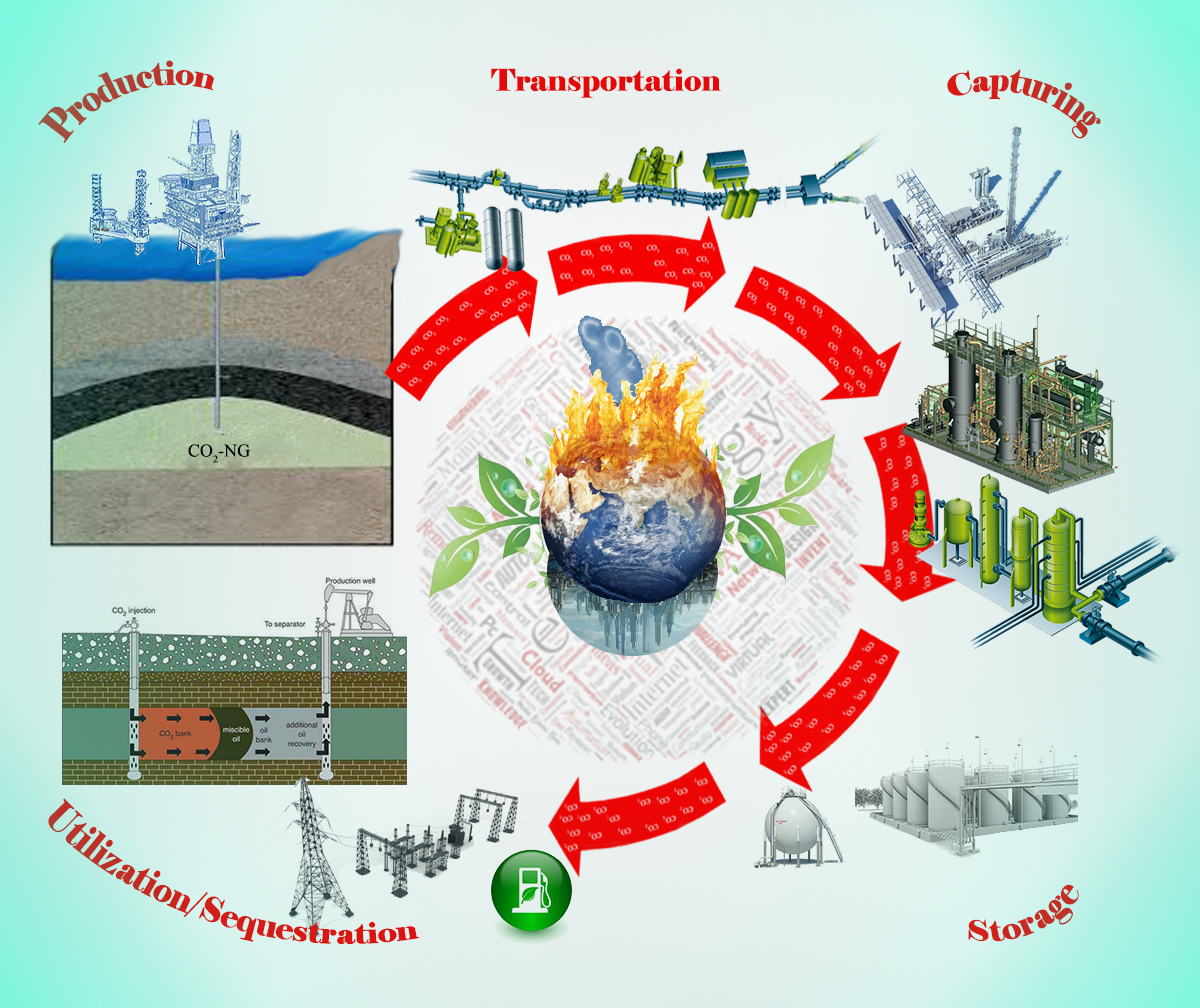

Producing liquid fuels for transportation with reduced carbon footprint has been the focus of many laboratories around the world. To succeed, this effort must utilize low cost aggregated feedstocks that can be converted efficiently to liquid fuels. Lignocellulosic biomass, has attracted much attention during the past 50 years, however, its conversion still presents many challenges stemming from its relatively high cost, broad distribution and recalcitrance to biological or chemical methods of conversion. These difficulties have prevented the widespread use of this abundant resource. On the other hand, with the cost of renewable electricity in continuous decline, an era of inexpensive electrons, (or hydrogen), is envisioned, when focus is shifted away from the supply of cheap electrons (energy) to the cost effective utilization of carbon. In such Carbon-, instead of energy-constrained world, processes that most efficiently utilize carbon will take priority over processes that emphasize optimal energy use. This vision alters dramatically the parameters of the landscape of energy research. In this talk, I will provide evidence of low cost electrons and discuss processes that have the potential to compete with fossil fuels. These processes are based on CO2 fixation by acetogenic bacteria and provide a promising scheme for the production of liquid fuels in combination with biological methods for producing lipids and hydrocarbons from volatile fatty acids.

Chemical engineering has been of immense value to mankind in the last 100 years but it needs to keep changing if it is to be of equal value to future generations. We need to recognise where its value really lies – not just as a collection of facts and a set of skills but in ways of thinking about problems. The discipline grew largely on the back of the oil and gas industry, but global concerns about sustainability have caused us to think about energy in completely different ways, in which chemical engineering needs to compete with other disciplines to maintain its relevance. Current concerns about our discipline’s over-concentration on supplying the needs of the fossil fuel industries are not new; a crisis of confidence in Europe from 2000 onwards has led to growth in activity in teaching and research which is aimed at sustainability and at “formulation engineering”. The latter is concerned with the manufacture of chemical and biochemical products that are sold by function or effect and are usually both chemically complex and physically ‘structured’. If chemical engineering is to maintain its relevance it needs strong institutions and professional organisations to grow and promote the discipline, and - crucially – to ensure that society has confidence in our professionalism, particularly in the area of safety. International collaboration between these organisations will ensure that global development priorities are met with rational and responsible solutions.

Over the next two decades the potential exists to transform the process industries through the use of large data sets, machine learning and artificial intelligence. Adoption of these emerging technologies should lead to increases in efficiencies, productivity and safety. Integrating process plant data with market data will allow improved agility, allowing companies to respond to changing market demands more rapidly, and profitably.

In the coming decades new processing facilities will be more highly instrumented than they are today. Artificial intelligence and machine learning coupled with data analytics tools will allow the development of semi-autonomous systems which will aid in plant operation. These systems will be able to provide management and operators with advice on a range of issues including system inspections, maintenance scheduling and troubleshooting. The most appropriate data will be provided to operators in the field allowing more informed decision to be made.

Presently, advances are occurring in a range of areas including improved sensors for process control, connectivity, simulation and training. At the same time that all these advances are taking place, the risk of cyber attacks through the unauthorised access into data centres and control systems will increase. The vulnerabilities of processing facilities will not only be through internet-based resources, but also through the interception of plant-based communications systems such as wifi.

This digital revolution is currently not reflected in our chemical engineering programs at either the undergraduate or graduate level. The majority of workers in the process industries are simply unprepared for taking advantage of the current advances in digital technologies. This therefore opens up significant opportunities for education and training in both the short term and the long term.

This presentation will look at the challenges and opportunities in preparing chemical engineers to work in Industry 4.0.

Today, the Asia-Pacific region is at the center of the world economy, but having this responsibility means that there will be many challenges and responsibilities for all of us. Production volume is growing in response to the continuous increase of global demand that is driving new innovations and businesses at unprecedented rates of growth that are thriving and being created almost simultaneously as new areas are discovered. Along with this remarkable economic growth and prosperity, our responsibility to the environment is also increasing; material intensity, which is the use of resources to produce products, is driving development of society with such large projections of consumption and production, that they can be considered to be unsustainable. We have to rethink some aspects of our growth and motivation.

As the result of a United Nations Conference on Sustainable Development in Rio de Janeiro in 2012, a new set of 17 sustainable development goals (SDGs) were formulated for 2030, which gives 17 Sustainable Development Goals (SDGs) in areas of People, Planet, Prosperity, Peace, and Partnership. While the Asia-Pacific region has the greatest growth in the World, its material intensity is also the greatest, which means that Earth's resources are increasingly being used inefficiently without regard to their environmental or social impact. One of the most important goals of the 18th Asian Pacific Confederation of Chemical Engineering Congress is to introduce innovative methods and techniques for reducing material intensity without degrading environmental and social conditions. The critical step in achieving the SDGs is philosophy for decoupling economic growth and environmental issues. So far, chemical engineering has contributed to the society through development and implementation of innovative chemical technologies and maximizing efficiency in process systems. However, to achieve sustainability, we have to embrace a completely new philosophy to include, as paramount, the well-being of society, Earth's environment and respect for nature. We propose to call this new philosophy “Sufficiency,” which has the goal of not only lowering material intensity and increasing process efficiency, but also, at the same time and with paramount importance, improving the well-being of people, their living and working conditions and the Earth's environment.

The theme of APCChE 2019 Congress is “Chemical Engineering for Sustainable Development Goals.” APCChE is an opportunity for all of us in the Asia-Pacific region to promote ideas to achieve the SDG 17 “Strengthen the means of implementation and revitalize the Global Partnership for Sustainable Development.” The Congress will provide many opportunities to discuss how chemical engineering will contribute to the SDGs in the world and will be a landmark event for promoting cooperation in the region.

UNIDO is the specialized agency of the United Nations that promotes inclusive and sustainable industrial development (ISID) for poverty reduction, inclusive globalization and environmental sustainability. Technology transfer and business management capacity building are one of the UNIDO's mainstream activities in promoting ISID involving various industrial activities related to chemical engineering. The refrigeration sector, which includes air conditioning, is currently responsible for around 17% of global electricity consumption. For some developing countries this percentage even exceeds 40% of total national electricity demand. Environmentally friendly manufacturing of refrigeration equipment and energy efficient cold supply chain are crucial for achieving the Sustainable Development Goals by 2030 and beyond. This presentation will share UNIDO's technology transfer examples in contributing to the achievement of the SDGs. In addition, it touches on the scope and share the expected output of this symposium.

Chemical engineering is uniquely placed to drive positive impact across the full spectrum of the SDG agenda. The UN pointed out ‘education is critical for promoting sustainable development and improving the capacity of the people to address sustainable development issues’. We, as the educators in chemical engineering, should enlighten the next generation on a diverse Chemical Engineering for sustainable development.

Diverse dimensions of sustainable development are embodied in the subjects of chemical engineering, yet the profound relations and representations are to be dug out and elucidated. The academia is obliged to explore the potential and boundary of how chemical engineering can make a more sustainable world. As the UN set up the roadmap of SDGs to 2030, people in the chemical engineering community shall contemplate and act proactively on how the instruction activities can be consistent with this process.

Among all the efforts, enhancing the next generation's recognitions of chemical engineering and guiding them to face the challenges matters most. Take my introductory course at Tsinghua University as a case. A group of professors, alumni and experts in the chemical industry are invited to share their understanding of chemical engineering to first-year undergraduates. Extracurricular activities such as practices, voices-from-young-professionals and demonstration videos also help them to draw a big picture. The integration of diverse information from the introductory class presents a wide range of SDG concepts and highlights some of them (e.g. SDG 5-gender; 6-water; 7-energy; 8-work; 9-innovation, 12-consumption and production, 13-climate change etc.), which allows us to think how to integrate SDG into teaching, starting from the freshmen. Inspired by APCChE-UNIDO Symposium, we will further upgrade the course with a systematic outlook of SDG. Hopefully, the discipline of chemical engineering could be enriched with more sustainability by our efforts at least starting from education.

The academic year 2018-2019 marks the introduction of a new 4-year B.S. Chemical Engineering curriculum to the first batch of K-12 graduates in the Philippines. The Commission on Higher Education (CHED), through its Technical Panel for Engineering and Technology (TPET) is tasked with monitoring the implementation of the 2018 Policies, Standards and Guidelines (PSG) on all higher Educational Institutions (HEIs) offering B.S. Engineering Programs to ensure that the attributes of our future graduates are comparable with global standards.

Apart from complying with the CHED-TPET guidelines, the Chemical Engineering Department at the University of Santo Tomas is re-engineering its 4-year undergraduate curriculum based on a localized Conceive, Design, Implement, Operate (CDIO) approach that integrates the Sustainable Development Goals (SDGs). The objective is to not only to integrate sustainability principles but also provide an action-oriented, transformative pedagogy, which supports self-directed learning, participative and interdisciplinary collaboration, creative problem-solving, and the linking of formal and informal learning.

An SDG map in the shape of a periodic table addresses specific targets for each SDG across the curriculum and identifies courses or modules where such target can be imparted to students. Similarly, a syllabus map is created for specific courses in order to allow faculty and students to merge awareness of the SDGs with a CDIO approach that will apply innovative solutions to sustainable development issues.

This presentation shall discuss the SDG-based CDIO approach in the preparation of the curriculum and syllabus map as well as issues and lessons learned from the endeavor.

Sapporo City is the central city in Hokkaido with a population of about 1.96 million people. Roughly 13 million tourists a year from Japan and other countries visit us for our abundant nature and attractive cuisine. This city is promoting environmental policies on its “second basic environment plan” as a mean to achieve the SDGs and making connections with various bodies. Sustainable consumption activity by residents in an urban city as Sapporo, that consumes a large amount of resources and energy, is vital to achieving SDGs. We introduce the efforts for sustainable consumption of citizens in Sapporo city and trends for achieving SDGs in Japan.

The Asia-Pacific region is the cradle of production and the center stage of the world economy today. At the same time, the region is a flourishing arena of new socio-economic development driven by digital innovation. In light of these trends, it is necessary to examine and practice emerging opportunities for ensuring sustainable society, in which socioeconomic development and increases in environmental loads are decoupled from the real sense of securing people's well-being and happiness. Sustainability is not one-dimensional issue such as the prevention of global warming but is a multifaceted challenge, as the 2030 Agenda for Sustainable development indicates 17 goals and 169 targets in areas of People, Planet, Prosperity, Peace, and Partnership,

Chemical engineers have been responding to social demands by developing and implementing innovative technologies since chemical engineering inherently pursues a problem-oriented approach. However, we have to expand our focus from increasing the efficiency of existing products and systems to aiming at the well-being of society by improving people's sufficiency in the SDGs era. For this purpose, the Society of Chemical Engineers, Japan launched many activities to extend chemical engineer's scope from efficiency to sufficiency: a study group on diversifying technology implementation, the Committee on Future Energy and Social Systems, the Gender Equality Committee and the SDGs Committee, and so forth. Likewise, APCChE can be a good place in the Asia-Pacific region to achieve Goal 17 “Strengthen the means of implementation and revitalize the Global Partnership for Sustainable Development.”

By integrating these activities, we will be able to live up to paragraph 67 of the 2030 Agenda that states “We call upon all businesses to apply their creativity and innovation to solving sustainable development challenges.”

In this work, we performed a life cycle assessment of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBH), which is made from biomass resources and has a characteristic of biodegradability in both soil and seawater. To reduce the dependency on petroleum resources and decrease marine plastics, increasing attention has been paid to bio-based and biodegradable polymers. Until now, many papers about the environmental impacts of these biopolymers have been reported. However, the environmental impact of a biodegradable polymer that dissolves in an aquatic environment has not been clearly investigated yet. To discuss the effect of bio-plastics introduction to the society, it is necessary to elucidate its impacts through its entire life cycle.

We applied a life cycle assessment to PHBH products from the cultivation of biomass resource to the end-of-life, and we considered their environmental benefit to the society. The selected target is PHBH products and comparable conventional plastic products with the same function. Their resource extraction, production processes and end-of-life are different from each other. Unlike the fossil-derived plastics, PHBH is biologically synthesized from plant oil and refined for pellets. We set a system boundary including biomass cultivation, microorganism fermentation, polymer extraction, product manufacture, use and end-of-life. The end-of-life was generated as several scenarios such as incineration, landfilling, recycling and dumping depending on local waste systems and consumer behaviors. To construct the inventory data, we investigated the actual production processes in Japan. Finally, we targeted global warming for the impact category to discuss whether PHBH can become a possible measure for climate change.

Through the assessments, we will discuss which process within life cycle has a significant environmental impact and which end-of-life scenario can contribute to reducing greenhouse gas emission. Our results will help design and construct a better social system for biopolymers and provide deep insights for utilizing PHBH.

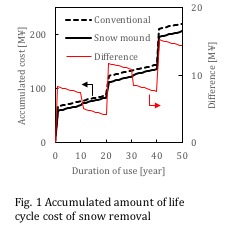

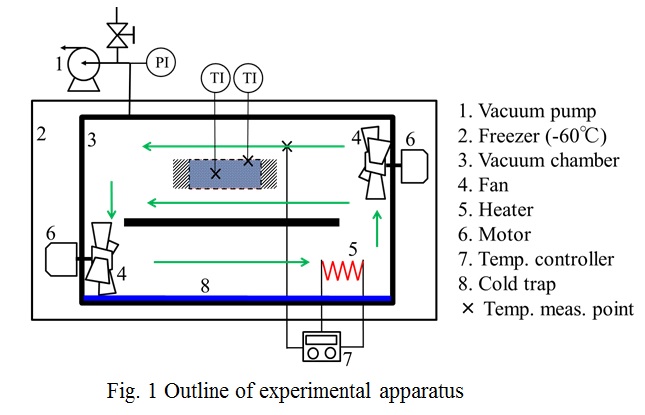

Promotion of cooling of building by snow is important in regions with heavy snowfall in terms of not only energy saving for cooling in summer, but also workload reduction of snow removal in winter because most of these regions in Japan now fases decrease of labor population. In the present study, life cycle cost (LCC) of cooling of apartment building by snow was calculated for three types of snow strage: open-air snow mound, half-underground storage, aboveground strage. Initial amount of snow storage, cooling area per household and annual cooling time were 100 t, 80 m2, 502 h, respectively. Number of households which shared the cooling energy from snow was modified from 1 to 20. Each household had 4 rooms with equivalent area. In case the amount of snow was not sufficient for cooling during the season, some of the rooms were cooled by electric air-conditioner.

Annually averaged value of the LCC (ALCC) per household showed convex dependence on number of households sharing the snow strage and there were optimum number of the households which minimized the ALCC. Snow strage of half-underground type and aboveground type had disadvantage especially smaller number of households because of high cost of construction.

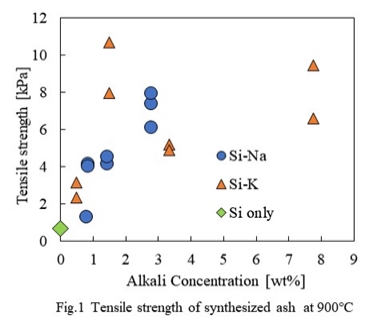

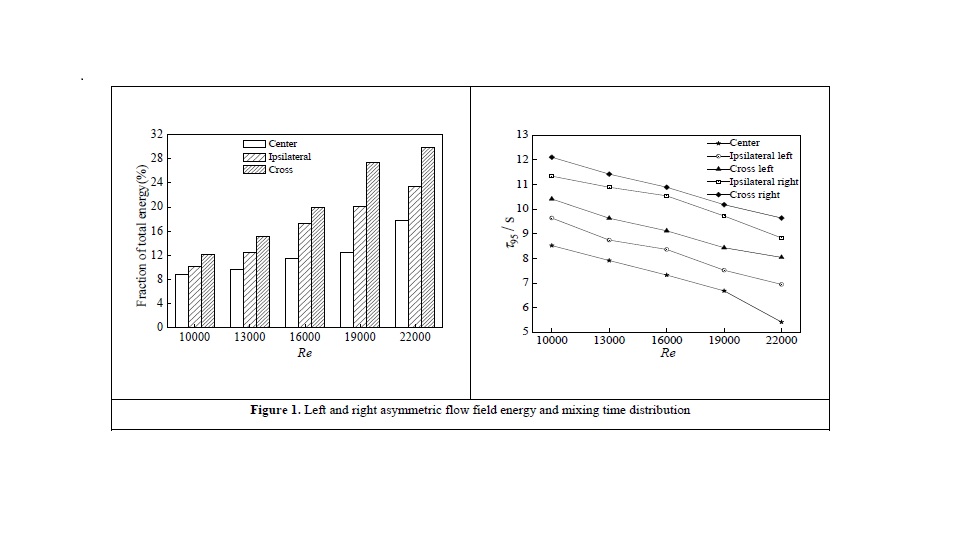

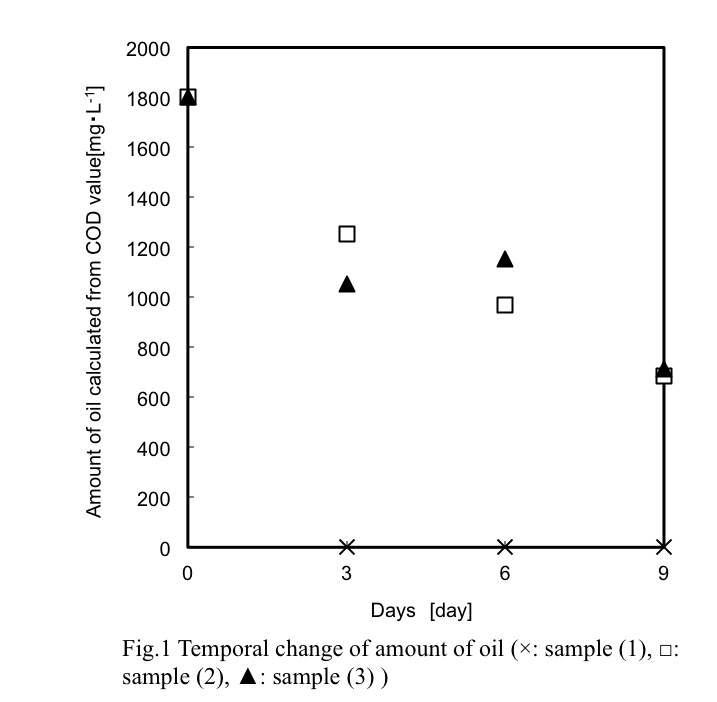

Cost reduction potential in snow removal by the snow strage was also calculated. It was estimated as 160,000 Yen for 10 households for 40 years of operation period as shown in Fig. 1. It was mainly attributed to reduction of transportation of snow to dumping site.

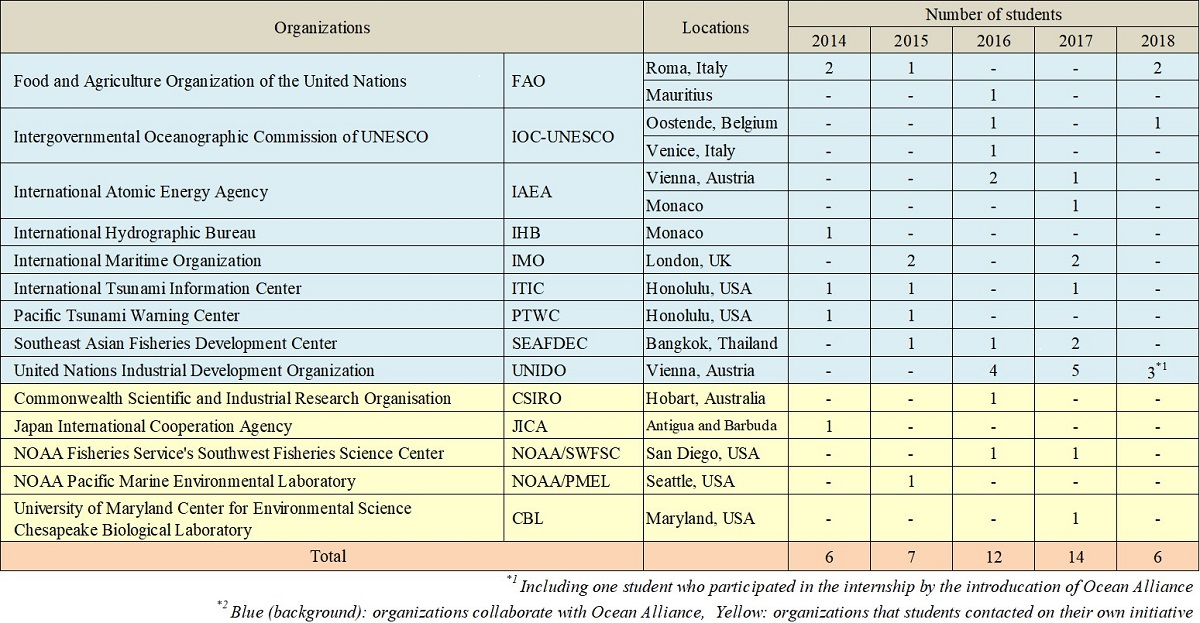

Developing international human resources that possess a high level of expertise in many fields including chemical engineering and that show leadership at the global stage is important for establishing a sustainable society and achieving the Sustainable Development Goals (SDGs). The University of Tokyo Ocean Alliance conducts educational initiatives for fostering individuals who can succeed worldwide in ocean related areas. We started an overseas internship project from the 2014 academic year (AY 2014) and built collaborative relationships among nine international organizations and research institutions, such as the United Nations Industrial Development Organization (UNIDO), the Food and Agriculture Organization of the United Nations (FAO) and the International Atomic Energy Agency (IAEA). In particular, we have a strong relationship with UNIDO. Forty five graduate students have been sent to these international organizations from AY 2014 to AY 2018 (Table 1), and have undergone internships for two to six months. They could engage in actual projects related to their own research fields including environmental and energy issues. The objective of this study is to investigate the effectiveness of the internship at the international organizations mainly by analyzing students' internship reports. Their impressions for internship were classified into three categories. The first one is the description related to students' future and their career paths, the second one is the influence of internship on their master and doctor researches, and the third one is related to the construction of human networks and all the rest of it. The analyses of the reports for five years show that the internship was considered to be effective in establishing students' career paths through work experiences and formation of interpersonal relationships in the international organizations. It is expected that this internship system can contribute to achieving the SDGs in the long term.

The last few years have been quite challenging for the chemical industry in Asia. Vibration of oil prices, regulatory pressures, global climate plans and competition, and changing demographics have a huge impact on chemical industry. In the last years chemical industry companies are working on two major production concepts to further improve their production of chemicals, materials or bio-technology products: cyclic economy and modularized production. The general goal of these activities is to produce faster, with a higher quality and in a less wasteful manner. The chemical industry is facing an increasing demand from fast growing and vibrant markets in Asia and a trend to customized specialty and fine chemicals. Asian chemical companies face different challenge from those in US, Europe and Middle East, such as energy-deficiency, high cost of energy and raw materials, strengthening environmental regulations, increasing labor-cost, etc.

The circular economy in developing countries can increase productivity and economic growth, improving the quality and quantity of employment, and save lives, by reducing environmental impacts such as water and air pollution. For most Asian countries there is huge potential to improve productivity by using resources more efficiently. However, many chemical plants in East Asia are old and need renovate to achieve new standard. With efficient technologies, there are huge business opportunities for companies.

The demand for lithium-ion batteries (LIBs) is expected to increase dramatically in the next decades because of the growing EV market. As a result, a large volume of batteries will reach their end-of-primary-life in the near future. However, the spent battery may still retain their capacity, which could be serviceable in its second-life, e.g. for the stationary energy system, or remanufactured to be used again in EVs. The LIB supply chain might benefit from reducing raw material consumption, if LIBs are reused through refurbishing, remanufacturing, or recycled. The reuse and recycle of LIB will also facilitate waste management by the recovery of all valued battery components to contribute to a circular economy. To devise a circular economy strategy for the LIB system, the material flows and the environmental impacts associated with their life cycle including manufacturing, use, and end-of-life phases should be assessed. Although numerous studies on the environmental impact of LIB production are available, the existing primary life cycle inventory data is often difficult to trace back, which is inflexible to discuss the different properties of LIB and energy demand related to the manufacturing process. The different LIB chemistries that have different combinations of metals, will make the material and energy consumption in production process vary. In this study, a bottom-up inventory model of LIB production, which enables to estimate the material requirements, energy demands and the associated environmental impacts such as greenhouse gas (GHG) emission, is developed. Here, we demonstrate that with this modeling approach, it becomes possible to assist devising a circular economy strategy from environmental impact perspective, reflecting envisioned future circumstances e.g. decarbonization of electricity generation, by coupling with a material flow analysis model.

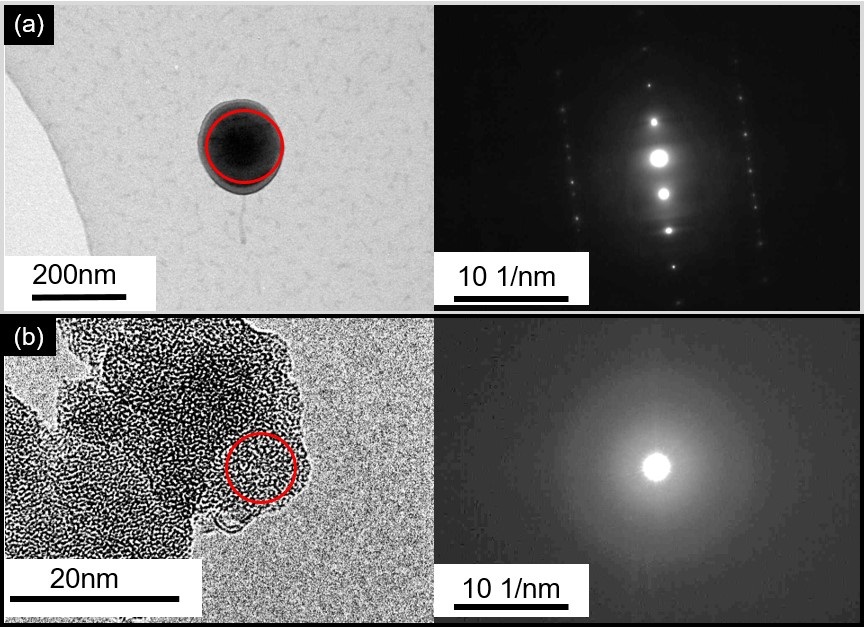

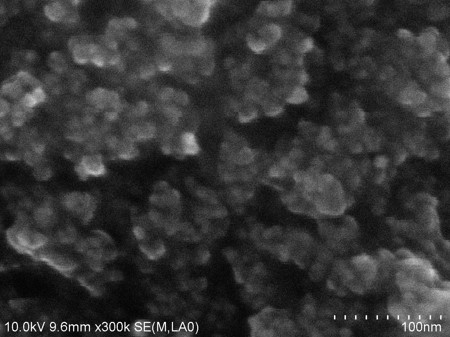

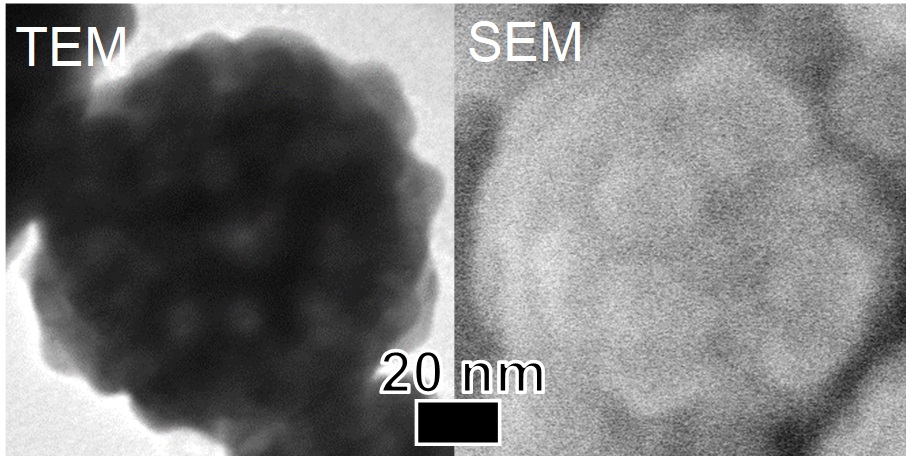

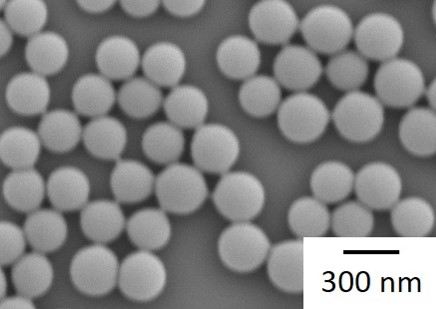

MgO@ZIF-8 catalysts with various MgO loadings (10-50 wt%) were prepared through a wet-impregnation and calcination process. The physicochemical properties of MgO@ZIF-8 catalysts were characterized using atomic absorption spectroscopy, X-ray diffraction, , nitrogen sorption isotherms, field-emission transmission electron microscopy, and thermogravimetric analysis. It is found that MgO nanoparticles could deposit onto the ZIF-8 surface with high atom efficiency and little influence on the ZIF-8 structure. It is suggested that the surface sites and microporosity of ZIF-8 support facilitate the deposition of Mg precursor and subsequent formation of MgO nanoparticles. MgO@ZIF-8 catalysts were tested for catalytic transesterification of glycerol and dimethyl carbonate. It is found that the 50 wt% MgO@ZIF-8 catalyst display an improved catalytic activity on glycerol carbonate production than those of MgO and ZIF-8. Furthermore, the MgO@ZIF-8 catalysts showed higher catalytic activities than their physically-mixed counterparts. These results suggest a synergistic effect between MgO and ZIF-8, which is explained by an acid-base bifunctional catalysis mechanism.

Inclusivity is a vital aspect of sustainable development which has been emerging as a challenge in economically developed, matured societies. In Japan, the rural areas are suffering from lagged economic development, the aging society, and declining population. Tackling sustainability challenges without leaving out problems in these areas are essential, but requires a new approach in industrial development. Creating sufficiently productive and profitable systems that utilize locally-available resources are seen as a potential key to vitalize the rural areas while tackling the SGDs.

Attempts to collect and study all the relevant information can lead to an excessive requirement on time and effort in the early stages of a design project. Because some of the unknowns are more important than others, prioritization of the unknown factors that requires a closer investigation can potentially reduce the time and cost for the initial design. In this study, a system synthesis method that generates combinations of resources, technology, and products, ranked in order, formulated as a MILP is applied to indirectly prioritize the unknowns, while comprehensively exploring the combinations of the known options.

The higher ranked systems will include some designs that are impractical due to missing practical constraints. The ranked list of the systems will help to identify overlooked constraints, starting from more important ones. The unknowns that are related to the identified constraints are then studied and added in the systems synthesis model. After several iterations, all the critical unknowns are studied to describe the key constraints and the most promising systems can be proposed.

Features added to existing studies, i.e., 1) consideration of the combinations at its suboptimal capacity of processing, 2) incorporation of material storage equipment and efficiency in order to overcome the seasonal variations in availability of resources and the demand of products, will be introduced with simple examples.

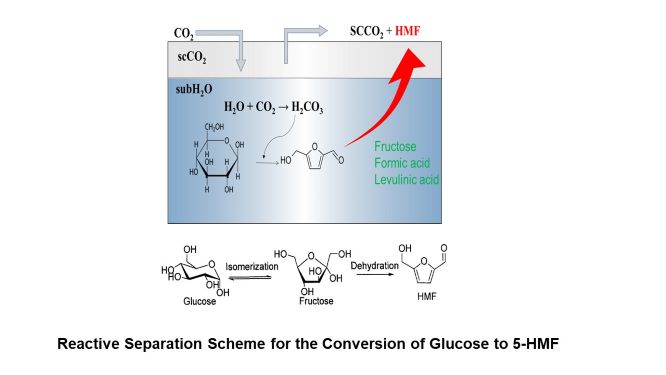

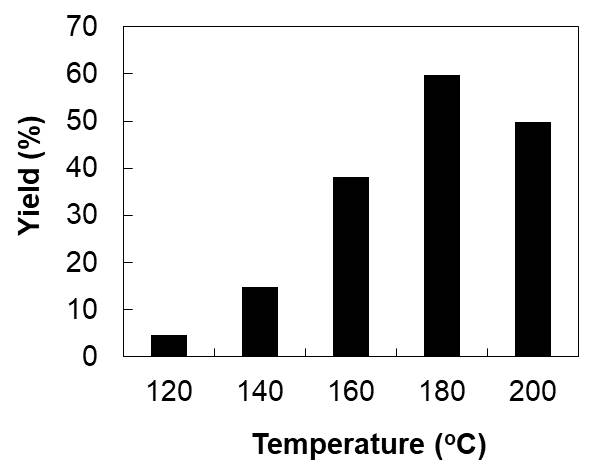

Methyltetrahydrofuran (MTHF) have received great attention for combustion system applications, because it can be readily used in blends with gasoline and diesel without major engine modifications. In this study, as a sustainable platform chemical for the biofuels and biochemicals, conversion of MTHF from lignocellulosic biomass was studied. For the conversion of MTHF, domestic grown woody biomass such as pine and oak in Korea were firstly treated by chemical and thermal treatment for the production of C6 substrate and further production of levulinic acid (LA) via 5-hydroxymethylfurfural (HMF) intermediate, which was then subjected to the catalytic conversion for the conversion of MTHF.

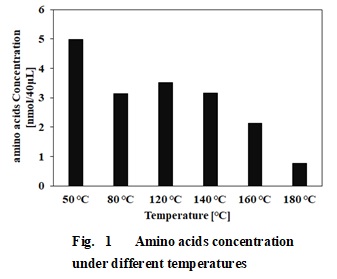

At the beginning of the conversion process, alkaline reagents (ex. sodium hydroxide and ammonium hydroxide) were applied to produce C6-rich substrate (>70%), which was then converted by de-hydration and re-hydration reactions into LA using sulfuric acid (1~5 wt%) at high temperature (121~190 °C). For the conversion of MTHF via gamma-valero lactone (GVL) intermediate using de-hydration and hydrogenation reactions under high temperature and pressure conditions, high-efficiency heterogeneous bimetal catalyst was synthesized and attempted for precious metal replacement in the presence of the effective CTH (catalytic transfer hydrogenation) solutions.

In this paper, conversion yields of C6, LA, and MTHF were evaluated and reported under various reaction conditions. For the increased MTHF production, various catalytic reaction conditions pertinent to effective and viable process were explored and discussed.

A continuous twin screw-driven reactor (CTSR) can provide a unique and efficient reaction environment for the pretreatment of lignocellulosic biomass. CTSR has the ability to provide high shear, rapid heat transfer, effective mixing. The thermo-mechanical energy provided by the continuously stirred screws in CTSR, which causes the shear forces, can be applied to the continuous pulverization of biomass, thus improving the overall rate of biomass conversion. Considering the high labor intensity and energy requirement of batch pretreatment, a CTSR process has great potential for increasing the efficiency of biomass pretreatment.

CTSR for the pretreatment of biomass would be practicable and useful for large scale production because it affords high-efficiency pulverization by a high shearing force, and adaptability to many different process modifications, such as application of simultaneous physical and chemical treatments using other catalysts. The performance of biomass pretreatment through CTSR is a complex function of screw rotational speed, throughput, and screw configuration etc. The interaction between different processing parameters leads to complex functions of shear conditions and reaction severities, both of which affect pretreatment performance.

With the aim to provide a further insight into CTSR pretreatment, enlarged CTSR to 100 kg/day scaled was developed and demonstrated. Mathematical modelling for fluid dynamics and heat transfer were developed by a set of ordinary differential equations (ODE) based on first-principle models. The resulting ODE set was experimentally validated using model biomass (sawdust) as feedstock. The kinetic parameters of biomass pretreatment performance were estimated from experimental results.

These results will contribute to improved reactor design and scale-up tasks, and in turn, to the successful deployment of novel industrial-scale technologies for biomass pretreatment.

Industrial symbiosis with unused local biomass can be one of a key approach from the viewpoint of sustainability of agriculture, forestry and the regions. Planning biomass-based industrial symbiosis necessitates hard decisions including long-term visioning of the regions and consensus building among various stakeholders such as agriculture, forestry, energy supplier, local government, and technology researchers. Chemical engineering approach with modeling and simulation can strongly support such planning process. The planning process of the symbiosis to be supported has not been well established nor systematized in previous studies. In this study, systematic planning process for biomass-based industrial symbiosis was proposed and the requirements of its supporting mechanisms were defined. The planning process was structured as the series of sub-activities based on the re-analysis of the case studies for planning industrial symbiosis integrating cane sugar industry and local forestry on a specific region. Modeling and simulation of regional energy systems with multiple co-generation plants fueled by local biomass from the industries were performed in the case studies. The planning process was defined that consists of the activities of planning tasks, i.e., <Examine present system>, <Generate alternatives>, <Simulate flows> and <Evaluate>. Additionally, these tasks are controlled by <Manage>, and the proposal of the symbiosis plan as the product by the tasks are checked by <Review>. These activities of planning tasks can be supported by the mechanisms, such as IoT monitoring system, technology matching tool, flow simulator and evaluation tool. The applicability of the planning process and the supporting mechanisms is to be discussed through new case studies in other regions. Human networks among region, academia and industries have significant roles to implement the symbiosis plans toward the regional sustainable visions even if the supporting tools highly developed in future.

To effectively mobilize the limited time and resources for the accomplishment of a transition towards sustainability, efforts on a technology development must be made in a manner coherent with other efforts under a vision on the sustainable society. Technology Roadmapping (TR) is amongst the several approaches that may cross-link a technology development with a future vision. Here, I provide an example of assisting TR by exploring the balances between technology performances with other exogenous variables in the future society with a dynamic Material Flow Analysis (dMFA).

In Japan, a future target of the power supply configuration (energy mix) based on the massive introduction of renewable energy has been advocated, in which Photovoltaics (PV) accounts for ~7% of the total power generation capacity, i.e., approximately 30% of the renewable power sources. On the other hand, a substantial amount of Si type PV (Si-PV) would reach their End of Life (EoL) soon. Therefore, the development of a technology recovering Si from EoL Si-PV may effectively respond to the demand to achieve the target without spending a massive amount of energy for Si purification from Silica sand. To consider such technology, a long-term evaluation of benefits and impacts on both economy and environment is required to invite stakeholders to jointly materialize the reasonable and comprehensive roadmap. Here, our team conducted a time series quantification of flows and stocks in an envisioned Si-circulation system. Then, we deduce the development directions as a roadmap with respect to various design variables (ex. an average lifetime of product) on the basis of multiple criteria (e.g., the net-energy acquisition and net-CO2 avoidance). With this example, I aim to highlight the potentials and challenges of vision-oriented technology development for the achievement of SDGs 9: Industry, Innovations and Infrastructure and SDGs 7: Affordable and Clean Energy.

A hydrogen supply chain consists of the production, transportation, storage, and distribution of hydrogen as an energy source. A variety of decision variables should be determined along the supply chain including technological options of producing hydrogen, phase of hydrogen, location and capacity of treating facility, and the amount of transportation between the regions. The optimization problem can be effectively formulated and solved for this complex systems. In this presentation, we have investigated for the optimal strategy for hydrogen supply chain and present the optimal solution to the case of South Korea.

CuInS2 (CIS) is a solar absorber with the energy band gap of 1.5 eV, suitable for hydrogen production from water splitting. The types of conductivity (n- or p-type) of CIS photoelectrode can be tuned as a function of Cu/In concentration ratio. In this report, CIS films were deposited using spray deposition onto ITO-coated glass substrates from aqueous solutions consisted of copper (II) chloride, indium chloride and thiourea. First, the ratios of the precursor solutions were varied and the transition from n- to p-type conductivity was observed. Next, Zn-doped CuInS2 (Zn-CIS) thin films exhibited p-type conductivity from electrochemical measurements. XRD results reveal the cubic-structured Zn-CIS films. The successive shift of XRD patterns toward higher angles with zinc molar fraction is evident of the formation of Cu-In-Zn-S solid solution. LSV results shows that the photocurrent density of Zn-CIS film reached 2.5 mA/cm2, higher than the bare CIS (0.3 mA/cm2). Finally, n-type ITO thin film was deposited onto the p-type CIS. Here, we want to demonstrate that suitable match of the p-n junction can create a high efficient photoelectrode for hydrogen production from water.

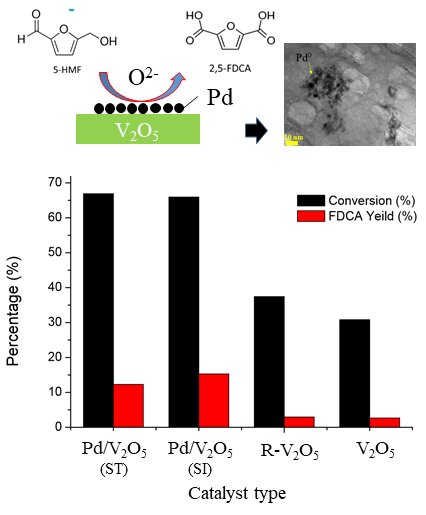

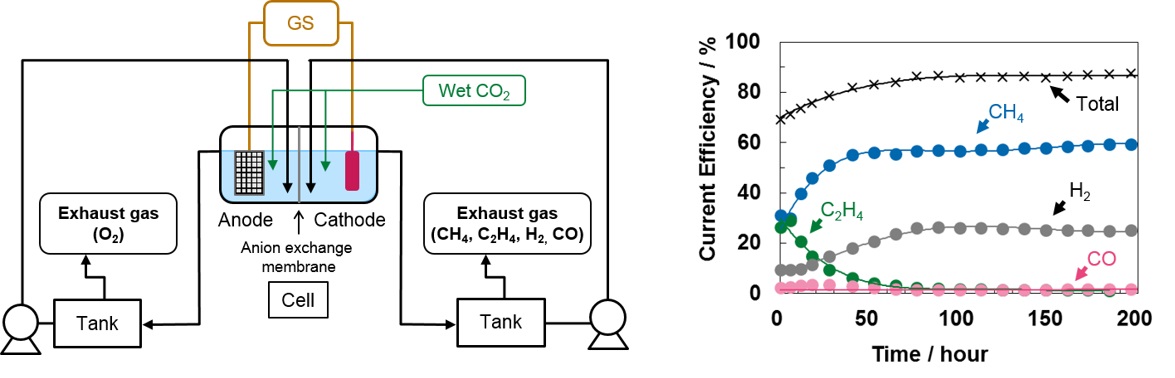

The electrochemical reduction of CO2 recently draws great attention because of its sustainable capability of producing fuels and chemicals. However, the high over potential of CO2 reduction reaction-oxygen evolution reaction (CO2RR-OER) have been pointed out as an obstacle of commercialization. Herein, we propose electrochemical co-production of CO2RR and oxidative reforming of organic materials. The oxidative reforming of organic materials not only potentially reduces operating cell voltages but also improves system economic feasibility by producing more valuable chemicals than oxygen. We introduces an automated and generalized platform for the techno- economic alanysis (TEA) of electrochemical coproduction system and investigate the 16 candidates of CO2RR for cathode and 18 candidates of organic oxidation reaction for anode. The TES platform generates a product oriented process systems design including reaction, separation, and recycle. Global sensitivity analysis of Faraday efficiency, current density, and overpotential for the levelized cost of each product to understand which index should be improved first. Hydrogen, carbon monoxide, formic acid, glycoladehyde, ally alcohol, ethylene glycol, acetic acid, and propanol can be the promising candidate for the CO2RR and 2,5-Furandicarboxylic acid (FDCA), oxalic acid, acrylic acid, glycolic acid, lactic acid, 2-furoic acid, and ethyl acetate can be the promising candidate for the anodic oxidation.

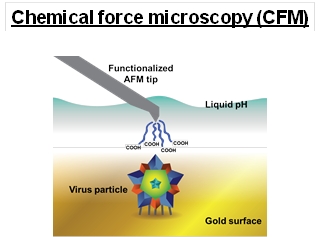

Virus surface chemistry plays a key role in virus sorption and partitioning processes, however there is very limited information on viral surface chemical properties. To enhance the toolbox of available characterization tools, chemical force microscopy (CFM) is being pioneered for viral particle characterization. CFM measures the adhesion force between a particle, in this case a virus particle, and a functionalized atomic force microscopy (AFM) tip. CFM reduces many of the difficulties of bulk characterization techniques by measuring adhesion of individual virus particles, likely reducing purification affects that can change surface properties. Two important surface characteristic that can dominate separation processes are isoelectric point (pI) and hydrophobicity. The surface charge of virus particles is pH dependent, which dictates the mobility and controls the colloidal behavior in virus sorption processes. While traditional characterization methods, including zeta potential and viral adsorption to a charged surface chemistry, have been used to study viral surface charges and determine the pI of virus, they are bulk measurements that can change when the studied particle has a different purification method. Hydrophobic interactions are known to be strong for virus particles and are implicated to be important in virus entry into cells. The single particle method of CFM allows not only the quantitation of the virus surface chemistry, but could be used to understand and better design purification processes. The adhesion of a viral particle to any chemical moiety in any solution condition can be tested with this method. The model non-enveloped porcine parvovirus (PPV) and enveloped bovine viral diarrhea virus (BVDV) were used to demonstrate the use of CFM to determine the hydrophobicity and pI for viral particles. This information is being used to determine the binding and elution conditions of a virus to a chromatographic column. With a thorough understanding of virus surface characteristics, virus sorption and desorption processes could be significantly improved and designed to specifically target viral particles using minimal viral material during development.

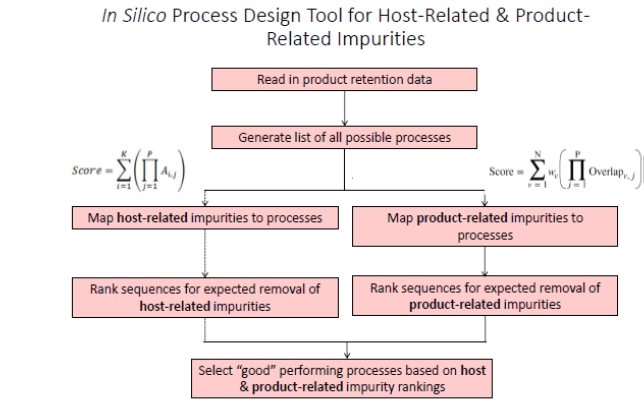

Designing integrated non-affinity downstream processes for biologics poses a significant challenge due to the broad range of design space available for resin selection and buffer conditions. To address this challenge, we developed an in silico-based approach to quickly design and rank a fully inclusive list of integrated downstream processes for their ability to remove impurities using only orthogonally selective multimodal and ion exchange resins. This approach involves the one-time characterization of an impurity database and considers both impurity profiles patterns and product retention behavior to generate and score all possible integrated purification trains. This database was then employed in concert with an in silico process development tool which generates and ranks all possible integrated chromatographic sequences for their ability to remove orthogonal impurities. Top-ranking outputs are then used to guide the experimental development and refinement of purification processes, significantly expediting the development of downstream processes. For Pichia pastoris, this approach was used for two non-mAb products, hGH and G-CSF, which were successfully purified from cell culture fluid process impurities in a process that resulted in high purity and product recovery. We also performed modifications to our process design approach in order to account for both process-related impurities and product-related impurities. This modified strategy was first shown to be successful for purifying IFN produced in Pichia pastoris, and was then applied to the non-affinity-based purification of a mAb-aggregate challenge in CHO, an expression system with a much higher HCP burden. Finally, results are presented on a mathematical framework to characterize and quantify orthogonality in multimodal systems. Using this, we observed several interesting and unexpected results including the existence of a highly orthogonal pair of resins belonging to the same class/family.

Bivalent bispecific antibodies (BiS) are produced by recombinantly expressing a whole monoclonal antibody (mAb) with two single chain variable fragments (scFv) using flexible polypeptide linkers. Three homologous BiS samples varying only by scFv attachment location show reversible, three-peak elution profiles on ProPac WCX-10 and Source 15S cation exchange columns. Collection and reinjection of any of the three peaks results in the same three-peak elution profile. This behavior is seen at pH values in the range 5–8.5. In-line DLS showed that all peaks have a monomer-sized hydrodynamic radius of 6.2 nm. Unlike the normal chromatographic behavior, decreasing flow rate decreased resolution. At the lowest flow rate tested, only a single symmetric peak was observed eluting between the first and second peak of the higher flow rate elution profiles. A hold step at strong binding conditions followed by gradient elution with high flow rate enriched the third, most retained, peak. Biophysical measurements including in-line fluorescence, chemical cross-linking, enzyme digestion to determine domain contributions, and a mechanistic model reveals that the three-peak elution is caused by conformational interconversion occurring on time sales comparable with chromatographic separation. From the peptide sequence, the scFvs carry a net positive charge. When the scFv is folded onto the base mAb weaker bind to the resin occurs whereas if the scFv is outstretched more favorable interaction and stronger binding occurs on the resin surface. The three peaks from weakest to strongest retention are: both scFvs interacting with base mAb, one scFv interacting with base mAb and one outstretched, and both scFvs outstretched. Equilibrium favors the tight conformation in solution and outstretched while adsorbed. The highly flexible linkers allow slow changes in tertiary structure responsible for reversible, three-peak elution behavior. Analogous results are observed on HIC columns suggesting that similar molecular interactions are responsible for the multi-peak elution behavior.

Recently, exosomal vesicles are known as a next generation of biomarkers for molecular diagnosis, and their separation methods has been studied last decades. T-cell Immunoglobulin and Mucin domain (TIM) which is Ca-dependent membrane protein has an ability to interact phosphatidyl serine (PS) clusters on inner cell membrane, and thus it is considered that TIM fragment is one of ligand candidates to separate exosomal vesicles from serum as well as culture supernatant. Also, Exosome can be released from the resin.

Here, we designed and characterized TIM fragments genetically-fused with Avi-tag and PMMA-tag for site-direct immobilization to solid supports.

Avi-tag-fused TIM fragments were successfully produced by HEK293T cells with co-expression with Biotin ligase BirA. Consequently, site-specific biotinylation at the C-terminal region of TIM fragments could be achieved. Mono-biotinylated TIM fragment (ABT-TIM-VM) could be immobilized on the surface of streptavidin-coated plate, and could recover 10-times lower concentration of exosomes, compared with the plate with randomly-biotinylated TIM (RBT-TIM-VM). These results indicated that orientation control of TIM on the surface of solid support is more important to improve recovery of exosomes. Furthermore, biotinylation yields of ABT-TIM-VM could be controllable by changing the ratio of expression vectors for TIM and BirA.

Another candidate, PMMA-tag was introduced at the C-terminal region of TIM fragments. TIM-VM-PM could also be produced by 293T cells, and purified by Ni-NTA chromatography. The optimal buffer condition for TIM-VM-PM was screened from 96 conditions with different pH and NaCl concentrations. Consequently, 25-times higher signal intensity of sandwich ELISA for detection of exosome was detected, compared with the plate with tagless TIM-VM. These results indicated that PMMA-tag introduced was functional and preferentially adsorbed the surface of PMMA plate.

Thus, both TIM fragments developed in this study, namely, ABT-TIM-VM and TIM-VM-PM are useful ligand proteins to separate exosomal vesicles from biological samples.

The synthetic DNA containing modified nucleotides comprise a powerful toolbox of manipulating the formation of nucleic acid duplexes for diagnosis and therapeutic purposes. We are interested in the DNA oligonucleotides containing site-specific neutral internucleoside methyl phosphotriester (MPTE) linkages, nDNA in short (n for neutral). nDNA is interesting because the electrostatic repulsion between nDNA and its complementary strand would decrease and the duplex formation could be enhanced. However, the methyl group of MPTEs may sterically hinder duplex formation and destabilize the duplexes. Therefore, the uses of nDNA may offer additional elements of maneuvering the stability of nucleic acid duplexes formation. The structural information and hybridization thermodynamics were reported in this study. Based on the structural and thermodynamics information of nDNA with natural DNA, successful results in the molecular detection method such as PCR and qPCR will be reported. The applications of nDNA on the in-situ hybridization will be discussed as well. Most importantly, using nDNA on the semi-conductor based biochip and biosensor, such as field effect transistor, has generated wide avenue for the precision medicine, which also will be highlighted in this report.

Keywords: methyl-phosphotriester linkage of DNA (nDNA); molecular detections; PCR and qPCR; In-situ hybridization; field effect transistor

The challenge for applications of viruses, virus-like particles, or other extra cellular bionanoparticles in gene-therapy or in cancer therapy is the high dose with up to 1014 particles per dose. Downstream processing is one bottleneck in the production of these bionanoparticles. It has been often overlooked that a heterogenous population of bionanoparticles is present and they must be separated from the product. The heterogeneous populations of bionanoparticles are released from the cells, carrying different host cell proteins, DNA and RNA fragments. Additionally, cells produce extracellular vesicles (microvesicles and exosomes) with similar size and surface properties. The biological activity of these different particle populations is not fully understood. Particle characterization and biological activity assays require the separation of these populations with high purity. Here we compare the results obtained for the purification, as well as particle populations' separation, of HIV-1 gag VLPs produced in CHO cell culture using different downstream processing approaches. These approaches include polymer grafted anion exchangers, monoliths (anion exchange and hydrophobic interaction), a combination of flow-through and heparin affinity chromatography, and membrane adsorbers. Several analytical tools including Nanoparticle Tracking Analysis and Mass Spectrometry were used for VLP characterization. An outlook will be given how continuous ultracentrifuges will complement these purification approaches.

PEGylation is a well-known technique to develop biopharmaceuticals, such as proteins and DNAs. It can increase the hydrodynamic radius to reduce their kidney excretion and prolong their in vivo half-life. On the other hand, the control of PEGylation reaction is difficult because of the formation of heterogeneous mixtures of target PEGylated product, its isomers, unreacted proteins and PEG reagents. As the differences in the sizes and the surface properties such as charge and hydrophobicity of the isomers are sometimes small, several purification steps are always combined to obtain the target product from the reaction mixture. Among the purification method, ion exchange chromatography has an advantage for the separation of isomers on the basis of their difference in size and charge with a single operation. However the separation mechanism is not fully understood. In this study, synthetic PEGylated DNAs were used as a model of well-defined structure isomers to investigate the charge shielding effect of PEG on the charged biomolecules. Poly T possessing 9 to 95 thymine bases, an amine group for conjugation and middle base was reacted with NHS-activated PEG reagents. The retention factors on anionic exchange chromatography, Q sepharose HP and QA monolith, were determined by liner salt gradient experiment. Elution salt concentration of PEGylated DNA was decreased depending on the molecular weight of PEG. However, the decrease was not pronounced when the number of bases increased. On the other hand, the number of binding site was practically unaffected by the PEGylation which means that the conjugated PEG chain did not disturb the interaction of DNA with cationic ligand while the interaction was weakened by the conjugated chain.

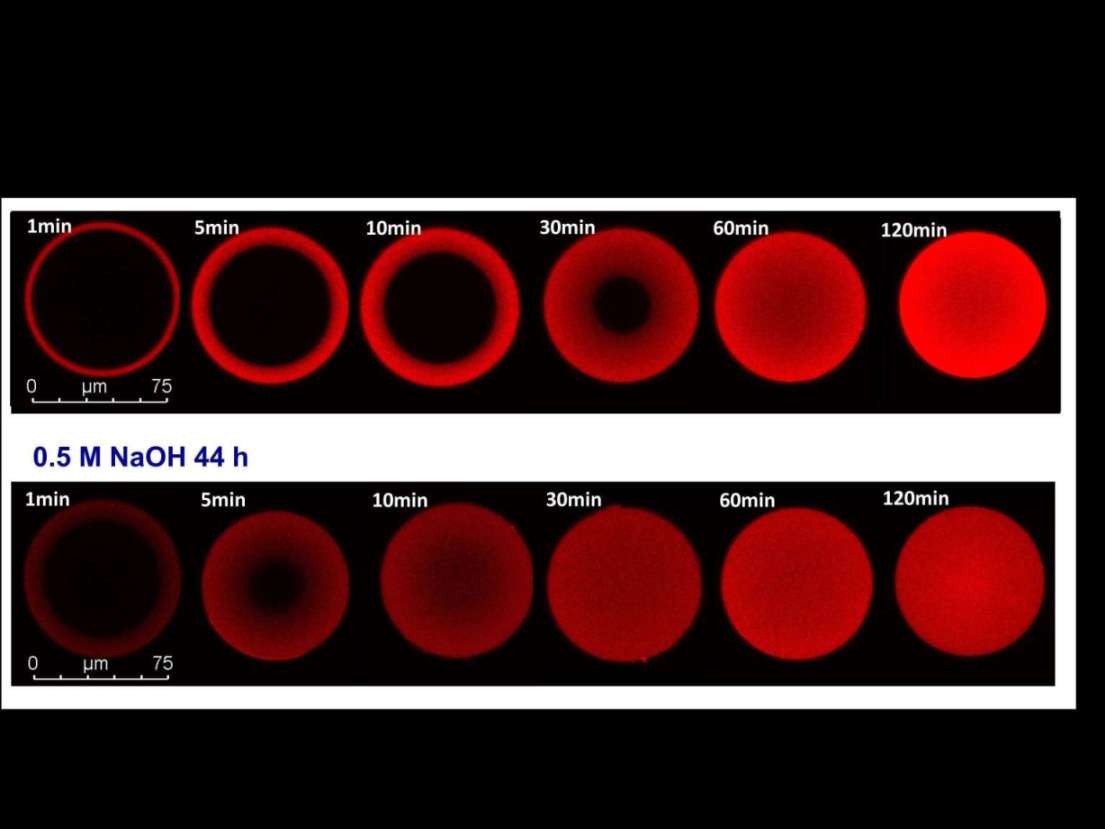

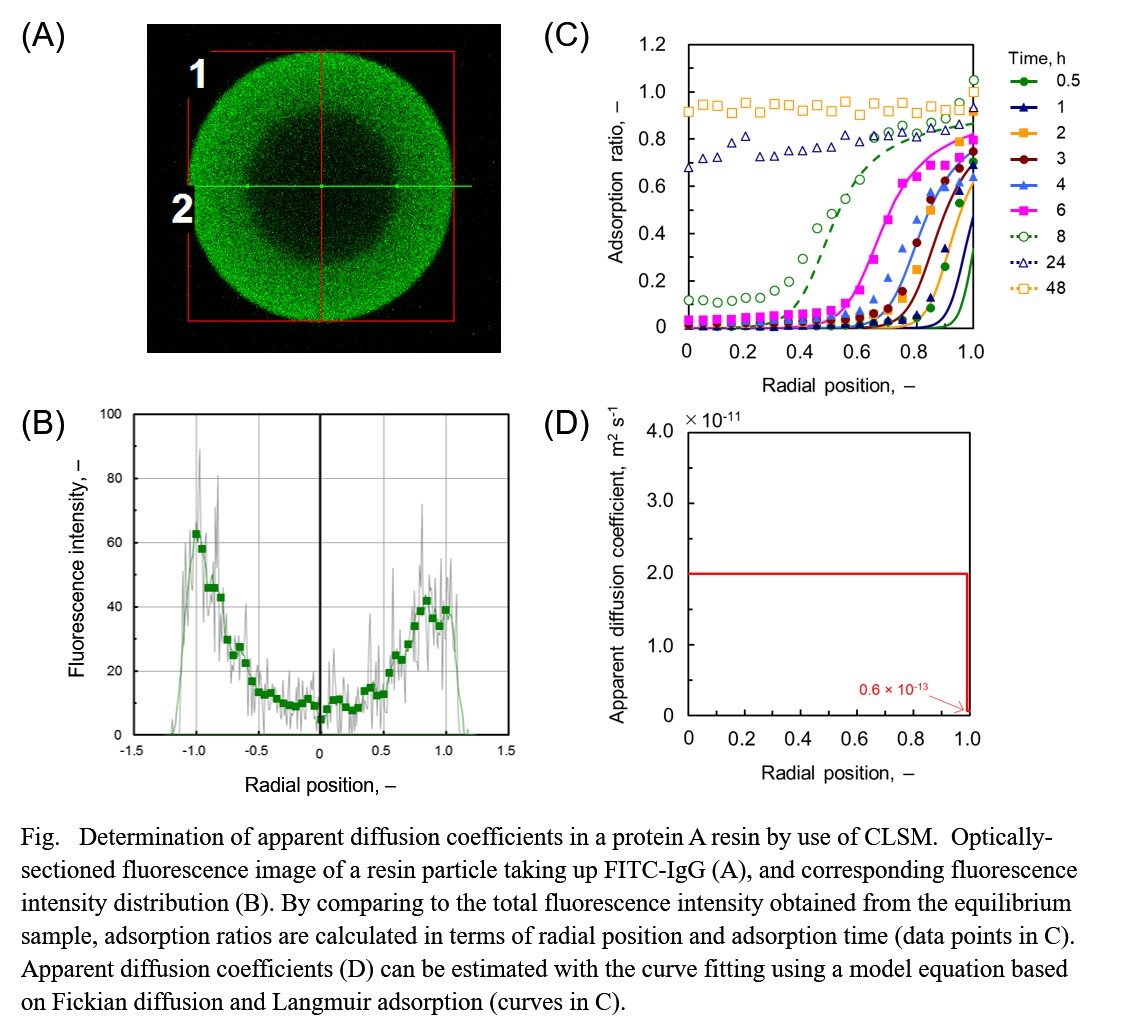

Protein A affinity chromatography is still the preferred option for antibody capture. In the past years, significant improvements have been made with respect to alkaline stability of the recombinant Protein A ligands, with resistance to 1 M NaOH over extended time periods as the latest milestone. We have investigated how exposure to alkaline conditions can alter antibody binding kinetics of Protein A resins. Break-through curves of fresh resins and resins after different time periods of alkaline exposure were compared using mAb and polyclonal IgG. As expected, equilibrium binding capacity dropped to some degree at long incubation times. In contrast, mass transfer of IgG was enhanced which was reflected by steeper break-through curves. Fitting of the break-through profiles with a pore diffusion model revealed effective pore diffusion coefficients which were increased by a factor of 2-3. Adsorption isotherm measurements showed that even after alkaline exposure, typical highly favorable isotherms were obtained, albeit with association constants that were reduced to some extent. Based on these altered binding properties we could identify a narrow window of specific operating conditions, where the alkaline treatment eventually led to an increase of the dynamic binding capacity. These conditions varied for different resins and strongly depended on the NaOH concentration and incubation time. Confocal laser scanning microscopy measurement showed that the accelerated mass transfer involved a transition from a shrinking core behavior with sharp fronts to a situation with more diffuse profiles typical for solid diffusion or pore diffusion with lower binding strength. Linear pH gradient elution studies showed that the desorption behavior was not changed significantly, as pH values at the peak maximum were almost the same as for fresh resin. The results of this study will contribute to a deeper understanding of phenomena associated with performance change of affinity media upon alkaline regeneration.

Polyacrylonitrile (PAN) nanofibrous membrane was prepared by electro-spinning technique. After heat treatment, alkaline hydrolysis and neutralization reaction, the ion exchange membrane (namely P-COOH) was further chemically grafted with chitosan molecule. The obtained P-Chitosan membrane (namely P-CS) was then covalently immobilized with Procion orange MX-2R dye from simulated textile wastewater to be used as a dye-ligand membrane. Fiber diameter, porosity, pore size, immobilized dye-ligand concentration, and protein binding capacity were characterized. Furthermore, the membrane was applied to evaluate the binding capacity of lysozyme under various operating parameters (e.g., pH, chitosan mass per volume ratio, immobilized dye concentration, ionic strength, and temperature) in batch mode. The experimental results were directly applied to purify lysozyme from chicken egg white by newly designed membrane chromatography module. The results showed that the recovery yield and purification factor were 98.9 % and 56.9-fold, respectively, in a single step. The binding capacity remained consistent after five repeated cycles of adsorption-desorption operations. This work demonstrates that the dye-ligand nanofibrous membrane holds great potential for purification of lysozyme from real feedstock.

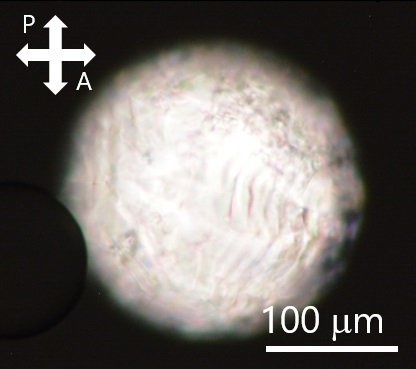

Protein precipitation by polyethylenglycol is a simple, robust and cost effective first capture step for purification. The resulting structure of the precipitate particles has a significant impact on process design and process performance like recovery and dissolution kinetics. Current technologies for visualizing and reconstructing 3D precipitate structures are either very time consuming and expensive (Cryo-TEM) or generate a single average value (a fractal dimension) for a population of precipitate particles (light scattering). We developed a new method using light microscopy to reconstruct the complete three dimensional structure of individual precipitate particles with a resolution of 0.1-0.2 μm. This methods was then used to reconstruct and characterize the three-dimensional structure of particles generated by batch precipitation by PEG as well as continuous precipitation in different shear stress environments. Both methods, batch and continuous precipitation, generate particle structures of very diverse nature, while the average fractal dimension is significantly different between the two (2.40 for batch in low shear environment and 2.52 for continuous in high shear environment). Besides the overall average, when investigating both populations in detail, the distributions of fractal dimensions of individual particles overlap significantly. We could also confirm that the generation of PEG-precipitated particles is diffusion limited, as simulations predict a fractal dimension of 2.4 for diffusion limited precipitation and 1.7 for reaction limited precipitation. A close inspection of the 3D structure of the precipitate also shows monofractality of the particles from micro to nano scale visualized by light microscopy. We showed that the fractal dimension and 3D reconstruction is a valuable tool for characterization of different shear stress conditions and mode of operation. The current switch from batch manufacturing to continuous manufacturing has to take the 3D structure and population of different protein precipitates into account in their design, engineering and scale up.

A preparative high-performance liquid chromatography is an extensively used technique for a purification of commercially important bio macromolecules, such as proteins and polynucleotides. Since process time is becoming more and more critical, fast and effective chromatographic methods are widely required. In this context, target molecule breakthrough point determination is of a great interest for optimization of downstream processing. Ideally, continuous analysis is preferred, such as UV absorbance or fluorescence monitoring, which in some cases however lack sufficient selectivity. An alternative is to perform fast analysis of column outlet fraction via chromatography providing equal or greater selectivity than purification step. This can be done using UPLC that however requires specialized equipment. On the other hand, fast analysis of macromolecules can also be achieved using convective chromatographic media at much lower pressure drop. This opens possibility to combine purification step and chromatographic analytics on a single chromatographic system.

In our case we implemented äKTA Explorer system to test feasibility of proposed approach. On-line analysis of preparative column outflow was performed by sequentially injecting outlet on convection based analytical column operating on the same chromatographic system where target molecules were analyzed. Cationic and/or anionic exchangers were used as chromatographic supports (along with selective protein A membrane), depending on feed sample and its characteristics. Three different case studies were tested: monoclonal antibodies purification, aggregate content and plasmid DNA (pDNA). To adjust limit of detection an algorithm varying number of injections was used. This enabled accurate monitoring of an early breakthrough for concentration below 1%. Due to its simplicity and flexibility such methodology can easily be adopted also in pharmaceutical environments.

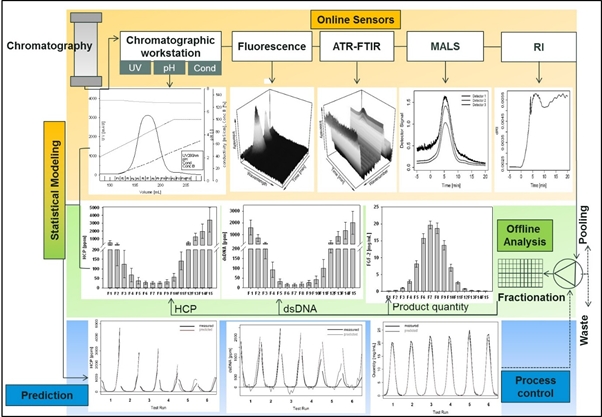

To enhance product quality and process robustness in biomanuacturing regulatory agencies have encouraged the implementation of process analytical technology (PAT). This combination of process understanding and control with real-time monitoring of quality and performance attributes also increases process efficiency and productivity. Currently, process performance is monitored by laborious and time-delayed offline analysis after each process step. This conventional approach increases hold times and overall process duration as well as the risk for batch failure. We have equipped a commercial chromatographic workstation with additional online sensors based on multi-angle light scattering, refractive index, attenuated total reflection Fourier-transform infrared, and fluorescence spectroscopy. The combination of these derived online data enables the prediction of product quantity and various purity attributes such as high molecular weight impurities, HCP and dsDNA content simultaneously during the elution phase of a chromatographic purification step. Such predictive models based solely on online data have been established for capture, intermediate and polishing steps of a monoclonal antibody produced in CHO and for fibroblast growth factor 2 overexpressed in E. coli. Online signals and corresponding offline data for product quantity and co-eluting impurities were analyzed by the statistical tools partial least square regression and boosted structured additive regression. Also chromatographic runs with varied process parameters were conducted to determine the predictive power of the models. The established methodology using complimentary online sensors enables the prediction of product quality and process performance attributes simultaneously in biopharmaceutical purification processes within a feedback time below 5 sec. The application of such models allows online pooling decisions and decreases the number of off-line analysis and hold times significantly. The costs for in-process analytics are lowered and the risk for batch failure is reduced. These findings are fundamental for the successful implementation of continuous manufacturing and real-time release in biomanufacturing.

Ion exchange chromatography is a widely used method for purification in all types of biomolecules in current biotechnological downstream processes. Knowledge on the binding behavior of proteins provides valuable insight for understanding the molecular mechanisms of protein interactions in a biological context. However, thermodynamic parameters such as enthalpy and entropy changes accompanied by protein adsorption and desorption are still unknown in ion exchange chromatography. This work relates the change in molar adsorption enthalpy, Δh0, with the salt concentration needed to elute a model protein with a gradient elution, IR. Bovine serum albumin (BSA) was adsorbed on four anion exchanger solid phases possessing grafted ligands (Toyopearl GigaCap Q-650M, Toyopearl SuperQ-650M, Toyopearl Q-600C AR, Q Sepharose XL). A linear relation was observed between the Δh0 and IR. From the highest Δh0 to the most negative: Toyopearl SuperQ > Q Sepharose XL > Toyopearl Gigacap Q-650M > Toyopearl Q-600C AR. The same experiments were also done with a non-grafted conventional solid phase, Q Sepharose FF. However, it did not fit in the same trend due to the ligand disposition. Δh0 was found to be endothermic for Q Sepharose FF and Toyopearl SuperQ-650M and exothermic for the other solid phases. Endothermic Δh0 indicate that entropic effects play a major role on the adsorption of BSA on these two solid phases.

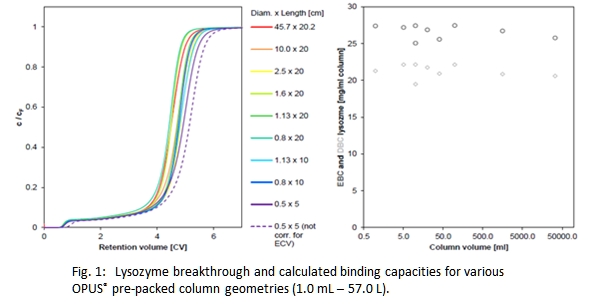

Flexible adaptation to constantly changing market demand is getting increasingly important in the manufacturing workflow of biopharmaceuticals. Moreover, fast development times and reliable scale-up are required and are key to success.

Pre-packed chromatography columns have been commonly adapted in industry during the recent years and allow to reach these requirements, however data showing scalability throughout various column sizes applied in early stage process development up to commercial manufacturing has been not available so far. This presentation confirms the scalability of column performance throughout Repligen's OPUS® pre-packed column line including MiniChrom, ValiChrom and OPUS® Process Scale columns covering a range of 0.5 to 60 cm inner diameter.

Scalability has been demonstrated for various resin types and functionalities and has been proven for both column packing performance and protein separation under isocratic conditions.

Experimental data on OPUS® packing performance has been compared to traditional self-packed columns and found at least equal if not better.

Furthermore a statistical data analysis using advanced software tools has been performed for more than 30.000 pre-packed columns supplied into global industry over a time span of 10 years.

Extra-column effects can have significant influence on separation performance. These effects are caused by dead-volumes, valves, column hardware and tubings. For small scale chromatography systems, and especially with very small columns, the extra-column band broadening can be dominant over the actual broadening of the column that is used for separation. This issue has long been recognized and has been investigated extensively by many researchers. However, though it is often overlooked, also for preparative and pilot scale chromatography extra-column effects can be an important factor. This is particularly valid, if the column size is relatively small. We have investigated the Aekta Pilot system volume contribution to band-broadening by non-binding tracer experiments on columns of various sizes using columns packed by axial compression to ensure consistent packing performance. Additionally, the influence of non-standard mixing behavior occurring in the bubble trap during step elution was investigated using a simplified model of interconnected reactors. Other flow parts of the chromatography system were modelled by dispersed plug flow reactors and CSTRs for dead zones, e.g. column in- and outlet and mixers. Essentially, the effective mixing volume of the bubble trap is affected by the flow rate and the density difference of the two buffers. As a consequence, the influence on the separation in the column varies with these parameters. Experimentally, the band broadening effect of the bubble trap on the chromatographic separation was investigated by performing linear gradient elution and step elution experiments using bovine serum albumin at analytical loads. There was no observable band broadening effect in linear gradient elution. However, during step elution the salt transition profile was affected leading to significant peak broadening of the BSA elution profile.

There is growing interest in mAb processing to improve individual unit operation performance and overall process train efficiency through linked processing. In the downstream process, several types of chromatography are typically performed to achieve the target of purity of therapeutic mAb. AEX chromatography is commonly operated under product flow-through conditions to bind negatively charged impurities such as HCP and virus. CEX chromatography focuses to separate the mAb related impurity. Ichihara et al., (mAbs J. 10-2, 325-334, 2018) reported the operating CEX chromatography in the flow-through mode for mAb aggregate removal. To intensified flow-through chromatography, controlling the feed concentration through single pass TFF (SPTFF) is one of the ideas to get the higher loadings from the isotherm binding condition, especially for AEX column. The use of SPTFF technology can help facilitate these process intensification efforts by modifying process intermediate volumes and concentrations without the need for recirculation. However, the impact of concentration change on other chromatography is not evaluated well on the fully combined in-series operation.

In this work, SPTFF by Pellicon® 3 30kD is used prior to a flow-through chromatography polishing step to boost chromatography resin loading. Then, Eshmuno® CP-FT resin was challenged with various concentrations of mAb feed and evaluated the difference of impurity removal. And results compared the performance of previously reported SPTFF-AEX results (Merck Application Note, AN5364EN00 2017), and evaluate the impact of connected flow-through polishing on feed concentration.

The biopharmaceutical downstream process is designed to achieve high product yield with efficient impurity removal. “Process derived impurities” such as host cell proteins (HCPs), lipid, DNA and fermentation ingredients and “Product related impurities” like aggregates and fragments should be reduced to meet each specification of drugs for quality and safely.

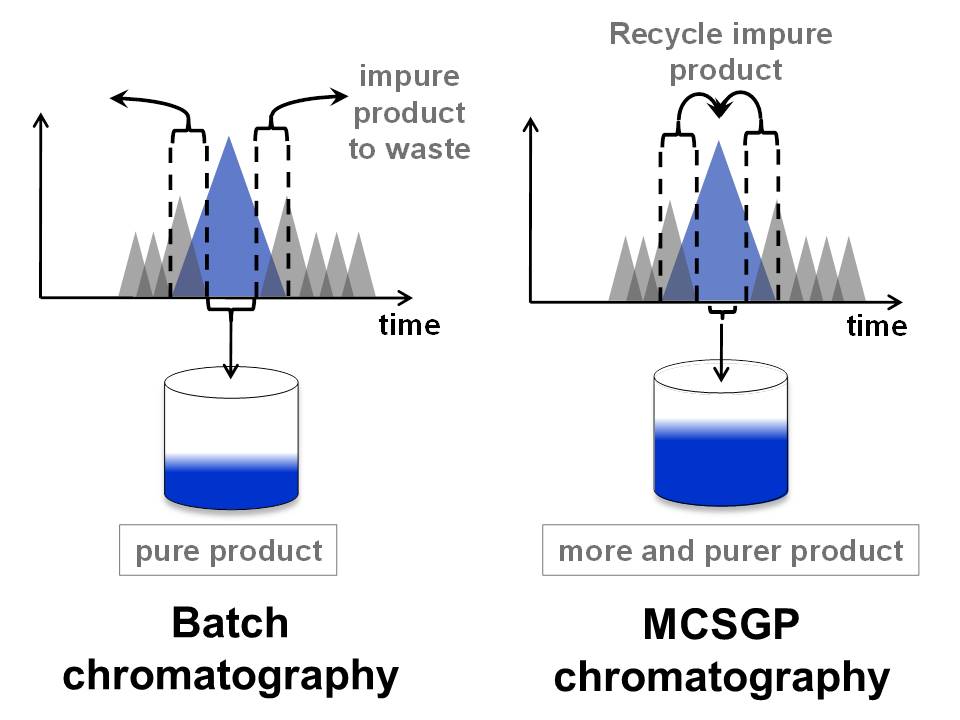

Economical pressure on biopharmaceuticals, especially monoclonal antibodies (mAb), has motivated to develop high capacity chromatography resins and new purification technologies including periodic counter-current chromatography and multi cycle batch chromatography using smaller particle size resins with high flow rate. Thus, load amount onto chromatography resins are tend to increase.

Higher amount loading of not only target proteins but also impurities on chromatography resins affect selectivity and life time of chromatography resins. Increased risk of fouling on chromatography resins by accumulation of impurities should be mitigated as much as possible to minimize burdens on each step to develop stable process with lower COGs.

We developed new impurity reduction method using co-precipitation of impurities without loss of target proteins. The method reduced HCPs and DNA in harvested cell culture fluid expressing mAb one third and one thousandth respectively. We also evaluated the effect on the quality of eluate from protein A chromatography and other benefits on the process.

1. Introduction

There is increased interest in continuous processing for monoclonal antibody (mAb) purification in bind and elute mode. This is because such continuous chromatography offers higher productivity and cost effectiveness than conventional batch mode. JSR developed and conducted a DoE for continuous chromatography process of mAb in bind and elute mode using a high-capacity Protein A resin, Amsphere™ A3.

2. Experimental

The mAb breakthrough was monitored by HPLC. The concentration of Protein A purified mAb was determined from the measured absorbance at 280 nm. Host cell protein (HCP) was quantified by CHO HCP ELISA kit, 3G (Cygnus Technologies). A harvested cell culture fluid (HCCF) contains IgG1 subclass mAb.

A three factor and three level DoE was designed using Minitab (Minitab, Inc.) to determine the impact of purification conditions on productivity (g/L/hr) and HCP concentration. The tested factors were IgG-loading, residence time for washing step and washing volume.

3. Results and discussion

Productivity of the continuous process with Amsphere A3 was calculated on various purification conditions. The results showed that the process time for sample loading and washing steps have significant effect on the productivity. The total amount of HCP in the eluates showed a positive correlation with the sample loading amount, especially when the flow rate for the loading step was relatively faster. That is, washing conditions have smaller effect on the HCP clearance performance with shorter residence time of sample loading step.

4. Conclusions

Amsphere A3 showed high productivity with continuous process because of its high DBC even for high linear flow velocity. Also, we found that the HCP clearance performance is independent from the residence time for washing step. This indicates that higher productivity and good HCP clearance can be achieved together by increasing flow rate and decreasing process time of washing step.

The development of efficient downstream processing plays an importance in therapeutic antibodies (mAb) purification. As an example, a continuous multicolumn chromatography technology in ProteinA capturing step has been attracted attention from biopharmaceutical companies. Recently an integrated flow-through (FT) process is considered to be one of effective approaches for mAb purification. FT mode has an advantage to increase loading amount of mAb per column volume. Further an integrated FT-FT process technology is expected to achieve much less installed chromatography resins, buffer and tanks to use in comparison with a conventional polishing step consisting of bind/elute (B/E) mode and FT mode. This technology will promise pool-less manufacturing for economical mAb process in near future.

Cellulose based chromatography resins are well-known to be stable to caustic condition for cleaning and less nonspecific adsorption properties. These unique properties are suitable to apply an integrated FT-FT process technology for mAb purification. In the past few years we succeeded in developing a unique cellulose based mixed mode resin, Cellufine MAX IB, which can remove impurities effectively in FT mode for mAb purification under high salt condition. The resin is further tested to use integrated FT-FT mode for mAb purification by examining mAb recovery and impurities removal. In this poster, we report development of efficient mAb polishing process by integrated FT-FT mode which consists of a combination of Cellufine MAX IB resin with other cellulose based cation exchange or hydrophobic chromatography resins.

To accelerate process development and optimization of chromatography, it is essential to use mechanistic models to simulate and predict the implementation of such operation for certain products. The universal prerequisites for chromatography modeling involve adsorption isotherm and mass transfer mechanism, where users can choose the models based on the balance of predictability and calculation ability. Unfortunately, most software packages are still not user-friendly because of complexity of models and input parameters.

In the study, different mechanistic models for various simulation platforms that depend on the same isotherm and mass transfer coefficients were tested for linear gradient elution (LGE) of proteins. The model system was separation of basic proteins such as lysozyme and IgG by ion exchange chromatography (IEC). Our model (Yamamoto model) was used for determining the two parameters (A, B) needed for steric mass action (SMA) isotherm model from LGE experiments. As for mass transfer, lumped kinetic model and linear driving force model (LDF) were used as only one lumped mass transfer coefficient (km) is included, which reduces the computational burden in determining individual effect from axial dispersion and pore diffusion, and such. The km value was determined also from LGE experiments based on Yamamoto LGE-HETP model, which includes the compression factor for the peak sharpening effect in LGE.

By a set of LGE experiment, the major parameters (A, B, HETP) can be obtained, and thus the adsorption and mass transfer models for mechanistic modeling can be constructed. Different simulation platforms have given similar outputs in comparison, which demonstrates that modeling for protein chromatography can be achieved from limited LGE data in different computational tools, albeit the coefficients definition varies in the software.

Reference Yoshimoto, Yamamoto, Simplified methods based on mechanistic models for understanding and designing chromatography processes-Yamamoto Models and Approach-, in Preparative chromatography for separation of proteins, 2017

The changes from stainless steel equipment to single-use solutions as well as switching from batch to continuous operations are currently strong discussed topics in the field of downstream processing. Besides the product yields and the purity grades, the footprint reduction and higher productivities result in decreased cost of goods (CoGs). With these developments, not only economic but also ecological goals will be achieved through buffer and materials savings. In the course of the present evaluation, we compared continuous and single use solutions to conventional platform processes and quantified their economic and ecological impact. In detail, we have compared a cell culture antibody process consisting of conventional broth clarification by centrifugation and batch capture by protein A affinity chromatography with a continuous process consisting of continuous clarification by depth flocculation and continuous precipitation and/or periodic counter current chromatography (PCC). Our results show potential cost saving strategies and how ecological goals and improved costs of goods can be combined. Possible savings of 30 % can be achieved by combining novel technologies and buffer savings of 60 % can be realized by the use of precipitation or PCC. The scenarios were evaluated for an existing facility with a bioreactor scale of 1,000 L as well as for two theoretical facilities scaled for either an orphan drug production of 50 kg/year or a blockbuster production of 1,000 kg/year.

The antibody manufacturing process is consisted of a cell culture process using animal cells and a purification process including several chromatography steps and filtration steps. The purification process is important to obtain high quality bio-pharmaceutical products by removing impurities, and measurement of antibody concentration is a fundamental and essential factor to control the manufacturing process and to confirm the yield of each purification step.

The concentration range in the purification process is wide, and over 100 mg/mL concentration can be observed for example in a final polishing step. In this study, optical rotation was applied for the first time to measure various concentrations of antibody and their accuracy was evaluated. Furthermore, the possibility of application to the process analytical technology was also discussed in the poster presentation.

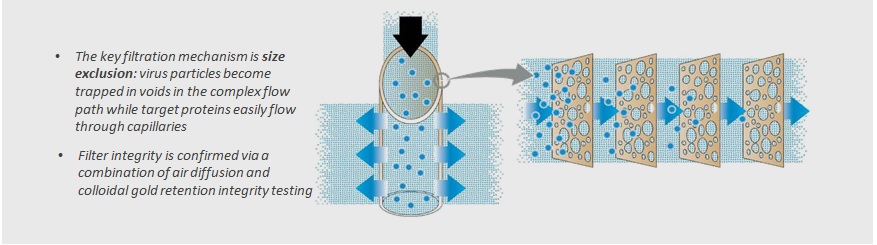

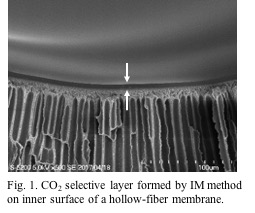

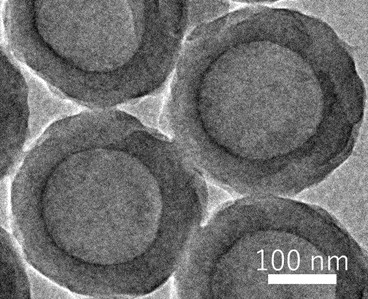

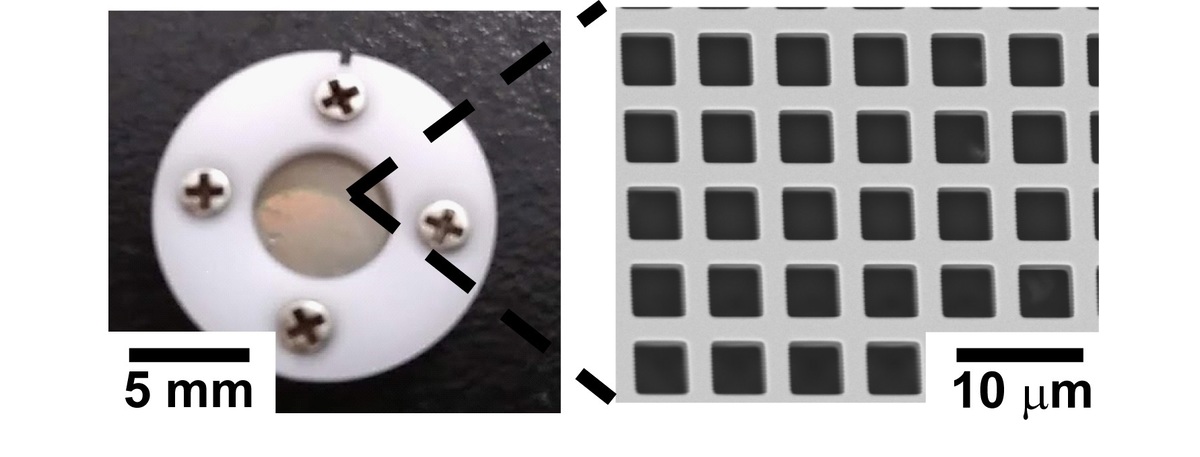

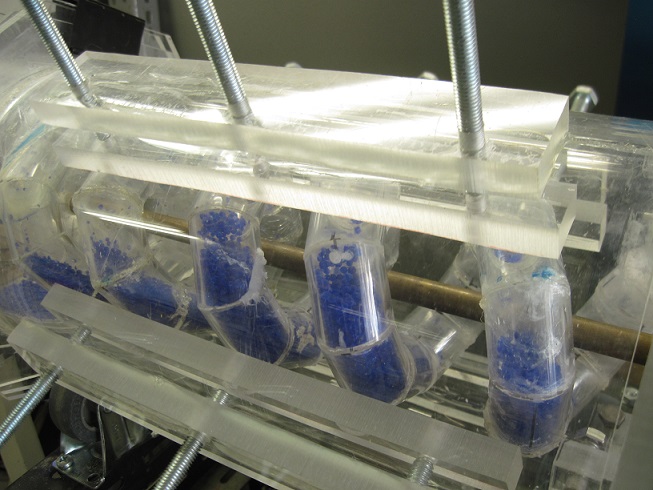

Virus filter is essential step to eliminate viruses in the Bio-pharmaceutical products. Continuous bioprocessing is of great interest for bioprocess manufacturers because of the possibilities of reducing production time, cost and footprint. One important element of continuous bioprocess is tankless connection between the adjacent steps, however virus filtration is mostly batch process, in which the target protein solution is pooled in a tank and then loaded to the virus filter with constant pressure. One reason of the preference of batch process is the concern of possible flux decay during the loading process Especially if chromatography process is connected directly to virus filter, flux decay by the sudden pressure rising is fatal for the manufacturing process. In this concern, virus filters with multi-layer structure as shown in the figure having high robustness in the continuous loading are necessary for the manufacturing process

Chromatography process is located just in front of the virus filter step and it affects the permeability of virus filter significantly. Especially ion exchange chromatography (IEX, AEX or CEX) step is usually just before the virus filter in the IgG purification process and impurity removability of IEX step is essential for the virus filter permeability.

In this study, the effect on the virus filter permeability of different types of IEX chromatography resins, i.e., normal IEX and mixed-mode IEX, are compared by using IgG solution with spiking aggregates. Mixed-mode AEX shows much higher aggregate removal than normal AEX. The virus filter permeability is tested both for constant pressure and constant flow rate loading. The dependencies of IgG concentration and flow rate are also tested. These results indicate that appropriate combination of IEX resin, column volume, virus filter membrane area and flow rate is very important for high protein recovery and the cost effectiveness process in the continuous bioprocessing.

Chromatography separation, which is essential in biopharmaceutical industry, is not widely used in food industry as food products are much less expensive than pharma products. However, as functional foods are highly anticipated, there is an increasing need for development of efficient and economically-feasible chromatography process for food separation.

In addition to the cost issues, food separations have many constraints and requirements, which make it difficult to use chromatography. As for the stationary phase (resins) and the mobile phase (liquid), they must be chosen based on the accepted materials by the regulatory agency. In addition, the resins must be cleaned and sanitized easily. Considering these requirements, polystyrene divinylbenzene (PS-DVB) resins-based chromatography with ethanol-water mobile phase is most attractive. The resins can be washed with sodium hydroxide. Ethanol is a very safe solvent, and can be recycled easily if needed.