Energy and water access for off-grid islands has been actively studied due to the difficulty of supplying these resources from the main land. In line with Sustainable Development Goals 6 and 7, the feasibility of supplying an off-grid island with renewable energy and water is often studied. Freshwater can be supplied to off-gird islands by purifying surrounding saltwater via desalination. However, recent studies have shown that there are tradeoffs between the production energy and water. In this work, the feasibility of implementing mechanical vapor compression (MVC), multi-effect distillation (MED), multi-stage flash (MSF), electrodialysis (ED), and reverse osmosis (RO) desalination technologies was investigated on an off-grid island with solar PV, diesel, and lithium ion battery storage. The water-energy system was simulated using the Island System LCOEmin Algorithm (ISLA) software, which has been validated with HOMER Pro. Principles in chemical engineering was used by the software to determine the energy consumed by the desalination technologies per unit of water produced. The distribution of energy between generation, storage, and desalination units was determined via energy balance. The optimum configuration was determined by iteratively using different component sizes. The optimum component sizes, levelized cost of electricity (LCOE), levelized cost of water (LCOW), and power flows were analyzed and policy recommendations on desalination implementation were made. PV+Diesel systems produced the lowest LCOE and LCOW, which is ideal because many off-grid islands are transitioning to this setup. Reverse osmosis plants produced the lowest LCOW.

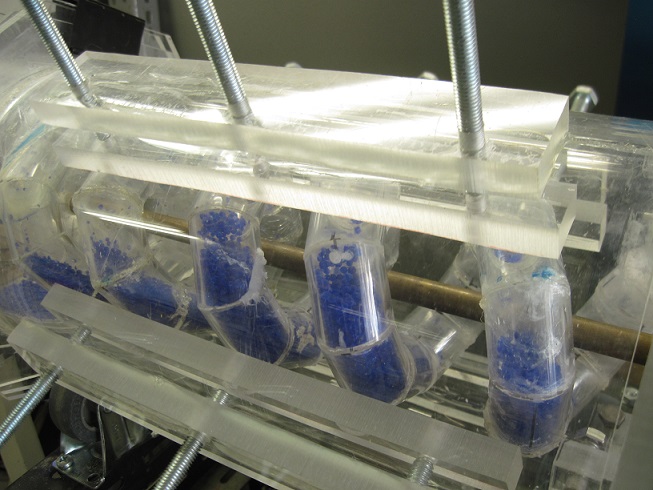

A novel rotating coil-shaped spiral gas-solid contacting device was proposed. The authors propose to make this spiral tube of 180 degree elbows which are commercially produced according industrial standard as piping parts. This device is considered to be suitable for biomass gasification because this enables good contact between volatile matter and solids so that tar can be decomposed over solids. Also external heating through the wall can be carried out with less thermal expansion stress. The solids in the spiral can be mechanically transported with rotation of the spiral, thus sticky material can be handled. Cold models of spiral structure were made by combining 180 degree elbows of half octagonal shape using ID 24 mm transparent plastic tube. A 1.5-cycle model which was driven by hand and a 5-cycle model which was continuously driven by a motor were used. As solid materials, three types of spherical glass beads and two types of spherical silica-gel particles were employed. In addition, one kind of non-spherical plastic pellet was used. The solids transportation rate by volume per rotation was determined to be about 30 cm3 for spherical particles irrespective of particle density, but the rate for non-spherical particles was lower. Solid back-mixing was evaluated by adding a batch of tracer particles with different color at the inlet of the 5-cycle model. The number of tracer particles was counted after taking the samples at the exit of rotating spiral reactor for each rotation. As an index to describe the back-mixing, the probability (p) of particles moving from one unit to the next with one rotation was proposed. The probability was higher than 0.9 for all particles. Average residence time and residence time distribution were derived from the probability.

Figure: Photograph of coil-shaped spiral reactor conveying blue silica-gel particles

Electrocatalytic hydrogen evolution reaction (HER) is used as a hydrogen production technology from electricity. Although platinum cathode is known to exhibit the highest HER activity at acidic condition, development of alternative cathode materials is expected from the viewpoint of resource constraints. Recently, metallic MoS2 nanosheets have attracted attention as a candidate of the cathode material. However, synthesis of metallic MoS2 is difficult due to its metastable phase and hence only a few of the bottom-up synthesis method has been reported. In this study, we fabricated metallic MoS2 thin film on glassy carbon (GC) substrate for HER cathode by hydrothermal electrodeoisition and conducted the detailed characterization.

To deposit metallic MoS2 thin film on GC, a mixed aqueous solution of (NH4)2MoS4 and KCl as the electrolyte was injected into the specially designed reactor with two electrodes system (cathode GC and anode gold foil). The reaction condition was set to 200 °C and 10 MPa, and a voltage was applied at 1.5 V for 1 minute.

The SEM observation showed an edge-exposed MoS2 thin film. XPS analysis revealed the formation of metallic MoS2 because the binding energy of Mo3d was shifted to the low energy side by about 1 eV. Although a hydrothermal synthesis of metallic MoS2 in a previous report required 12 hours of the reaction time, our synthesis requires only 1 minute-electrolysis. This can be attributed to the electrochemical reaction promotes the reaction to generate MoS2 from MoS3. In order to ascertain HER activity, we carried out linear sweep voltammetry with the three-electrode method (working: fabricated MoS2, counter: Pt and reference: reversible hydrogen electrode). As a result, we obtained high HER activity corresponding to those of the previous report. Particularly, the value of Tafel slope was much lower than that of stable MoS2 semiconductor, also suggesting that metallic MoS2 was synthesized.

Scheelite-monoclinic BiVO4 serving as a photoanode for photoelectrochemical water oxidation is known for its fast electron-hole recombination and slow kinetics, thus limiting its efficiency. In this study, a highly active oxygen evolution reaction catalyst, FeOx, is successfully deposited on BiVO4 by a simple and low energy needed photochemical metal organic deposition (PMOD) process under ambient environment. During the PMOD process, metal organic precursor goes through ligand-to-metal charge transfer, triggered by UV irradiation, and then react with oxygen to form a thin amorphous FeOx catalyst layer. This FeOx coated BiVO4 photoanode boosts the hole injection efficiency to ~100% which is almost triple comparing to the bare BiVO4. Furthermore, with FeOx layer, the onset potential shifts cathodically for about 0.4 V and the photocurrent density at 1.23 V vs. reversible hydrogen electrode (RHE) reaches 1.1 mA/cm2 which is 2.5 times of a bare BiVO4 photoanode. The stability of the photoanode is also improved. The FeOx coated BiVO4 demonstrates a substantial enhancement of the incident photon to current efficiency (IPCE) and the absorbed photon to current efficiency (APCE) due to its ability in increasing the hole injection efficiency and oxygen evolution reaction (OER) kinetics.

At present, thermal power still accounts for more than half of the power generation. Therefore, the shortage of fossil fuel caused by coal combustion and the air pollution caused by carbon dioxide released after combustion are still issues that we should consider. At the same time, study on the use of renewable energy and the hydrogen supply chain had begun to attract international attention. But in China today, there are still relatively few studies on hydrogen power generation, and the efficiency of the hydrogen energy supply chain is still under research and development.In this research, we investigated an energy supply system in China based on compressed hydrogen derived from renewable energy. Here, we will use the existed natural gas pipelines to transport compressed hydrogen. And we will build an energy and excergy flow chart for the hydrogen energy supply chain to calculate the energy efficiency of the energy system.By analyzing the energy and excergy loss of every device in system, the energy efficiency based on the calorific value was 34.5% when the output of renewable energy was set to 100%, the total electrical power efficiency was about 18% and the efficiency of the heat supply was 16.5%.