One of the essential thermal heat storage is phase change material which is methyl palmitate in this work because of high latent heat and suitable transition temperature range. However, the major problem is supercooling an undesired property in terms of crystallization during cooling. Moreover, microencapsulation preventing liquid form to leak makes phase change material suffer more. Microencapsulated methyl palmitate was synthesized by sol-gel method using tetraethyl orthosilicate as shell initiator, and spray drying process developed it into powder form. Palmitic acid was used as a nucleating agent. Differential scanning calorimetry (DSC) determined what supercooling degree of microcapsules was, and morphology structure and particle size distribution were characterized using scanning electron microscopy (SEM) and laser particle size distribution analyzer (PSD), respectively. The present study aimed to determine if factors of each production process are associated with microcapsules' supercooling degree. They delved deeply in my research consisted of HCl quantity, sol-gel reaction time, types of emulsifiers, homogenizer speed and duration, nucleating agent quantity, and spray dryer's inlet air temperature. The results showed that increasing HCl quantity didn't significantly affect to the supercooling degree, but made latent heat decrease. As for sol-gel reaction time, the more reaction time spent, the less degree of supercooling happened; on the other hand, the more latent heat had. The positive charge of emulsifiers was better microcapsules properties than negative. Supercooling degree at homogenizer speed of 8000 rpm was lesser than of 6000 and 10000 rpm; nonetheless, latent heat was the lowest of them, and three minutes of homogenization is the best. Furthermore, the supercooling degree was decreased by palmitic acid as a nucleating agent, and at an inlet air temperature of 160 °C, it was appropriate for applying to the spray drying process.

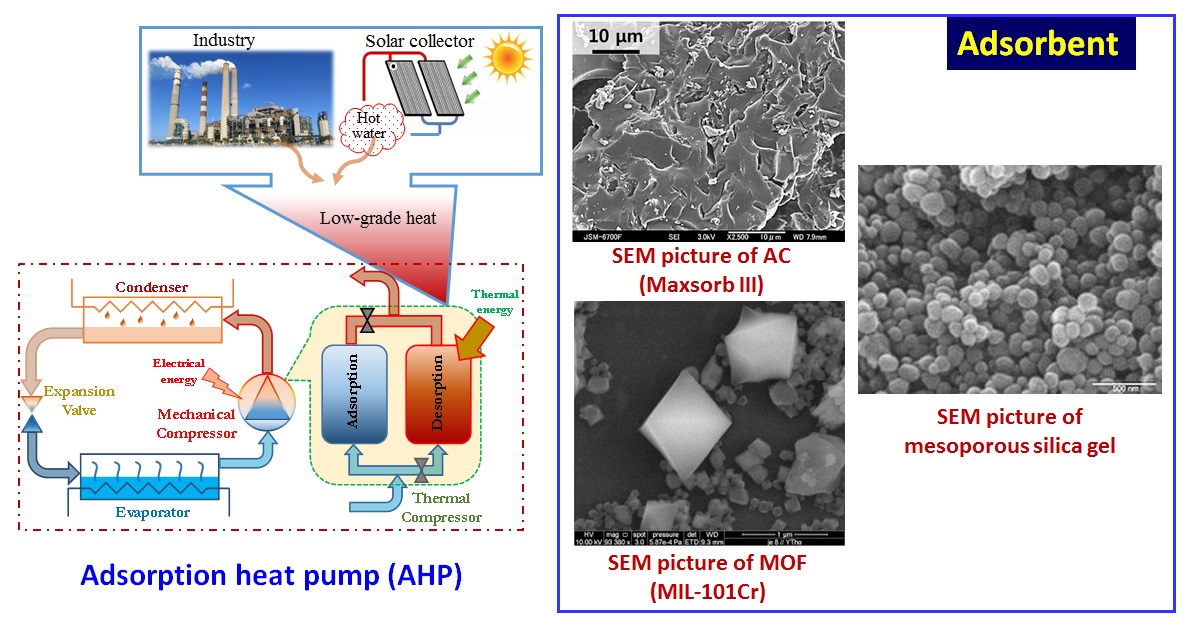

The research on adsorption cooling cycles got momentum after observing the worldwide energy crisis along with the obligation of international protocols which limits the production and utilization of CFCs and HCFCs as refrigerants. This paper presents the synthesis procedure of high grade activated carbons (ACs) derived from biomass precursors, namely waste palm trunk (WPT), and mangrove (M) which are abundantly available in nature. The thermophysical properties and adsorption characteristics of WPT and M activated carbons along with silica gel and metal organic frameworks (MOFs) are presented from the perspective of performance in cooling applications.

Various thermal energy storage (TES) systems have been studied in an effort to increase energy efficiency. Among these are phase change materials (PCMs) which have the advantage of high energy density from their latent heats. Research developments have progressed so far as to identify fatty acids and their mixtures to be materials that have great potential for this technology – given their chemical stability, non-toxicity, reproducible freezing and melting characteristics, low corrosion activity, and the renewable raw materials from which they are derived. The Capric-Lauric eutectic mixture is a PCM that has been thoroughly studied, and has theoretically been proven to have great potential for TES. The study investigates the thermal energy storage performance of the binary eutectic mixture of fatty acids embedded in gypsum wallboards, and experimentally verifies its viability for actual space cooling application. The small-scale test space unit is found to prolong the maintenance of cool internal temperatures (18 °C - 26 °C) for periods two to three times as long with the incorporation of C-L acid in the wallboards of the unit.

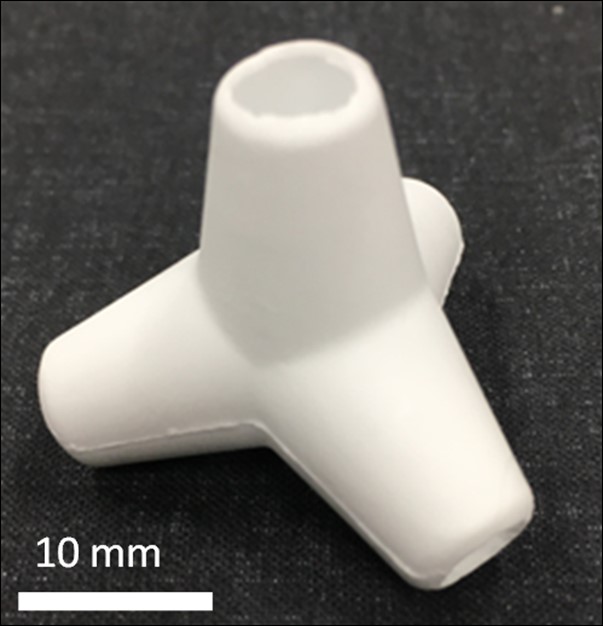

In order to utilize the renewable energy such as waste heat emitted from plant and solar heat more efficiently, compact and high performance heat storage system is one of the bottleneck technologies. Heat storage tank filled with ceramic sensible heat storage body have been used as effective utilization for high temperature waste heat > 500 °C from an industrial furnace such as regenerative burner system. However, the development and design of the heat storage body optimized for the temperature range and the heat storage and release rate is not performed yet. In prevalent ceramic heat storage body such as Al2O3 sphere, there were problems that the inside of Al2O3 sphere was not effectively utilized for heat storage. To solve these problems, we proposed newly non-spherical shell structure made of fine ceramics as effective heat storage body. In this research, one-step fabrication of the tetrapod shell structure ceramics body by slip-casting method was introduced. And the heat storage property was evaluated experimentally using the heat storage tank filled with tetrapod shell structure ceramic body.