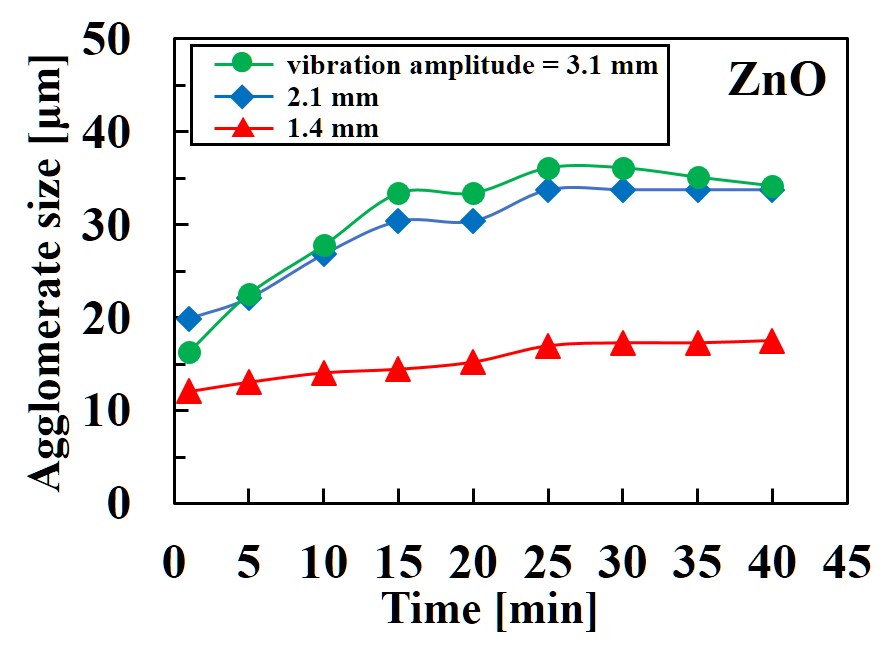

The recycling and utilization of powdery waste are becoming increasingly important for not only ensuring a sustainable environment but also decreasing the cost of waste disposal. In our previous work, focusing on the fact that the cohesion differs depending on the powder components, we report that it is possible to concentrate and separate specific components from binary mixed powders by using a vibrating fluidized bed. In order to apply this concentration and separation technology to various powders, systematically understand the aggregation and fracture characteristics of each powder in the vibrating fluidized bed are essential. In this study, the gas fluidization of three fine powder, viz. ZnO, TiO2 rutil, and TiO2 anatase were studied in a mechanically vibrating fluidized bed. The effects of the powder particle components and vibration amplitude on agglomeration and disruption in the fluidized bed were investigated. The temporal change of apparent agglomerate size was evaluated using the Ergun equation from the temporal change of bed height and pressure drop. Furthermore, the effects of powder species and vibration amplitude on aggregate size during aggregation-disruption equilibrium were evaluated based on a energy equilibrium model.

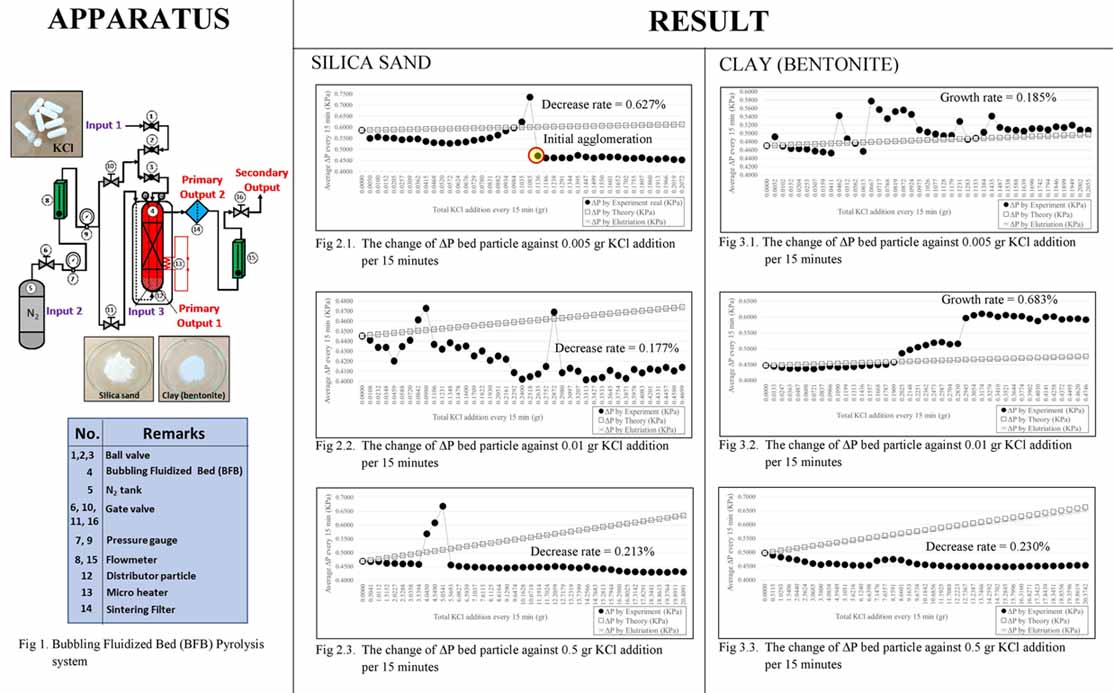

Bubbling fluidization process enables to enhance performance thermal conversion reaction between bed particles and raw material like biomass inside a bed column supported by gas distribution from the particle distributor at the bottom side. However, some unwanted inorganic materials like alkaline compounds contained inside biomass have the potency to create a slagging formation with oxide compounds from either inside or outside the bed column. The pyrolysis process was selected reaction to ensure the oxide compounds that were only coming from all particles placed first inside the bed column that easily associated with alkaline compounds at the high-temperature condition. The +88-125 μm silica sand and clay (bentonite) were the bed particles of Bubbling Fluidized Bed (BFB) pyrolysis process against Potassium Chloride (KCl) addition at 700oC as the use of biomass representation under superficial-N2-velocity condition. An agglomeration formation was confirmed by the decrease of average ΔP by the experiment which will theoretically should to increase by KCl additions, while the defluidization condition was initiated by the stuck up the whole particle movement that already stop moving completely even after getting more some KCl additions. Investigation on 0.05 gr and 0.1 gr encapsulated KCl addition variables within 40 samples x 15 minutes interval reaction time showed that the silica sand has a faster tendency to form initial agglomeration than clay started from 0.1136 gr KCl addition (by 0.174% of total silica sand weight). Meanwhile, the clay has more tendency to achieve defluidization formation easily than silica sand particle on variable 0.5 gr KCl addition by the rate of ΔP decrease 0.230% and 0.213% respectively. The endurance of silica sand to maintain fluidization in a longer time than clay indicates that silica sand could be considered as the better particle to be applied in this process.

Separation is one of the important unit operations for industry. Wet separations such as froth flotation are utilized for particulate mixture. However, the conventional wet separations, which require large amount of water, are not convenient in dry districts. In particular, the lack of water is becoming a critical issue in mining areas with drought due to global warming. Therefore, the development of dry separations to replace the commonly used wet separations is in great demand. A gas-solid fluidized bed is one of the candidates for dry separation. When a particulate mixture having density difference is fluidized, lighter particles move up and heavier particles move down in the fluidized bed. This phenomenon is called “density-segregation”. Recently, we found that the density-segregation is enhanced when vibration is added to the fluidized bed. The vibro-fluidized bed is effective to separate particulate mixtures with small density difference. Here we investigated the dry separation of particulate ore with small density difference using the vibro-fluidized bed. We found that the density-segregation does not occur using only the fluidized bed without vibration regardless of fluidizing air velocity. In contrast, the vibro-fluidized bed enables us to separate the lighter mineral and heavier mineral based on the density segregation. The fluidizing air velocity is an important key factor to enhance the density-segregation by adding the vibration to the fluidized bed.

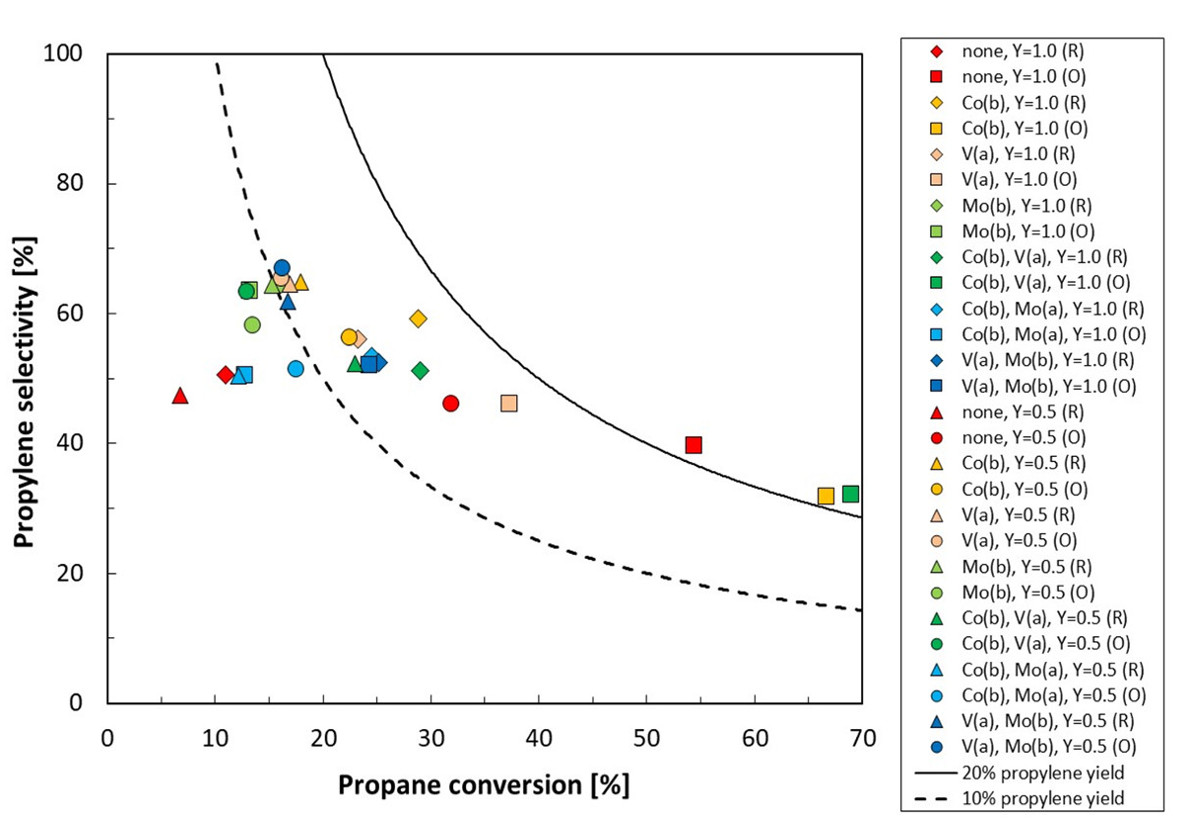

Hydroxyapatite-supported metal catalysts (M/HAp) has attracted attention in recent years especially in the oxidative dehydrogenation of light alkanes because hydroxyapatite (HAp) is a promising carrier with adjustable acid-base characteristics, high stability, and various metal substitutions. In the literature, HAp itself had shown very small catalytic activity in the oxidative dehydrogenation of propane (ODHP). Recently, we found that our heat treatment method, drip thermal treatment using a fluidized bed (DTFB), could improve the catalytic activity of nickel-incorporated hydroxyapatite (Ni-HAp) catalysts in partial oxidation of methane. In this study, HAp, metallic and bimetallic incorporated HAp (M-HAp or M1-M2-HAp) were prepared via DTFB under different atmospheres, and their catalytic activity in ODHP was investigated in a fixed bed reactor at different stoichiometric ratios of gas reactants. It was found that DTFB improved the catalytic activity of HAp itself in ODHP, and that metal species such as Co, V, and Mo were useful for metallic and bi-metallic incorporated HAp catalysts.

Thermochemical conversion of fuels via pyrolysis / carbonization, cracking, gasification and combustion has to involve a number of individual reactions called attribution reactions to form an intercorrelated reaction network for any conversion process. By separating one or some attribution reactions from the others to decouple their interactions existing in the reaction network, the so-called reaction decoupling enables a better understanding of the complex thermal conversion process and further the optimization of the conditions for attribution reactions as well as the entire conversion process to realize advanced performances. By far, numerous research works have been conducted about the application of reaction-decoupling method on gasification and combustion process in our research team. Some interesting findings were obtained: (1) catalytic cracking and reforming of tar on the surface of char is critical to deeply remove tar in gasification process, and there exists a loop between deactivation and regeneration of catalytic activity of char for tar removal; (2) tar generated from fuel pyrolysis has the highest activity and also capacity of NO reduction than char and pyrolysis gas do. Based on these fundamental findings, processes of fluidized bed two-stage gasification (FBTSG) and fluidized bed decoupling combustion (FBDC) have been proposed and commercially developed to break through the problems of tar generation for gasification and NOx emission reduction for combustion, respectively. After a series of tests at laboratory and pilot scales, two industrial demonstration plants with treating capacities respectively of 10000 t/a for gasifying herb residue and 60000 t/a for burning distilled spirit lees have been designed and built to verify the technical advantages of the proposed new processes. The results show that the FBTSG technology enables tar content below 50 mg/Nm3 in product gas and the FBDC technology lowers NO emission in flue gas to about 150 mg/Nm3 even burning fuel with 4 wt.% N (dye base). This report will summarize the fundamental finding, technical innvation, pilot test and industrial demonstration for both such technologies based on reaction decoupling.