Management and disposal of sewage sludge (SS) is drawing great attraction due to its large quantity and potential environmental concern. On one hand, SS contains relatively high heating value that could be recovered through further thermal treatments such as incineration and gasification. On the other hand, high nitrogen content leads to potential NOx emission during the thermal treatments. Hydrothermal carbonization (HTC) pretreatment could enhance fuel quality and remove unwanted pollutants like nitrogen and sulfur. Thus, it is popularly applied in the field of SS disposal. In this study, an integrated HTC pretreatment and CO2 gasification system was proposed and studied. Cold gas efficiency (CGE), carbon conversion factor (CCF) and ammonia emission were evaluated as key performance indicators. Nitrogen transformation behaviour from HC was studied from 400 °C to 900 °C indicating that the release of NH3 was mainly because of the decomposition of amide group. Meanwhile, gasification products from SS and hydrochar (HC) showed that NH3 (NOx precursor) emission could be reduced by 57% through HTC pretreatment although CGE and CCF were inhibited. However, this could be improved through co-gasification of HC with horticulture waste (HW). The preferred experimental condition was found to be 1:1 HC/HW mix ratio that CGE could reach 66%. The synergetic effect was believed due to the presence of calcium compounds in the HW. It was also observed that calcium element could improve both nitrogen removal efficiency during HTC and CGE during gasification.

Fluidized beds are used extensively in the petrochemical, metallurgical, food and pharmaceutical industries. Although a rich literature focusing almost entirely on large scale fluidized bed systems has been developed, little is known about gas fluidization in mini-channels. Such mini-fluidized beds have the potential to provide large interfacial areas, high transport rates, large wall surface area for heat exchange and may find important applications for various chemical and biological processes. However, the behaviors of mini-fluidized beds differ from their large scale counterparts and correlations that have been developed for the latter have been observed to be inadequate for predicting bubbling and slugging behaviors in mini-fluidized beds. In this study, the Discrete Element Method combined with Computational Fluid Dynamics (CFD-DEM) was applied for studies of solids mixing in a mini-fluidized bed. The effects of different operating conditions, such as superficial gas velocity, continuous and pulsating flow at the inlet, interparticle van der Waals interactions, on the efficiency with which mixing takes place were investigated through the simulations.

Small white glass particles (0.84 – 1.00 mm) and large black glass particles (1.19 – 1.41 mm) are mixed in a 40% fill, 20 rpm drum which is 100 mm in length and 98 mm in diameter. An inner particle axial motion blocking plate is placed in a rotating drum and the effect of its position on the particle mixing is studied. The plate has 78 mm inner diameter and blocks 34% particles' axial motion. The experimental results show that the degree of mixing increases by the blocking plate shearing. The shearing changes the dynamic angle of repose of the particles and the location of the plate affects the degree of mixing and segregation patterns. The particle motion in this system is realized by DEM simulation. It is found that the plate blocks particle motion deep in the bed, but enhances axial motion at the bed surface. The plate inserting increases the particle plate crossing number, the average particle axial velocity and the particle axial moving distance per revolution.

The dispersion of solid particles plays an important role in solid-liquid agitation. For example, “moderate” agitation is necessary in crystallization. Insufficient agitation causes crystals to stay at the bottom of the tank; thereby particles stick together or stick to the wall of tanks. This poses handling problems such as clogging of bottom lines and insufficient quality by coarse lumps. On the other hand, overpowering agitation causes crystals to break into small particles due to a strong shearing force, causing malfunction in subsequent processes, such as, a filtration process. Thus, it is extremely important to design both a proper apparatus and proper agitating speed to obtain desirable dispersion in solid-liquid agitation.

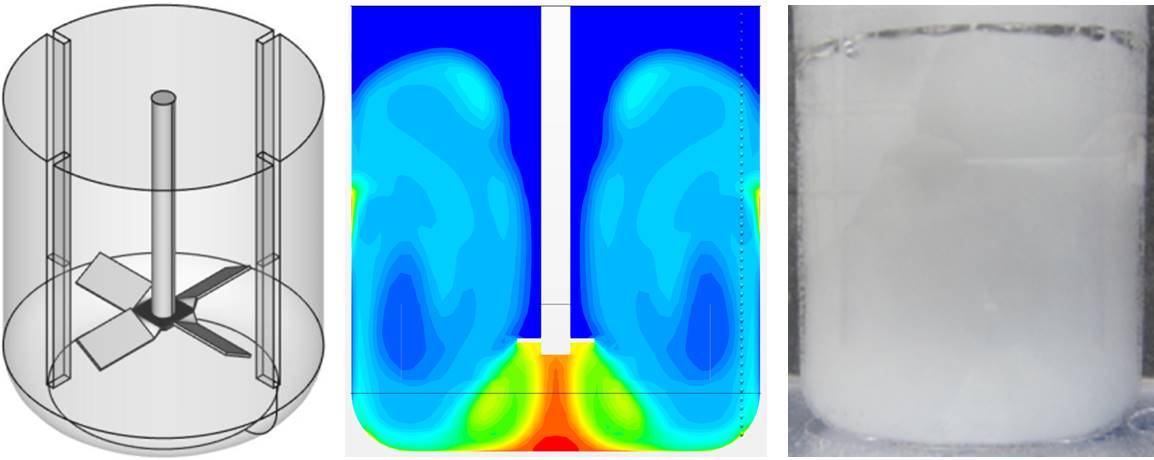

Designing solid-liquid agitated tanks, just suspension speed NJS and segregation state are important. To estimate NJS, Zwietering's empirical formula is widely adopted. The formula requires a geometrical constant which depends on the shapes of apparatus: The geometrical constant is often unavailable so that it needs to be obtained experimentally for each apparatus which has a lot of factors such as the shape of the agitating blade, the shape of the tank, the number of blades, and the blade position, thereby taking cost and time. Thus, NJS has been estimated with Computational Fluid Dynamics (CFD) instead of experiment. In addition, the extent of segregation has been evaluated at NJS based on particle concentration distribution obtained with CFD.

NJS, obtained with CFD simulation and experiment have been found to be adequately consistent with each other. Furthermore, the shape of apparatus has been found to affect the state of segregation at NJS.

Processes using particle coagulation are one of prominent parts of many branches of industry. With growing interest in unsteady operations, they have been applied to agglomeration processes. Coagulates produced from unsteady operations tend to have unique properties and, in terms of industrial applications, more understanding of the relationship between unsteady flow and particle agglomeration is needed. As an unsteady flow, laminar chaotic mixing induced by adding periodical perturbation has attracted a lot of attention. In fact, it has been eagerly investigated to enhance mixing efficiency and to apply to industrial processes since 1980s. There is, however, no reports on particle aggregation behavior in a chaotic mixing field. Therefore, aiming at the development of a novel coagulation process, this study investigated particle aggregation in a simplified two-dimensional chaotic flow.

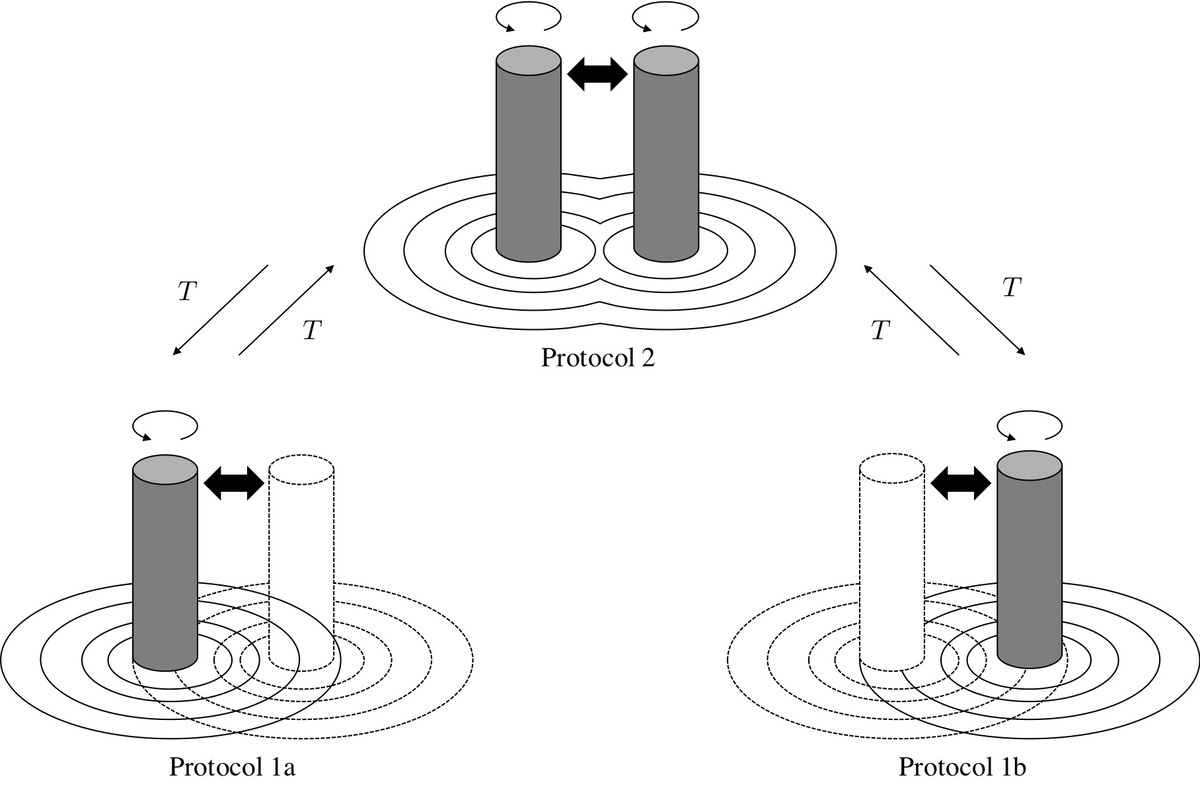

A schematic of the model flow in this study is shown in Figure 1. In this model, the system consists of two rotating cylinders. The motion of cylinders can be divided into three units protocols (protocol 1a, 1b and 2). In protocol 1a and 1b, one cylinder rotates for fixed time T. On the other hand, both cylinders rotate in protocol 2. This periodic operation is supposed to perturb the fixed point which locates at the center in between the two cylinders in protocol 2 and to induce chaotic mixing.

The temporal evolution of the number of aggregates can be described using an exponential model equation. Aggregation rate constant k showed less dependency on rotation rate of cylinders マ・/I> and higher k was obtained when T was shorter. These results indicate that chaotic agitation decreases the effect of breakage and promoted coagulation. The smaller マ・/I> or T where the system has higher unsteadiness, the larger aggregates were obtained.