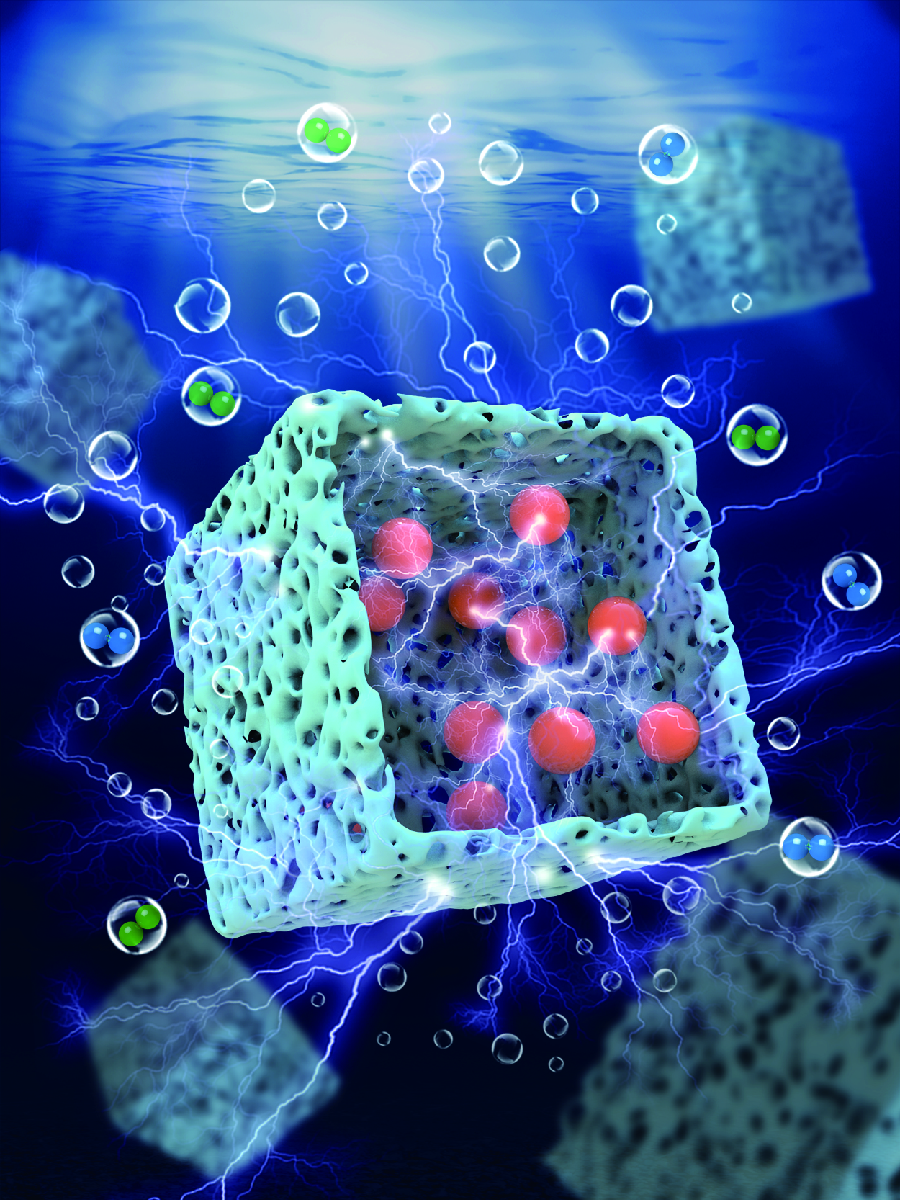

With the increasing demand for energy supply and awareness of climate crisis, green energy generation has attracted intensive and extensive research attention during the past decades. Hydrogen, as a high energy density non-carbon energy source, has been one of the spotlights and its green production has been one of the top research topics in scientific community. Among the many existing hydrogen generation processes, electrolytic water splitting (H2O → H2 + 1/2 O2) driven by renewable energies is considered by many an everlasting process for hydrogen supply. The most concerned issue of this process is its disadvantageous production cost as compared with competing technologies, such as steam reforming of fossil fuels. Electricity accounts for more than 50 % of the production cost for electrolytic water splitting. Consequently, extensive efforts have been devoted to develop more efficient catalysts to lower the over-potential and thus electricity consumption of the process to strengthen its competiveness. To function well as an efficient catalyst for electrolytic water splitting, not only material but also nanostructure are critical. In this presentation, several recent examples from our lab are offered to illustrate the point.

Titanium dioxide (TiO2) photocatalysts have been extensively studied for water treament, air purification and antibacterial. Due to it has many properties such as chemical stability, electronic properties and especially strong photocatalysts. However, TiO2 should be irradiated with ultraviolet (UV) radiation for photocatalytic activity. In this study, Ag doped Titanium dioxide (Ag-TiO2) was synthesized by a wet ball milling sol-gel method (WBMS). Various amount Ag/TiO2 molar ratio from 0% to 10%. To study phase transition and crystallite size of Ag-TiO2 from X-ray diffraction (XRD). The particle size, surface area, morphology and electronic properties synthesized of Ag-TiO2 were determined by transmission electron microscopy (TEM), Brunauer-Emmett-Teller (BET), Scanning electron microscopy (SEM) and UV-vis diffuse reflectance spectroscopy. Photocatalytic activity and antibacterial were also investigated. The results demonstrated that when Ag/TiO2 molar ratio increased from 0% to 10%, the doping of Ag promoted the phase transformation and and inhibited crystallite size of Ag-TiO2. At 5% Ag-TiO2 showed the small particle size and, crystallite size and also presented the highest surface area. Intensity of surface plasmon absorption (SPA) peak of Ag-TiO2 increased and their peak position shifted to a longer wavelength range. Furthermore, back scatter electron microscopy (BSC) confirmed silver nanoparticle deposited on surface of TiO2 powder. The photocatalytic activity degradation of methylene blue (MB) of Ag-TiO2 increased from 1.12×10-3 to 1.62×10-3 min-1 when increasing of Ag/TiO2 molar ratio from 0% to 5%. When Ag/TiO2 molar ratio was increased more than 5% the photocatalytic activity decreased. The optimal 3–5% Ag-TiO2 for antibacterial was found high antibacterial for Escherichia coli (E. coli) and Staphylococcus aureus (S. aureus) under visible light.

Manufacture of Composite Materials for Bullet-proofing Helmets Using Multi Reinforcement Based on Epoxy Resin

Tania Natasha Dharmakusumah1*, Asep Handaya Saputra2

1tania.natasha@ui.ac.id; E-mail: taniadharmakusumah@gmail.com

2asephandaya@gmail.com

In recent years, Indonesia has faced many military challenges which are the center of attention of the military defense industry. Military Defense industry players in Indonesia such as BUMN (State-Owned Enterprises) and private companies, need new innovative material technology to make military equipment components such as bulletproof helmets that are light and practical so as not to disturb the mobility of military personnel. For this reason, this study uses composite materials consisting of multi reinforcement, such as carbon fiber and Kevlar, and epoxy resin as a matrix. The method of making is done by an open molding technique, hand lay-up. The choice of reinforcement with the right number of layers must be done to see the performance of carbon fiber and Kevlar to form a composite material that has bullet resistance, through Barcol hardness test and ballistic test. To find out how many layers are needed for one specimen by calculating the thickness. The factors that influence the thickness calculation are tensile strength values, the average resistance force of composite material specimen, cross-sectional area, and kinetic energy produced by bullets. The calculation results will be tested through ballistic tests using weapons and bullets that are in accordance with the National Institute of Justice Standards for bulletproof helmets.

Keywords: Carbon fiber, Kevlar, epoxy resin, hand lay-up, ballistic helmet

Silica aerogel is regarded as one of the most promising thermal insulating materials due to its extremely low thermal conductivity. The porosity higher than 90% and the pore size smaller than micron scale make the thermal conductivity lower than that of air. The bottleneck to the practical application of silica aerogel is its mechanical fragility. In this study, the composite aerogels comprised of individually crosslinked silica and chitosan networks were fabricated and their thermal insulating properties were investigated.

Silica sol was prepared by hydrolyzing methyltrimethoxy silane (MTMS) in an acetic acid aqueous solution containing cetyltrimethylammonium bromide (CTAB), urea and chitosan. Then glutaraldehyde (GTA) was added and the solution was heated to accelerate the crosslinking of chitosan with GTA and the gelation of silica. The obtained composite hydrogel was converted to aerogel via supercritical CO2 drying. The balance between the rates of crosslinking of chitosan and gelation of silica was the important factor of obtaining the uniform composite aerogel. The composite aerogels had the smaller average pore sizes and more uniform pore size distribution than the silica aerogel without chitosan. The thermal conductivity of the composite aerogels was nearly the same as that of the silica aerogel. The bending elastic modulus of composite aerogels was slightly higher than that of silica aerogel.

Calcium phosphate ceramics, such as hydroxyapatite (HAp: Ca10(PO4)6(OH)2) and β-tricalcium phosphate (β-TCP: β-Ca3(PO4)2) have been applied as bioactive and substituted materials for hard tissues in dental and medical fields due to excellent biocompatibility and osteoconductivity. For bioceramics, it will be very important to have absorption capability of biomaterials incorporated into bio-metabolic system because solubility absorption or giant cellular absorption may be indispensable for bioceramics harmonized with bone remodeling. The partial dissolution- precipitation with supersonic treatment is a convenient wet synthesis technique adding biomimetic characteristics for surface modification of biomaterials. Supersonic wave can bring bubble cavitation and make hot spot. So, many chemical reactions are activated by the formation of radical groups and the locally rising temperature. The purpose of this study is to investigate surface structure and nature of modified porous ceramics and to clarify the absorption characteristics in animal experiments. Commercial β-TCP products were modified to functionally graded calcium phosphate ceramics by the partial dissolution–precipitation (PDP) technique, which involved a supersonic treatment at 120 W and 38 kHz in 2% HNO3 solutions containing Ca2+ and PO43– ions. The dissolution efficiency of porous β-TCP ceramics drastically increased with time, depending on the porosity of ceramics. Enhancement of micro-pores and propagation of nano-cracks were recognized by the supersonic treatment for 7 min. After the specific PDP technique, HAp nano-crystals were precipitated all over the pore wall surfaces in macro- and micro-pores of the ceramics. The β-TCP and PDP-TCP ceramics were implanted into the subcutaneous tissues of back parts in 4 week-old Wistar rats. At 3 weeks after the implantation, the PDP-TCP ceramics showed more numbers of osteoclast like giant cells and better affinity for body fluid than original β-TCP ceramics. Based on these results, it was found that PDP-β-TCP ceramics would be one of bioactive scaffolds inducing good giant cell-absorption.