Microalgal biofuel was produced by a continuous hydrothermal liquefaction (HTL) of native microalgae using a bench-scale tubular reactor. Native microalgae cultivated and harvested with high biomass productivity (> 29 g/m2/day) in a cool temperate zone (Minamisoma, Fukushima, Japan) were used. The lipid content of harvested native microalgae was 5.0 – 16.9 wt%. The usage of native microalgae as a biomass offers benefits in terms of stable culture and productivity with easy maintenance. The slurry of native algae was continuously injected to a bench-scale tubular reactor by high-pressure pumps, and then gradually heated up to the reaction temperature through preheating tube, resulting in the production of biocrude. Produced biocrude was collected, and then the bio-oil was extracted from the biocrude using organic solvents. Both biocrude and bio-oil products as microalgal biofuel were characterized by a thermogravimetric analysis. Among the examined conditions, HTL processing at algal biomass concentration of 19.4 wt% at 350 °C showed reasonable biocrude yield and highest bio-oil yield (8.6 % by hexane, 24.9 % by chloroform-methanol mixture). Bio-oil products obtained at this condition were composed more of light oils substances compared to heavy oils, useful regarding biofuel production. Thermogravimetric analysis showed that some of the heavy oil components in microalgal biomass was converted into the light oil substances. Thus, native microalgae could be successfully converted to biofuel by HTL processing using a continuous bench-scale tubular reactor.

Supercritical water gasification is gasification of biomass in hot compressed water. It is suitable for wet biomass treatment because it uses water as reaction medium and does not require costly and energy consuming drying pretreatment. Because of the high temperature, water is very reactive, and almost complete gasification is possible. However, it cannot be free from tarry material production. Detail study on tarry material production showed that tarry material can be produced by both ionic and radical reactions. To suppress ion tar, rapid heating up of feedstock was found to be effective. To suppress radical tar, radical scavenger addition was found to be effective. In this study, food processing waste was processed in continuous supercritical water gasification experimentally. The result of the operation is presented. This study was supported by NEDO.

The Philippines being an agricultural country generates bio-based residues that can be utilized as low-cost fuel for biomass plants to generate electricity. The aim of this study is to assess the amount of bio-based residues together with their theoretical bio-energy potential (BEP) on each of the regions of the Philippines. The residues considered include agricultural and agro-industrial residues, animal by-products, woody biomass and marine biomass residues. Considering the limitations in the recovery these residues and the technological limitations on existing direct combustion power generation facilities, their available and recoverable bio-energy potentials are also estimated, respectively. According to the estimate, biomass residues have a theoretical bio-energy potential ~660 PJ/yr with majority contributed by agricultural and agro-industrial residues (~66%). While approximately half of this potential is available for recovery, only ~74 PJ/yr (3,300 MW) can be possibly harnessed as electrical power considering the efficiencies of co-generation plants. This potential, of which 6% is already harnessed, could possibly contribute to 15% of the current national power generation capacity and can potentially displace 15 million tons (Mt) of coal annually. Western and Central Visayas have the highest recoverable BEP among 17 regions with 14.2 and 11.3 PJ/yr, respectively.

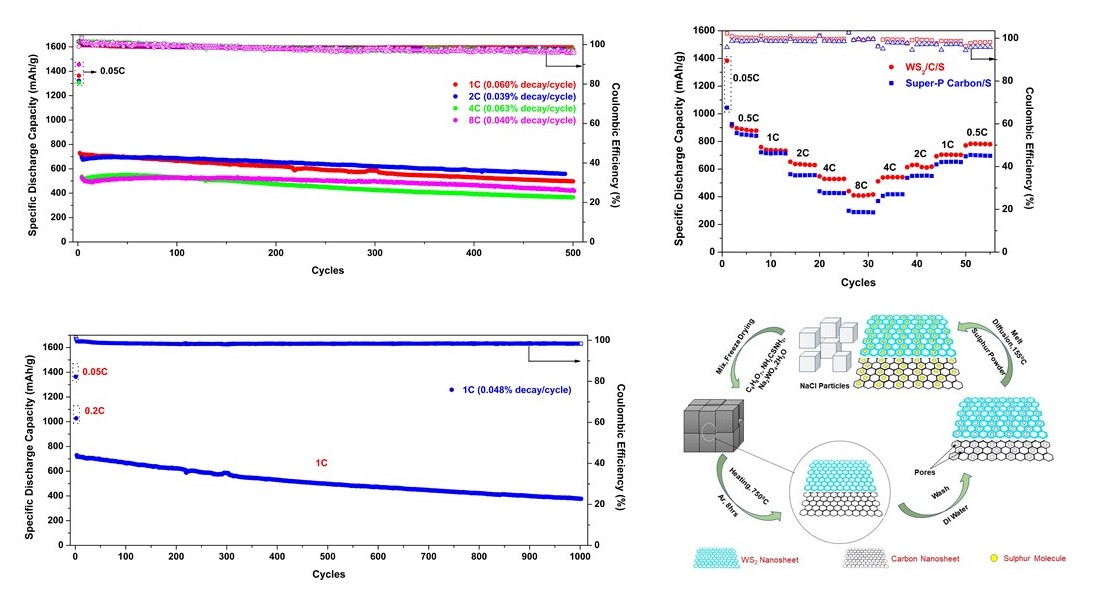

Mesoporous sulfur host consisting of tungsten disulfide (WS2) and carbon nanosheets has been synthesized in situ by using sodium chloride (NaCl) particles as the template. Two-dimensional architecture of WS2/C composite provided large specific surface area (643 m2g-1) and facilitated the rapid diffusion of lithium-ions during cycling of lithium sulfur batteries. The WS2/C porous nanosheets served dual function by providing physical barrier and strong chemical affinity to restrict the shuttling of intermediate lithium polysulfides. The sulfur rich cathode showed an excellent cycling performance by maintaining low capacity decay rate of 0.048% per cycle for 1000 cycles at 1C rate (1C=1675 mAh g-1). Moreover, it revealed an impressive rate performance by delivering high specific discharge capacity of 419 mAh g-1 at 8C after 500 cycles (80% capacity retention). At high areal loading of sulfur, 4.7 mg cm-2, were the battery delivered a high areal capacity of 3.4 mAh cm-2 after 100 cycles at 0.5C rate. Self-discharge analysis was also carried out to investigate the effect of polysulfide shuttling while the batteries were rested. It greatly suppressed self-discharge capacity loss by maintaining 94.5% of its initial capacity after 10 days of resting. The electrochemical impedance spectroscopy (EIS) analysis illustrated that even after 400 cycles, the interfacial and charge transfer resistance only increased by 1.2 and 1.7 Ω, respectively, explaining faster electrochemical kinetics and inhibiting the formation of insulating layer of lithium sulfide (Li2S) on the surface of the electrodes. The facile synthesis procedure of porous WS2/C nanosheets and its superior electrochemical performance as a host provide valuable options to engineer practical sulfur cathode for high performance lithium sulfur batteries.

Acknowledgement: Financial support provided by Hong Kong Research Grant Council, National Natural Science Foundation, China (NSFC, N_PolyU601/16) and the Hong Kong Polytechnic University (1-ZE30).

Oxygen reduction reaction (ORR) is the most demanding process in the commercialization of fuel cell. To replace expensive rare earth metals in electrocatalyst, carbonized metal-organic frameworks became an emerging candidate. Zeolitic imidazolate frameworks (ZIFs), a sub-class of MOFs, is a hybrid crystalline material consisting of metal nodes and organic linkers. It has a big advantage on easy production and high specific surface area. If the ZIFs are synthesized in hollow structure, they have notable advantage to reduce the mass transfer resistance. However, the conventional synthesis method to make hollow structure requires multi-steps in small-scale. In this work, Co-N-C hollow-spheres were prepared from CoZn-ZIFs hollow-sphere in a facile method. Co/ZnO was prepared in a spherical form by ultrasonic spray pyrolysis, which has a big advantage in mass production. Then, it was converted into CoZn-ZIFs in ligand solution with simple stirring, followed by the carbonization to Co-NC hollow-sphere. The ORR activity for the final product was tested and it showed outstanding performance comparing to the materials in the literatures.