Glucose biofuel cells (GBC) using glucose and oxygen fuels are devices converting chemical energy of the fuels to electrical energy with an addition of the biocatalysts containing enzyme molecules. Since the GBC can be operated even in physiological conditions, the glucose and oxygen that are included in human body can be utilized as the fuels for the devices embedded into human body. However, critical problems to be solved still remain. In particular, its slow reaction rate should be improved. To do that, the use of mediator may be an appropriate solution. With the introduction of the proper mediator, electron transfer rate for the anodic and cathodic reactions can increase. To optimize the electron transfer rate and explain the electron transfer mechanism, a new electron transfer mechanism dubbed as a mediator embedded electron transfer (EMET) is introduced. With the mechanism, the target mediator, which can show outstanding benefits, is well immobilized on the enzyme and substrate materials. In this conference, I will explain the related electron transfer theory, the synthetic procedure of corresponding biocatalysts and the configuration and performance of GBC utilized.

To keep high energy conversion efficiency under variable electricity demand/supply is a highly important requirement for next-generation energy system which includes energy conversion processes. While SOFCs are expected to have high efficiency, they cannot avoid the drop in fuel utilization under abrupt output change.

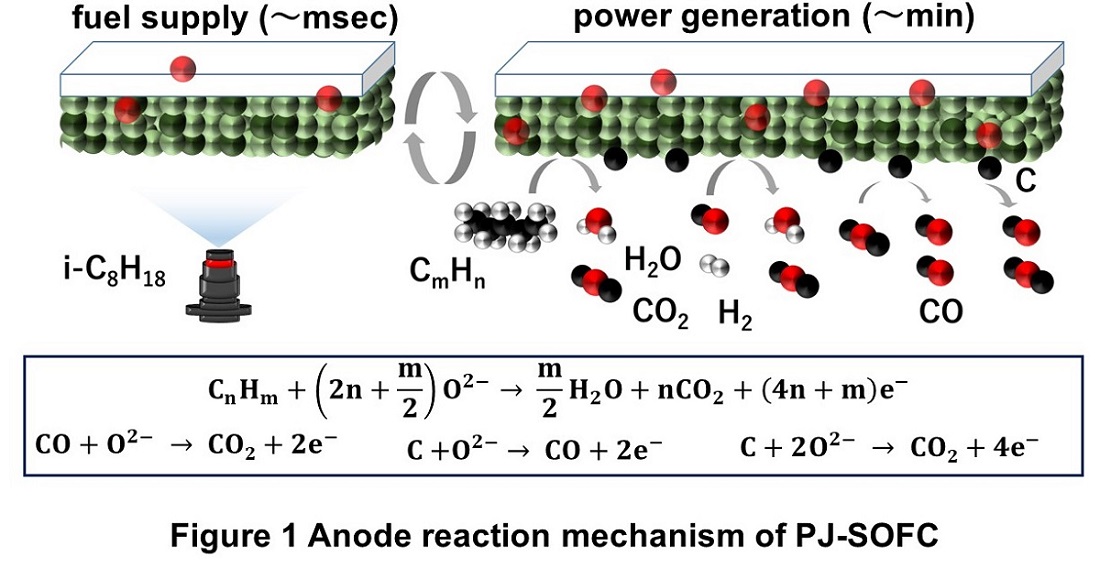

We proposed pulse jet solid oxide fuel cell (PJ-SOFC) which adopts the direct supply of liquid fuel via injector set below the anode. PJ-SOFC can keep high fuel utilization even in steep output power variation because it can change the gas atmosphere around the anode locally even with a small amount of fuel.

We have discussed the relationship between electrochemical/thermochemical reactions and the gas atmosphere around the anode, but the power generation property with steep output variation was not discussed, and the availability of PJ-SOFC as a load-followable SOFC was not evaluated.

In this research, we investigated the influence of operating condition for anode degradation quantitatively to realize stable operation under variable output with keeping high fuel utilization. Also, the advantage of PJ-SOFC for load following was discussed based on the actual data of the smart grid system “Ene-Swallow” developed at our laboratory and implemented at TokyoTech.

The power generation properties were investigated by electrolyte supported coin cells with YSZ electrolyte. Anode material was Ni/YSZ (3:2 wt%) and Ni/GDC(3:2, 1:1 wt%), and cathode material was LSM/ScSZ. Power generation was conducted at 900 °C with fixed fuel utilization as 60%.

Maximum power density was achieved 239 mWcm-2 with Ni/GDC(3:2). Better performance and stability were obtained with Ni/GDC(3:2) than Ni/YSZ(3:2). Higher stability was achieved with Ni/GDC(1:1) whereas higher power density was achieved with Ni/GDC(3:2). Step response was demonstrated and 1.3 times of output change, from 80 mWcm-2 to 105 mWcm-2, could be achieved in a moment without causing fuel utilization decrease.

Water treatment using membranes forms a key technology for solving water shortage and pollution worldwide. Some advantages of purifying water with membrane technology include low energy and small space requirements. Fouling which causes a reduction in separation performance and shortens membrane life is a serious problem to be solved. Although surface modification with a hydrophilic polymer such as zwitterionic polymer is effective for antifouling, there is no design guideline concerning membrane surface modification due to difficulty in controlling the molecular weight and density of the modified polymer during the membrane fabrication.

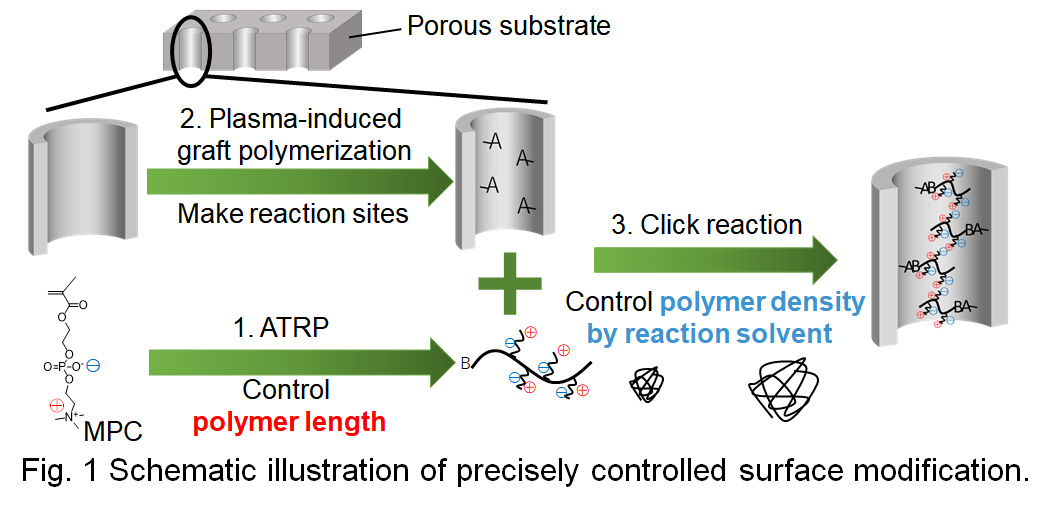

Here, we propose a precise surface modification method for the water treatment membrane(Fig. 1) and evaluate the influence of graft density and length of modified polymer on fouling phenomena using the prepared membrane.

In our suggested approach, poly(2-Methacryloyloxyethyl phosphorylcholine) (polyMPC) is synthesized initially by atom transfer radical polymerization(ATRP). Then, glycidyl methacrylate is grafted to the pores of polyethylene terephthalate(PET) as the reaction point of polymer immobilization, using plasma graft polymerization, followed by the immobilization of pre-synthesized polyMPCs by Click reaction. The key advantages of this concept are that polymers with pre-determined molecular weight and narrow molecular weight distribution can be effectively introduced into the pores. Furthermore, the density of the polymers inside the pores can be controlled by considering the structure of polymer chains in each solvent during Click reaction. Surface modification was confirmed by weight change observed for the membrane before and after the Click reaction and PET membranes modified by different molecular weight polyMPCs having different densities were successfully fabricated.

Permeation test of Bovine Serum Albumin solution though the prepared PET membranes was performed using a dead end filtration system. The PET membrane modified using high molecular weight polyMPC with high density showed highest flux recovery ratio, namely such surface modification of membrane is effective for antifouling.

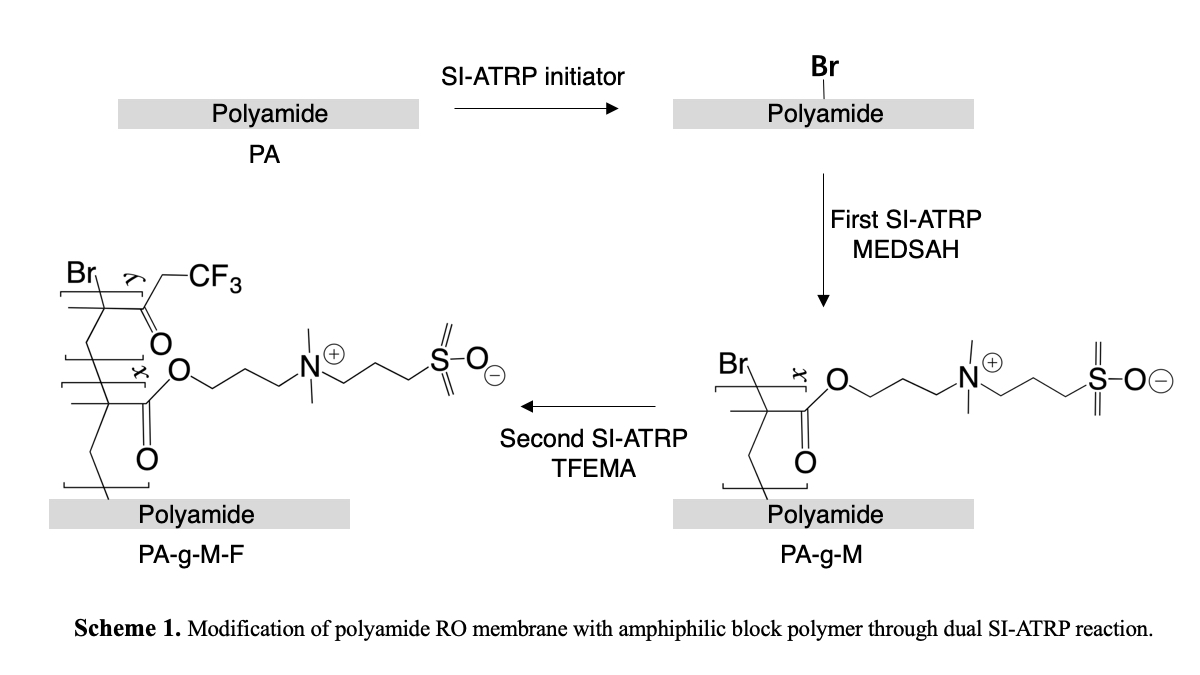

Membrane fouling is a severe hindrance to the effective application of reverse-osmosis (RO) process. For enhanced anti-fouling properties, majority efforts toward membrane surface modification have focused on rendering the surface more hydrophilic, smooth, and less charged, which prevents the foulant from contacting with membrane surface (“fouling resistant”). Probably, weakening the interfacial interaction between membrane and foulants is another strategy to tailor membrane anti-fouling characteristics, which makes adhered foulants easier to be removed (“fouling release”). Therefore, in this study, a new amphiphilic block polymer combining fouling resistance with fouling release features was synthesized by using [(2-methacryloyloxy)ethyl]dimethyl[3-sulfopropyl]ammonium hydroxide (MEDSAH) and 2,2,2-trifluoroethyl methacrylate (TFEMA) and grafted on polyamide (PA) RO membrane surface by dual surface-initiated atom transfer radical polymerization (SI-ATRP) reaction (Scheme 1). The surface composition, membrane morphology, surface hydrophilicity, and surface energy were assessed for the evaluation of the fouling resistance and fouling release potential of the membrane modified with the amphiphilic block polymer (PA-g-M-F). The long-term sodium alginate filtration experiment results indicated that compared to the pristine membrane (PA), PA-g-M-F membrane showed lower water flux decline and higher water flux recovery, remaining high stability.

Polymer composite materials are the subject of extensive studies because of their novel and excellent properties compared to their constituent materials. Dispersion stability of sub-micron sized particles in the medium is an important research theme from the point of colloidal views. And also, these particles are often used to synthesize polymer composite materials using resins and gels as matrix. Herein, dispersion of nano-materials, such as nano particles, in the matrix polymer is one of the most important problems to enhance their mechanical properties. We tackled this problem to carry out surface modification of the nano-materials, such as polymer particles or carbon nano tubes (CNTs), using amphiphilic polymers, poly-N-vinylacetamide (PNVA), synthesized thorough radical polymerization. Hydrogen bond worked between PNVA onto the modified nano-materials and hydrophilic matrix, such as polyvinyl alcohol (PVA) and nylon, to improve surface adhesions and dispersions of the nano-materials in the matrix. As a result, the mechanical properties of their composites were strengthened. When CNTs were used in PVA, the transparency of the composite was also increased owing to improvement of their dispersions. Additionally, if the CNTs formed the networks in the composites, the highly conductive and transparent composite polymer films were fabricated.