Annual production of crude steel reached 1.8 billion tons in 2018, and is projected to grow further. A major portion of iron is currently produced from iron ore in blast furnace. Because it uses coal as fuel and reductant, significant amount of CO2 is produced along with the steel. Therefore, iron and steel industry is considered to be in a category of "difficult to eliminate emissions". The blast furnace of Japan, the second biggest steel-making country, is the world-leading clean process. Nevertheless, CO2 emission from iron and steel industry accounts for nearly 15% of the total domestic CO2 emission. In view of global concern on the earth's warming, alternative green approaches must be introduced for the iron-making. To address this issue, herein a new concept for iron-making process is proposed. The iron ore reduction process is consisted of three steps: dissolution of iron ore using organic acids, photochemical reaction of the dissolved iron complex for the reduction and recovery as solid, and then pyrolytic recovery of iron under reductive atmosphere. The reactions in each step occur at temperatures much lower than that of conventional process. Although CO2 is formed at the reduction process, if it is recovered, converted to organic acids, and recycled to the process, the stoichiometry of overall process can be written without carbon. In other words, the process has a potential to be net-zero emission. The present study explains details of chemistry involved in the process, and discuss current status of technologies for key reactions with information from past studies to find technical barriers and challenges. Moreover, the iron-making process (iron ore reduction part) is experimentally demonstrated in a diluted reaction system.

Evolution profiles of Hg during sintering was investigated with flow-type fixed bed reactor at 10 °C/min up to 950 °C in air. Five types of iron ores were used in this study, and Hg contents ranged from 60 to 180 ppbw. Hg content depended on the iron ore types, and there was no correlation between Hg content and composition of iron ores. Hg released from iron ores as a Hgo and Hg2+ during the sintering, and mass balance ranged within 100±10%. Proportion of total gaseous-Hg and remained-Hg in solid after sintering were 20-70% and 30-70%, respectively. Hg evolution started beyond 100 °C and continued until 950 °C. Main and shoulder peaks of Hg evolution profiles were observed at 150-250, 300-400, 450-550, 500-700 and 700-900 °C, and the evolution profiles depended on the iron ore types. The temperature-programmed-desorption (TPD) experiments of physical mixtures of Hg compounds (HgCl, HgCl2, HgO, HgS and HgSO4) and Fe2O3 were carried out to investigate Hg form in iron ore under above-mentioned conditions. When pure Hg compounds were heated in air, the main peaks of Hg evolution profile were observed at 140-715 °C. However, Fe2O3 and HgCl2, HgCl, HgS, HgO or HgSO4 mixture showed the Hg evolution profile having the main peaks at 150, 165, 390, 510 or 565 °C, respectively. With the mixture samples, all peaks shifted to the low temperature compared with those of pure Hg compounds, and new peaks appeared at 347 or 434 °C for the mixture of Fe2O3 and HgCl or HgCl2. This result shows the occurrence of interactions between Hg compounds and Fe2O3 during sintering of the mixture. Therefore, Hg evolution below 600 °C may occur from HgCl2, HgS, HgO, and HgSO4 in iron ores.

Coal pulverization is essential for coal combustion systems due to leading to enhance the efficiency of coal combustion. Coal consists of components as macerals and minerals, so that coal particles generated by pulverization have different grindability. The difference of grindability between the coal particles generated results in the difficulty of predicting the performance of coal pulverizer. Generally, the grindability of coal is evaluated by a Hardgrove grindability index referred to as HGI. The problem of HGI is to assume a uniform particle and evaluate an initial stage in a grinding process. Therefore, a semi-continuous test by an HGI test equipment were conducted. Based on the semi-continuous test, grinding rate constant distribution was derived from a multicomponent consecutive grinding model. The grinding rate constant distributions of high ash coal and low ash coal having approximately same HGI showed to be different. The grinding rate constant distribution of coal provided grinding information in detail.

In this study, pyrolysis characteristics of Mongolian brown coals were investigated in a fluidized bed reactor under a nitrogen atmosphere at temperature up to 1173 K. 1) The porous alumina and quartz sand were used as bed material for investigating the influence of bed material on the products yield. 2) The effect of the temperature on the properties of pyrolysis products (gas and char) was characterized.

The results have shown that the pyrolysis temperature affects significantly the product yield and distribution. With the increase of the pyrolysis temperature, the char yield decreases and the gas yield increases. Elemental composition of formed chars is similar with high rank coals at higher temperatures. Molar ratios of oxygen and hydrogen to carbon were analyzed with a coalification diagram.

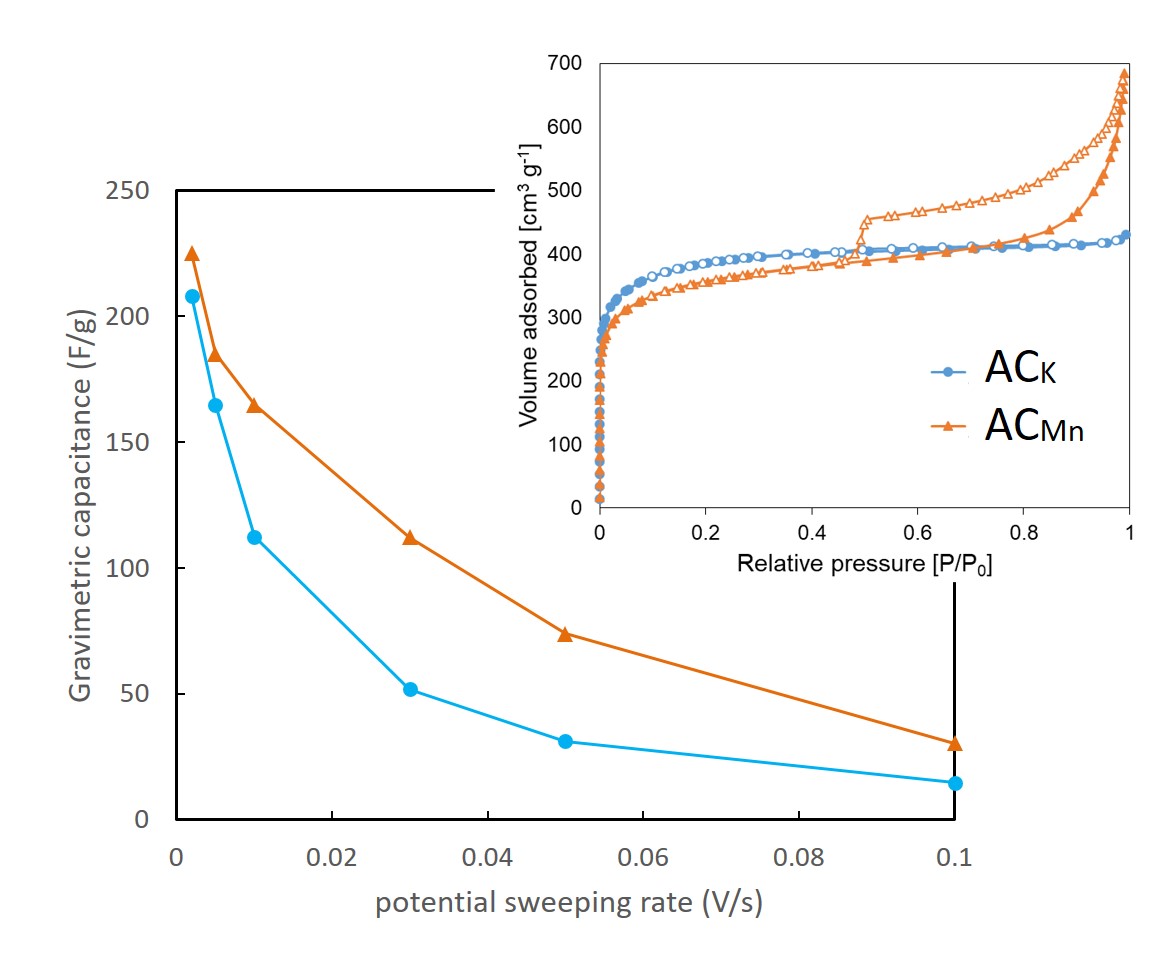

In this work, activated carbons (ACK and ACMn) were developed from bamboo powder by pyrolysis carbonization and KOH or KMnO4 activation process using one-step strategy. N2 adsorption-desorption, X-ray diffraction (XRD), scanning electron microscopy (SEM) and transmission electron microscopy (TEM) were used to investigate the characteristics of the produced activated carbons. The electrochemical performance of the activated carbons as electrode materials for supercapacitors were studied by electrochemical measurements. The as-prepared ACK and ACMn samples using KOH and KMnO4 respectively possessed a porous structure with a large specific surface area of 930 and 915 m2/g and abundant micropores. However, the ACMn sample has more mesopores and macropores than the ACK has. Further electrochemical measurements revealed that the ACMn electrode exhibited a specific capacitance of 75.0 F/g at a potential sweeping rate of 0.05 V/s, which was higher than that of the ACK electrode (35.0 F/g). Moreover, it was observed that when the potential sweeping rate was increased, the capacitance of both ACK and ACMn electrode tends to decrease, but the decreasing rate by ACK was more severe than ACMn. This is considered that the KMnO4 activation process of the bamboo powder resulted in the enhancement of the meso-macro structure, and improved the storage capacity and transport behavior. This one-step strategy using bamboo powder and KMnO4 activation process can be highly expected to achieve low cost, green and industrial-grade production of renewable biomass-derived carbon materials for advanced energy storage applications in the future.

Torrefaction is a thermal pretreatment method at relative low temperature range of 200 – 300 °C in an inert atmosphere, which aims to increase the energy density and to decrease the grinding energy of biomass. In this study, the torrefaction of two types of wood pellets, which are rubber wood pellet and leucaena pellet, was carried out in the temperature range of 260 – 300 °C for 30 min residence time. The products yield, its compositions and fuel properties at various torrefaction temperatures were also determined. The increase in temperature from 260 to 300 °C reduced the torrefied pellet yield from 87.4 % to 63.5 % for rubber wood pellet. The heating value (21.4 MJ/kg) and the volumetric energy density (17.5 GJ/m3) of torrefied pellets at 300 °C were comparable to that of coal. The increase in torrefaction temperature also improved the hydrophobicity (resistance to water uptake). Moreover, the combustion behavior of torrefied pellets show some improvement compare to raw pellets. These results showed that the torrefaction of wood pellets (TAP process) is a potential pathway to produce energy-dense pellets as a tradable solid biofuel to replace coal.

There are energy issues such as carbon dioxide emissions and depletion of fossil fuel, energy supply not depending on fossil fuel would be required. So increasing of biomass and waste biomass using for energy would be able to solve in these problems. There is carbonization of sewage sludge as one of methods of waste biomass using. And in the case of carbonizing sludge with mixing coal, high quality fuel better than sludge could be manufactured. Char manufactured from both materials is called co-char in this paper. In this study, gasification rate of co-char was measured, and effect of co-carbonization of both materials on co-char reactivity was evaluated by comparing reactivity between co-char and single char made from a material. In the experiment, char was heated up in reactive gas agent flow, weight loss by reacting char and gas was measured by thermo-balance. As a result, weight loss rate in gasification of char was low speed with increasing coal ratio in co-char. In arrhenius plot calculated from gasification model, activation energy of coal char (coal ratio in co-char is 100 %) was largest, and activation energy of sludge char (coal ratio in co-char is 0 %) was lowest. And activation energy of co-char was in ranging between coal char's value and sludge char's value. On the other hand, graphite structure of co-char was developed with increasing coal ratio from measurement of raman spectrum. So, carbon structure in co-char was different in every coal ratio, it was considered changing of carbon structure affected reactivity of co-char in gasification.

Biomass have been attracting much attention as a renewable and sustainable energy resource to substitute fossil fuels. Thermochemical treatments of biomass such as pyrolysis and gasification are general technologies to utilize biomass energy. However, these technologies have the common problem of the high temperature required for the reaction, which results in a low energy efficiency. Therefore, a method for reducing the activation energy of the biomass pyrolysis reaction and promoting the reaction at a low temperature is needed. One effective method is the use of catalyst. Although a lot of researches have been dedicated to develop efficient catalysts, this study focuses on various kinds of non-precious metal oxide catalysts including semiconductor and non-semiconductor materials. Then, the purpose of this study is to clarify the influence of such metal oxide catalysts on pyrolysis behavior of woody biomass.

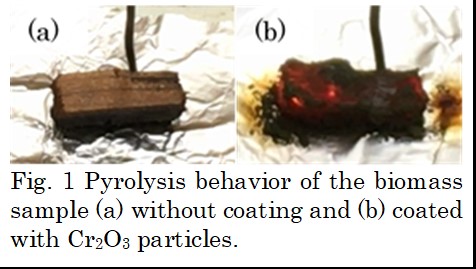

The pyrolysis behavior of a rectangular piece of cypress coated with different kinds of metal oxide particles was investigated on a hot plate in a room air. Al2O3, Cr2O3, Fe2O3 and TiO2 were tested. A sample without coating of any metal oxide was also used. As shown in Fig. 1, the sample pieces coated with Al2O3 and without catalyst coating were slowly carbonized with increasing the hot plate temperature, and finally charcoal remained at 500 °C. On the other hand, the sample pieces coated with Cr2O3, Fe2O3 and TiO2 began to glow red from the edge when the plate temperature exceeded around 300 °C, and then the glowing spread throughout the sample and the decomposition was rapidly completed. Only ash and the metal oxide particles remained at the end. The results suggest that semiconductor metal oxides have an effect of promoting biomass pyrolysis in the oxidizing atmosphere.

Although biomass has been attracting much attention as a sustainable energy resource, the biomass has the problems such as high moisture content and high transportation cost due to its low density. Then, we focused on carbonization as a pretreatment to solve these problems. Carbonization of biomass, however, reduces the yield and density by losing much mass and energy as tar. To overcome these drawbacks, this study proposes to increase the yield by tar recovery with the produced char during carbonization, and to densify the tar-containing char by compression molding.

A cylindrical piece of Japanese cypress was placed in the quartz glass tube installed in two tubular furnaces aligned vertically. The char particles, which were produced from the same biomass piece under the same condition in advance, were packed to form a layer for tar recovery around the boundary between the two furnaces above the biomass sample. The biomass sample was heated at 300-400 °C in the nitrogen flow and the generated tar was recovered by the packed char particles. After heating for 30 mins, the carbonization and tar recovery yields were calculated from the mass changes of the biomass sample and the packed char particles, respectively. The carbon contents and calorific values of the biomass sample, the produced char and the tar-containing char were measured to estimate the carbon and energy yields. Also, the tar-containing char was compressed in a mold to densify it.

The tar-containing char obtained at 350 °C carbonization had a high calorific value of 27.0 MJ/kg and a carbon content of 68.5 %. Both the energy and carbon yields exceeded 70%. The char particles were pelletized with the adsorbed tar as a binder by the compression molding. The density was 1 g/cm3 or more, which is about three times that of the raw biomass.

Background

Polyurethane (PU) was originally synthetized by Otto Bayer in 1937 in Germany. Usages of them cause significantly environmental impacts. This material is very stable on a lot of different applications, such as, transportation, packaging, footwear, paint, and insulation component for refrigerators and buildings. In 2016, approximately 18 million tons of PU will be produced and 3/4 of them were in foam format. Asian countries used most of them.

Methods

A new study on biomass-polyurethane co-gasification for syngas production was performed. The feed stock blending ratio, equivalent ratio (ER), steam to biomass ratio (SB), catalyst, and CO2 blending ratio were the key experimental design parameters and the experimental design was performe by the Taguchi L18 orthogonal array. The gasification temperature was set to be 800 °C of all experiments. The reaction was performed at a continuous feed fluidized bed gasifier. The conversion of carbon in the feed, yield of various products, and the low heating values of the effluent gas was analyzed.

Results

With the presence of the polyurethane and CO2 blending in the feed stream, the yield of the syn gas and the heating value of the effluent gas were increased. The carbon conversion of the feed was increased presence of the catalyst blended in the feed. This study suggested potential route for the energy production by blending the agriculture and municipal waste in the future.

Acknowledgement

Financial support: Ministry of Science and Technology in Taiwan, ROC (MOST 107-2218-E-035-017).

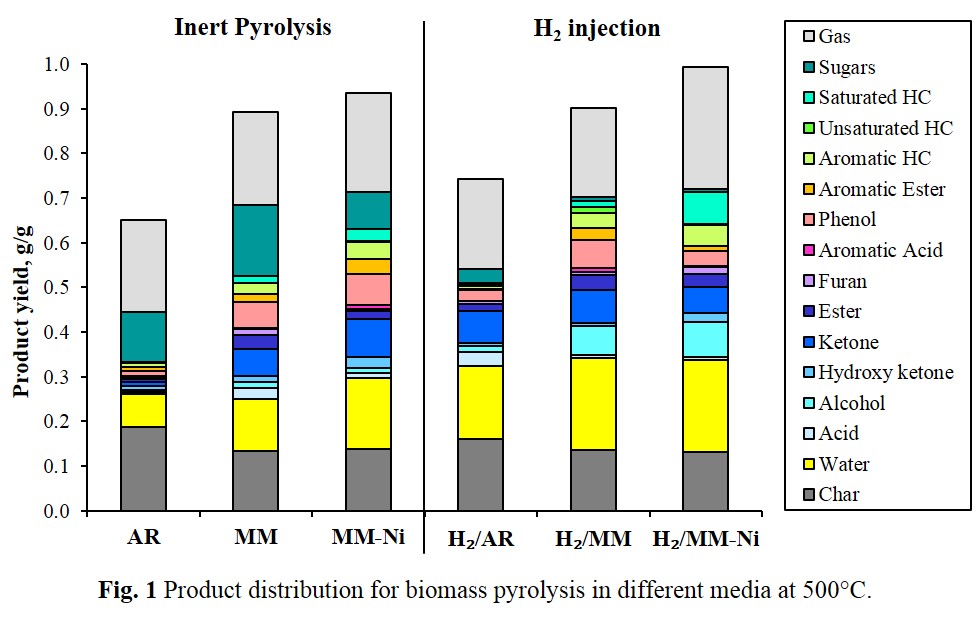

Rapid heat transfer in molten metal could potentially enhance biomass decomposition, and combining this with Ni-catalyst could also promote hydrogenation reactions. We have already indicated the effectiveness of Sn-Bi molten metal and its combination with Ni/Al2O3 for the gasification of biomass [1]. The aim of this work was to investigate the effects of these media with respect to bio-oil production. Aspen wood pyrolysis was performed at 500 °C at high heating rate in the molten metal medium (MM) and molten metal with catalyst medium (MM-Ni). Pyrolysis in the inert argon atmosphere (AR) was conducted as the control case. In addition, hydrogen injection was studied for hydro-deoxygenation of pyrolysis vapors. The results shown in Fig. 1 demonstrate that the biomass pyrolysis in the proposed media increased the yield of liquid products and reduced the char formation, thus improving carbon conversion efficiency. Fast heating rate in the media promoted the cracking of large molecules, which resulted in the production of the bio-oil having lower average molecular weight. Ni-catalyst aided dehydration, decarboxylation, and hydrogenation reactions, thereby increasing the hydrocarbon yields. Hydrogen injection further upgraded the bio-oil by successful oxygen removal and hydrogenation of unsaturated bonds. The proposed media were thus effective for the production of a higher grade bio-oil from lignocellulosic biomass.

[1] A. Arenova et al. J. Anal. Appl. Pyrolysis., 137, 61-69 (2019).

This study investigated the optimal reaction conditions for biodiesel production from soursop (Annona muricata) seeds. A high oil yield of 29.6% (w/w) could be obtained from soursop seeds. Oil extracted from soursop seeds was then converted into biodiesel through two-step transesterification process. A highest biodiesel yield of 97.02% was achieved under optimal acid-catalyzed esterification conditions (temperature: 65 degree C, 1% H2SO4, reaction time: 90 min, and a methanol:oil molar ratio: 10:1) and optimal alkali-catalyzed transesterification conditions (temperature: 65 degree C, reaction time: 30 min, 0.6% NaOH, and a methanol:oil molar ratio: 8:1). The properties of soursop biodiesel were determined and most were found to meet the European standard EN 14214 and American Society for Testing and Materials standard D6751. This study suggests that soursop seed oil is a promising biodiesel feedstock and that soursop biodiesel is a viable alternative to petrodiesel.

Saturated monoglyceride (SMG) is a main cause of precipitate formed above cloud point of biodiesel (B100), which leads to filter plugging in diesel engine. In this work, we studied the effect of SMG content (0.1–0.7 wt%) of palm biodiesel (PO-B100) on the cloud point of diesel fuels blended with PO-B100 at different concentrations (B0, B7, B10 and B20). Euro 4 and Euro 5 diesels with high and low aromatic content, respectively, were used. In case of B7, B10 and B20, the results show that the SMG content in the range of 0.015–0.020 wt% increased the cloud point for 10 oC, 5 oC and 4 oC, respectively. An adsorptive removal of SMG in PO-B100 was investigated by using natural zeolite as much cheaper adsorbents than commercial magnesium silicate (MS) and silica gel. The crystalline structure of natural zeolite and MS was studied by X-ray diffraction. Both MS and silica gel exhibited higher performance than natural zeolite in the SMG removal at 45 oC. To improve the SMG adsorption capacity, natural zeolite was treated with 1 M nitric acid solution at 60 oC. The resulting modified zeolite had an increased SiO2 content, as measured by X-ray fluorescence spectroscopy, due to dealumination effect. Moreover, it showed an improved adsorption performance: the capacity of SMG adsorption was 31.5 mgSMG g-1, corresponding to a decrease of SMG content of PO-B100 from 0.7 wt% to 0.35 wt%, when using 10 wt% adsorbent loading at 45 oC for 50 min. As a result, an increase in the cloud point of biodiesel blends was significantly retarded.

In this study, direct transesterification with a combination of methanol and a cosolvent was demon- strated to be promising for the production of biodiesel from black soldier fly larvae (BSFL) biomass. Of the solvents tested, n-hexane was identified as the most effective cosolvent for the reaction, resulting in a 14.5-fold increase in the biodiesel yield, compared with the reaction without a cosolvent. The direct transesterification using n-hexane as a cosolvent was then optimized to maximize the biodiesel yield. The highest biodiesel yield of 94.14% was achieved at an n-hexane:methanol volume ratio of 1:2 (v/v), a solvent dosage of 12 mL, a catalyst loading of 1.2 mL, a temperature of 120 °C, and a reaction time of 90 min. The properties of the BSFL biodiesel were also tested, and most—such as the biodiesel's density (875 kg/m3), water content (0.03 mg/kg), ester content (98.3%), acid value (< 0.8 mg KOH/g), viscosity (5.2 mm2/s), flash point (121 °C), and cetane index (50)— met the specifications of the European standard EN 14214. This study suggested that direct transesterification using n-hexane as a cosolvent could be a promising method for biodiesel production from BSFL and decrease production costs.

The main obstacles to the widespread use of lignocellulosic biomass include its high moisture content and low grindability. To overcome these problems, we have proposed a novel method, viz. the self-steam explosion (SE) method, which utilizes the moisture content of biomass to both reduce the particle size and enhance it properties. More specifically, the moisture content of the biomass sample is fully utilized as a steam resource to auto-hydrolyze the biomass component and yield fine particles with diameters < 2 mm through self-explosion. In this study, we demonstrated self-SE method effectively reduced the particle sizes of 8 various kinds of biomass, starting form woody biomass (hardwood, softwood, bark), bamboo, to agricultural waste biomass (rice husk, rice straw, EFB), into fine particles with high yields and quality. We calculated energy consumption of our proposed system which combines self-SE treatment and post-drying process to produce fine particles, by using aspen plus V9. It is found that our proposed system consumes 5.22 MJ/kg, which accounts for ~23% of the HHV of the solid products. However, the calculated energy consumption depends on the yield of fine particles and the moisture content of solid product after self-SE treatment.

Lignin-silica composites (LSC) has attracted much attention as a bio-renewable material. Currently, biomass is mainly used as an energy source for local power plants. However, this usage is uneconomical because of low thermal efficiency. Lignin and silica are the main components of rice straw and rice husk, and few of them are used for producing materials. Therefore LSC production was examined in this study. LSC is one of the organic-inorganic hybrid materials and considered to be applicable to a cathode material, an adsorbent for metal ions, and a polymer filler. The main problem in the application of lignin as a component of composites is the complex solubility due to the unclear structure. The structure strongly depends on the extraction process from the biomass resource. In addition, lignin has a low affinity with inorganic components. To synthesize homogeneous LSC, improvement of the affinity by chemical modification is required. In this study, we adopted kraft lignin and organosolv lignin as lignin materials and synthesized LSC by sol-gel method.

Lignin was chemically modified by reaction with formaldehyde and 3-aminopropyltriethoxysilane (APTES) in acidic 80 vol% 1,4-dioxane aqueous solution. Thus modified lignin was co-hydrolyzed with tetraethoxysilane. After the sol matured, the solution was dried to obtain LSC. FTIR was used to confirm the presence of Si in LSC. The more amount of APTES was used for modification, the more LSC was obtained. This implied the LSC contained more silica, thus modification by APTES was achieved. Organosolv LSC has more homogeneity than kraft LSC. Thus, it was concluded that the structure of the lignin greatly affected the properties of the obtained LSC.

Economic and environmental concerns have resulted in a great amount of research in the past couple of decades on renewable resources, particularly biomass, to replace fossil fuels. However, biomass is mainly used in an uneconomical way such as energy recovery by combustion. To establish the economical usage and promote the utilization of biomass, it is required to develop the scheme for producing the value-added products from biomass. To realize it, we propose a multi-step hydrolysis in hot compressed water for selective recovery of the component. This method takes advantage of the difference in the dissolving temperatures of biomass main components, cellulose, hemicellulose, lignin, and ash, enables selective recovery of each component in water by dissolving at sequential step optimal temperatures. This study aims to examine the optimal hydrolysis conditions for selective recovery of biomass main components.

At first, hydrothermal treatment was conducted at 130 °C. As a result, ash was recovered at the yield of 0.444 g/g-(ash in biomass), and this step avoided the other components decomposition, resulting in selective recovery of ash. Second, the residue was subsequently hydrolyzed at 180 °C. At this stage, hemicellulose was decomposed and xylo-oligosaccharide, known as high-value-added products in a wide range of areas, was recovered at the yield of 88.1%-(hemicellulose in biomass). At the second stage of hydrolysis, lignin was also recovered at the yield of 60.4%-(lignin in biomass). The remaining residue after hydrothermal treatment mainly consisted of cellulose, which can be saccharified by enzyme. Therefore, the proposed process can be envisaged as a great contribution to utilization of biomass.

The future energy system will be based on sustainable and renewable sources. However, the intermittent nature of solar and wind power will lead to the greater need for energy storage and flexibility of the energy infrastructure. The additional renewable energy facilities of 48.7 GW, which is composed of 63% (30.8GW) of solar power plants and 34% (16.5GW) of wind power plants will be constructed by 2030 in Korea. The power-to-gas (PtG) is a technology that enables flexible operation in the short and long term by storing renewable electricity energy into storable methane via electrolysis and subsequent methanation. Especially for power-to-methane (PtM) technology, Korea is the world's second liquefied natural gas (LNG) import country and the domestic supply rate reached over 80% in 2017. The total LNG line length in Korea is over 42,714 km; which means the existing gas distribution grid can be used and accessed easily. In KIER (Korea Institute of Energy Research), the alkaline electrolysis system with the production of 5 Nm3/h of H2 and the fluidized bed CO2 methanation reactor with the production of 1 Nm3/h of CH4 is designed and developed for the PtM technology. The operating range extended alkaline water electrolysis (AWE) technology to cope with power load fluctuation down to 10% is developed. The bubbling fluidized bed reactor was chosen for CO2 methanation reaction. The result shows that the stable operation is possible to cope with intermittent and fluctuating renewable surplus power.

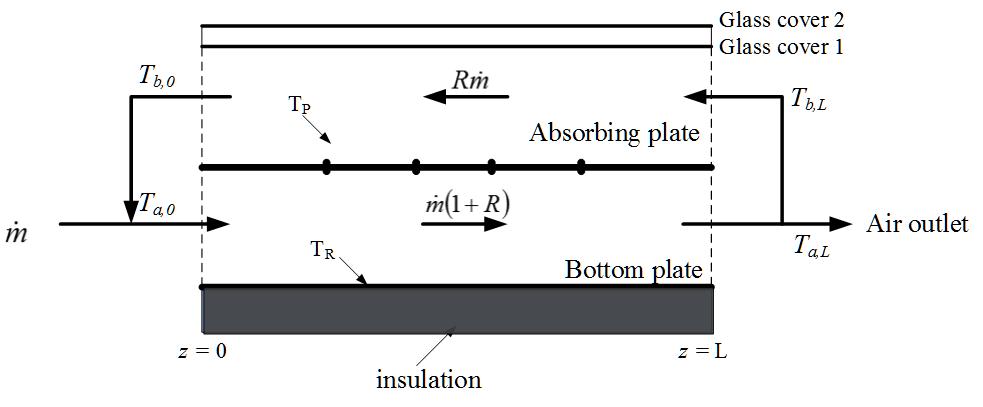

The device efficiency enhancement of the recycling double-pass solar air collectors with welding W-ribs on the absorber plate was investigated experimentally and theoretically. Operations of the solar air collector with welding W-ribs on both sides of the absorber plate were proposed to strengthen the convective heat-transfer coefficient due to the turbulent intensity increment. An economic consideration in terms of both heat transfer efficiency improvement and power consumption increment was studied to determine the optimal operating condition. A considerable device performance improvement on recycling W-ribs double-pass solar air collectors was obtained as compared to that of the flat-plate device under the same working dimensions. The good agreement between the experimental measurements and theoretical predictions was achieved within acceptable accuracy.

In recent years, most of the power supply on remote islands is by diesel power generation, and the generation of carbon dioxide accompanying the use of fuel is becoming a problem. Therefore, introduction of renewable energy such as solar power generation and wind power generation is being considered in remote islands in various places. In this study, we will construct an isolated island microgrid for the purpose of reducing carbon dioxide emissions of the Teuri island and Yagisiri island, which belong to Haboro-cho in northern Hokkaido.

At present, the power consumed by the Teuris Island and Yaishiri Island is supplied by a diesel generator already installed at the Yaishiri Island, and power is transmitted to the Teuri Island using a submarine cable. Therefore, if an abnormality occurs in the submarine cable due to a disaster or an accident, Teuri Island becomes unpowered. Therefore, in the proposed system, power is supplied by diesel power generation, solar power generation, and wind power generation. In addition, renewable energy will be installed on the Teuri Island and linked to a diesel generator to compensate for output fluctuations. In this paper, we create an analysis model using the above system using MATLAB / Simulink, analyze the introduction limit amount of renewable energy, and investigate the reduction amount of carbon dioxide emitted from the diesel generator.

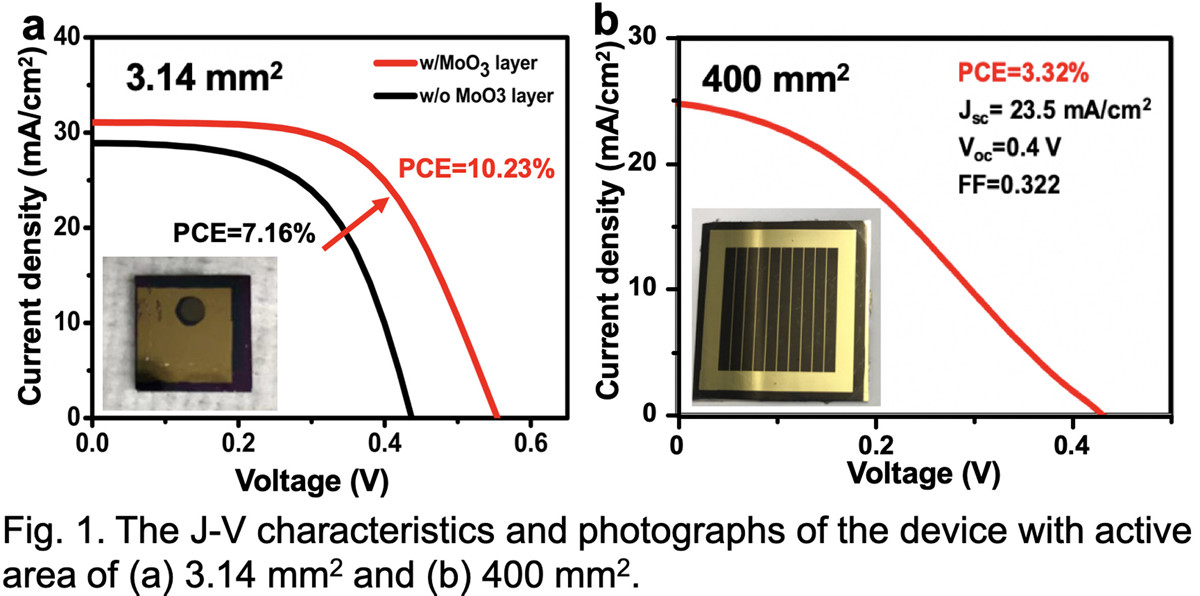

Carbon-based Si heterojunction solar cells, combining the transparent conductive carbon nanotube (CNT) films and crystalline Si wafers, have attracted increasing attention. The advantage is that the high-efficiency solar cell can be achieved in a cost-effective manner owing to the low-temperature solution process to fabricate the CNT/Si heterojunction. Since the first report of the CNT/Si heterojunction solar cell with the power conversion efficiency (PCE) of around 1.3 % by Wei et al. in 2007 [1], PCE has been improved drastically. Wang et al. reported the record-high efficiency over 17 % with an active area of 0.785 mm2 by applying a thermally evaporated MoO3 layer in 2015 [2]. However, it is essential to enlarge the active area toward practice application.

Herein, we applied the solution-processed MoO3 layer to the CNT/n-Si cells via hydration of the ammonium heptamolybdate ((NH4)6Mo7O24·4H2O) precursor [3]. Compared with the thermal evaporation of the MoO3 layer in high-vacuum, the low-cost and simple preparation process can be expected. The MoO3 layer enhanced the PCE significantly from 7.16 % to 10.23 % for the small cell (Fig. 1a). For the large cell (400 mm2), however, the efficiency remained at 3.32 % even the CNT film was doped with HNO3 (Fig. 1b). The Au bar electrodes were formed on the MoO3/CNT/n-Si structure to carry current for a large distance, and the uniformity of the MoO3 layer needs to be improved to prevent the short-circuit between Au and n-Si. It is noteworthy that the device with the solution-processed MoO3 layer showed considerable stability that remained the PCE at 80 % of its original value for more than 60 days in air without any protective layer.

The power generated from the Gibbs free energy of mixing through reverse electrodialysis (RED) is a promising renewable energy of great potential. In this study the performance of nanochannels having a pH-regulated surface in RED is examined, focusing on the influence of the bulk salt concentration, the nanochannel size, and its geometry. Taking account of the effect of osmotic flow, we consider two types of nanochannel: bullet-shaped nanochannel and trumpet-shaped nanochannel. The variations in the maximum power generation, the power efficiency, the diffusion potential, and the transference number under various conditions are investigated, and the underlying mechanisms discussed comprehensively. The results of numerical simulation reveal that the more a nanochannel is trumpet-shaped the better its ion selectivity. This is because the smaller the nanochannel space, the more significant the degree of electric double layer overlapping. For a bullet-shaped nanochannel, the maximum power generated has a local maximum as the ratio of (nanochannel length/curvature radius) varies. This can be explained by the associated diffusion potential and the electric current passing through the nanochannel. The results gathered provide desirable and necessary information for designing a RED system.

MoS2 has a layered structure and its electrocatalytic activity of hydrogen evolution reaction (HER) is strongly dependent on layer number of its nanosheets. For example, few-layered MoS2 is well known to show efficient HER activity, whereas multi-layered or bulk MoS2 show poor HER activity.Thus, a MoS2 synthesis process that allows controlling the layer number is required. We recently developed a synthesis method on few-layered MoS2 nanosheets using supercritical ethanol process and showed that synthesized materials possess a certain HER activity.

In this study, we propose a layer-number selective MoS2 symthesis process under supercritical hydrothermal reductive conditions using organic reducing agents. We systematically synthesized MoS2 nanosheets using various synthesis condition and precursors. Physical characterizations (such as XRD and TEM) and measurements of HER activity of synthesized MoS2 nanosheets are conducted. It was found that product (MoS2 or other Mo containing by-products), layer-number and HER activity of our synthesized materials are strongly dependent on synthesis condition and precursors. Detailed result of characterizations and formation mechanism of MoS2 nanosheets with different layer number are discussed in the poster session.

Water electrolysis seems to be well established technology with high energy conversion efficiency. The biggest problem is high costs of electrical energy, especially in Japan. The seawater electrolysis is one of the solutions for reduction of costs because seawater is infinite natural source. In seawater electrolysis for energy production, a huge amount of chlorine emission is not allowed. But, appropriate amount of chlorine production can be used to sterilization and industrial source. In this study, we examined to the clarify the relation between the hydrogen, oxygen and chlorine evolution behavior and electrolyte and supply conditions (pH, concentration, flow rate, etc.). The flow-type electrolysis cell was consisted that active area is 70cm2 and flow path thickness is 5 mm.

The experimentally observed the potentials of oxygen and chlorine evolution reaction are similar potentials in 3.5wt% NaCl solution (pH 6.5). However, the current efficiency of chlorine calculated from the concentration in the exit flow (impressed current density; 7.14 mA/cm2, linear velocity; 1.78 cm/s). It caused by the decreasing of chloride ion on the electrode surface due to the difference of ionic mobility.

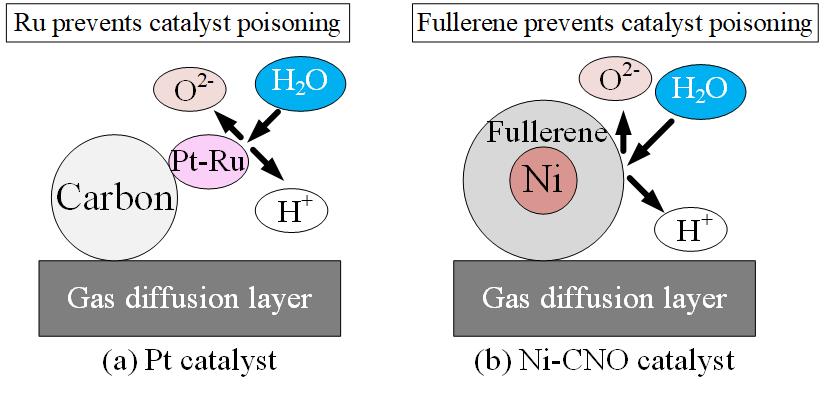

Currently, we aim for a clean energy society by introducing a large amount of renewable energy. As a method, hydrogen production using surplus power is attracting attention. In this research, we focused on PEM (Polymer Electrolyte Membrane) type water electrolyzer which electrolyzes distilled water. PEM-type water electrolyser have the advantage of not discharging carbon dioxide when producing hydrogen, but have the problem of using expensive Pt metal for the catalyst. Therefore, in this research, we used Ni-CNO (Nickel-Carbon nano Onion) coated with fullerene, consisting of a large number of carbon atoms in a closed shell cavity, which is less expensive than Pt metal. Figure 1 shows the difference in hydrogen generation mechanism between Ni-CNO and a general Pt catalyst. PEM-type water electrolyser is comprised by a separator and MEA (Membrane Electrolyte Assembly). MEA is a place where the water electrolysis reaction actually occurs, and it is a combination of a gas diffusion layer, a catalyst layer, and an ion exchange membrane. Although PEM-type water electrolyser is affected by the material as well, it is also greatly influenced by the MEA manufacturing conditions. In addition, conditions for producing MEA (Membrane Electrolyte Assembly) suitable for the Ni-CNO catalyst are unknown. Therefore, in this research, we investigated suitable MEA fabrication conditions and evaluated their performance. As the performance evaluation method, we used the energy conversion efficiency obtained by dividing heat quantity of generated hydrogen per second and the

power supplied. The best result was an energy conversion efficiency of approximately 80% compared to a common Pt catalyst. In addition, since the cost of the catalyst material is about 1/8, it is considered to be sufficient performance. As a future subject, it is necessary to investigate how the energy conversion efficiency changes when a voltage fluctuation simulating renewable energy is added.

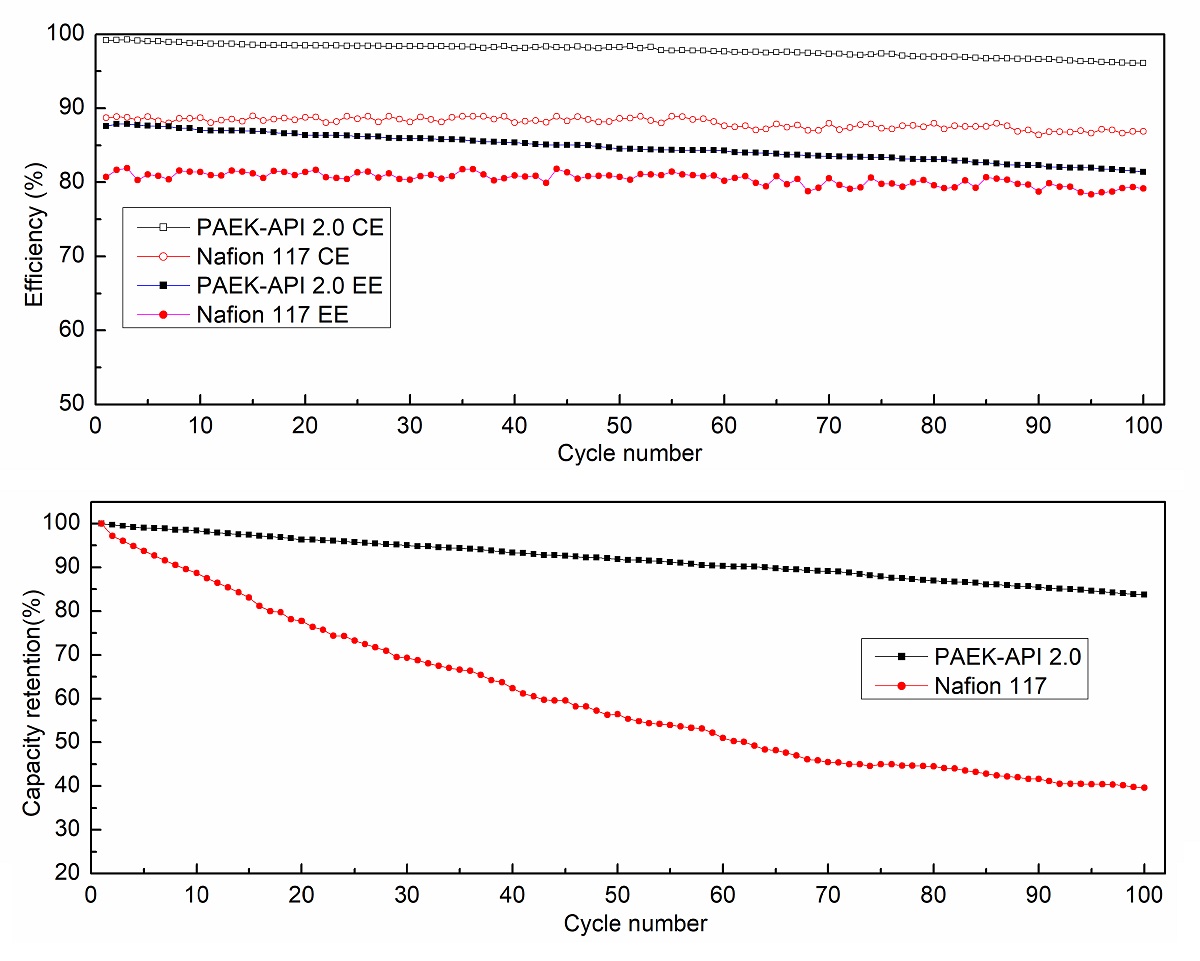

Vanadium redox flow battery (VRFB) is one kind of energy storage system (ESS), which converts electricity to chemical energy by redox reaction in each electrolyte tank. Vanadium redox flow battery is recently an attractive energy storage system of renewable energy sources for its low cost and flexible design. For the operation of VRFB, ion exchange membrane plays important role. Ion exchange membrane provides ion transfer channel for charge carriers, and it prevents electrolyte of each electrode from cross-mixing. Commercially, Nafion membrane is used for ion exchange membrane for VRFB. Although Nafion has high proton conductivity and good chemical stability, high vanadium ion permeability, which is main factor of self-discharge reaction, is major defect to be used in VRFB.

In this study, the anion exchange membrane is synthesized from poly(arylene ether ketone) with 1-(3-aminopropyl) imidazole(API) as pendant groups for vanadium redox flow battery application. PAEK is one of the hydrocarbon based polymer which has good mechanical and chemical stability, and it can be modified easiliy by introducing functional groups. Imidazolium group is one kind of positively charged functional groups, which can reduce permeability of vanadium ion by Donnan exclusion phenomena. And due to the N-heterocyclic structure in functional groups, excellent chemical stability in electrolyte solution can be expected.

As the content of imidazolium group increases, the ion exchange capacity of membrane increases, showing higher value than Nafion 117 membranes. All of the synthesized membranes show significantly low vanadium ion permeability compared to Nafion 117 membranes. In addition, During the 100 cycling test, PAEK-API 2.0 membrane shows higher coulombic and energy efficiencies than Nafion 117 membrane without any degradation.

There has been a considerable interest in one-dimensional nanostructures owing to their remarkable characteristics in particular these electronic properties which have been considered to significantly improve the electron transport time and reduce the recombination rate. The range of research area of one-dimensional nanostructures covers meanwhile a wide range of transition metal oxides. Among them, TiO2 is the most widely studied material because of its promising applications in solar-cells, photoelectrochemical hydrogen production, and CO2 reduction etc. Because, highly aligned TiO2 nanostructures have been suitable semiconductive properties with ∼3 eV and optimum band-edges to water, fast electron path way, and chemical stability.

Recently, noble metal decorated TiO2 nanotubes has been considered a key materials for photocatalytic hydrogen production. In the present presentation, we show that when growing anodic self-organized TiO2 nanotubes from Ti-noble metal alloy (Ti-Au, Ti-Pt) with at low noble metal contents, after formation the resulting oxide nanotubes show a regular self-decoration with Au or Pt nanoparticles of ∼5 nm in diameter. The average spacing is probably adjustable by the anodization conditions (in the range of ∼60 nm). The type of decoration the co-catalyst on TiO2 nanotubes leads to a very high activity for photocatalytic H2 production under UV or visible light conditions.

Anode recirculation in the solid oxide fuel cell (SOFC) increases the system fuel utilization so that the electrical efficiency of the system would be improved. However, large amounts of water (steam) existing in the recirculation loop not only decreases the cell open circuit voltage but also aggravates the concentration polarization, thereby limiting the enhancement of electrical efficiency. Therefore, proposed systems consisting of water separators could be a solution of this problem. In this study, intermediate temperature SOFC (IT-SOFC) CHP systems with anode recirculation and water separators are investigated by using Aspen Plus software to evaluate their performances. Several system configurations with various steam separator layouts are considered and the effects of anode recirculation ratio on the system performance are analyzed. Simulation results indicates that electrical and thermal efficiency of the conventional system (without water separator) could be significantly improved by adding a water separator at the outlet of the anode. On the other hand, the system adding a water separator at the inlet of the afterburner exhibits superior thermal efficiency and total efficiency at a high recirculation ratio.

In this study polybenzimidazole (PBI) nanocomposite membranes using sulfophenylated titanium oxide (s-TiO2) nanoparticles was synthesized for application in high temperature polymer electrolyte membrane fuel cell (HT-PEMFC). The neat TiO2 was surface modified via two-step synthesis to improve proton conductivity and cell performance of PBI, Different concentrations of inorganic fillers were incorporated to test their effect. The PBI nanocomposite membranes were doped with phosphoric acid (PA) for performance evaluation. Properties relating to fuel cell performance such as PA doping level, proton conductivity, PA retention and cell performance were evaluated and compared to neat PBI. Increase in performance was observed for certain concentrations while excess caused decline in performance.

Low temperature heat below 473 K is produced massively. It is useful to convert low temperature heat into electricity. In carbon dioxide (CO2) capturing systems, amine solutions absorb CO2 at 313 K and the CO2 partial pressure (PCO2) of 0.01 - 10 kPa and desorb CO2 at 393 K and PCO2 of 100-200 kPa. We consider the possibility of the low temperature cycle whose turbine is driven by the desorbed CO2 and H2O. The power cycle is as follows. An amine - CO2 - H2O mixture is cooled to 313 K in a cooler. The cooled amine - CO2 - H2O solution is pressurized in a pump and heated in a recuperator. The preheated fluid is heated at a heat exchanger by hot fluid. The CO2 - H2O gas mixture desorbed from the preheated fliud and the residue are separated by a gas - liquid separator. The CO2 - H2O gas mixture drives a turbine and expanded adiabatically. The residue heats the pressurized solution. The expanded CO2 - H2O gas mixture and the cooled residue are mixed in a mixer. The basic configuration is the same as the water - ammonia based Kalina cycle. However, it is a feature of this cycle that it contains CO2 and a large amount of water vapor in the generated gas. In our thermodynamic study, it was expected that this cycle can obtain the performance equal to or higher than that of the current ORC. Therefore, a principle verification test was carried out. The test showed ten per cent of thermal efficiency at 393 K and CO2 loading of 20 NL/L. We are planning a 10 kW amine-CO2 cycle test.

In a low temperature power cycle using amine – CO2 fluid, an amine solution absorbs CO2 at 313 K in an absorber/condenser, the CO2 absorbed amine solution is pressurized by a pump, heated by a recuperator and a boiler, and desorbs CO2 – H2O gas mixture, which drives a turbine. In our thermodynamic study, it was expected that low temperature power cycle using amine-CO2 fluid can obtain the performance equal to or higher than that of the current ORC. Therefore, a principle verification test was carried out. The test showed ten per cent of thermal efficiency at 393 K and CO2 loading of 20 NL/L. We are designing a 10 kW test equipment. We set high temperature heat source is hot water at the temperature of 363 K, which is used as a coolant of a gas engine. The heat and mass balance of the equipment was calculated thermodynamically. The result showed the flow rate of the hot water flow and amine – CO2 fluid, the turbine expansion ratio, the power, and the system efficiency are 8,200 kg/h, 1,000 kg/h, 4.8, 10.5 kW, and 7.3 per cent, respectively. The preliminary estimation shows as follows. The diameter and rotational speed of the turbine blade are 0.115 m and 54,400 min-1, respectively. The numbers of tubes in the boiler, the recuperator, and the absorber/condenser, which are shell and tube heat exchangers, are 4400, 910, 1020, respectively. The length and diameter of the tube are 1 m and 6 mm, respectively.

In the background of global warming and scarce resources depletion, Japan depends on the fossil fuel for most of energy resources. So utilization expanding of renewable energy and thorough energy conservation are necessary for stable utilization of energies and climate change measures in the future. Since Hokkaido prefecture that is a northern island of Japan has the abundant renewable energy, such as solar, wind, small and medium-sized hydropower, biomass, and geothermal energy, it will show the highest feasibility for renewable energy throughout Japan, toward the utilization of new energy. Then use concept of various energies has been proposed as an opportunity of the local production for local consumption of energy or feed-in tariffs. In this study, optimum mix and dispersed models of energy in Hokkaido prefecture were investigated to develop the technology support system utilizing energy resource dispersed in wide regions, like renewable energy and to construct the appropriate energy demand and supply system increasing the regional development or activation and the energy self-sufficiency rate. Many methods estimating substantial, available and demand amounts of regional energy were evaluated. Integrated geographic information system (GIS) supporting local governments or independent workers was designed by combining the collected and calculated amounts of regional energy. The GIS is divided into two types of Web site and stand-alone. The Web site type can be viewed for anyone in Hokkaido by accessing required data to computer. The stand-alone one may be efficient for planning and coordinating energy policies in each of local governments. Moreover, various element technologies, such as combustible waste fuel, combustion system and energy best mix for facilities group were developed to improve the regional energy balance and creation of new industry. Regarding Furano region as a typical local model, dispersed utilization models for the energy suitable to regional and industrial characteristics were proposed.

A microgrid is a localized group of electricity sources and loads typically connected to and synchronous with the traditional centralized grid (macrogrid), but it can disconnect and maintain operation autonomously. This study utilise analysis of correlation to determine the impact factors which is used to predict the demand of electricity, renewable energy sources (RES) and prices. Power dispatch of distributed generators (DG) and optimization of microgrid is designed to minimize the consumption and cost of fuel and emissions of exhaust. It is essential for power system security to set an adequate operating reserve (OR) power to compensate the unpredicted imbalance between RES generation and consumption. Matlab is used to create the prediction model and GAMS is utilised to optimize the unit commitment problem (UCP).

Keywords: Microgrid; Prediction; Neural Network; Power Dispatch; Optimization.

A chemical heat storage is advantageous in terms long periods of time storage and the high storage density are possible as compared to the direct storage methods. Normally, a reversible single reaction is utilized, then the heat storage temperature is limited. There were several MeO/H2O systems such as MgO/H2O and CaO/H2O as chemical heat storage material. However, in order to store industrial waste ranging widely in the temperatures, it's necessary to develop a new material which allows heat storage in a stepwise manner in response to temperature changes. Hydrotalcite [Mg6Al2(OH)16(CO3)4H2O] which is a kind of Layered double hydroxide (LDH), have possibility to get multi-step chemical heat storage reaction using dehydration – hydration reaction of Mg-OH, Al-OH and interlayer water. However, in order to occur the above hydration reaction, the supply of the interlayer anion of CO2 is essential, which is a major problem for the reaction rate and cycleability for chemical heat storage. Then, although it is necessary to design the kind of interlayer anions and metal ion, there have been few studies focusing on reaction reversibility of LDH. In this study, we have investigated the effect of interlayer anion on the dehydration-hydration reaction of Hydrotalcite and the application for chemical heat storage material. In addition, the potentials of the multistep chemical heat storage property have been investigated.

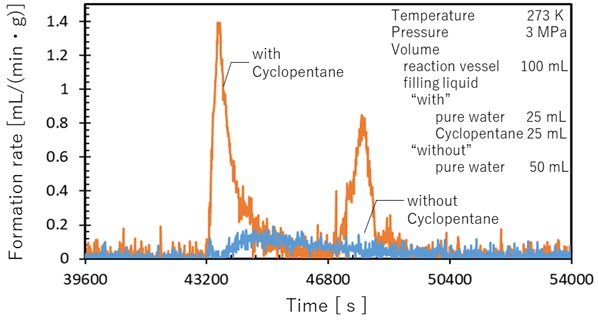

A CO2 hydrate power generation system for cold regions has been proposed, in which carbon dioxide hydrate is formed by cold heat from the outside air, and a generator is driven by high pressure gas obtained by dissociating the hydrate by supply of low temperature waste heat. The purpose of this study is to clarify the effect of formation reaction promoters on the improvement of carbon dioxide hydrate formation rate and increase of formation temperature upper limit. Cyclopentane, which shifts the phase equilibrium pressure curve to higher temperatures and lower pressures, was used as a formation reaction promoter in this study. This shift is expected to have the desirable effect of improving the formation rate, but adding the formation reaction promoter has the negative effect of reducing the amount of formation by reducing the amount of net water. In the experiment, we filled a 100 ml stainless steel reaction vessel with 50 ml of pure water or 50 ml of a mixed solution of pure water and cyclopentane at a mixing ratio of 1:1. After enough initial dissolution was performed at a desired pressure, thermal cycles of formation and dissociation for 6 hours were repeated by alternately flowing 273 K and 293 K heat media around the periphery of the reaction vessel. To calculate the formation rate, the measured values of pressure and temperature in the sealed reaction vessel were used, and the compression coefficient of CO2 was considered using the physical property database REFPROP. As a result, we were able to confirm that cyclopentane increased the formation rate and amount under the conditions without power stirring. This result suggests the possibility of improving the energy storage rate and the energy storage capacity per unit water volume of the proposed power generation system using cyclopentane.

Recently, there is an increase in energy consumption of air conditioning for a comfortable life in the residential sector. Desiccant humidity control system has been gaining an attention to improve energy utilization efficiency of air conditioning. The system can be driven by low-temperature heat and control latent heat loads easily, independent of sensible heat loads. However, dehumidification performance is getting low by lowering regeneration temperature, because effective water adsorptivity, which is a difference in the amount of adsorbed water between dehumidification and regeneration, greatly decreases at lower temperatures. To solve this problem, we have focused on thermosensitive polymer gel as a novel adsorbent for desiccant humidity control system. The thermosensitive polymer gel is well-known to switch hydrophilic and hydrophobic natures in water at a lower critical solution temperature (LCST). We expected that thermosensitive gel adsorbs water vapor below the LCST and desorbs a large amount of adsorbed water over the LCST, resulting that it can achieve a high effective water adsorptivity even by a small temperature difference between dehumidification and regeneration. In this study, N-isopropylacrylamide, 2-(Dimethylamino)ethyl methacrylate, and N-isopropylmethacrylamide were employed as thermosensitive monomers which have different LCSTs in water. They were polymerized using a radical polymerization method with N,N′-methylenebisacrylamide (MBAA) as a crosslinker at various MBAA concentrations and polymerization temperatures. Water vapor adsorption behavior of the prepared gels were measured at several adsorption temperatures and relative humidities. Finally, the applicability of the gels toward a desiccant humidity control system was evaluated from the viewpoint of effective water adsorptivity in the operation range of the system.

The improvement of chiller cycle performance has been investigated. We suggested the thermal and electric hybrid absorption refrigerator cycle. In this cycle, we selected the refrigerant and absorbent as HFC-134a (1,1,1,2-Tetrafluoroethane) and 1-Butyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide [BMIM][Tf2N] (Ionic Liquid), respectively. In this study, The Coefficient of Performance (COP) based on input heat energy for regeneration absorbent and electric power for compressor was calculated using a static analysis based on a state equilibrium in order to evaluate the effect of a compressor work on COP and regeneration temperature. As the results from analysis, the hybrid cycle could be generated cold heat below 0 °C, and driven below regeneration temperature 60 °C by assist of compressor. In addition, the absorption pressure working compressor was increased as the amount of absorption in Ionic liquid and COPsystem were obtained high value. The COPsystem was affected on the regeneration temperature, which the input sensible heat and amount of absorption in Ionic Liquid was depended on. For heat source in the temperature range of 60-90 °C, the hybrid cycle is superior in terms of COPelectricity compared to the mechanical cycle. COPelectricity was affected by liquid pump efficiency. The COPelectricity of hybrid cycle was higher than the COPelectricity of mechanical type when the liquid pump efficiency was over 0.15.

Vegetables cannot grow outside in cold regions because of snow in winter, so we focused on the plant factory which can provide a stable supply of crops. However, the plant factory consume a lot of power because they use air conditioning and lighting to grow plants. Therefore, in this research, we will consider the energy system of a clean plant factory with low power consumption. The vegetables grown in the plant factory are spinach. Spinach increase sugar content when exposed to low temperatures. This is called savoy-spinach. Therefore, in this paper, we propose a plant factory system that assumes low temperature processing of spinach. The plant factory install photovoltaics and a solid oxide fuel cell (SOFC cogeneration) with high power generation efficiency. Furthermore, in order to utilize the exhaust heat of SOFC cogeneration, an absorption refrigerator is installed to supply cold heat to the plant factory. The room temperature of the plant factory is cooled to 7 degrees Celsius, because the ambient temperature needs to be 7 degrees Celsius or less in order to perform the low temperature processing of spinach. Because the daily maximum temperature of from December to March of Kitami is less than 7 degrees Celsius, the room temperature of the plant factory is air cooled by a ventilation fan from December to March and cooled by an absorption refrigerator from April to November. The above system can be expected to reduce the power consumption of the air conditioning equipment because it effectively uses unused energy such as exhaust heat of SOFC cogeneration and outside air. Also, by introducing photovoltaics, CO2 emissions can be reduced by up to 8.45×106 kg-CO2. This corresponds to a reduction of fuel (natural gas) consumption of 3.91×106 kg, and it can be expected to reduce environmental burden.

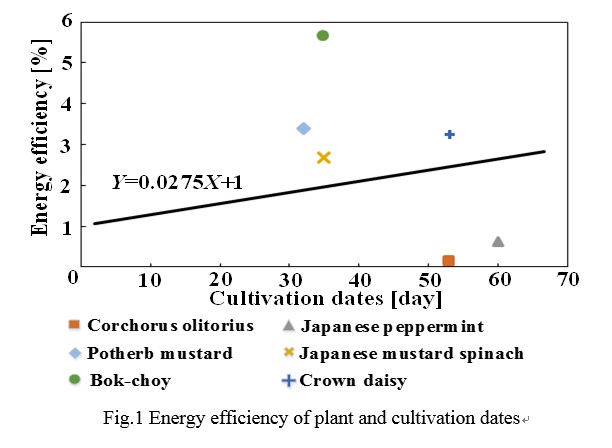

Plant factories have attracted attention because the decrease in the number of employed farmers in Japan has become a problem. However, energy costs affect profitability, as plant factories use artificial light. Therefore, we will consider the profitability of a cold region plant factory from the energy efficiency (= calorific value of plant / energy input) of Corchorus olitorius, Japanese peppermint, Potherb mustard, Japanese mustard spinach, Bok choy and Crown daisy which have vegetation in the Okhotsk region. In order to investigate the calorific value of a plant, cultivation was performed using LED, and the calorific value of the plant was measured using DSC (Differential Scanning Calorimeter). In addition, in order to investigate the input energy, the heat demand and the power demand were investigated for the cold region plant factory installed at the University. As a result of investigation, the relationship between the energy efficiency of each plant and the number of cultivation days is as shown in Fig 1. Assuming that the energy efficiency is Y and the number of cultivation days is X, an approximate expression Y=0.0275X+1 can be obtained. Furthermore, as a result of investigating profitability from the running cost at the time of cultivation at a plant factory, it was found that Corchorus olitorius and Japanese peppermint have no profit, and the other 4 types have profit. Since the lower part of the approximation line is Corchorus olitorius and the Japanese peppermint, and the upper part is the other four types, it is considered that if the energy efficiency of the plant becomes larger than the approximation formula, it may be possible to be profitable. As future issues, it is considered necessary to increase the number of surveys due to lack of data on plants that can be harvested within 30 days.

Based on the elementary reaction database on the steam reforming of methane on the Ni catalyst, an elementary reaction simulation of CO2 hydrogenation was performed. DETCHEM was used to calculate a one-dimensional reaction assuming a fixed bed reactor. The obtained results were compared with not only the methanation reaction test using commercial catalysts but also the actual measurement data obtained from the literature. The identification of the rate limiting step and the correlation between the reaction characteristics and the catalyst physical properties were examined. The temperature profile in the catalyst bed was obtained and The measured values of CO2 conversion and the reaction simulation predictions agree well.