We have successfully applied a multiscale simulation (MSS) method [Murashima and Taniguchi, Europhys. Lett., 96, 18002 (2011)] to flows of a mono-dispersed linear entangled polymer melt in a contraction-expansion channel and in concentric cylinders. In our MSS method, a macroscopic model is coupled with a microscopic model through the velocity gradient tensor and the stress tensor. As the macroscopic model, the Smoothed Particle Hydrodynamics (SPH) method is employed, on the other hand, as the microscopic model, a slip-link model is employed. By using our MSS method, two-dimensional flows in a 4:1:4 contraction-expansion channel and axial flow in concentric cylinders are examined. From our multiscale simulations, we have evaluated detailed microscopic information that comes from the polymer chain dynamics, such as the local orientation of polymer chains, the average number of entanglements and the number density of entanglements along a polymer chain. In addition, we found that the number of entanglements generally decreases in the middle section of a polymer chain under flows. To explain this behavior, an equation for the entanglement density on a primitive path is proposed. These microscopic insights will bring us a stepping stone to design a polymer melt that has a specific property.

It is well known that certain cationic surfactant solutions with a counter ion cause significant drag reduction. In comparison with the coherent structure of the normal turbulence, vortex motion of drag-reducing flow can be restrained by the rheological property of surfactant solutions; consequently flow pattern might be greatly changed. The objective of this study is to clarify the flow characteristics of drag-reducing flow and to discuss the mechanism of the phenomenon.

The surfactant and counter ion we used were Ethoquad O/12 (C18H35N+(CH3)(C2H4OH)2Cl- and sodium salicylate (HOC6H4COO- Na+), respectively. Drag reduction rate (DR%) was measured by using PVC pipeline system having the diameter of 25 mm. We also measured the flow characteristics of the surfactant solutions with different concentrations and temperatures by using particle image velocimetry (PIV). From the experimental results, DR% at average velocity of 2.0 m/s increased from zero to 73% with the increase of the temperature from 10 to 50 °C at constant concentration of the surfactant (300 mg/L). From the velocity contour plot obtained from PIV, we found that the thickness of the lower velocity region of the drag-reducing flow was thick at 10 °C, while vortex motions seems controlled at 30 °C. On the contrary, the lower velocity region thickened with the increase of the concentration of the surfactant with constant temperature. Even if the same level of drag-reducing effects are taking place, we expected that the flow patterns are quite different depending on the concentration and temperature.

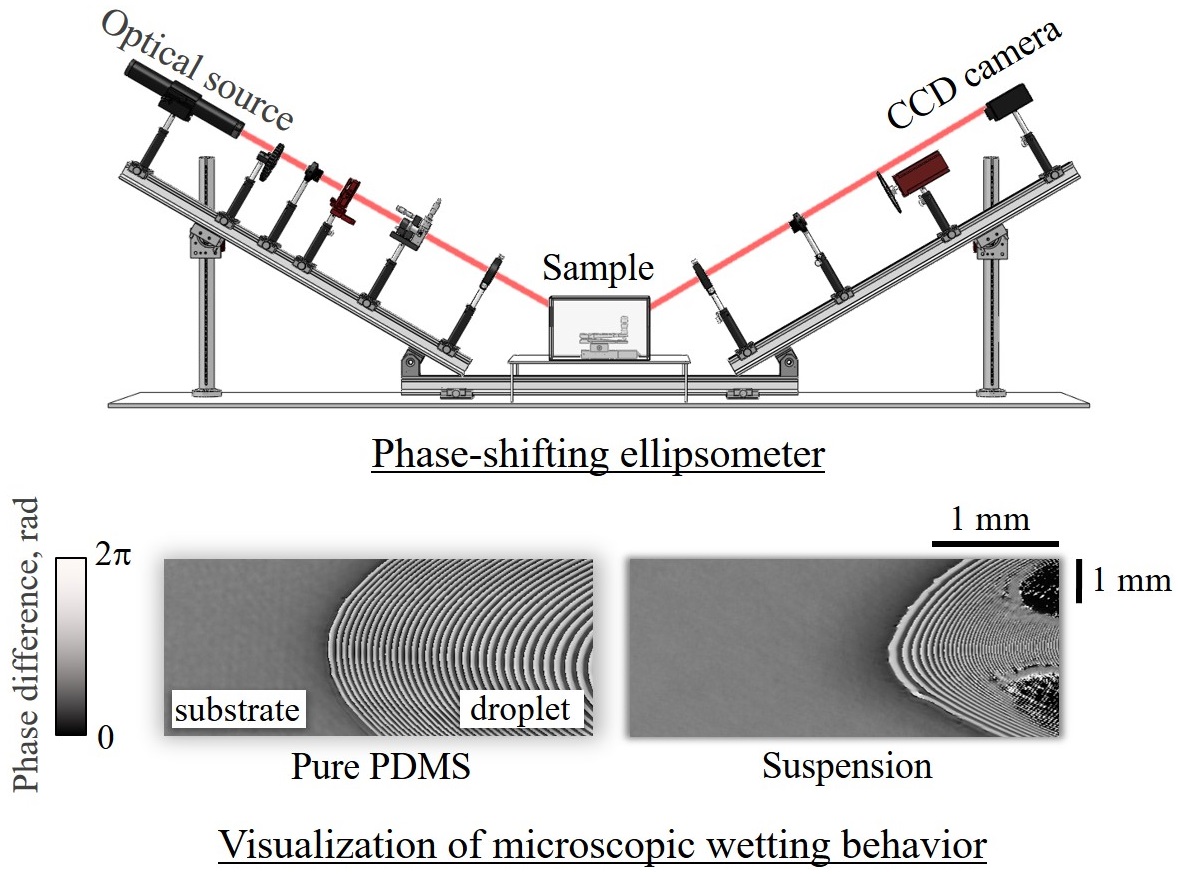

A nanofluid is a suspension of nanoparticles in a liquid and has attracted attention in diverse engineering fields, e.g. the nanofluid is expected as nano-ink for printed electronics. In such a situation, the knowledge of the effect of nanoparticles on wetting phenomena of nanofluid on a substrate is required. Therefore, the objective of this study is to investigate the effect of nanoparticles on wetting behavior in microscopic view using a phase-shifting ellipsometry we developed.

In this study, polydimethylsiloxane (PDMS) was used as a solvent, and PDMS-modified SiO2 nanoparticles were added within 3 wt% in the solvent. The particle size distributions of the nanoparticle suspension were evaluated using dynamic light scattering method, and consequently aggregates with a micrometer size were observed although the mean diameter was approximately 600 nm. In experiment, a droplet of pure PDMS or SiO2 nanoparticle suspension was put on a silicon substrate, and the microscopic wetting behavior near the contact line was quantitatively visualized by the phase-shifting ellipsometer. The phase-shifting ellipsometer can measure the two-dimensional thickness distribution of a liquid film at the nanoscale. Relations of the contact angle and the length of precursor film with a nanometer-scale thickness ahead of the contact line with capillary number were evaluated from the obtained thickness distributions to analyze the effect of nanoparticles.

The large difference in contact angle between the pure PDMS and the suspensions at the same capillary number was observed though the viscosity change with adding the nanoparticles is small. On the other hand, there was little difference in the precursor film lengths of both fluids at the same capillary number. These results indicate that the nanoparticles did not affect the precursor film region.

Most milky lotions and creams as cosmetics are emulsions and non-Newtonian liquids. In the emulsifying process of these manufacturing, a rotor-stator type emulsifying device is widely used. Each emulsifying device has a different shape of the rotating blades and stators. The size of the emulsified particles of the resulting emulsions varies depending on the device and its rotational velocity of the blades. The higher the shear rate produced by the emulsifying device, the smaller the size of emulsified particles produced. That is, it is considered that the size of the emulsified particles is greatly affected by the maximum value of the shear rate that the liquid receives as it passes through the emulsifying device. The emulsifying device is designed to generate a high shear rate. But the shear rate that the liquid receives is distributed because it depends on the route through the device. So far, we have evaluated the capabilities of emulsifying devices by experiments using specific model formulations. Today, we obtain the distribution diagram of the maximum shear rate that the liquid receives by numerical analysis. This distribution diagram can be used as an indicator of the capability of the emulsifying device.

In addition, the emulsifying device works like a pump that sucks and discharges liquid by high-speed rotation of the blades. This discharge amount is the processing capacity of the apparatus itself. When it is used in a mixing kettle, it also contributes greatly to total mixing.

This paper reports the evaluation of the capacity of the emulsifying devices by calculation of their maximum shear rate distributions and discharge amounts by using numerical analysis.