues (GALTs) and induced antigen-specific IgA secretion and T cell engagements. Compared with the currently employed RA-involved formulations, the immunoticket capsules stimulated enhanced RA-mediated gut-tropism by mounting the inflammatory innate immunity. Through controlling RA payloads, the potential regulatory T cell engagement was circumvented. In OVA and EV71 vaccinations, the immunoticket capsules induced potent serum IgG titer, antigen-specific cytotoxic T cells in the peripheral lymph tissues, as well as robust IgA secretion and T cell engagements on gastrointestinal sites. Our data suggested the potential of the immunotickets to serve as facile, effective and safe strategy to provide comprehensive immune responses against gastrointestinal infections and diseases.

Using delivery system shows promising signs on biobased therapy. However, there's a huge challenge for incorporating all the bioactive factors into one single carrier, leading to unsatisfied efficiency for present antigen/drug delivery system (A/DDS). To break this bottleneck, we uncover the cellular response that induced by graphene oxide (GO) and establish specific A/DDS based on this two dimensional material. On one hand, the flat micro GO exhibit unique properties, including extraordinarily high level of antigen adsorption, intracellular folding effect, and autophagy induction. Such a “One but All” vaccine delivery system induces high level of anti-tumor responses in a programmable way and finally results in the in vivo tumor regression. On the other hand, we evidence sandwiched graphene-cell membrane superstructures in different cells and reveal the transport of GO varies from Brownian to Lévy and even directional dynamics. In terms of above unique advantages, the applicability of sandwiched GOs in enhanced efficiency of membrane-specific drug delivery is thus demonstrated. Our findings inform approaches to program two-dimensional nanomaterials towards advantageous tumor vaccine delivery and intramembrane drug transport.

References:

[1] Pengyu Chen#, Hua Yue#, Xiaobo Zhai, Zihan Huang, Guanghui Ma, Wei Wei, and Li-Tang Yan. Transport of graphene nanosheet sandwiched inside cell membranes. Sci Adv, 2019. Accepted (# Authors contributed equally)

[2] Hua Yue, Wei Wei, Zonglin Gu, Dezhi Ni, Nana Luo, Zaixing Yang, Lin Zhao, Jose-Antonio Garate, Ruhong Zhou, Zhiguo Su, Guanghui Ma. Exploration of graphene oxide as an intelligent platform for cancer vaccines. Nanoscale, 2015, 7, 19949-19957 (Back cover story)

[3] Hua Yue, Wei Wei, Zhanguo Yue, Bin Wang, Nana Luo, Yongjun Gao, Ding Ma, Guanghui Ma, Zhiguo Su. The role of the lateral dimension of graphene oxide in the regulation of cellular responses. Biomaterials, 2012, 33(16): 4013–4020