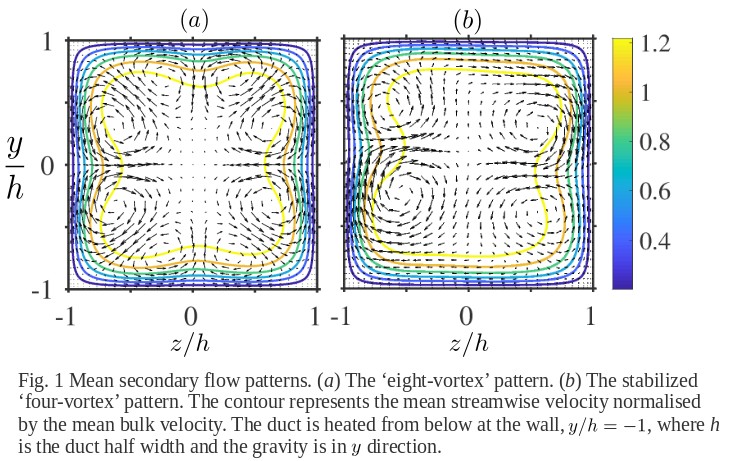

In an isothermal straight duct flow, the 'eight-vortex' secondary flow of Prandtl's second kind as in Fig. 1(a) is generated as a footprint of turbulent coherent structures [1]. When the bottom wall of the horizontal square duct is heated from below, the buoyancy affects these turbulent structures and drastically changes the skin friction and heat transfer rate over the walls and the behavior of coherent vortices under a various strength of buoyancy force the corner has been revealed at low Reynolds numbers [2]. However, at a transitional Reynolds number, the buoyancy effect has not been investigated.

At very low Reynolds numbers, the mean diameter of turbulent vortices is the same order of the duct width, therefore, the duct geometry strongly affects the generation mechanism of the secondary flow. As the bulk Reynolds number decreases, the secondary flow pattern drastically changes and becomes 'four-vortex' patterns [3]. And, at lower Reynolds number, the streamwise-localized turbulent puffs appear as in circular pipe flow.

In this study, the buoyancy effect on the four-vortex secondary flow pattern and localized puffs are investigated using direct numerical simulations. It is revealed that one of the four-vortex secondary flow patterns as in Fig. 1(b) is selectively stabilized by a weak buoyancy effect, and the generation of puffs is suppressed. Furthermore, it is revealed that the secondary flow also depends on the thermal physical property, i.e. the Prandtl number.

[1] Pinelli, A. et al., Reynolds number dependence of mean flow structure in square duct turbulence, J. Fluid Mech. 644, 107-122, (2009)

[2] Sekimoto, A. et al., Turbulence- and buoyancy-driven secondary flow in a horizontal square duct heated from below, Phys. Fluids 23, 075103 (2011)

[3] Uhlmann, M. et al., Marginally turbulent flow in a square duct, J. Fluid Mech. 588, 153-162 (2007)

Heat transfer from a heated semi-circular cylinder placed in rectangular confinement has been investigated over wide ranges of the governing parameters as Reynolds number (1≤Re≤50), Prandtl number (0.7≤Pr≤50) and blockage ratio (0.2≤β≤0.8). The numerical solutions of the obtained governing equations for flow and heat transfer have been solved by considering, steady laminar flow in a channel. The combined influence of all governing parameters (Reynolds number, Prandtl number, and blockage ratio) on the flow and heat transfer characteristics have been delineated for the above ranges of the governing parameters. The streamline and isotherm profiles are obtained and used to represent the detailed flow and heat transfer characteristics. The gross engineering design parameters like recirculation length, drag coefficient, and Nusselt number are presented for scientific calculations and record. The distribution of pressure coefficient and local Nusselt number along the surface of the semi-circular cylinder are also presented to show the local variation in the quantities. The drag coefficient has shown an inverse relationship with the Reynolds number and positive dependencies on the blockage ratio, whereas the recirculation length has shown a reverse trend. Similar to drag coefficients, the Nusselt number shown positive dependencies on Reynolds number, Prandtl number and blockage ratio. Additionally, The functional dependence of recirculation length and average Nusselt number on Reynolds number, Prandtl number, and blockage ratio have been explored and the appropriate correlations to predict the intermediate values.

Keywords: Confined flow; Semi-circular cylinder; Nusselt number; Reynolds number; Blockage ratio; Prandtl number; Newtonian fluid

The flow and sedimentation characteristics of the microcapsules including phase change materials were investigated. As a phase change material, trimethylolethane (TME) clathrate hydrate which has the latent heat of 218kJ/kg was used at the concentration of 25 wt%. The mean diameter of microcapsules was 17 μm and the density of them with TME was 1.32kg/m-3 The concentration of silica hard shell microcapsules with TME was set at 10wt%. As drag reducing surfactants, oleylbishydroxyethylmethylammonium chloride was used with counter-ions of sodium salicylate whose molar ratio to the surfactant was fixed at 1.5. The concentration of surfactans was changed from 2.000 to 6,000 ppm. Polyvinyl alcohol (PVA) was also used as a stabilizer. The concentration of PVA was changed in two steps; 0 and 2000 ppm. Sedimentation experiments were performed in a test tube and the time variation of the apparent volume fraction of micorcapsule dispersion to the slurry was measured at 10 °C of temperature. The friction coefficients of the slurries treated with those additives were measured with a once-through flow system. The Reynolds number defined with water viscosity was changed from 200 to 25,000.

From the results, it was found that the microcapsules in the cases without additives and only with PVA settled to the bottom of the test tube immediately. On the other hand, the sedimentation delays in the cases with the combination additives of surfactants and PVA. The sedimentation was also found to occur slower with increase of surfactant concentration. From the measurements of the friction coefficients, it was found the friction coefficients show lower values in the larger region of 15,000 of Reynolds number. However, the friction coefficients increase with the surfactant concentration. Thus, the optimum condition was concluded to exist for the sedimentation and fluidity.

Acknowledgements: This study was supported by JST-Mirai-project:#JPMJMI17EK.

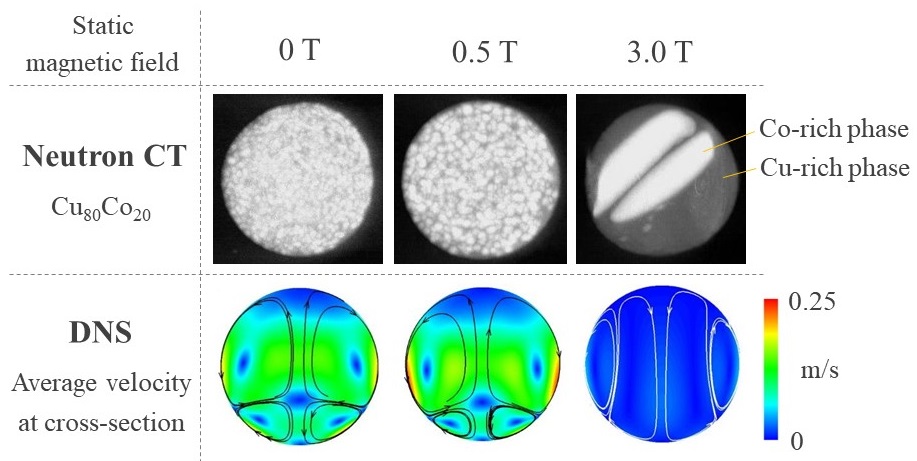

Since some Cu-based alloys, such as Cu–Co or Cu-Fe alloy, exhibit a metastable miscibility gap in the undercooled state, phase separation occurs when undercooling the alloys below their liquidus-line temperature. Such alloys are expected as new materials with novel properties depending on the phase separation structures. Although the phase separation structure is obviously affected by melt convection during undercooling, the correlation between the phase separation structure and the melt convection is not still clear.

The objective of this study is to elucidate the correlation between them in the Cu-Co alloy system. We utilized an electromagnetic levitator superimposed with a static magnetic field, which can control the strength of melt convection in an electromagnetically levitated molten alloy sample by the static magnetic field, to investigate the effect of melt convection on the phase separation structures of Cu-Co alloys. The sample diameter was 5 mm and the composition of alloys were Cu80CO20 and Cu58Co42. The strength of static magnetic field ranged from 0 to 5 T. Neutron computed tomography (CT) was used to visualize the three-dimensional phase separation structures. In addition, a series of direct numerical simulation (DNS) was also performed to calculate the three-dimensional velocity fields of melt convection in an electromagnetically levitated molten Cu-Co droplet under static magnetic fields, particularly magnetohydrodynamic (MHD) convection was focused on.

The neutron CT results showed that the phase separation structures depend on the static magnetic field strength. In particular, the marked difference in structure between 0.5 T and 3 T was observed, i.e., the size of Co-rich phases at 3.0 T is much larger than that at 0.5 T. The DNS results showed laminar-turbulent transition around 1 T. These results indicate that the marked change of phase separation structures has a strong relation with the laminar-turbulent transition.

Containerless processing is an attractive synthesis technique as it permits deep undercooling in molten materials and the catalytic sites for heterogeneous nucleation are minimized. Thus, it provides a possibility to solidify the undercooled liquid into a selected phase to synthesize metastable materials with higher density and novel properties. It also offers a new approach to grow single crystal and forming new optical glasses using the containerless processing.

For oxide material, the containless processing is usually perfomed by aerodynamic levitation and electrostatic levitation methods. Electrostatic levitation furnace (ELF) is been operated in international space station (ISS) by Japan Aerospace Exploration Agency (JAXA) for thermophysical properties measuring of oxide melts in microgravity environment. Chinese academy of science (CAS) also is developing a new electrostatic levitation furnace for using in China space station (CNN).

In the recent years, we have successfully fabricated some fuctional oxide materails: the hexagonal BaTiO3 single crystal exhibited a dielectric constant value higher than 100,000 at room temperature; the new LaTi2O5 glass with a distorted five-coordinated TiO5 polyhedra glassy structure and a refractive index value higher than about 2.2. The thermophysical properties of density, viscosity and surface tension for high temperature melts up to 3,000 K have been measured using containerless levitation technology.