In order to develop a novel material for chemical heat pumps using hydration/dehydration of calcium chloride, the hydration equilibrium characteristics of calcium chloride encapsulated in silica hard-shell microcapsules has been investigated. The microcapsule with the mean diameter of about 20 micron has nano-size holes on their surfaces for hydration and dehydration reaction. In this study, the effect of the nano-hole size was focused on. The effects of the shell thickness on the equilibrium characteristics of calcium chloride were also discussed. The nano-hole size was changed from 147 to 1110 nm. The open ratio of hole area to the microcapsule surface increases with nano-hole size from 0.80 to 3.9 % in the present condition. The shell thickness was changed in two steps of 1.9 and 2.3 micron. The calcium chloride six hydration was inserted into the microcapsules. The equilibrium temperature of the dehydration was measured by a thermogravimetry at atmospheric pressure. The heating rate was set at 5 K/min.

From the results, it was found that the dehydration temperature of calcium chloride included in a microcapsule is slightly low. It was also found that the equilibrium temperature decreases with the nano-hole size decrease, in spite of the pressures loss increase for finer nano-hole cases. This indicates the equilibrium condition changes due to a capillary force by interface tension or osmosis effects in the nano-holes. In the case of thin shell, the dehydration temperature was found drastically to decrease. This might occur due to the above reasons under the condition of decrease of pressure loss effects. From the present results, it was concluded that the calcium chloride encapsulated in the microcapsules with fine nano-holes and with thin shell is a promising candidate for the high-performance chemical heat pump composites.

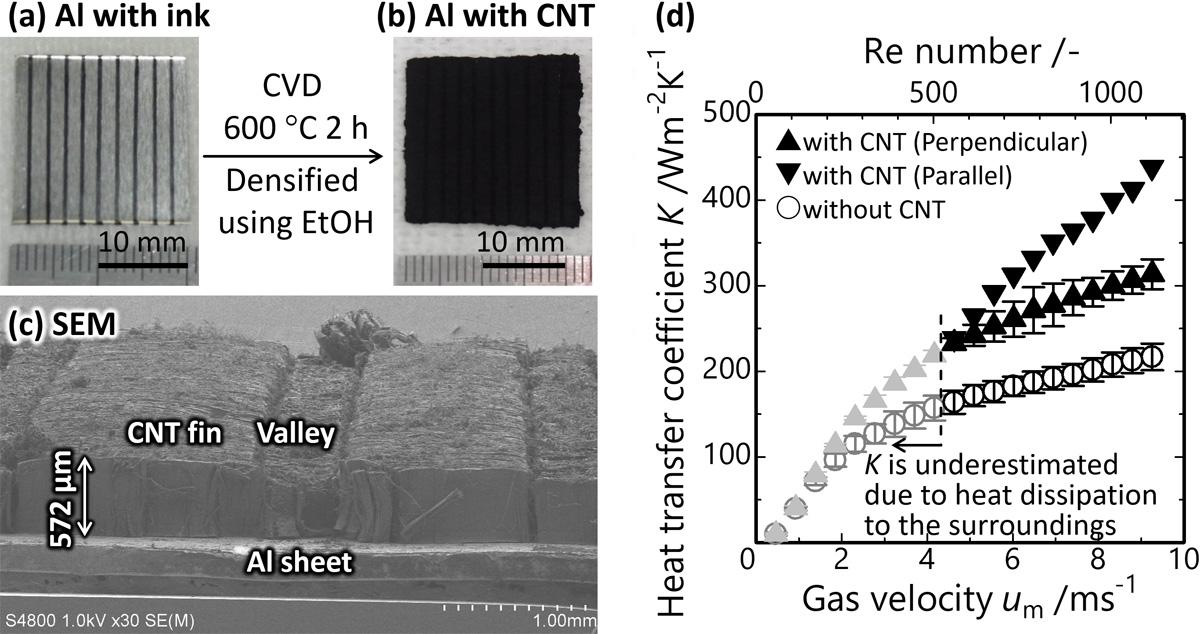

Al is widely used as a material for various heat exchangers because of its high thermal conductivity, small mass density, and high plasticity. The device performance has been improved by making the fins finer, however, it is difficult to make finer structure (< 1 mm). Carbon nanotubes (CNTs) also have high thermal conductivity and small mass density. In addition, simple fabrication of fine structure is possible via their self-organization process. Here we propose CNT-Al hybrid heat exchangers by growing micro-fins of CNTs directly on the conventional Al fins.

CNT arrays can be grown directly on Al sheets by chemical vapor deposition (CVD), however, their height remained 0.1 mm or less due to the low melting point of Al (660 °C). We realized 1.1 mm-tall CNT arrays by CVD at 600 °C [1]. To prevent the deactivation of catalyst pre-sputtered on Al, the C2H2 source was fed at low concentration with CO2 additive at high concentration. This method enabled tall CNT arrays but in a long CVD time (1.1 mm in 12 h). Then we elevated the C2H2 concentration and fed ferrocene (Fc) simultaneously, to grow CNTs fast and deposit Fe catalyst continuously. This method enabled >0.5 mm-tall CNT array in 2 h. Al sheet was prepatterned by using a pen-ink for selective catalyst deactivation (Fig. 1a) and the resulting CNT array was densified by wetting with ethanol and successive drying (Fig. 1b,c). Finally, we examined the heat dissipation performance using plate heater and N2 gas flow. Compared with the Al sheet, the performance improved about 1.5 times with the CNT fin arrays set parallel to the flow and about over twice set perpendicular to the flow (Fig. 1d). It is surprising to obtain such significant improvement. CNT fin structure induces vortex and make boundary layer thinner. Detailed analysis is underway.

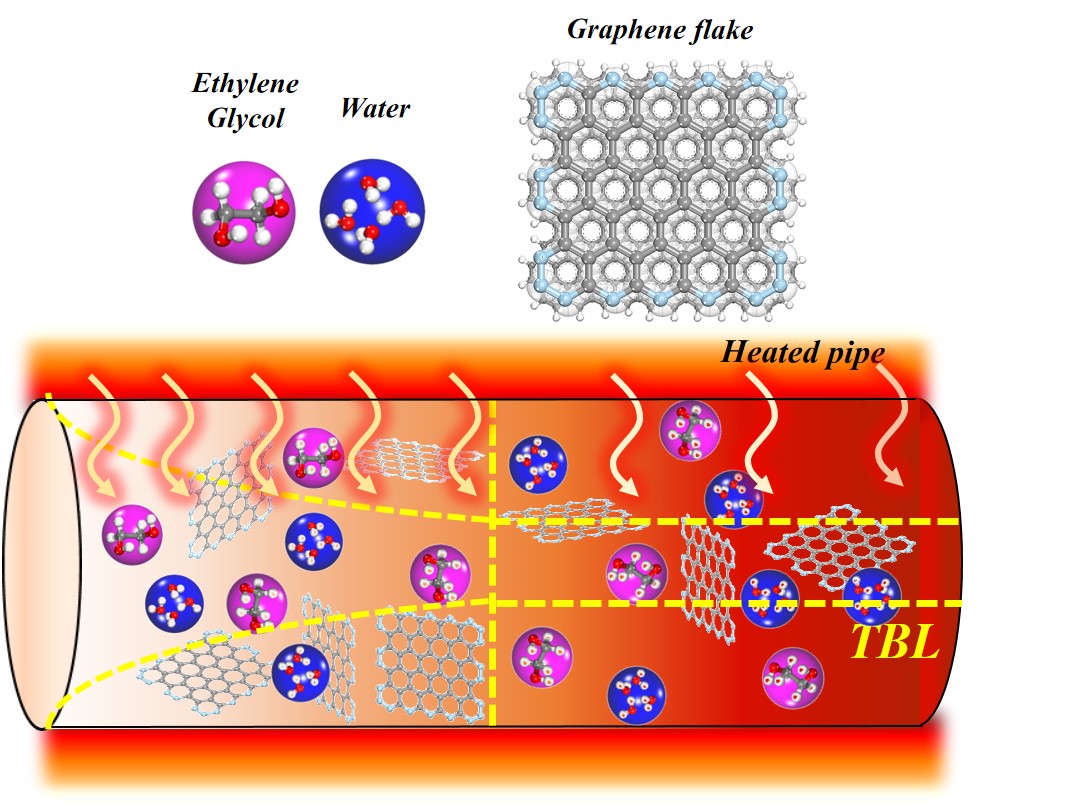

Nanoparticles in heated pipe flow are known to enhance the heat transfer ability of fluids. Although positive effects on the improvement of heat transfer ability of nanoparticles have been experimentally confirmed, it is difficult to identify the reason and mechanism of heat transfer with solely empirical way. Thus, we theoretically investigated the heat transfer mechanism of nanofluid containing graphene flakes (GFs), which exhibits good thermal conductivity, using coarse-grained molecular dynamics (CGMD). The size of 2.2 nm GF was used for nanofluids and four carbon atoms were replaced by one CG bead to maintain the hexagonal structure of GF. Heat transfer coefficient (HTC) of coolant, a mixture (50:50 wt%) of water and ethylene glycol (EG), containing GFs (1 wt%) was estimated in nanopipe flow system, of which the pipe is made of iron. Heat transfer trend was studied according to the functional groups (-H, -OH, -COOH) of GF. GF with hydrophilic functional groups (-OH, -COOH) showed higher dispersibility in the fluids than H-terminated GF. Also, nanofluid with COOH-terminated GF showed 25% higher thermal conductivity than that of without GF. In the nanopipe flow system with 0.1 â/ps of flow rate, we presented temperature, velocity, HTC profiles of nanofluids to elucidate the heat transfer mechanism. In the entrance region, GFs were located near the pipe wall and worked to transfer the heat of pipe to fluid. In the thermally fully developed region, GFs gradually moved to the center of pipe. Interestingly, the thermal boundary layer was maintained in the thermally fully developed region in the fluid. Additionally, GFs with hydrophilic functional groups showed larger HTC with higher rotation rate in the fluid.

Copper nanowire (Cu NW) with high aspect ratio was obtained by D-glucose reduction under mild hydrothermal conditions. Use of oleylamine/oleic acid as Cu NW surface stabilizer led to obtain high aspect ratio over 1,000 of Cu NWs. Addition of small amount of sodium chloride for improvement of yields of Cu NWs up to over 90 % at optimum experimental condition. After centrifugal washing and recovery, direct surface modification of Cu NWs by immersing into hexane solution of fluoroalkylthiol self-assembled monolayer (SAM) were performed for achieving long lifetime well-dispersibility of Cu NWs into hydrofluorocarbon (HFE) -base heat transfer fluids. Applying the vacuum drying process of fluoroalkylthiol SAM functionalized Cu NWs in order to remove resume solvent such as deionized water and hexane surface led to obtaining highly dispersion stability over six months of fluoroalkylthiol SAM functionalized Cu NWs into HFE fluids.

The thermal conductivities of fluoroalkylthiol SAM functionalized Cu NWs dispersed HFC base nanofluid were measured by using transit thin hot wire (THW) method. A platinum thin wire coated with 3-mercaptopropyltrimethoxysilane (MPS) / tetraethoxysilane (TEOS) / 1H, H, 2H, 2H-perfluorodecyltriethoxysilane (PFDTS) hybrid film was used as a heating element and a resistance thermometer. High quality thermal conductivity measurement could be achieved by using thicker MPS/TEOS/PEDTS hybrid insulator coated platinum thin wire because of minimizing electrical leakage of fluoroalkylthiol SAM functionalized Cu NWs nanofluid in measurement cell. The effective thermal conductivities of obtained SAM functionalized Cu NWs dispersed nanofluids were increased as Cu NW concentration increases and maximum increase ratio was up to 80% comparing with the base HFC fluid.

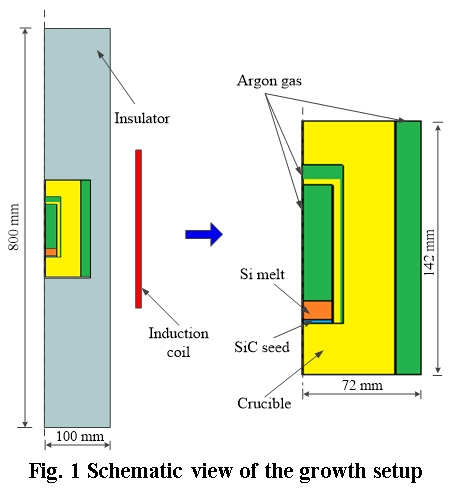

Silicon carbide (SiC) is a promising wide-band gap semiconductor material for power devices due to its high electrical breakdown field and high thermal conductivity. But the performance of SiC devices is limited by the quality of the crystal growth because of the high dislocation density and high residual stress. In order to remedy these shortfalls, solution growth processes have been developed to grow high quality crystals. One of such solution growth processes is the Top Seeded Solution Growth (TSSG) method. However, it was found that in this growth process the Marangoni convection developing in the melt is strong and has an adverse effect on crystal homogeneity [1]. Therefore, we focus on the bottom seeded solution growth (BSSG) method shown in Fig. 1, since this technique had shown reduction in dislocation density in growth of GaAs [2]. In addition, the adverse effect of Marangoni convection is not significant because the seed is at the bottom of the crucible.

To the best of our knowledge, most numerical simulations in the literature were conducted in 2D. In this study, we carried out a 3D numerical simulation to investigate the transport phenomena occurring during the BSSG process of SiC. The simulation model includes the induced electromagnetic field, the radiative and conductive heat transfer in the furnace, and the mass transfer and fluid flow in the melt. The results showed that the Lorentz force in the 3D flow structures of melt is dominant while the contributions of buoyancy and Marangoni flows are small and the corresponding flow patterns remain axisymmetric. It was also found that the crucible rotation has a significant effect on growth rate. While the crucible rotation improves crystal uniformity, it decreases the average growth rate.

[1] T. Yamamoto et al., J. Cryst. Growth., 470 (2017), 75-88.

[2] K. Hoshikawa et al., J. Cryst. Growth., 94 (1989), 643-650.

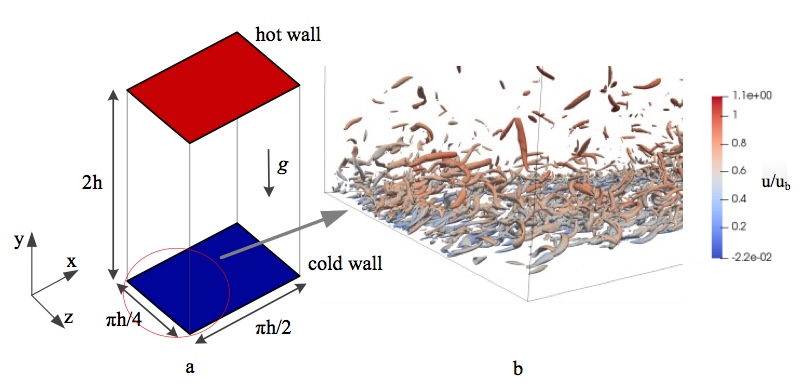

The direct numerical simulations of fully-developed turbulent plane channel flow with a spanwise narrow computational box to understand the turbulent heat transfer over the wall. We would like to demonstrate the effects of near-wall turbulent vortices on the heat transfer rate. The configuration is stably stratified channel flow with an imposed temperature difference between the top and bottom walls as shown in Fig. 1(a). The equations of continuity, Navier-Stokes and energy are discretized by using a high-fidelity spectral method and third-order Runge-Kutta semi-implicit scheme in the time integration [1].

In the present configuration, the spanwise narrow computational domain significantly reduces the computational cost and enables a parametric study of buoyancy effect on the instantaneous turbulent structures. In this study, the effect of the Richardson number which is the ratio of buoyancy force and inertial force are investigated at relatively high Reynolds number at the Prandtl number, Pr = 1. The obtained turbulent statistics are used to validate by comparing with the existing databases and the agreements and discrepancies due to the spanwise narrow computational domain are also discussed.

The vortical structures in the lower half of the channel flow are visualized as in Fig .1b using so-called Q criterion, i.e. the second invariant of the velocity gradient tensor. These turbulent vortices contribute strong turbulent intensity near the wall and turbulent heat transfer over the wall is enhanced. The effect of buoyancy on the turbulent statistics and the relationship between coherent vortices and the mean heat transfer rate will be discussed.

[1] J. Kim, P. Moin, and R. D. Moser. Turbulent statistics in fully developed channel flow at low Reynolds number. J. Fluid Mech., 177:133-166, 1987.

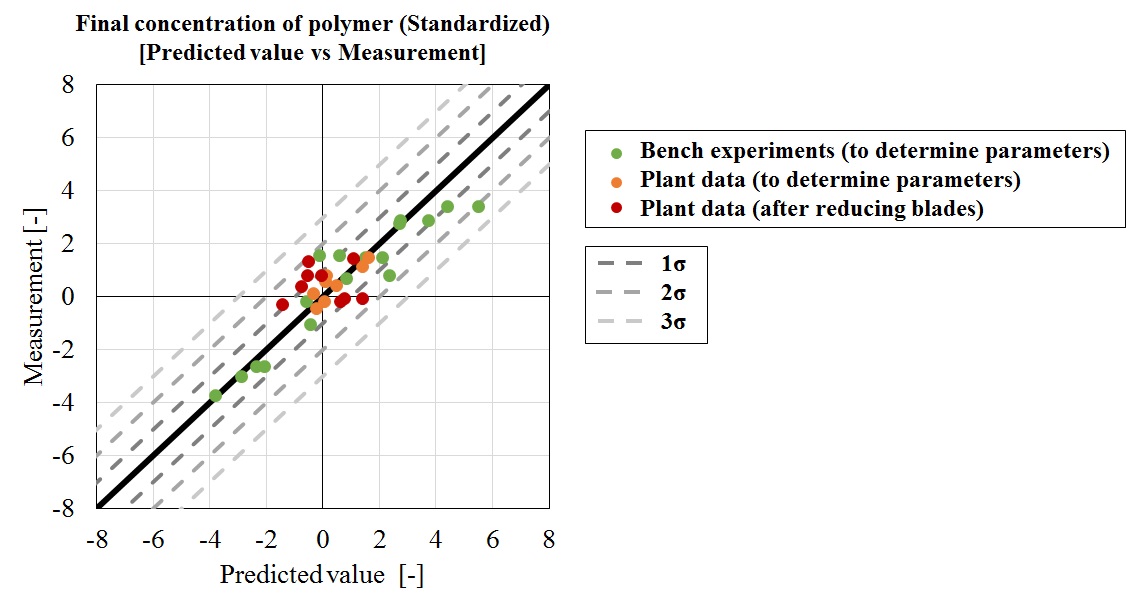

In a thin film evaporator (TFE), the axial distribution of liquid concentration is not clear, so it is difficult to predict the final concentration under various equipment design patterns and operating conditions. The focus of this research is on the evaporation of an acrylic polymer solution in TFE, a simulation model of which is proposed in this research.

In this model, the axial distribution of the concentration from top(inlet) to bottom(outlet) in TFE is simulated by sequentially calculating the shell balance of energy and mass. As outputs of this simulation, final concentration of the acrylic polymer is obtained. Parameters for correlating heat transfer coefficients and some factors are determined by least squares method using bench scale and plant scale equipment.

This simulation model is useful for predicting final concentration of polymer solution under unknown design patterns. For example, in case of changing blades number, there are several patterns (ex. position, number), and each of them have a different final concentration. By using this simulation, the several patterns of the final concentration can be calculated. As a result of changing blades number in plant scale, the measurements of the final concentration are within 2σ (95% confidence limit) of the predicted value, and it can be seen that both of them is in good agreement.

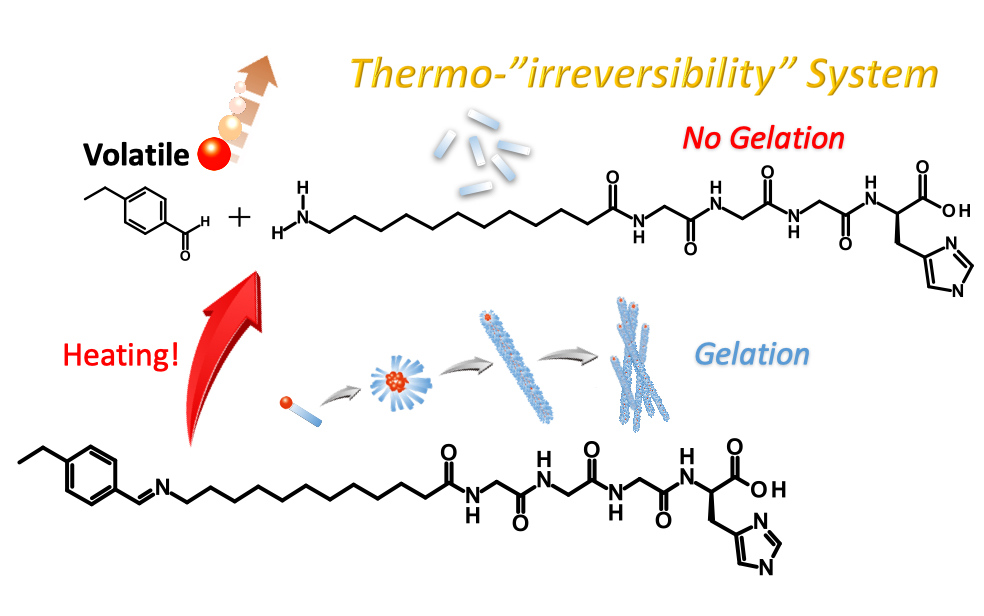

In general, a supramolecular gel is known to show reversible gel-sol transition responsive to various external stimuli such as heat and pH changes because of its weak non-covalent crosslinking. In this study, however, we designed a thermo-irreversible supramolecular gelator. The gelator was prepared by mixing a peptide lipid, NH2-C12-Gly-Gly-Gly-His (amino-C12G3H), and 4-ethylbenzaldehyde (EBAL) in an aqueous solution (pH 10.0). Mixing amino-C12G3H and EBAL forms an imine bond, which is a reversible reaction (Figure 1). We anticipated that the formation of an imine bond produced a supramolecular gelator to gelate an aqueous solution. Heating the resultant gel caused the gel-sol transition and evaporated the volatile aldehyde (EBAL). The removal of EBAL did not allow gelation upon cooling, which would achieve thermo-irreversible gel-sol transition in the supramolecular gel. In fact, the formation of a supramolecular gelator gave a supramolecular hydrogel and a microfibrous structure (self-assembly of the gelator molecules) was observed by TEM. After the supramolecular gel was heated at 80 °C for 40 min with keeping a cap of a sample vial open, the solution never turned to gel again (thermo-irreversible gel-sol transition). 1H-NMR measurements confirmed the removal of EBAL after heating. Finally, we tried to visibly record thermal hysteresis on a supramolecular gel. Tuning the EBAL concentration and heating time at 80 °C controlled the thermo-irreversible gel-sol transition, indicating that the present system can visualize and record the thermal hysteresis as gel or sol. The use of benzaldehyde as an aldehyde, which is more volatile than EBAL, allowed the thermo-irreversible gel-sol transition at 50 °C, meaning that the temperature for the thermo-irreversibility can be controlled by the selection of an aldehyde.

Power generation by variable renewable energy (VRE) is increased for decarbonization, which need suppress output to control the quality of electricity. As a power reserve, wind powered thermal energy system was proposed, which stores heat generated from rotating energy and produces steam to drive turbine or direct use. In this study, we examine Thermal Energy Storage system in Paper mill (TESP) and simulate to estimate capacity of thermal energy storage (TES) at paper mills all over Japan. Paper mills converts large amounts of energy by in-house boilers and turbines , the capacity utilization ratios (CUR) of which are fluctuated depending on the paper demand and fuel prices .

A concept of TESP is that heat from boilers and VRE is stored in TES and converted into steam or electricity like the system of concentrated solar power. Excess heat stored in TES generates constant electricity to sell to power grid. Constant generation of steam and electricity can reduce cost by raising CUR of energy plants, and decarbonize by accepting VRE .

We simulated energy balances with and without TES in a paper mills. Without TES, CUR of energy plants were low due to the fluctuation of energy demand. With TES, CUR were basically increased by storing excess heat. The necessitated capacity of TES varies by operation patterns. When production lines stop all together, large capacity of TES is required since large amounts of excess heat is generated. Through this simulation, we can estimate capacity of TES depending on paper demand all over Japan.

We conducted a simulation to design appropriate specification of TES depending on paper milling process and operation. This simulation will facilitate the design of appropriate scale of TESP depending on paper demand, cost and environmental impacts. Paper mills may be a supplier of heat and electricity from distributed energy sources.

Some processes such as flotation with nano or micro bubbles, mechanical operation like centrifuge separations and electro conglutination have been used for the demulsification of the wastewater produced from the well. Recently, demulsification by mean of usage of quick thermal response of microwave heating has been proposed as an efficient method. Our previous study found special microwave behaviors for interfacial tension between two liquids [1]. For example, there is hysteresis of interfacial tension between heating and cooling process and the tension after the irradiation does not return to the original value. Moreover, difference between thermal effect and non-thermal effect like non-equilibrium local heating, which is caused by the vibration of water molecule around the interface, is not clear. In this study, interfacial tension between decane-water was measured during and after microwave irradiation when concentration of NaCl in water was changed to investigate effect of saline solution on the microwave special behavior. First, hysteresis was observed between the heating and cooling interfacial tension as well. The above special behavior such interfacial tension reduction was confirmed and the effect was prompted by addition of salt in water phase. This is because microwave absorbs in water phase with salt more strongly. As a result, more emulsions are produced around the interface, and they interrupt tension along the interface. Recently, the efficient separation process of emulsion water produced at mining crude oil has been required. Finally, this technique has a potential as higher performance of the separation process by interface modification.

Thermal analysis of packed bed with two particles, which show different emissivities and thermal conductivities, was conducted by homogenization method. Sigmoidal curve as a function of Nusselt number with a thermal radiation coefficient was obtained. The emissivities are enclosed in the Nusselt number, and parameters representing shape of sigmoidal curve are mainly decided by ratio of the particle number and the thermal conductivities of two particles. Finally, it was found that thermal radiation analysis in more complex structures like packed bed and porous medium became simpler by homogenization method, and this multi-scale simulation is expected to contribute reduction of computational cost.

Fluctuation phenomena of plasma jet flow in an innovative long DC arc system with ring-shaped anode were successfully clarified on the basis of the high-speed camera visualization. The long DC arc with long electrode gap distance more than 350 mm has been applied to gas decomposition due to its advantages of long plasma length, resulting in long residence time of treated gas. However, large heat loss at a conventional hemispherical-shaped anode was critical issue in the long DC arc system. Therefore, a ring-shaped anode was utilized to convert large energy loss at the anode into the plasma jet flow. Calorimetric measurements were carried out to evaluate energy balance in the long DC arc system with the ring-shaped anode. Results indicated that the 60% of heat loss at the conventional hemispherical-shaped anode was converted into the plasma jet flow when the ring-shaped anode was utilized. High-speed camera observation revealed the effect of external magnetic field on the fluctuation phenomena in the long DC arc. Figure 1 shows the high-speed snapshots of arc and plasma jet (a) with and (b) without external magnetic field. Upper images correspond to the arc images while bottom images show the plasma jets. External magnetic field leads to arc swirl motion. Plasma jet fluctuates with the frequency of several tenth Hz when the magnetic field was applied. These understanding of arc and plasma jet fluctuation enables to improve the capability of long DC arc system.

Food market in Asia is expanding at dramatic rate. In the near future, there will be about 400 million rich people who will eat raw vegetables as well as Japanese people, which is a great business opportunity for the farmer in Japan who has the know-how to produce high-quality vegetables. However, the weather conditions in Asia, especially in south-east Asia, can induce poor growth of plants because of its distinctive high temperature and humidity. In this case, it is effective to put a light shielding material on the outside of the house film, but the yield loss may be caused by shy bearing of fruits due to the lack of solar radiation.

In this study, the authors investigated the effects of some greenhouse heat-shielding sheets on the yield of tomato production in hot and humid regions of Asia. In particular, the spectral and optical properties of the heat-shielding sheets were compared with those of conventional greenhouse sheets, and the thermal properties such as the temperature and the amount of solar radiation in the greenhouse covered with these were analyzed. Modern greenhouse sheets must be sufficiently strong to withstand different climatic conditions. It should allow good transmission of solar photosynthetically active radiation (PAR) and maintain the good heat insulation properties over a long time period.

Consequently, it became possible to analyze the degree of suppression of the temperature rise of the greenhouse due to absorption of heat rays and the distribution of visible light necessary for photosynthesis when using heat-shielding materials for the greenhouse at high temperature. It was suggested that focusing on the absorption rate and considering characteristic of film by wavelength are also important by this simulation.

There are many reports on calculation method for homogeneous food, but few method for heterogeneous foods such as cooked rice. In this study, using some containers for storing frozen cooked rice, which are commercially available, microwave thawing calculation method for heterogeneous food was proposed. Furthermore, change of temperature distribution with time for calculation result was compared to that of experiment result to verify accuracy.

As experiment method, cooked rice of 177g was filled into a container and was frozen with domestic refrigerator for 24 hours. When filled rice, 0.2 mm thick polypropylene film was set in the center of container to bisect the rice and get temperature distribution easily. After that, that sample was heated by microwave with 600W and temperature distribution of vertical section was captured by infrared thermal camera. Heating time was 180 s, time interval for camera shooting was 30 s.

Using FEMAP which is a commercial software, 3D model was made based on the size of microwave oven, cooked rice and container. Created model of cooked rice had 29% pore elements which were assigned randomly in the rice model. Calculation conditions were determined for electromagnetic field analysis and heat transfer analysis. When frozen cooked rice is heated, heat convection of vapor will be occurred because cooked rice has pore in the system. But heat transfer model used in this study can't calculate convection heat transfer. Therefore, we tried to estimate apparent thermal conductivity to represent heat convection. After setting condition, calculation was carried out by coupling two models.

As a experiment result, the temperature was risen from bottom side of container, then cold spot was confirmed above dent structure after microwave heating. Calculation results also showed the same tendency and change of temperature distribution with time was agreed with the experiment result. Thus, the calculation method for heterogeneous food was established.

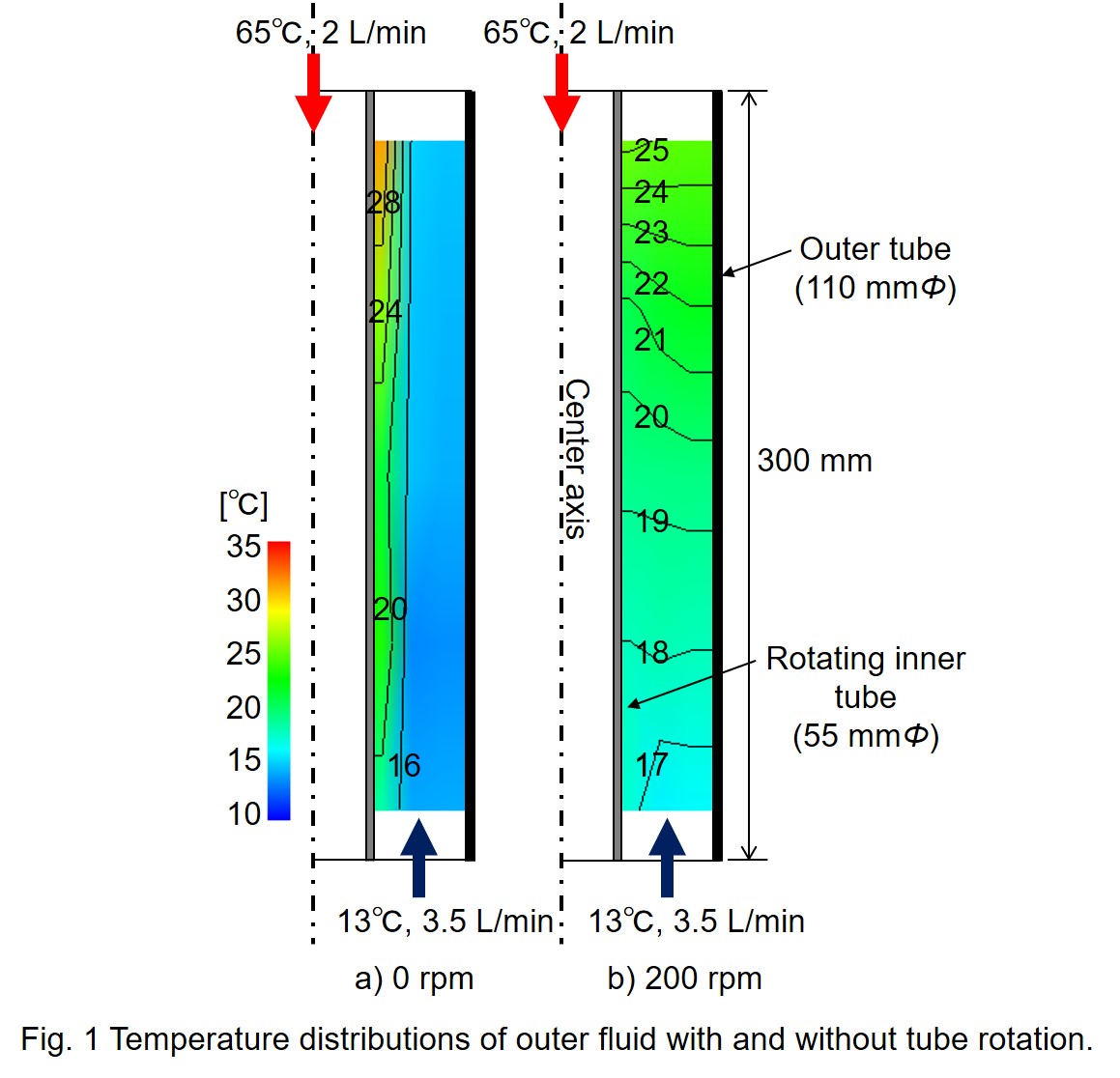

Double film robber (DFR) heat exchanger that mechanically scrapes the temperature boundary layer by the combination of the rotating heat transfer tube and the fixed blades can achieve quite high performance, namely the heat transfer coefficient higher than 10000 Wm-2K-1. It, however, is known that its performance largely depends on the operating condition, and it is necessary to grasp the improving mechanism of heat transfer rate for designing the equipment and the operating conditions. This study discussed the heat transfer mechanism from thermal fluid flow in the DFR heat exchanger. The temperature distribution in the heat exchanger was measured by inserting the multiple thermocouples. Fig. 1 shows the temperature distributions of outer fluid with and without the tube rotation. Without tube rotation, the temperature of the fluid only in the vicinity of the heat transfer tube rises. Contrarily, the temperature of fluid rises uniformly over the whole radius. This means that, not only scraping the temperature boundary layer but also the fluid mixing that lets the fluid away from the heat transfer tube to participate in the heat exchange improves the heat transfer performance.

A mathematical model that simulates atmospheric freeze-drying for minced salmon was developed and validated with experimental drying runs. This study was targeted for an atmospheric freeze-drying that operated far over the glass transition temperature of the products, where we must admit the product deformation such as shrinkage and micro-collapse due to glass-rubber transition. The developed mathematical model was based on the mass and heat balance equations, and the solution could be obtained by assuming the quasi-steady-state energy balance at the sublimation interface. Air temperature could be programmed to increase as the progress of drying in order to accelerate drying rate. A simulation was carried out based on the mathematical model by applying the experimentally obtained parameters such as mass and heat transfer coefficients, air flow temperature etc. The apparent water vapor pressure of products was assumed to be dependent on the temperature and moisture content, and it was experimentally measured by carrying out the pressure rise test for samples with different temperature and moisture content. It was confirmed that the simulation well predicts the experimental drying kinetics. The present simulation is based on a mechanistic mathematical model, so it simultaneously gives the other important values such as product temperature, mass and heat flow rates, etc. The simulated product temperature suggested that the drying progressed far above the glass transition temperature of salmon, so some phenomena that may occur in a rubbery system (e.g. shrinkage, micro-collapse) are not avoidable in this drying system. This simulation approach would be useful to design favorable drying protocol, where freeze-drying progresses under atmospheric condition.