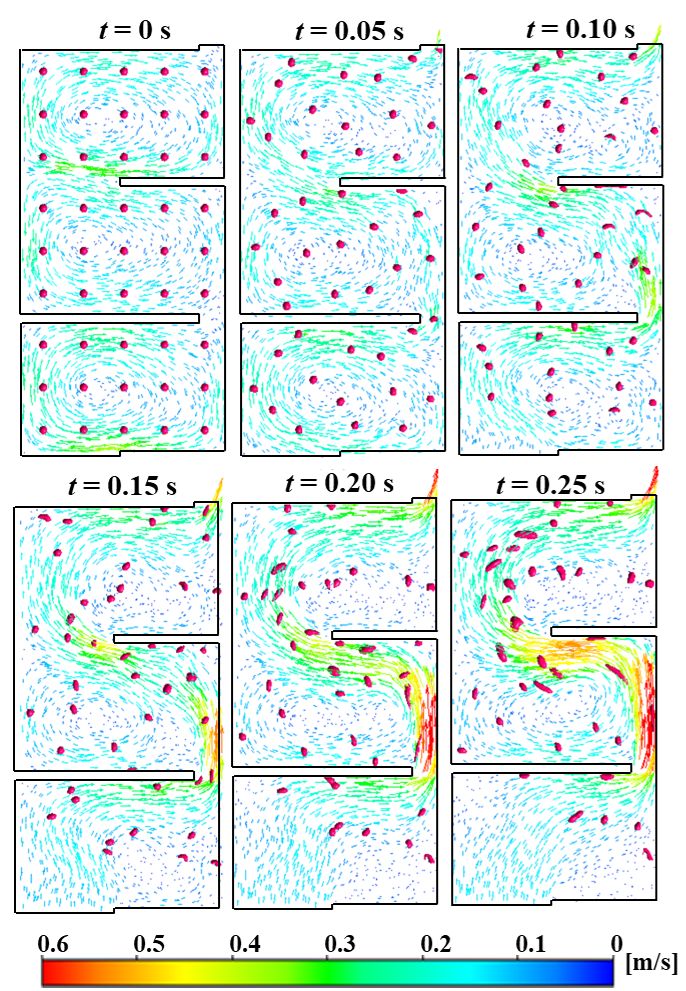

Particle suspension characteristics are predicted computationally in a stirred tank with solid concentration of 25% and driven by rigid-flexible impeller. The software of Fluent was utilized to investigate flow field structures in stirred tank. The effects of impeller type, length of flexible material, connect way of flexible material, mixing time were investigated by using the Eulerian–Eulerian two-fluid model and the standard k–ε turbulence model. It turned out that the structure of impeller has an obvious effect on solid particle distribution. The suspension of solid particles in the rigid-flexible impeller system was more homogeneous. It was also suggested that longer flexible material and longer mixing time results in well homogenous distribution of solid particles in the tank equipped with rigid-flexible impeller. On the whole, the rigid-flexible impeller could enhance the suspension of solid particles effectively.

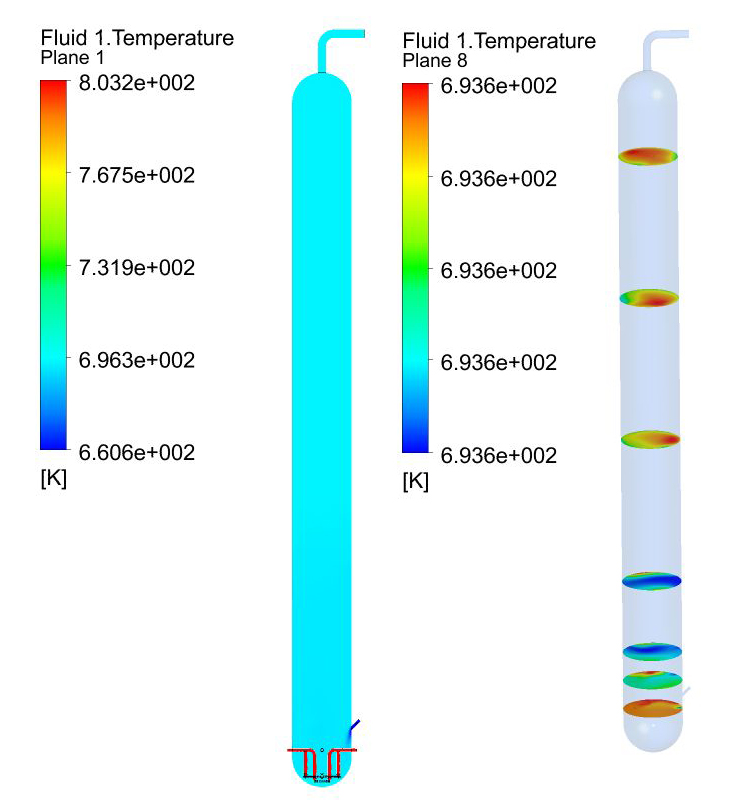

Hydro thermal cracking process of residue oil is an important technical route in the area of heavy oil processing. Because of a few catalyst loading, low cost, and low blocking probability, the slurry bed is better to be applied in processing residue oil, especially for heavy residue. With the increase of conversion, the stability of residue oil becomes weaker, and some unstable compounds may be crystallized easier. The precipitates will be attached at the surface of catalysts and reactor, which will lead to the deposition of catalyst and blocking. The distribution of velocity and temperature inside the reactor is essential for reducing precipitation of unstable compounds, and preventing reactor from blocking. Based on the results of a pilot plant, an industrial hydro thermal cracking reactor of residue oil was developed. Then, the flowing and distribution of fluid and deposition of catalysts were simulated by CFD. To reduce the deposition of catalysts inside the large slurry bed reactor, the position of inlet of residue oil was optimized. Furthermore, the distribution of temperature inside the reactor was predicted by CFD. It can be found that the distribution of temperature inside the reactor was very uniform, the difference in axial temperature is less than 3K, the difference in radial temperature is less than 1K.

Though the grinding operation is a unit operation that has been known for a long time, it still often occupies an important position in industry. Thus, various grinders have been evolved and produced in a variety of shapes to meet changing needs. In principle, bead mills can provide grinding conditions under a high packing density and high energy density of the media as well as cover a broad range of output. Therefore, their future application is highly expected to respond to the requirements of various grinding operations by the current industry. However, bead mills have a short history compared to other types of grinders. Especially for dry bead mills, it is hard to say that they are well known. That is why we studied and reported the performance of horizontal dry bead mills in this presentation.

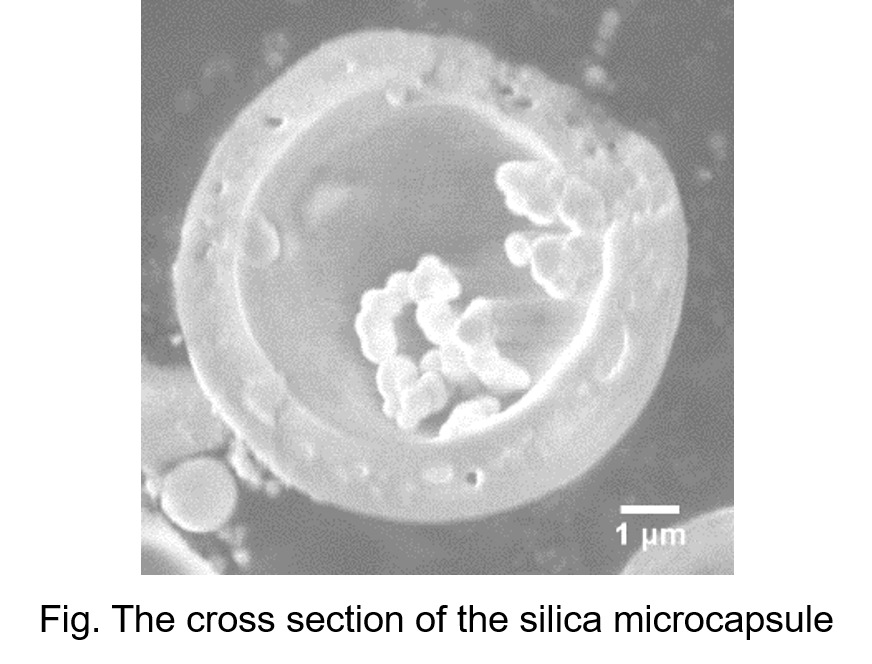

For the experiments, 2 sizes of horizontal dry bead mills with different capacities, lab and manufacturing scale, were used to study scaling up and down. The grinding experiments were performed by changing each typical grinding factor for bead mills, including the agitator peripheral speed, bead packing density, bead diameter, and material feeding speed. This set of experiments was conducted for 3 kinds of materials, silica sand of natural inorganic materials, alumina of synthetic inorganic materials, and activated carbon of organic materials.

As a result, common for all materials, similar rules were found between the particle size and specific energy, the amount of mechanical energy per unit amount of material. In addition, these rules were applicable for the different-size mills, indicating that the scale can be controlled by the rules and specific energy. Also, it is revealed that when using a single type of material, changing the bead diameter changes the energy efficiency, indicating that using small-diameter bead was effective for efficient grinding.

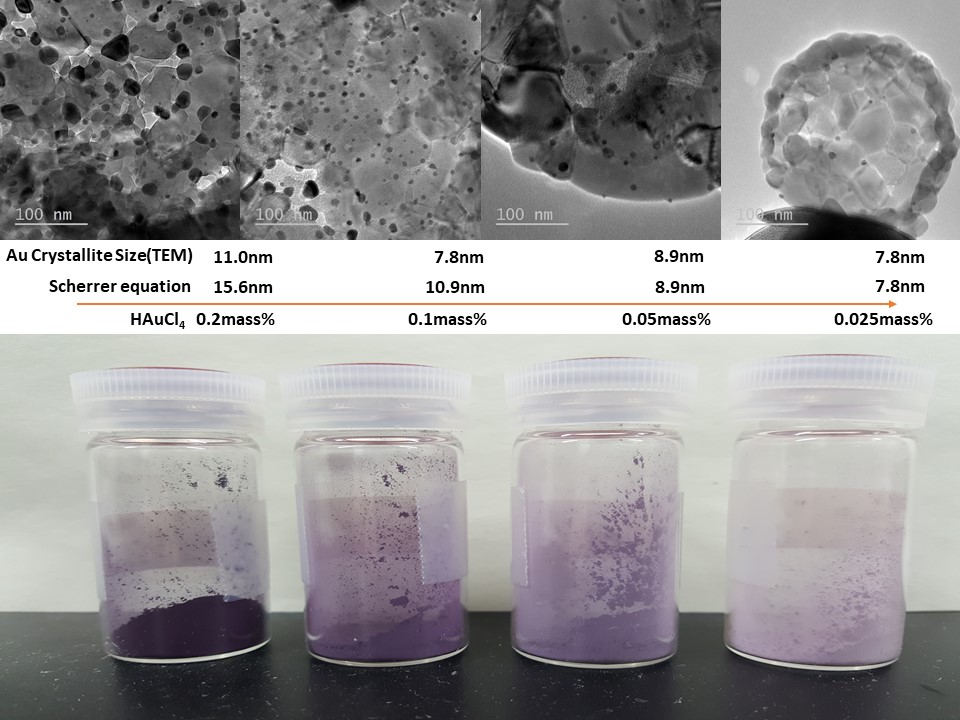

In an effort to achieve the highly efficient synthesize upconversion nanoparticles (UCNPs) with controlling over properties, we report for the first time a continuous flow synthesis of hexagonal β-phase NaREF4 NPs using microflow system. The precursor solution was prepared by the reaction of rare earth oleate, sodium oleate and ammonium fluoride, which avoided the production of NaF at room temperature and speeded up the hexagonal nanoparticle growth rates at high temperature. Specifically, the separation of nucleation stage and growth stage was achieved by means of segmented temperature control in the microflow system. The nucleation and growth reaction mechanism were further studied and the experiments of using different temperature, reactant concentration and flow rate were designed to study the influence on the shape and size of β-phase NaREF4. The ultra-small (5-6nm) β-NaYF4:Yb,Er nanoparticles were prepared by Gd3+ doping in the microflow system. And the monodisperse sub-10 nm core-shell nanoparticles β-NaYF4(Gd):Yb,Er@NaYF4 were prepared successfully by mixing the core solution and the shell precursor solution via a continuous microfluidic process. The β-phase nanoparticles exhibit green and red emissions under excitation of laser at 980 nm. Our research opens a door for the synthesis of upconverting nanocrystals in the continuous flow reaction system.

The growth of a pinhole generated in a thin coated liquid film was simulated numerically in order to study the mechanism of dewetting on a thin coated adhesives. Navier-Stokes equations of a one-fluid formulation were solved by projection method and the motion of the liquid-air interface was traced by a VOF method. Rheological properties of the liquid were approximated by a Carreau-Yasuda model. The OpenFOAM tool box was utilized to perform the numerical simulations. Simulated results were in good agreement with experiments where a pinhole was spread on a coated film of adhesives. The growth rate was proportional to the inverse of Ohnesorge number and therefore it decreases when the viscosity of the liquid is high and the surface tension is low.

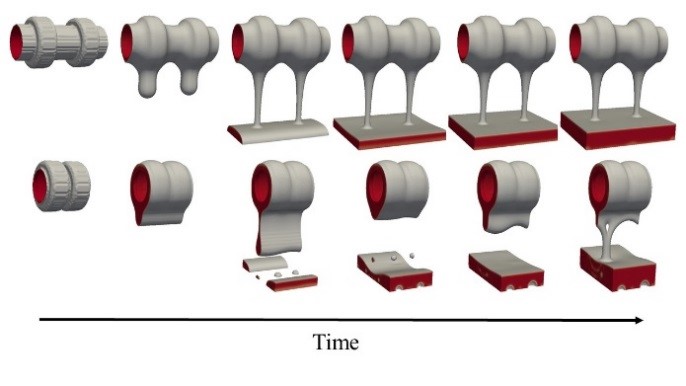

Laminar film condensation of saturated vapor on the surface of a low-fin tube was numerically simulated in order to examine the effect of the shape of the tube. Navier-Stokes equations, an energy equation, and a continuity equation including phase change were solved simultaneously. Vapor-liquid interfaces were traced by VOF method. The OpenFOAM tool box was utilized to perform the numerical simulations.

Figure 1 shows an example of the simulation results. When the fin pitch is large, the condensate drips as a tuft from the lower part of the fin. When the fin pitch is small, on the other hand, the condensate falls as a curtain after filing the condensate between the fins.

The rate of condensation was obtained from the numerical simulations. When the fin pitch is small, the rate of condensation increases with the fin pitch. However, the rate decreases with the pitch when the pitch is larger than the certain value. It has thus suggested that there is an optimum fin pitch. Numerical simulations are expected to be able to optimize the shape of low-fin tubes.

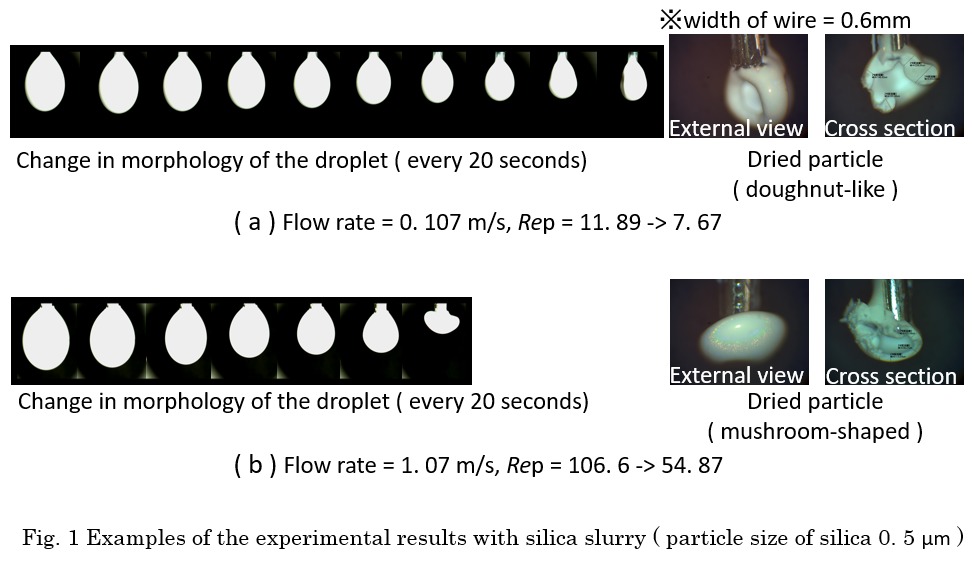

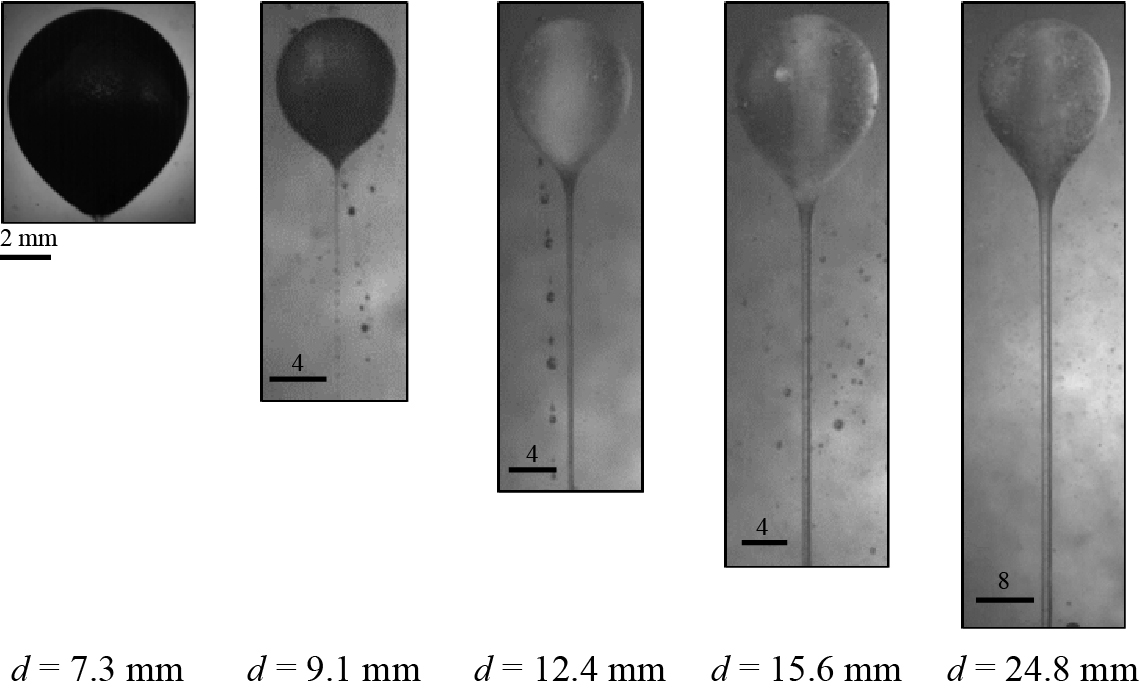

Particle generation process from droplet in a spray dryer is investigated. In the spray dryer, droplets generated from an atomizer are introduced to the dryer with hot air. While droplets are heated in the airflow, the air is cooled by exchanging heat with droplets. The atmosphere of the droplet such as temperature and humidity therefore changes with time in the dryer. Because drying behavior is influenced by the temperature and humidity around the droplet, drying of droplet should be evaluated by considering change in atmosphere of droplet. However, the drying of droplet has been studied under fixed conditions in the past researches. In this study, to observe the drying behavior, a droplet suspended on the tip of a wire is heated by the controlled air flow.

A slurry droplet of silica particles in water is studied. The effect of flow rate on the drying of droplet is investigated because flow around the droplet would affect the local heat transfer rate. Fig. 1 shows examples of the drying results with slurry droplet. At higher flow rate, mushroom-shaped particle are obtained. On the other hand, doughnut-like particle is obtained at lower flow rate. The results could be explained in terms of the particle Reynolds number.

The solution droplet of dextrin in water is also investigated. The effect of temperature on the drying is especially studied. As the drying proceeds, a solute layer is formed on the surface of the droplet. The permeability of water vapor through the solute layer is low especially for the use of dextrin. When the temperature is higher than the boiling point of the solution, boiling happens inside of the droplet then expanded particle is formed. On the other hand, the particle containing water inside of the particle is formed for the lower temperatures.

The gas dispersion in stirred tank is a widespread operation in the chemical and biochemical industry. In the process of gas dispersion, control of bubble size is important factor for the mass transfer process, and the performance relies heavily on its impeller design. Rushton turbine (RT) has been commonly used for the process because of its strong shear force. Thus, we proposed a novel kind of impellers, what we call fractal shaped impellers based on the RT. A kind of fractal structure, Koch curve was applied on blade tips of RT as shown in Figure. We expected that increase of the length of a side by iterations of fractal structure promoted shear around the wingtip and generated multiscale vortex to break up bubbles in gas dispersion.

Consequently, we investigated the effect of fractal shaped impellers on mass transfer process in gas dispersion. A stirred tank of transparent acrylic with four baffles was used for the experiment. An optical dissolved oxygen sensor was located in the front face of a baffle to evaluate the volumetric mass transfer coefficient (kLa) from variation of oxygen concentration in the tank. The bubbles discharged from a blade were visualized by high speed camera. The bubble size was measured by both photographic method and image analysis.

First, the kLa of each impellers was evaluated under the same power consumption. The kLa increased by using KF-I type impellers and KF-Ⅱtype impellers didn't make a difference. The generate bubble size also became smaller by using KF-I type impellers. Finally, we confirmed that the more small bubble generated from the blade, the more kLa increased in the tank.

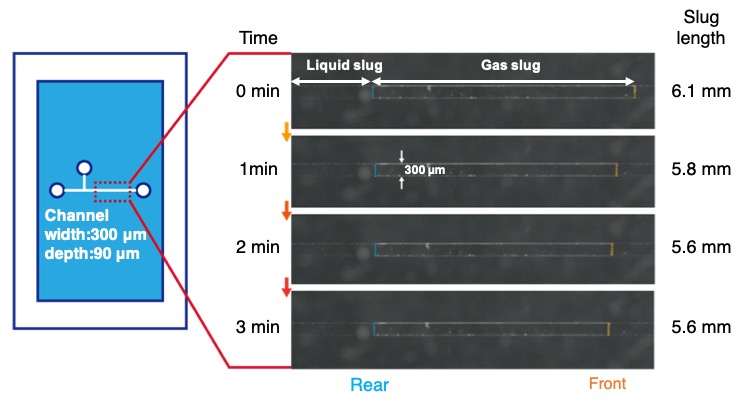

Gas-liquid slug flow is a flow pattern in which gas and liquid flow alternately.

There are numbers of prior researches on enhancement of extraction and reaction using the mixing effect of circulating flow inside a liquid slug, however, there are few experimental examples focusing on the shape change of gas slug due to dissolution.

This investigation focuses on the shape changing of gas slug in order to control slug size by changing flow rate and channel geometry to apply it for size-controlled micro bubble production.

Liquid phase was degassed and then pressurized from a reservoir to T-junction microchannel made of PDMS with controlling flow rate. Oxygen gas was injected to the microchannel through the gas-injection nozzle by using syringe pump. Size-controlled gas-liquid slug was produced by injecting both fluid and observed with a close focus lens above the microchannel. The change of slug volume and shape effected by liquid flow rate were investigated from captured images.

Figure shows the time course of oxygen slug shrinking behaviour in condition of no flow of gas and liquid phase after slug production.

The change rate of slug length for flowing condition of liquid phase was larger than that of no flow condition, therefore, liquid phase flow promoted gas slug dissolution.

Without degassing of liquid phase, shrinking of gas slug was not observed. It is thought that dissolved gas concentration is important parameter to control gas slug size.

By measuring slug size, the possibility to control the gas slug size was indicated and precisely controlled microbubble production is expected using this method by injecting size-controlled gas slug into vessels filled with liquid.

This method for microbubble production might be the solution to overcome difficulties of small bubble detaching in conventional bubble formation from a nozzle or a slit.

In many processes in which particles are operated, adhered particles on the wall of equipment and pipes cause problems such as contamination and blockage in feeding or transportation. Therefore, it is required to reflect the adhesion characteristics in the process design and the determination of operating conditions. However, the designing method and the prediction method of operating conditions with taking into the adhesion characteristics have not been established yet.

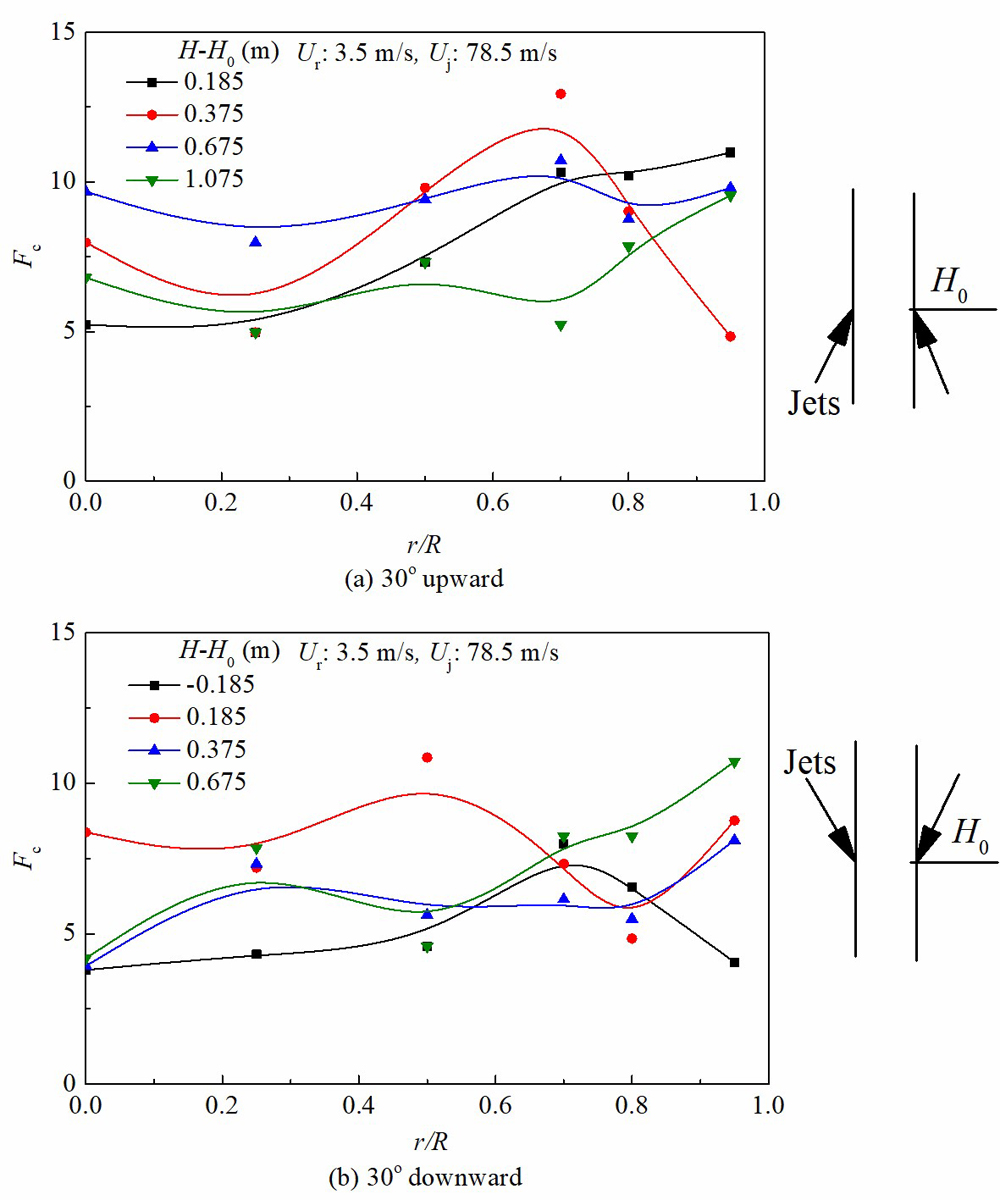

Because a particle behavior in these process operation is affected by fluid motion, the evaluation of adhesion characteristics based on the force induced by fluid motion is useful for establishment of the designing or the prediction method. As one of simple operation relating to the adhesion and fluid motion, we focused on the air jet removal of particles. In the air jet removal, adhered particles are separated from a wall by high-speed air flow ejected from a nozzle. The removal efficiency of the air jet removal depends on the dynamic pressure of the impinging air flow on a wall. It suggests that the separation force acting on a particle is determined by the dynamic pressure.

In this study, a slit nozzle having a width of 0.25 mm and a length of 20 mm was used as a reference nozzle, and 7-types of spherical silica particles having different particle diameter ranges were used as a reference particle. The removal efficiency of these particles from the borosilicate flat glass plate was determined experimentally. From the correlation between the diameter of reference particles and the required dynamic pressure for the removal, the separation force acting on reference particles was determined as a function of particle diameter and dynamic pressure. By means of these reference particles known to the separation force, the adhesion between the various wall surfaces and the reference particles was determined.

Lack of experimental data for droplet breakup is one of the limitations for the application of population balance model (PBM). We present here a new method to directly measure the breakage of droplet swarm in a pulsed disc and doughnut column (PDDC). A high speed camera was used to directly measure the droplet breakup frequency and daughter size distribution for a series of liquid-liquid systems. The multiple breakup was treated as an original breakup and several intermediate breakups in order to characterize the process quantitatively. The effects of pulsation intensity, dispersed phase viscosity and flow rate, interfacial tension were investigated in detail. The data covers the main factors affecting the droplet breakage in the PDDC and are sufficient to support the establishment of useful empirical correlations for breakup frequency and daughter droplet size distribution. The experimental results and correlations all indicate that the breakup frequency increases with the decreasing of the dispersed-phase viscosity or the interfacial tension, or the increasing of the pulsation intensity. The daughter droplet size distribution broadens considerably with decreasing interfacial tension. The correlation equations were then used in a CFD-PBM simulation to calculate the droplet number density, which further proved the feasibility of the correlations.

The bubbles in rice flour dough were investigated under constant temperature. The change of distribution in bubble size plays an important role in controlling food texture. If the formed bubble size depended mainly on three kinds of force, such as inertial, viscous, and surface tension, then the normalized mean bubble diameter should be a function of Reynolds Number and Weber Number. We obtained our experimental data mainly using a home size whipper, and we compared the data with the results obtained from the dough with nine kinds of rice flours prepared by different milling process in this work. We also added the size effect of rice flour particle as Bond Number. Furthermore, we carried out a dynamic wettability test in order to estimate wettability of rice flour surface. The results of the dynamic wettability test were described well by Washburn equation, and dccosθ was calculated as a parameter of wettability (dc : effective diameter of capillary in powder bed, θ: contact angle). The relationship between Bo and dccosθ/dp, normalized wettability parameter by particle size (dp) of rice flour, was obeyed by a straight line. Thus, it was suggested that the powder properties of rice flour could classify by interface properties. The mean diameter of the bubbles (dbm) generated by whipping was expected to be affected by the thickness (d) of the rod of whipper, its movement speed, physical properties of material and gravitational acceleration. The dimensionless mean diameter (dbm/d) was expressed by a dimensionless equation. It was found that We was high contribution for mean diameter from the result of its power index obtained from the dimensionless equation demonstrated. The empirical equation obtained was generally applicable to the variety of materials selected. Consequently, the bubbles in rice flour dough generated by whipping process could evaluate with the interface properties of rice flour.

Nitrile Rubber (NBR) latex is used for making various gloves. The rheological properties of Nitrile Rubber Latex blended with Titanium Dioxide (TiO2) were investigated using a rheometer. By carry out rotational and oscillatory tests, the relationships of viscoelastic properties such as viscosity, complex viscosity, storage modulus, loss modulus and phase angles were investigated.

Rotational test determine the relationship of viscosity and shear rate. Respond on the viscosity was investigated by increasing the shear rate. The samples under studied were pure NBR, compound NBR and compound NBR with different phr value of filler. In these tests, the viscosity of the NBR decreased with increasing shear rates.

Oscillatory tests were carried out to determine the relationship between complex modulus and angular frequency. The higher the angular frequency applied, the lower the complex viscosity were obtained for the samples. Viscoelastic properties such as storage modulus, loss modulus and phase angles were studied. The storage modulus of the sample decreased when angular frequency increased. Whereas the loss modulus increased with increasing angular frequency. This indicates that the fluids are more favourable on energy loosing rather than energy storing. By referring to the phase angles, the fluid's flow behaviour can be easily known. 0 °phase angle indicates the fluid exhibit perfect elastic behaviour, whereas 90 °phase angle indicates that the fluid is exhibiting Newtonian flow (water behaviour). NBR compounds shows viscoelastic behaviour

It is known that high pressure grinding roll (HPGR) is an effective grinding method to enhance the liberation of minerals with high energy efficiency. HPGR grinding has many kinds of operating parameters which affect the liberation state and the optimum operating parameters strongly depend on a types of ores. From the viewpoint of industrial application of HPGR in mineral processing, it is essential to decide the optimum operating conditions depending on ores. Since a batch of HPGR experiment in pilot scale requires huge amount of ore samples, it is difficult to conduct and repeat experiments in various operating conditions. Therefore, it is highly anticipated to newly develop a laboratory-scale HPGR which only requires small amounts of ores at an early stage of mine development.

The objective of this study was to develop a laboratory-scale HPGR which can reproduce grinding results similar to those obtained from a pilot-scale HPGR. To achieve this objective, the discrete element method (DEM) coupled with T10 breakage model was applied to reproduce a HPGR grinding process. First, grinding processes of ores in a pilot-scale HPGR were simulated by the DEM coupled with T10 breakage model. Comparison between simulation results and experimental results was also conducted for the validation of the simulation model. Good agreement was confirmed for throughput of ore, energy consumption and a working roll gap. After the validation of simulation model for a pilot-scale HPGR, this simulation model was applied to a laboratory-scale HPGR. An appropriate shape of a roll installed in a laboratory-scale HPGR was investigated. Simulation results indicated that the suitable roll shape for a laboratory-scale HPGR was designed by a dimensionless roll gap and dimensionless throughput. A laboratory-scale HPGR designed based on simulation results could experimentally reproduce grinding results similar to those obtained from a pilot-scale HPGR.

Very dilute high-molecular-weight polymer solutions induce complex flow behaviors. This is due to polymer deformation in a flow, which causes mechanical interaction between a deformed polymer and fluids, and between polymers in flows. We consider such polymer-fluids interaction and polymer-polymer interaction clarify the complex behaviors of polymer solution.

In this study, we measured the drag force of polyethyleneglycol (PEG) in flows by using a scanning probe microscope (SPM). Methoxy polyethyleneglycol thiol (mPEG-SH) was attached to the cantilever probe of the SPM, which was further immersed in flows of glycerol and polyethyleneglycol (PEG) solutions. Here, we have prepared several molecular weight of mPEG-SH from 10k to 40k. The mPEG-SH-bonded cantilever detects the extra force due to polymer-fluids and polymer-polymer interaction in flowing fluids. The extra force was increased with increasing the molecular weight. The conformation of the mPEG-SH polymer bonded to the probe of the cantilever was predicted, and the drag force due to the deformed mPEG-SH was calculated. The forces detected by experiments using the SPM and the forces obtained by model calculations were compared, and found to be reasonably close.

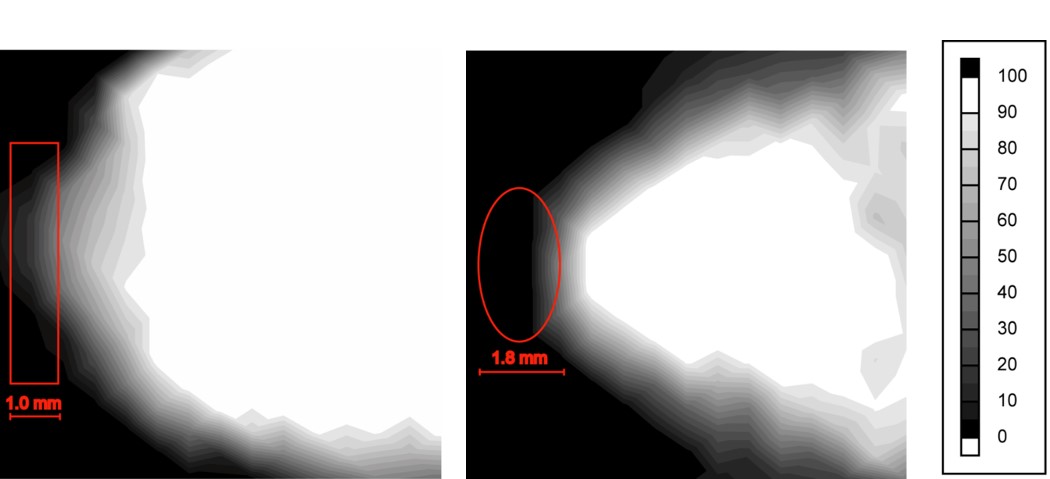

The mass transfer of the liquid-liquid extraction process in the alternating flow of two immiscible liquids in the microchannel was experimentally visualized. In this flow, each segment flows alternatively in the microchannel. In this study, water with congo red as the indicator, and cyclohexane with acetic acid were induced into the microchannel with the rugged wall of the diamond shape. The alternating flow of these two kinds of liquids was observed, and the mass transfer of acetic acid from aqueous phase into organic phase was visualized as the change of the color of aqueous phase. Figure 1 shows the experimental result. The microchannel was made of stainless-steel and placed between two quartz glass plates. The narrowest width of the microchannel is 0.3 mm, and the widest one is 1.45 mm in the diamond shape. Two kinds of liquids were fed into the microchannel with the syringe pumps at 0.07 mL/min (13 mm/s). Orange area is aqueous phase of water with congo red, white area is organic phase of cyclohexane with acetic acid. Blue area is aqueous phase of water, congo red and acetic acid which transfers from organic phase, and the color of aqueous phase changes from orange to blue as the concentration of acetic acid increases. The color of the aqueous phase completely changed from orange to blue after 9.95 mm from the confluent point. As the result, the distance from the confluent point where the color changed completely from orange to blue becomes longer as the inlet velocity increases. This result suggests that the ruggedness of the wall is not effective for this extraction process. This work was supported by the Grant for the Promotion of OUS Research Project (OUS-RP-30-4) of Okayama University of Science.

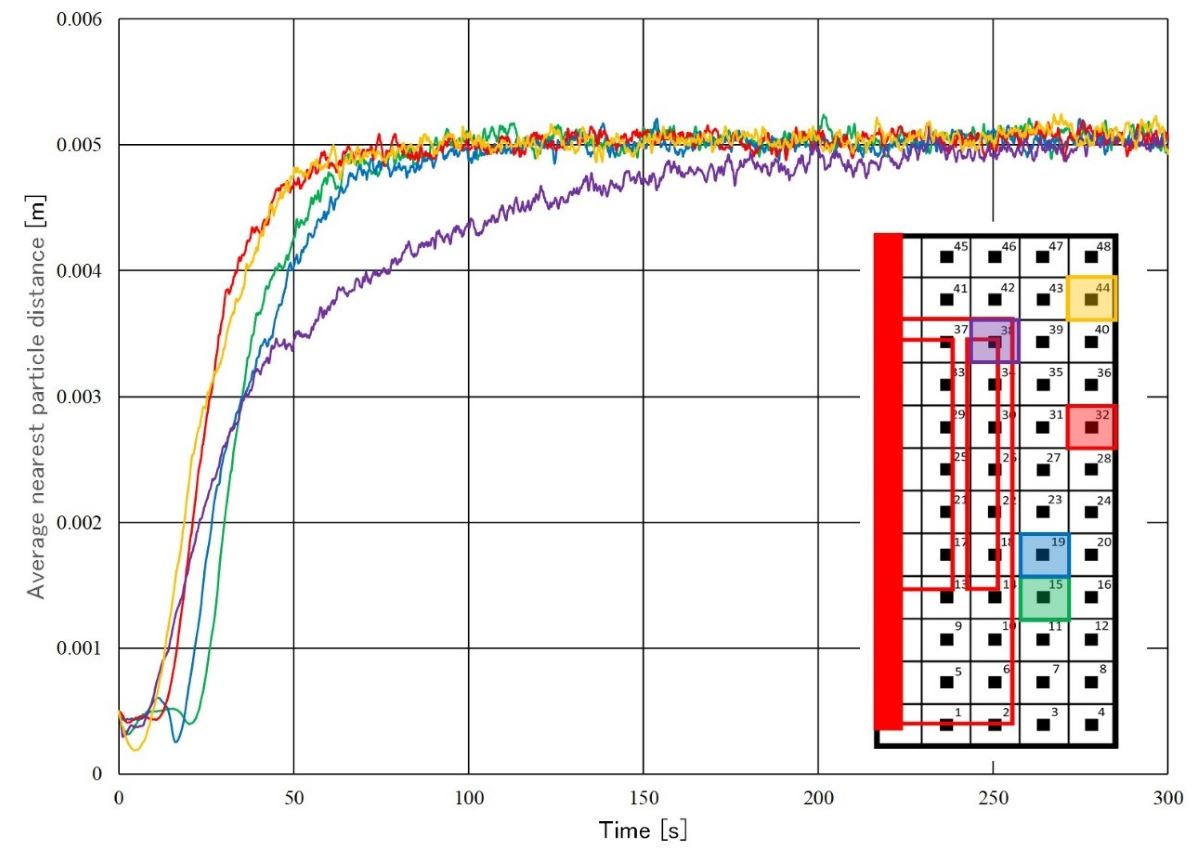

In laminar mixing with a large-type impeller, the initial injection point of the mixing object is known to influence mixing processes and the mixing completion time. This study investigated the relation between the injection points and the mixing performance of MAXBLEND, a large-type impeller, by CFD of tracer particles.

For this study, a 0.1 m diameter vessel was used. 1331 particles were placed on an injection point as a 53 mm3 cube. Based on the three-dimensional particle coordinates for every time, the distance from each particle to the nearest particle is calculated (Lnp). The average of these distances was calculated for every time (Lnp, ave).

In all, we investigated 48 injection points (Fig. 1). In Fig. 1, the results of the numerical simulation of mixing are shown as a relation between time and Lnp, ave . As shown there Lnp, ave gradually becomes larger with advanced mixing from 1 mm (t = 0). It becomes almost constant in a complete mixing state. For injection point No. 32, the mixing completion time was the shortest. However, the mixing completion time of No. 38 was the longest. Results showed a large difference in the complete mixing time depending on the injection point.

To investigate the scale-up effect, mixing in the 0.15 m diameter vessel was simulated. When the Reynolds number was equal using the same liquid, the relation between Lnp, ave and time in a large vessel differs from that in a small vessel.

However, these data are arranged similarly to the lines, independently of scale, using dimensionless mixing time, which is the product of the time and the impeller rotational speed, and the normalized average nearest particle distance, which is calculated by dividing Lnp, ave by the vessel diameter. Results demonstrated that mixing in the large vessel can be estimated from results of the small vessel using this relation.

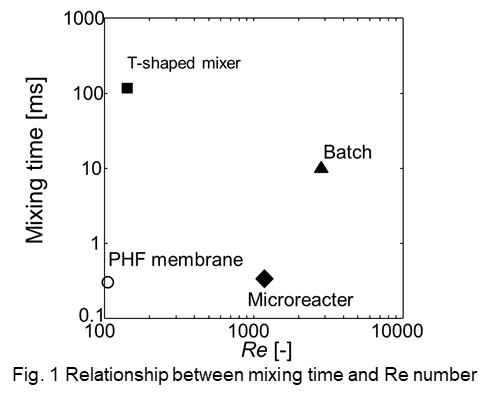

Fine particles make an important role for the production of functional materials in various industries such as foods, pharmaceuticals and paints. Because physical properties of fine particles depend on the particle size and the particle size distribution, it is important to accurately control these properties during the processing. Recent developments in functional materials have been required for more accurate control of the particles size and the particle size distribution.

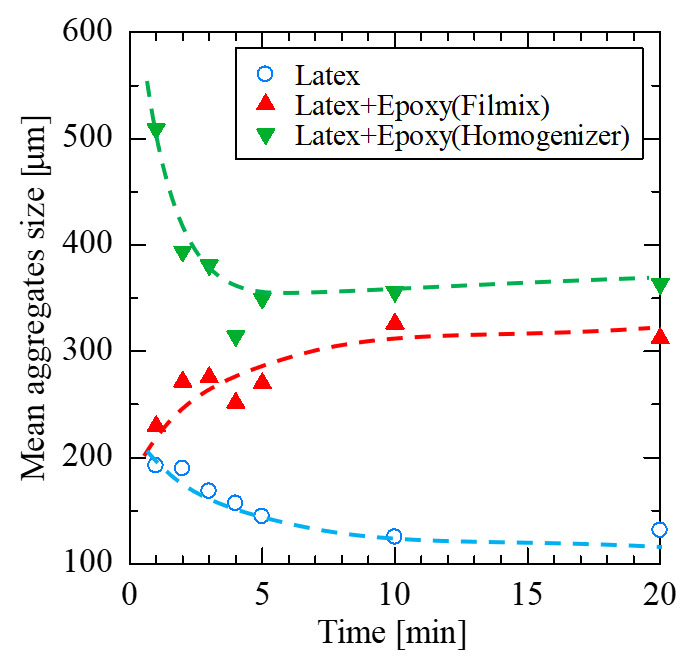

Generally, fine particles are produced using a stirred tank with the aim of large-scale production. However, in the stirring tank, fine particles easily aggregate due to shear in a flow filed. Therefore, in order to control the particle size and the particle size distribution, the effect of shear on particle aggregation should be understood. However, there is the shear force (shear-rate) distribution in a stirred vessel and it differs with the impeller type. It is necessary to clarify how the difference in the impeller type affects the particle size and the particle size distribution. This study investigated the effect of impeller type on the size distribution of aggregate of fine particles.

Two types of impeller, a Rushton turbine and a 3-retreat impeller were used for particle aggregation. The size distribution of aggregates was measured by a microscope (VHX-100, Keyence Co., Ltd.) and a laser diffraction particle size analyzer (SALD-300V, Shimadzu Corp.).

It has been found that the 3-retreat impeller promotes particle aggregation as compared with the Rushton turbine impeller. Besides, energy dissipation with the 3-retreat impeller was larger than it with the Rushton turbine impeller. These results imply that an impeller with smaller energy dissipation would suppress particle aggregation. In the conference, the results using a Taylor-Couette flow apparatus having the relatively narrow shear-rate distribution will be also reported.

During the past decades, nanoparticles (NPs) have been widely studied as carriers of drug delivery system. Unlike the animal cells, plant cells have a rigid cell wall, and it is physical barrier for intracellular NP uptake. However, past our study revealed that the poly lactic-co-glycolic acid (PLGA) NPs were taken into the tobacco BY-2 cells with cell wall by controlling the NP exposure condition. In this study, we attempted to deliver PLGA NPs containing hydrophilic biomaterials into the tobacco BY-2 cells. The fluorescent BSA was used as model biomaterials. BSA adsorbed PLGA NPs were prepared as follows: PLGA NP was prepared by the emulsion solvent diffusion method. In order to adsorb negatively charged BSA on the PLGA NPs, the cationic lipid DOTAP was adsorbed on the PLGA NPs and BSA was then adsorbed on them. BSA encapsulated PLGA NPs were prepared as follows: In order to encapsulate hydrophilic BSA in hydrophobic PLGA NP, BSA was hydrophobized using DOTAP and the BSA/DOTAP complex was then encapsulated in PLGA NPs. BY-2 cells and PLGA NPs were mixed in MS medium for 1 hour. Then, the localization of NP and BSA was observed using CLSM. When exposing BSA adsorbed PLGA NPs, the PLGA NPs were taken up into the cells but BSA was remained on the cell wall. This is presumably because the adsorption of BSA on the NP surface reduced the cell affinity of PLGA. In contrast, when exposing BSA encapsulated PLGA NPs, the BSA was found to be taken up into the cells when the charge of the NP surface changed from negative to positive with the increase of DOTAP. These results indicate that hydrophilic biomaterials can be delivered into plant cells by hydrophobizing BSA with DOTAP and encapsulating in PLGA NPs.

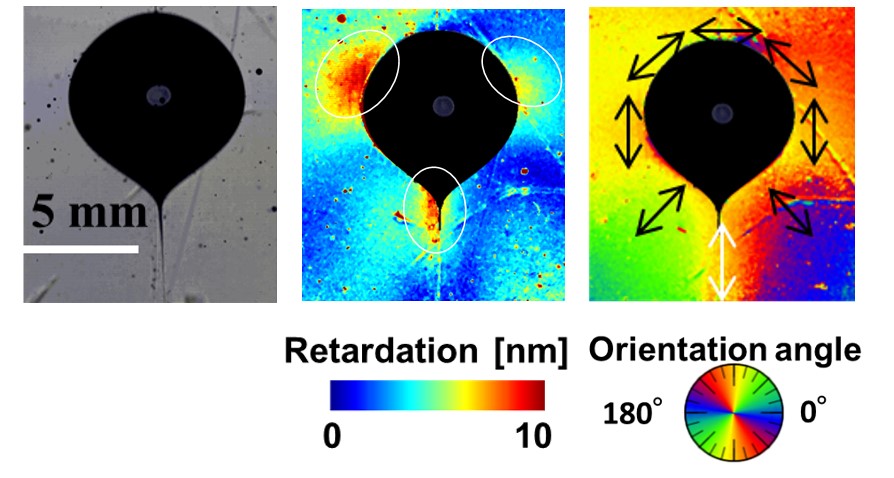

Flow polarization images around a rising bubble launched periodically in a cooling 3 wt% gelatin aqueous solution were captured by the two-dimensional high-speed polarization camera. The flow polarization imaging involves two dimensional retardation profile and orientation angle profile, respectively. The retardation profile correlates significantly with elasticity of the transparent solution under the validity of the optical-stress rule. The gel point of the aqueous solution of gelatin was evaluated in terms of viscoelastic properties of the gelling solution measured by the rheometer.

When the solution temperature was kept at 33 deg-C, shape of the rising bubble with diameter of 8.4 mm was sphere. Because the solution behaves Newtonian fluid of sol and the bubble Reynolds number was order of 1. There is almost no observable change for both retardation and orientation angle profiles.

After cooling down of the prepared mixture to 23 deg-C at a cooling rate of 0.254 deg-C/min for 39.3 minutes, and then the solution was kept at 23 deg-C. The growth of network structure of gelation causes the transition of the bubble shape from spherical to spherical with a cusp at about 3400 seconds. Slight change in retardation and clear orientation angle profile can be observed around the rising bubble. This suggests that at this event the elasticity of the gelling solution became dominant.

At about 3600 seconds of gelation, the bubble shape transformed to oblate shape with a long tail. The long tail was surrounded by high retardation region (i.e., high elasticity solution) in vertical orientation much higher than the others mentioned before. Therefore, the solution surrounding the long tail, which was supplied by the negative wake, was stretched vertically.

We have developed a flow system for systematic study of the dynamics of two-fluid displacement and flow in annuli. This flow is relevant to many industrial applications, especially in the cementing operations in oil/gas well completions, where drilling fluids are displaced from the annulus between the casing and the well bore by a series of spacer fluids and cement slurries. The annular flow apparatus was designed such that it can be operated at various degrees of eccentricity and different angles of inclination to simulate the type of flows in oilfield drilling and cementing operations. A special feature of the flow system is that the inner cylinder can be rotated during displacement, allowing the effects of helical flow on the performance of the annular displacement process to be studied. Flow and displacement tests with various model non-Newtonian fluids representing drilling and cementing fluids have been conducted at different eccentricities, pipe inclinations, and over a range of flow rates and cylinder rotational speeds. Flow visualization results consist of video images capturing the movement and evolution of the fluid-fluid interface that clearly illustrate the effects of annular eccentricity, displacement rate, cylinder rotation and fluid rheology on the displacement process. In addition, the velocity profiles through the annulus at a fixed point downstream were determined by Particle Image Velocimetry (PIV) method to elucidate the dynamics of the displacement fluid-fluid interface. PIV results obtained have revealed interesting phenomena in the two-fluid displacement region that depend on the fluid viscosity ratio and the annular eccentricity. Pressure drop measurements produce data that can be used to develop models for predicting friction losses associated with single-fluid flow and two-fluid displacement in eccentric annuli. The results obtained will be useful for assessing the effects of important variables such as eccentricity, pipe inclination, flow rate, pipe rotation and fluid rheology, that impact on the effectiveness of the annular displacement process.

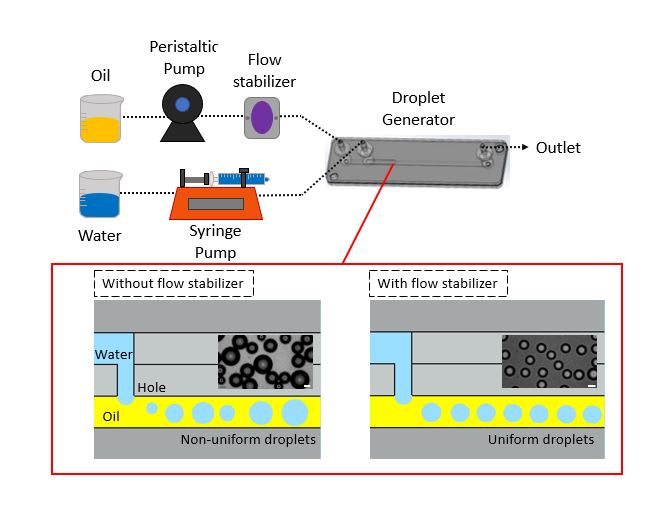

Peristaltic pump is a most commonly used equipment to continuously introduce the fluids. However, the peristaltic pump may produce a pulsatile flow, limiting the applications for multiple purpose. To address this issue, we design a flow stabilizer connected to the outlet of the peristaltic pump. When the pulsatile flow enters the flow stabilizer, the elastic membrane is expanded, providing a buffer area for the pulsatile flow to deliver a steady flow at the outlet. The dampener was fabricated with PET and acrylic embedded with polyurethane as elastic membrane. The results show that the flow stabilizer with larger overall membrane area has better Fluctuation Reduced (FR) value. The elastic membrane arranged in parallel shows better FR than in series. Furthermore, we established a droplet generating system, which can continuously form uniform water-in-oil droplets. The system included a droplet generator, a flow stabilizer, and pumps. To continuously generate the droplets, a peristaltic pump connected with a flow stabilizer were used to feed the continuous phase. We used soybean oil with 5% w/v Polyglycerol polyricinoleate (PGPR) as the continuous phase, while pure water as the discontinuous phase. The results demonstrate that the monodisperse water-in-oil droplets with uniform size could be successfully generated. Moreover, the size of the droplets could be well controlled by altering the flow rate of the water. The droplet diameter increased from 0.311 mm to 0.519 mm (CV < 5.7 %) as the water flow rate increased from 5 μL/min to 80 μL/min. In conclusion, the integration of the flow stabilizer reduced the pulsatile flow of the peristaltic pump up to 99.25 %, allowing to continuously generate monodisperse droplets. We envision our continuous droplet generator system can apply to continuous and scalable production of chemical.

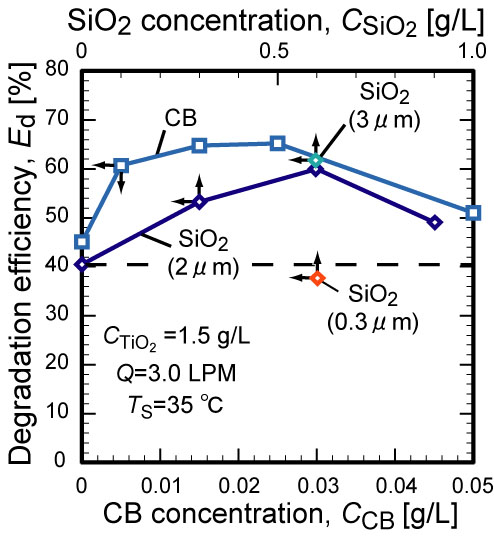

It has been well-known that photocatalytic degradation of indoor air pollutants such as volatile organic compounds (VOCs) requires a high degradation efficiency for a long time without lowering the efficiency due to coking on UV-irradiated TiO2 surface.

In our previous work, we fabricated a photocatalytic reactor where photocatalytic degradation of toluene vapor took place on TiO2-containing droplets formed by ultrasonic atomization under UV irradiation, and demonstrated that a stable degradation efficiency was kept continuously under the optimal operation conditions. Therefore, the present study aimed to improve the degradation efficiency by dispensing additive particles, such as carbon black (CB) and silica (SiO2) ones, into TiO2 suspension.

Two sorts of additives were added to the suspension of TiO2 particles in the photocatalytic reactor, and then the toluene generated at a concentration of 5 ppm was fed to the reactor where TiO2-contaninung droplets irradiating with UV-A ray. The test air was sampled at the inlet and outlet of the photocatalytic reactor, and the concentration of toluene was determined by a GC-FID to determine the decomposition efficiency Ed.

As a result, Fig1 shows the change in the toluene degradation efficiency with additive particle concentrations in the TiO2 suspension. It was found that the degradation efficiency was increased by dispensing the additives, and had an optimum value at the additive concentration. The addition of CB might increases the adsorption capacity to toluene while it might be considered that CB coats the surface of TiO2 particles and UV-ray does not reach TiO2 when the amount of addition exceeds a certain level. Although the effective surface area of TiO2 particles contributing to the photocatalysis increased due to the presence of suspended TiO2 agglomerates coated with SiO2 particles, the extreme increase in SiO2 particles could enhance the ultraviolet light shielding effect of the SiO2 particles themselves.

In this study, the growth of single bubbles, due to nucleate boiling, is computationally examined using the moment-of-fluid (MOF) method. The MOF method represents sharp deforming boundaries between phases by evolving both volume fractions and centroids. The numerical simulations are carried out by solving the conservation law equations for mass, momentum, and energy, taking into account the appropriate jump conditions at the interfaces between substrate, liquid, and vapor. The substrate is modeled as a rigid body and the liquid and vapor are simulated as incompressible fluids. In order to carry out the computations as efficiently as possible, dynamic adaptive mesh refinement (AMR) is used in which the computational domain is an adaptive hierarchy of rectangular grids as opposed to a single, uniform, rectangular grid. In this study, the single bubbles periodically growing from a single nucleation site is two-dimensionally and axisymmetrically computed under the temperature difference of 7 K between the heated wall and water. The continuous generation process of nucleate boiling bubbles is successfully reproduced and thermal and flow fields in nucleate boiling are clearly shown. It is showed that the second and subsequent bubbles after the first bubble is released are stably formed. The growth rate of the second and subsequent bubble is faster than that for the first bubble and the growth rate of the second and subsequent bubble becomes constant. It is verify that our computational results for the growth rate of bubbles, the bubble departure time and the bubble volume for the second and subsequent forming bubbles agree well with the previous study. Our computational method using the MOF method can be effective for computing boiling problem.

The dynamic motion of a drop rising in a highly viscous hydrophobically modified alkali-soluble emulsion polymer (HASE) solution with pH = 9.0 is experimentally examined. In this study, a 1.65 wt% HASE polymer solution, which is adjusted to pH ≈ 7.0 by adding a sodium hydroxide solution, is used as the matrix fluid and salad oil is used as the drop. For sufficiently small drops, a threadlike long trailing edge at the rear of a drop is observed, similarly as for the case of a small bubble. It is newly observed that the threadlike trailing edge for the drop is much longer and thicker than that for the bubble. From experimental observations, it is found that a drop is more susceptible to the effect of viscoelastic properties of the surrounding HASE solution than the for the bubble case. For the case of bubble rise motion, the threadlike long trailing edge turned into threadlike branches for increasing bubble size; no such the tendency can be observed for the drop case. In microscopic observations for the bubble, it was reported that very unique microstructures emerged from gas-liquid interfaces in the motion of large bubbles, but on the other hand, microstructures at the liquid-liquid interface cannot be observed for drops. It is revealed that there is a pronounced difference between how the viscoelastic properties of a HASE solution effects bubble morphology versus drop morphology.

In the present work, a level set method with multi-levels was developed to simulate the breakup behaviors of multi-droplets in a macro extraction device, the pulsed disc and doughnut column (PDDC). The deformation and breakage behaviors of droplets in droplet swarm were accurately captured. It was found that the shearing effect of the continuous phase flow, the collision between droplets and internals, and the Plateau–Rayleigh instability of the interface of liquid column would lead to the breakup of droplets. These breakup patterns were in good agreements with the experimental results. Moreover, the influences of pulsation intensity and droplet size in droplet breakup behaviors were investigated. It was concluded that the higher the pulsation intensity, the easier the droplets to break up. In addition, large droplets were found to be more likely to break up into multiple daughter droplets. Generally, the droplet breakup frequencies predicted by numerical simulation presented acceptable agreements with experimental results.

Interfacial tension is an essential physical property in liquid-liquid extraction. Under mass transfer conditions, the interfacial tension changes due to mass transfer and concentration variation. The measurement of dynamic interfacial tension in such condition is of vital importance to direct the design of extraction equipment. In previous study (Zhou at al., Chemical Engineering Science, 197, 172–183), we presented the quantitative relation between the droplet breakup frequency function and interfacial tension. In this work, the droplet breakup frequency function in mass transfer process is measured at four different heights of the pulsed column using the method developed in our previous work (Zhou at al., AIChE Journal, 63(9), 4188-4200). The dynamic interfacial tension at different height of the column is then calculated by regression method. With acetic acid – water as the dispersed phase and 5%TBP – kerosene as the continuous phase, the results show that the dynamic interfacial tension increases with height decreasing. Comparing the dynamic interfacial tension with the static interfacial tension of equilibrium liquid-liquid system, we have found that the former is smaller than the latter when the concentration of acetic acid in the continuous or dispersed phase is the same. This result indicates that interphase mass transfer leads to decreasing of the interfacial tension. The decreasing extent of the dynamic interfacial tension has a positive correlation with the mass transfer flux. Furthermore, under mass transfer conditions, binary breakage occupy the dominant position at different height and up to quintuple breakage can be observed.

Particulate flows in a mixture of gas and liquid, i.e. gas-liquid-solid three-phase flows are encountered in many powder handling processes, and it is of paramount importance to understand the complex interactions among phases. This work presents a simulation model for the study of gas-liquid-solid flows. In the given model, the solid-fluid interaction force is introduced by the Volume penalization (VP) method inherited by the study of Engles et al. (2015). Considering solid phase as a porous media, fluid is allowed to flow through the solid body with a certain value of permeability. The solution for determining the local permeability at solid surface is described in this study. The interface between gas and liquid is captured by the Volume of fluid (VOF) method coupled with the Level Set (LS) method. The interfacial interactions, such as the wetting of solid surface and surface tension force, are taken into account by using the Immersed free surface (IFS) model proposed by Fujita et al. (2015). The IFS model is originally designed for LS method, and it is adapted to the VOF framework in this work. Several simulations are performed to validate the proposed model. The resultant drag force acting on the particle as well as the computed surface tension force and contact angle are in good agreement with the theoretical values.

Global water scarcity and pollution became a serious problem around the world. In order to relieve this issue, membranes processes have been widely applied to water treatment. With the increasing requirement for water, it is indispensable to continue search for membranes that can perform more efficiency on water flux and ion rejection. Although novel Aquaporin channel synchronously transports water rapidly while completely rejecting ions [1], Aquaporin is very costly and has a complex fragile molecular structure. These drawbacks make it formidable to apply or produce on an industrial scale. Some materials were searched for replacing Aquaporin channel, an Amphotericin B-Ergosterol channel (AmBEr) is a type of self-assembly organic channel [2], AmBEr is considered to be potential candidates for the biomimetic artificial channels. In this study, AmBEr was constructed and explored via molecular simulations to understand the structural characteristics and transport mechanism on a molecular scale. The chemical structures of Amphotericin B and Ergosterol monomer were shown in Fig. 1. AmBEr molecular models were constructed and investigated via molecular dynamics (MD) simulation procedures, Monte Carlo (MC) simulations and Quasi-non equilibrium MD were adopted to simulate the properties of calculation models. Structural characteristics and water sorption behaviors were introduced. All these molecular models were constructed using BIOVIA Materials Studio® commercial software.

When we mix particles of different sizes in a rotating drum, segregation may be observed. In this study, the segregation of a granular mixture consisting of 50% v/v 0.55 mm glass particles and 0.77 mm glass particles in a high fill level rotating drum is investigated. The segregation patterns appear after few revolutions, and the surface segregation band size and number become stable within 30 min. For the spatio-temporal diagram, the two smaller-particle-rich segregation bands take longer time to move toward the drum center when the fill level increases from 60%, 70% to 80%. The segregation patterns inside the bed are observed by the cross-sectional slices. Peculiar segregation patterns composed by strikes and core-in-core regions are observed for the first time.

It is well known that the low-rank coals such as lignite and sub-bituminous with higher volatile and moisture accounts for a large proportion of coal, which is the most abundant fossil energy resource in the world.Compared to the conventional fixed and Circulating Fluidized Bed (CFB) riser, the downer reactor, in which gas and solids move downwards concurrently, provides prominent advantages such as more uniform gas-solids flow structures, shorter particles residence time, less gas-solids back-mixing.These unique characteristics is particularly beneficial and suitable for coal fast pyrolysis, which need short but uniform contact time to achieve high reaction selectivity and yields of desirable products.

The CPFD approach based on the MP-PIC method was used to study the hydrodynamics, heat transfer and reactions in CFB downer reactor for coal pyrolysis with binary particles. Firstly, the comparison of solids distribution profiles of binary particles showed the CPFD approach with the cluster-based drag model is capable of accurately predicting the gas-solids flow and particle mixing characteristics. On the basis of the suitable gas-solids flow model, we further simulate the heat characteristic by coupling the heat transfer model. The simulation results show the temperature mixing index predicted by the coupled heat transfer model is in good agreement with the experimental value. By analyzing the heat transfer characteristics of particles, it can be found that the heat transfer process mainly occurs near the entrance, the interaction between gas and particles near the nozzle plays a key role. Therefore, more attention needs to be paid on the inlet of particles design of the downer. Finally, the CPFD model was further extended to reveal the coupled flow-reaction behaviors on coal pyrolysis reactor with binary particles. The results demonstrate that the CPFD model can accurately predict the hydrodynamics, heat transfer and reactions behavior of binary particles.

Transfer lines are used for petroleum transportation in petrochemical industry, which refers to a pipeline connection between the furnace and the vacuum column in the crude oil distillation unit. A well designed transfer line can increase the evaporation rate of the feed in the vacuum distillation tower, improve oil product quality and save energy for vacuum distillation unit. To better design new pipelines or optimize the existing ones, it is necessary to describe the hydrodynamic behaviors of the multi component fluids flow in the pipelines. However, due to the complexity of the system, the model for analysis of the flow inside the transfer line has been paid less attention.

In this study, a commercial computational fluid dynamics package was used to develop a three-dimensional, fully turbulent flow model for the simulations of the multi component mixture across a pipeline. The simulated results of the pressure, velocity and Ma number distributions provided an insight into the phenomena occurring within the flow field in the transfer line. The analysis showed that the pressure drop of a transfer line is strongly affected by the structure of transition section and junction. On the basis of this, a new structure is presented to optimize the flow, and the pressure drop is lower than that of the original one. The modeling methodology and the results presented will be useful for evolving better designs of transfer line or other similar pipelines.

The bonded magnet is a composite material formed by mixing a resin and magnetic powder and is used as a magnet for a motor or a sensor. In the case of a bonded magnet by injection molding, it can be molded into various shapes, the degree of freedom in motor design is increased. Furthermore, if the magnetic properties of the injection molded bonded magnet can be enhanced, a more sophisticated motor can be manufactured. To enhance the magnetic properties, it is necessary to increase the concentration of the magnetic powder. However, as the addition amount of the magnetic powder is increased, aggregation of the magnetic powder occurs, the flowability decreases, and there is a problem that molding becomes difficult. To address this problem, measures have been taken to treat the surface of the magnetic powder with a silane coupling agent or the like to improve the affinity to the resin and to disperse the resin highly. However, at present the selection of surface treatment agents is conducted empirically.

Therefore, I focused on Hansen Solubility Parameter (HSP). HSP is a physical property value quantitatively evaluated the affinity between substances, and it is applied in various fields.

In this study, we examined the influence of HSP of magnetic powder on the flowability after mixing. First, the magnetic powder was surface-treated with various silane coupling agents, and HSP was measured to evaluate its affinity to PA6. Thereafter, the magnetic powder was added to PA6 at the same concentration, and the viscosity was measured to measure the fluidity. As a result, as the combination of the magnetic powder and the resin with better affinity in HSP theory, the flowability was improved, and it was possible to confirm a high correlation between the HSP and the flowability.

Evaluation of the flow properties of powders is essential for the designing and operations in powder-related industrial processes. In this study, the powder cohesion is evaluated by the measurement of the pressure drop across the bed during the fluidization and defluidization procedure in a FT4 Powder Rheometer (Freeman Technology). Glass beads with the diameter between 88 μm to 105 μm are fluidized in a cylindrical glass column with inner diameter of 50 mm by dried nitrogen. The pressure drop overshooting at incipient fluidization is used to characterize the powder cohesion and the bed cohesion is altered by Polyethylene glycol (PEG) addition and powder bed normal stress. When no normal stress is applied to the powder bed, the pressure drop shows a linear increasing during the overshooting period. However, when a 20 kPa normal stress is applied to the powder bed, the pressure drop shows a two-stage increasing during the overshooting period. A new cohesive powder fixed bed fluidized bed transition state is initially reported. The measured bed cohesion is ca. 45 Pa, which is comparable to the theoretical prediction of Molerus (1975) and Rumpf (1975).

In industrial incinerators, hazardous substances from the combustion waste are concentrated in fine particles. Collecting and reducing fine particles is particularly challenging, and thus it becomes one of the major problems in industrial incinerators. A control plate was introduced into an industrial incinerator to reduce the emissions of hazardous fine particles. However, the efficiency of the control plate against smaller sized particles is necessary to be investigated. The coupled discrete element method and computation fluid dynamic (DEM-CFD) are employed in a solid-fluid coupling problem even where the solid particle size is fine. One of the concerns in the DEM-CFD is the requirement of excessive computer capacity when the numerous particles are applied. Therefore, a coarse grain model is adopted here to perform the calculations using a single computer. For the sake of approaching the actual condition of industrial incinerators, poly-dispersed particle system is employed in this study, where expressed by a combination of two coarse ratio. The simulation results show that the control plate works well to capture the fine particles. In addition, the velocity of particle flow is significantly decreasing when a control plate is employed.

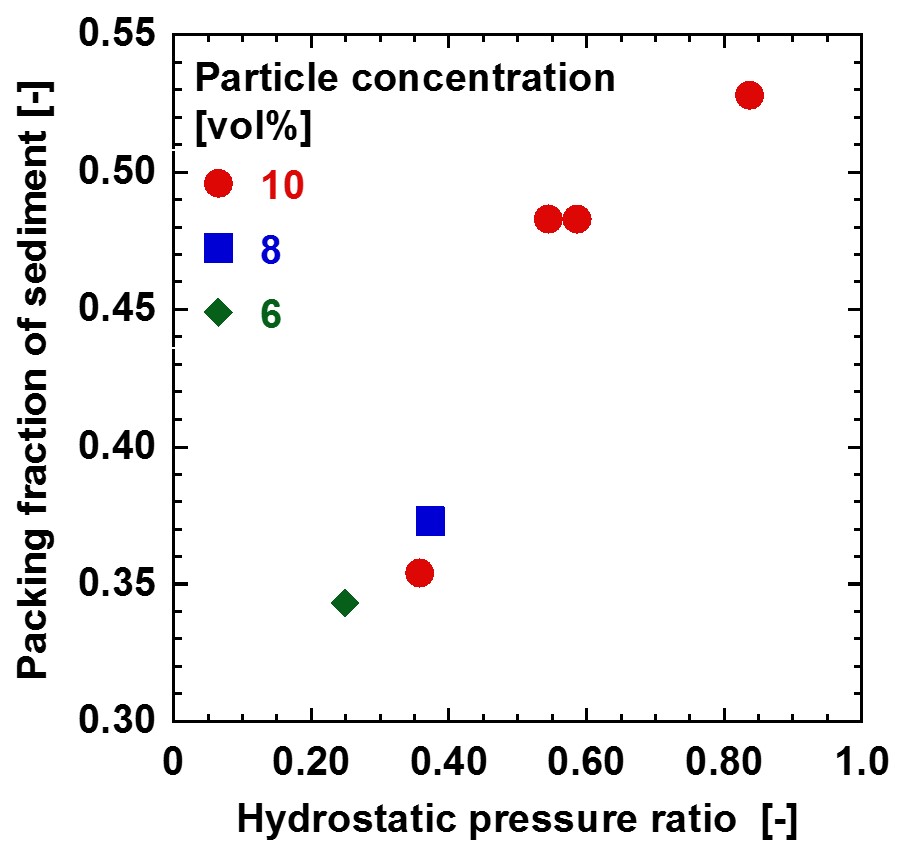

In wet-shaping process, it is well known that the particle dispersion state greatly affects the product qualities. Thus, it is important to evaluate and control the slurry characteristics properly. However, quantitative evaluation index that can compare the particles dispersion state under different slurry conditions such as particle concentration, primary particle size, particle density, shape, and solvent viscosity, etc. has not been established, yet. In this study, we measured the hydrostatic pressure of slurry prepared in various conditions under gravitational settling. Additionally, the time change of hydrostatic pressure for the slurry whose particles are assumed to perfectly disperse as primary particle was calculated for the slurries used in this study. In order to calculate the hydrostatic pressure curve more precisely, the particle size distribution measured by sedimentation was considered. The novel index, the ratio of measured hydrostatic pressure to calculated one, was introduced to discuss the particles dispersion state. It was shown that the index (hydrostatic pressure ratio) had a good connection to the final packing fraction of the sediment, indicating that the index should be useful to quantitatively represent the particle dispersion state regardless of the slurry conditions.

Phospholipid vesicles (liposomes) are soft colloidal particles which are applicable to fabricating carriers of biopharmaceuticals, protocell models, and immobilized enzymes. The permeability of lipid bilayer membranes towards small molecular mass compounds is of significance for the above applications of liposomes. In the present work, 5(6)-carboxyfluorescein-containing large unilamellar liposomes were prepared and suspended in gas-liquid flow generated in external loop airlift bubble columns. The release rate of the dye molecules from the liposomes was examined at 40 °C under various operation conditions of the bubble columns with different configurations. The permeability coefficient of the dye molecules through the bilayers of 1-palmitoyl-2-oleoyl-sn-glycero-3-phosphocholine lipids was clearly dependent on the superficial gas velocity of the bubble column (1-3 cm/s). The mean diameter and size distribution of liposomes were practically unaffected by being suspended in the bubble column, as evaluated with the dynamic light scattering measurements. These results indicate that the permeability of liposomes increased in the gas-liquid flow. On the other hand, the release rate of the dye molecules through the lipid bilayers incorporated with small fractions (1-5 mol%) of poly(ethylene glycol)-conjugated lipids exhibited significantly higher than that through unmodified lipid bilayers. The size distribution of the modified liposomes was altered by being suspended in the bubble column, indicating that the membrane integrity of liposomes was significantly altered. The effect of liquid shear stress on the structural stability of liposomes was separately examined by shearing the liposomes in a cone-and-plate geometry to assess the bubbles-liposomes interaction in the bubble column. All of the above results demonstrate that the structural stability of liposomes was controllable using the gas-liquid flow.

A small amount of polymer in turbulent flow reduces turbulent drag, which is called drag reduction. It is said that extensional rheological properties, such as long relaxation time and extensional viscosity of the fluid are keys for the phenomena. The characteristic extensional rheological properties of the solution deform vortices in turbulent flow, thus, the turbulent flow is also affected.

In this study, in order to focus on the effects of extensional rheological properties of fluids on vortex deformation in a turbulent flow, a flowing soap film known as a two-dimensional (2D) flow with a small influence of shear stress is used. The vortex shedding in the flow were visualized using interference patterns, and the local velocity fields were measured by particle image velocimetry (PIV). The vortices shed at the grid in the 2D flow was affected by polyethylene oxide (PEO, Mw = 3,500,000) concentration. The original shape of the vortices was deformed by increasing the PEO concentration, and the vortices were disappeared close to the grid at a certain concentration. However, the vortices again appeared at even higher concentration. In this study, we categorized these vortices into three types. Indeed, the generation of these vortices were affected by the extensional relaxation time of the PEO solution. The difference of these vortices were also analyzed by the fluctuation intensity of the flow field and by the turbulent statistics. Turbulent kinetic energy transfer, production and dissipation term of the turbulent kinetic energy were calculated the local velocity. The turbulent statistics implies variation of energy transfer in 2D flows, which was caused by the viscoelasticity of PEO solution.

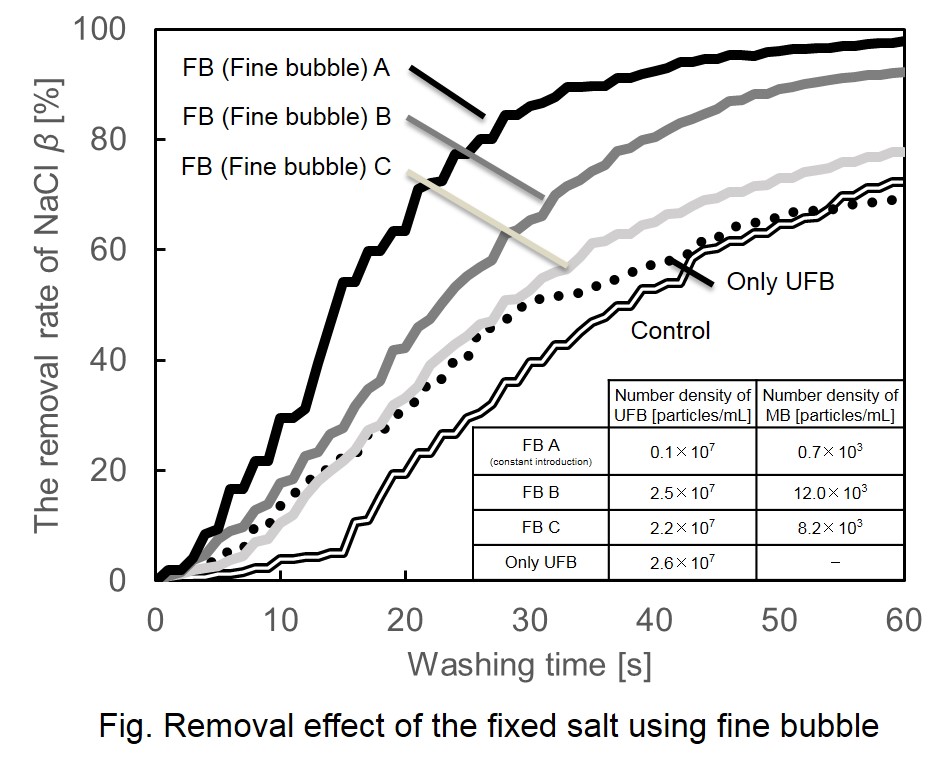

In recent years, it has become clear that fine bubble (micro/ultrafine bubble) have properties different from those of ordinary bubble. For example, the surface area of fine bubbles per the same volume is larger than that of normal bubbles, including chemical reactions and physical adsorption at the gas-liquid interface, a dramatic improvement in mass transport, and having a positive/negative charge (zeta potential) on the surface of fine bubble. Cleaning using the features of fine bubble in particular has been noticed, and there is also a high industrial need. For example, the use of plastic cleaning in recycling industries and anti-corrosion cleaning of structures with flying sea salt particles in coastal areas has begun.

Therefore, in this study, the effect of fixed salt removal by fine bubble was investigated. As a result, it was confirmed that the cleaning effect of fine bubble water was higher than that of control water, and the effect was dependent on the concentration of fine bubble. It was also confirmed that the cleaning effect was higher in the cleaning of ultrafine bubble water than in the control water. The removal mechanism of the fixed salt seems to be that gas in the fine bubble dissolves by the pressure change around the fixed salt, resulting in supersaturation, and the bubble nucleus is generated, and a part of the salt is lifted by the micro bubble, which promotes the fixed salt exfoliation. And, it was confirmed that the cleaning effect was higher by the constant introduction of fine bubble than the system in which fine bubble existed only in the cleaning initial stage (Fig). From these results, the usefulness of fine bubble in cleaning can be expected.

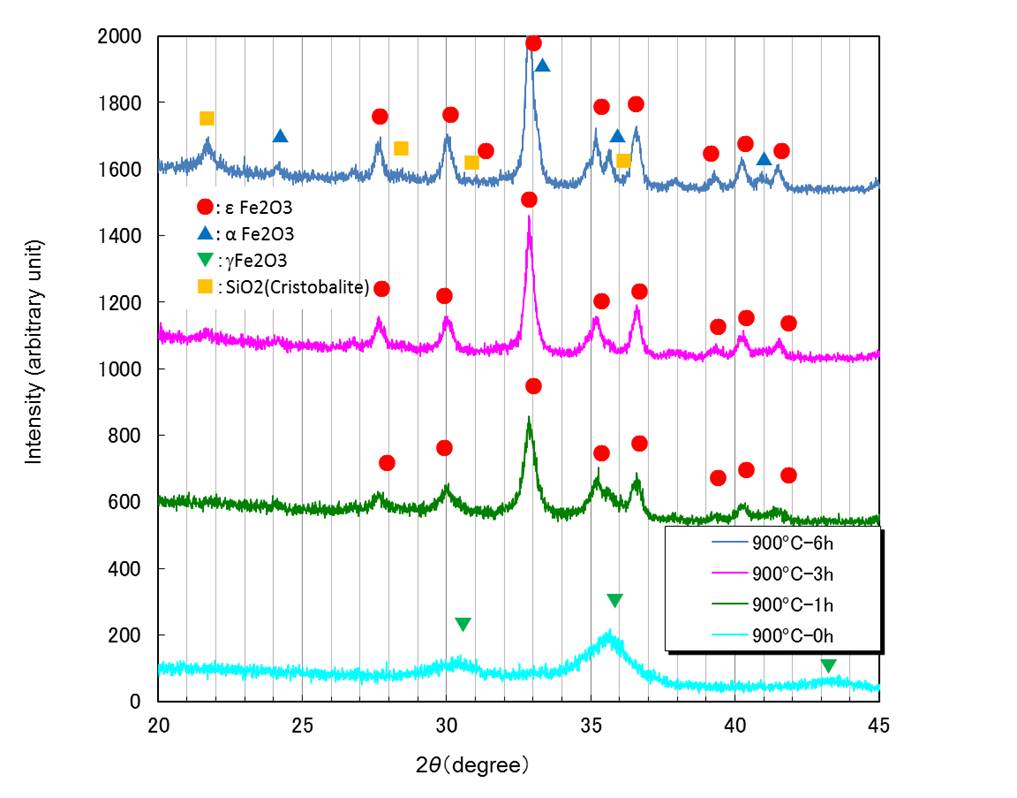

The magnetite nanoparticles including strontium were synthesized by hydrothermal method. After these particles were dispersed in the ethanol aqueous solution, and coated with the several nano meter silica shell by adding TEOS solution. The ε Fe2O3 particles were prepared by heat-treating these core-shell particles by the fixed temperature. Silica was removed from these core-shell particles by use of the NaOH solution, and the particles only of ε Fe2O3 were made. The magnetic property and the special quality of the form of particle and the particle diameter were argued to the dope amount of the strontium, the silica covering amount and the synthesis condition of the heat treatment temperature to this particle. As a result, the crystal system by heat-treatment time and the change in form of particle were checked by XRD and TEM.

Samples with 5% added Sr2+ were examined for several holding times set at 900 °C. Figure was XRD at 900 °C. The sample held for 1 hour has an aspect ratio of 1, and mostly contains ε phase and a little γ phase. Furthermore, in the sample which passed for 6 hours, although it was mainly ε phase, a little α phase was generated. The aspect ratio increased to 2 or more, and the rod width also increased to 60 nm. The crystal of silica developed with the increase of the amount of Sr2+. It is considered that this is because Sr2+ infiltrates into the silica by the doping of Sr2+, and influences the crystallization. It was found that the addition of Sr2+ causes the formation of an ε phase at a low temperature, the extension of the particles in a rod shape, and the change of the magnetic properties.

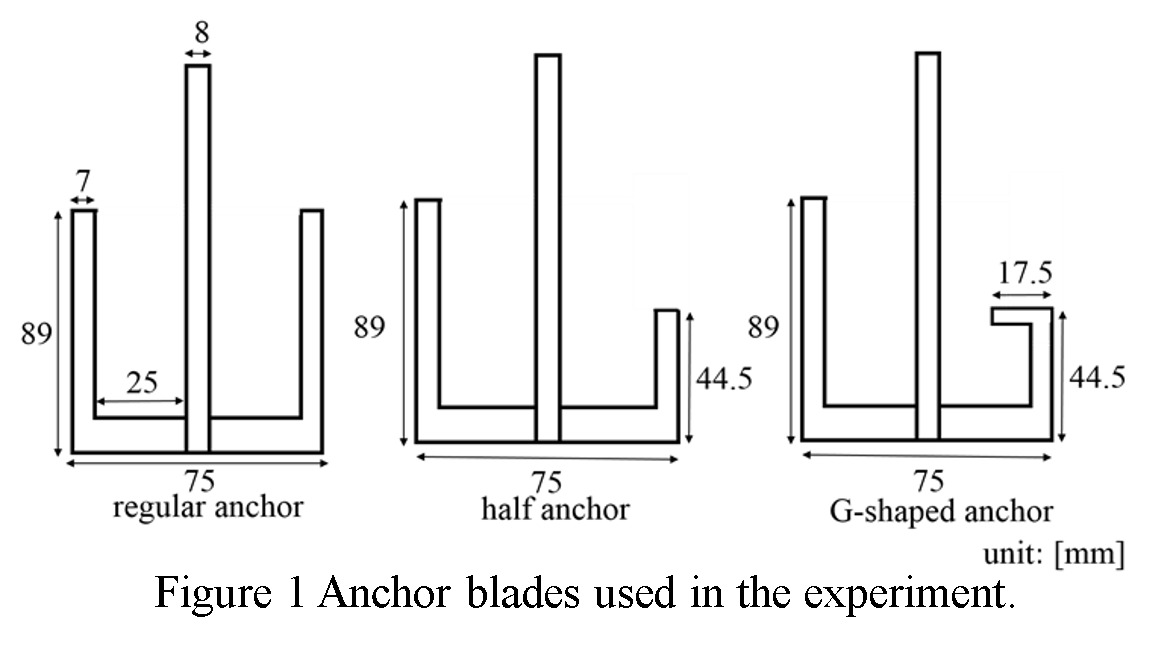

In chemical process industries, research and development on liquid mixing is important to save energy and resources, improve productivity and develop new materials. An appropriate impeller shape is selected to optimize mixing state in a chemical process. Very high viscosity of a fluid is an obstacle for performance of mixing processes. An anchor blade impeller is frequently used for mixing of highly viscous fluid is effective for heat transfer by scraping the tank wall but poor for the mixing. This is because the axial flow is not enough to be developed. It has been reported that mixing of highly viscous fluid can be improved by imposing unsteadiness on the flow field. This study, therefore, proposed two types of asymmetric anchor blade to improve agitation performance. Power consumption and flow patterns were experimentally and numerically observed. The asymmetric anchor blades proposed in this study were half anchor and G-shaped anchor. It is shown in Figure 1. As the results obtained by numerical simulation using a commercial CFD code (R-Flow), the power consumption using the asymmetrical anchor blades becomes smaller than that of the regular anchor blade. However, no significant difference between the half anchor and G-shaped anchor could be found. As the results of the flow pattern observation, it has been found that the mixing performance is improved in asymmetric anchor blades as compared with the regular anchor blade. It can be considered that asymmetric anchor blades make the flow field unsteady. Furthermore, it has been found that using the G-shaped anchor shows better mixing performance than the half anchor. The axial flow can be generated by the protruding portion of the G-shaped anchor. Mixing time was measured by decolorization experiments using iodine and sodium thiosulfate. The G-shaped anchor progressed the decoloring reaction most quickly and the mixing time the shortest.

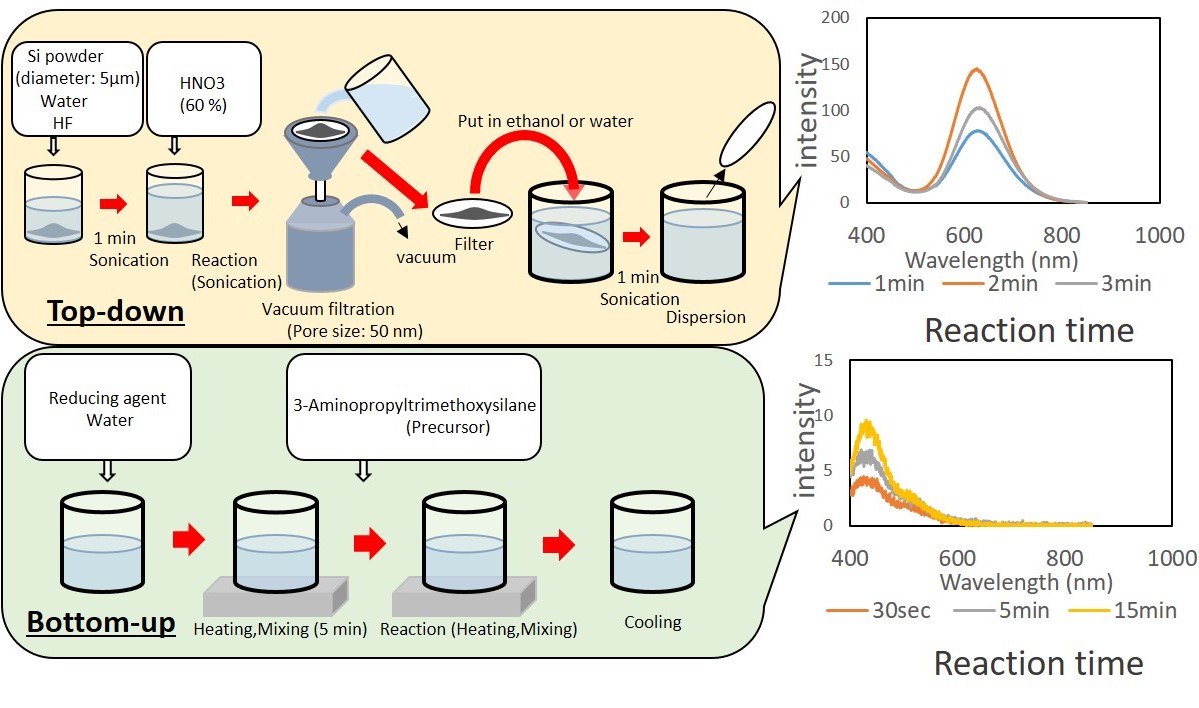

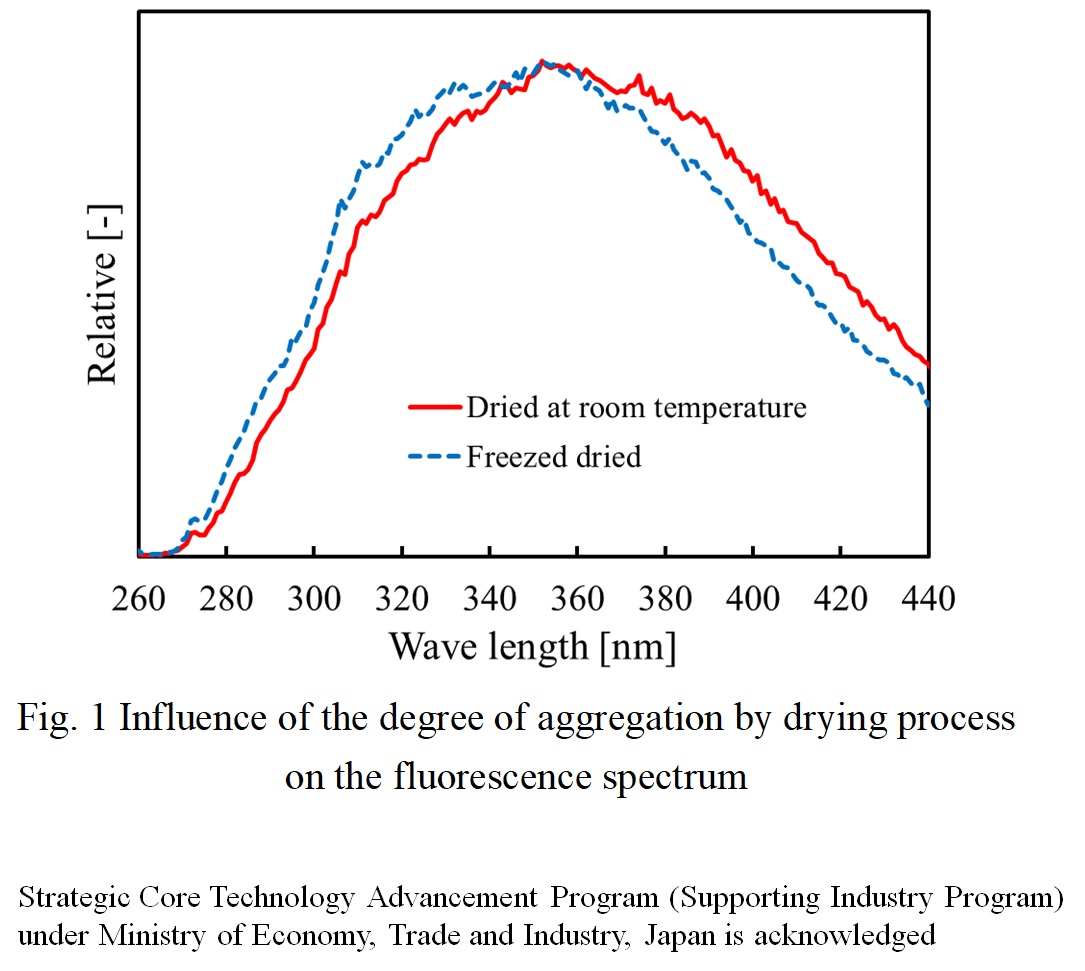

Semiconductor nanoparticles, known as quantum dots, are biocompatible semiconductor fluorophores and highly stable against exposure of light, which cannot be expected for organic fluorescent materials.1 Controllability of luminescence energy is also advantageous for bio-imaging since bio-permeability is good in near infrared to visible red region. However, toxic metals frequently used in quantum dots are problematic for practical use. In this context, non-toxic silicon-based nanoparticles meet the demand of bio-imaging although its stability cause the difficulty in the liquid phase synthesis, which realize large scale fabrication.

In this paper we fabricated silicon nanoparticles with two different liquid-based approaches, “Top-down” and “Bottom-up” methods. In “Top-down” method, Si powders are etched by hydrofluoric-nitric acid and decreased in its particle size to nm scale in suspension to obtain silicon nanoparticles, which show red light emitting (about 620 nm) in its PL spectra. In “Bottom-up” method, 3-Aminopropyltrimethoxysilane was used as precursors and reduced by reducing agent to obtain Si nanoparticles. The PL spectra of the nanoparticles show blue light emitting (about 420 nm), indicating that the obtained nanoparticles have smaller diameter than the nanoparticles prepared by “Top-down” method.

The dependence of the paddle rotating speed and its optimal paddle length for flow homogenization inside honeycomb has been investigated experimentally. Three types of honeycomb having various square hole size and the number of holes was used. The paddle length was varied within the range of 62, 81.6 and 120 mm and its width was 22 mm. The paddle was made of polylactic acid, which was fabricated using a 3D printer. The inlet volumetric flow rate was constant, 200 L/min. The air flowed into the header section and then into the honeycomb. The paddle attached to the motor was set to the windward side of the honeycomb. The flow rate was measured with a hot-film anemometer, which was positioned using a traverse device. The uniformity of the velocity at the honeycomb outlet was evaluated using the standard deviation of the velocity. The standard deviation is the arithmetic mean value calculated with the 169-point velocity data.

Table1 shows the experimental results. It was found that the optimum condition was almost 500 rpm of rotational speed with 120 mm paddle diameter.

Construction waste residue (CWR) consists of particulate organic and inorganic materials like woodchips and gravels. In Japan, the CWR should be discarded at a controlled landfill site to avoid decay of the organic materials. However, illegal dumping of the CWR is a serious trouble, because the discard at a controlled landfill site is “expensive”. If the organic materials are separated to reduce the amount to be < 5 wt%, the CWR can be discarded at an “inexpensive” least-controlled landfill site (≈ 1/5 $ of controlled landfill site). The organic materials can be easily removed from the CWR using a wet separation. Woodchips float and gravels sink in water. However, the wet separation has disadvantages; waste water treatment is necessary to avoid water pollution, a drying process is required after separation, and leakage of water may occur from the separator. Therefore, the development of dry separation is in great demand as a substitute for the wet separation. In this study, we focused on “density-segregation” in a vibro-fluidized bed. If a particulate mixture having different density is fluidized by an airflow through the bottom, lighter particles move up and heavier particles go down; this phenomenon is called “density-segregation”. If vibration is added to the fluidized bed, the density-segregation becomes clearer. We applied the vibro-fluidization to reduce the amount of organic materials in the CWR. We found that the upper layers of the fluidized bed consist of the organic materials, and the amount of organic materials in the lower layers is reduced to be < 5 wt%.

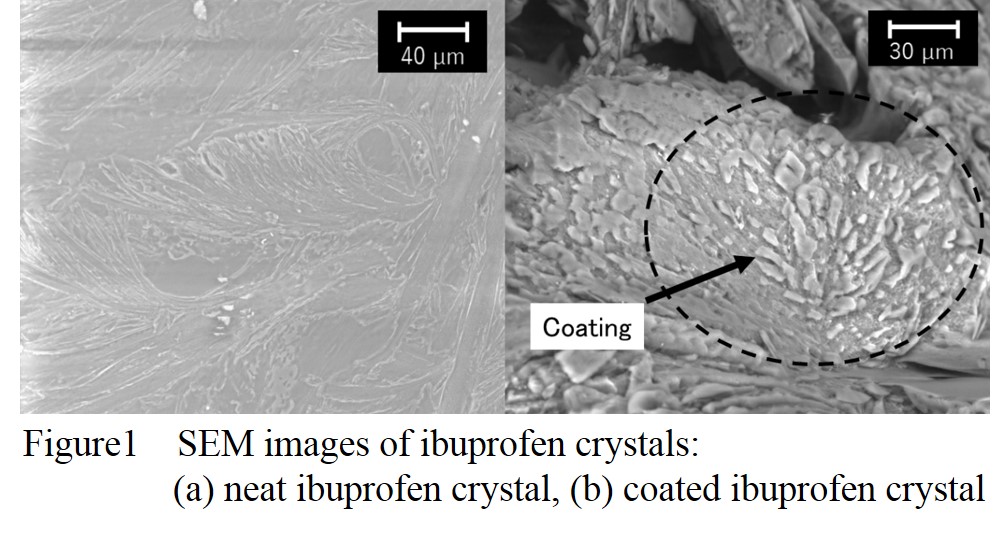

In the pharmaceutical industry, many of drugs are poorly soluble in water [1]. Ibuprofen, a nonsteroidal anti-inflammatory drug [2], is widely used to reduce fever and to treat pain or inflammation but it is poorly soluble in water. Coating with sugar is commonly used to enhance water solubility of drugs and expected to improve solubility, mask bitter taste of drugs and preserve medical effects. Due to relatively high values of the ionic product of H+ and OH- [3], mono- and oligosaccharides can be produced from the hydrothermal hydrolysis of polysaccharides [4]. The objective of this study is to demonstrate coating of less soluble drug crystal with products derived from hydrothermal hydrolysis of polysaccharides: ibuprofen was employed as a drug species, and polygalacturonic acid as a polysaccharide component. Mono- and oligo-galacturonic acids were hydrolytically obtained in a semi-batch flow reactor. The hydrolysis product solution played as a role of an anti-solvent for ibuprofen crystallization. The morphology and surface of ibuprofen crystal was observed with a scanning electron microscopy (SEM). Figure 1 (a) and (b) shows the SEM images of the neat ibuprofen crystal and coated ibuprofen crystal, respectively. The crystal structure was analyzed with the X-ray diffraction, and melting temperature of the ibuprofen crystals by differential scanning calorimetry. The effects of operating conditions on the amount of coating layer on the ibuprofen crystal surface were investigated.

References

[1] E. Merisko-Liversidge et al., Eur. J. Pharm. Sci., 2003, 18, 113-120

[2] A. Mauricio et al., Fluid Phase Equilib., 2013, 354, 185-190

[3] T. Funazukuri et al., J. Chem. Technol. Biotechnol., 2004, 79, 229-233

[4] T. Miyazawa et al., Ind. Eng. Chem. Res., 2004, 43, 2310-2314

Fine bubble (FB) attracts keen attention and the appilcation is spreading in various fields. FB is classified into microbubbles (MB) and ultrafine bubbles (UFB) depending on the size. Although benefits of UFB have been recognized in many applications, there are many obstacles for deeper understanding of the effect due to the lack of methods to characterize UFB. This study aims to introduce series of UFB generators invented by the author and propose methods to identify and characterize UFB.

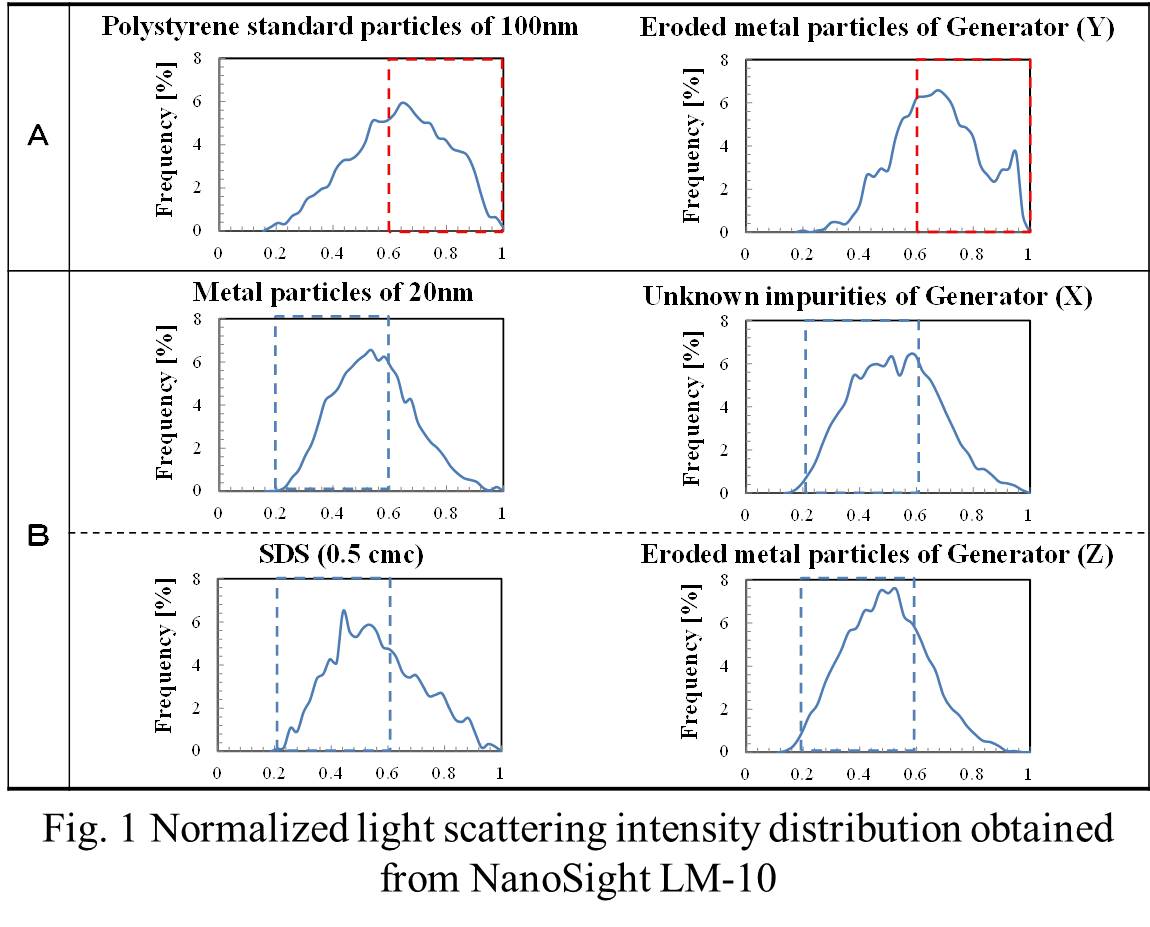

For identification, a method to differentiate bubbles and impurities was proposed. The dominant matter in water, either bubbles or impurities was successfully differentiated by analyzing signals obtained from a laser-based instrument, Nanosight LM-10. Comparison of the distribution patterns obtained from mixtures of UFB and various impurities (Fig. 1) suggested that UFBs are stabilized by adsorbing impurities in water. For characterization, the effect of salt addition on the number density and size distribution of UFBs was examined. Addition of NaCl solution into UFB water gave rise to UFBs' expansion and agglomeration depending on the condition. The dissolved gas concentration in NaCl solution and UFB determines the dominant change to occur. When the gas concentration in NaCl solution concentration is higher than that in UFB water, majority of the UFBs expand while the rest of UFBs agglomerate, vice versa. Furthermore, the net surface tension of single UFB in water was experimentally determined by using the invented system to estimate the volume of gas dissolved and/or dispersed in liquid. The net surface tension was lower than the surface tension of pure water.

These results provide supporting information for a suggested mechanism for stability of UFB in water by Yasui (2016) and the report of decreased surface tension of UFB water by Terasaka (2018).

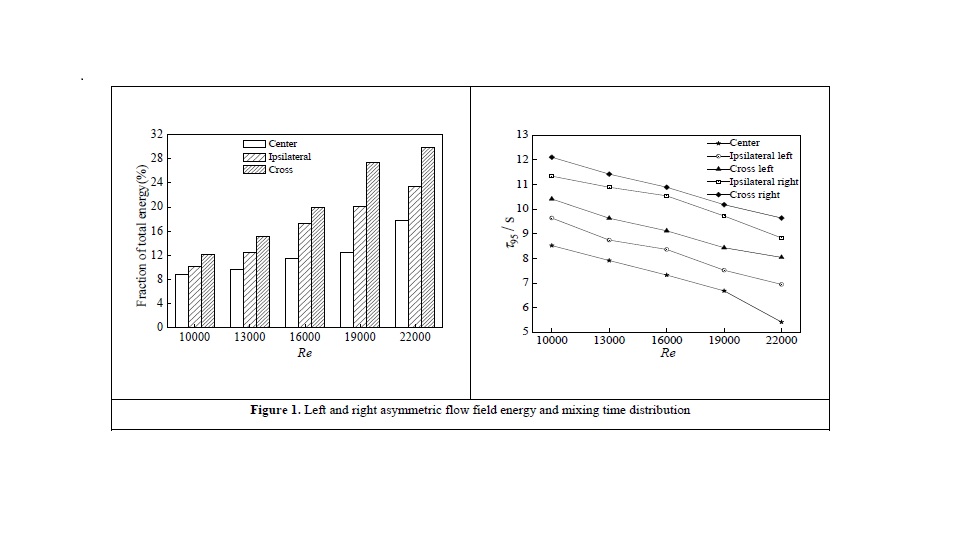

The flow field energy and mixing characteristics of the two-component layer jet asymmetric impingement mixer were studied by two-dimensional high-speed particle image testing technology (TR-PIV) and laser induced fluorescence (PLIF). In this study, the POD analysis method is used to extract the large-scale structure of the flow field and decompose the instantaneous flow field to obtain the main modal energy. The flow field energy is mainly concentrated in the first-order mode, which is easy to describe the flow characteristics of the whole flow field. Flow field reconstruction can accurately reduce the distribution of the initial flow field vortex structure. The asymmetric flow field energy formed by the up and down and left and right offsets of the stagnation point is always larger than the symmetrical flow field, and the mixing rate is lower than the symmetrical flow field. Under the same working condition, the stagnation cross flow field energy is higher than the stagnation point on the same side. The mixing efficiency is opposite; the lower tracer (stagnation point) is left (fully developed) to facilitate flow field mixing (Figure 1). Therefore, this asymmetry of the jet is beneficial to increase the flow field energy, and the initial development of the tracer promotes flow field mixing.

The extrusion process of ceramic pastes is commonly used for the production of high-value products such as catalyst pellets for the chemical reactor, honeycomb catalyst for purifying gas exhausted from an automobile, ceramic packings for adsorption and direct heat transfer, etc. Recently, extrusion-based 3D printing was successfully applied for manufacturing of ceramic superconductors, zeolite monoliths, and porous scaffolds.

Ceramic paste extrusion is a complex process which depends on the paste rheological properties, die and extruder geometries, and operational parameters. The paste rheological properties are controlled by several factors including volume fraction of particles and their size distribution, shape, packing density and surface characteristics, as well as amount and properties of binder and other additives. Modeling and quantitative analysis of paste molding are important to design the extrusion process for the production of high-value extrudates of desired strength, shape and morphology.

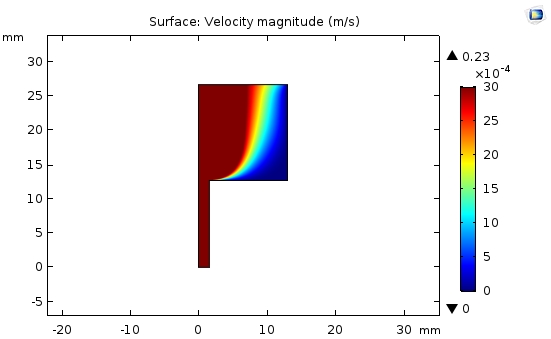

The objective of this paper is to construct the mathematical model of ram extrusion of ceramic materials and use it for the optimization of the extrusion process. The paste extrusion was modeled as a flow of non-Newtonian fluid. The paste continuity and momentum equations were solved numerically for fluid based on the modified Herschel-Bulkley viscous model. Fig. 1 illustrates the velocity distribution in the extruder. The effects of materials properties, extruder and die geometries, temperature and inlet paste velocity on the distributions of paste velocity and pressure in the extruder and die were investigated numerically.

References

1. M. Li, L.Tang, R.G. Landers, M.C.Leu, Extrusion process modeling for aqueous-based ceramic pastes, J Manuf Sci E-T ASME, 135, 051008, 2013.

2. N.Labsi, Y.K.Benkahla, A. Boutra, Hydrodynamic and thermal characterization of the flow of a Herschel-Bulkley fluid in a pipe, ESCAPE20, 1-6, 2010.

Bubbling beds are widely used in process industry, e.g. stripper of Fluid Catalytic Cracking (FCC) in petrochemical industry. It is important to enhance gas-solids contacting by improving the gas-solid flow, bubble distribution, bubble diameter and gas-solid backmixing in the stripper by adding internal structures. Different types of internal structures have been reported including disk and donut baffles and grid baffles. In this study, an Eulerian–Eulerian approach was used to compare the gas–solids flow behaviors in strippers with disk and donut and grid packing and in the empty stripper. Simulation results with respect to the solid volume fraction agrees well with experiments, indicating that the model is accurate in predicting gas-solids flow behaviors in bubbling beds. The CFD model also clearly predicts the local dead zones underneath the disc and donut baffles. The gas-solids flow behaviors are more uniform in the grid stripper than in other types of strippers. A machine-learning based method of capturing and characterizing the bubble was proposed. It was found that any strippers with internal structures can obtain smaller bubbles than the empty bubbling bed. The number of bubbles in the grid stripper is about 10 times more, and the bubble size is much smaller than those in the empty-type stripper. The present work indicates that the internal structures can enhance bubble breakup. The performance of the bubbling bed can further be improved by optimizing the internal structures.

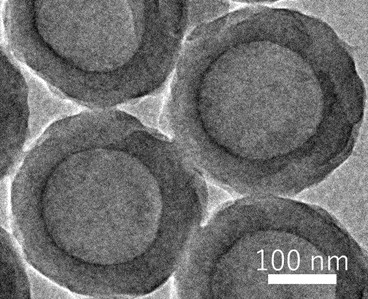

Polymer hollow particles have many advantages: great light diffusivity, high heat blocking rate, low density, low cost, and good dispersion in resin. However, the conventional synthesis methods have problems with their uniformity and productivity, which prevent application for products. In this research, we developed a new method to synthesize a large amount of uniform hollow polymer particles. Polymer solid particles were synthesized by soap-free emulsion polymerization using styrene as a monomer and 2,2'-Azobis [2- (2-imidazolin-2yl) propane] dihydrochloride (VA-044) as a polymerization initiator. In the colloid of the polymer solid particles prepared above, methyl methacrylate (hydrophilic monomer) divinylbenzene (crosslinker), and ethyl acetate (good solvent for polystyrene) were added and the polymer solid particles were swollen with the monomers and the solvent. Then, VA-044 was added and the polymerization was started. Through drying the fine particles, polymer hollow particles were obtained. A TEM image of the polymer hollow particles synthesized by this method is shown in following. Monodispersed hollow particles were synthesized (Cv: 9.2%, Cv = particle diameter dispersion / particle diameter distribution × 100). In addition, it was shown that the hollow polymer particles have different optical characteristics and heat blocking properties.