In recent years, renewable energy has been attracting as alternative energy to replace the thermal power and nuclear power due to the power situation. Wind power generation has been attracting attention from power generation efficiency and equipment cost. But, there are problems about the installation of the generations, such as site area and noise, and few suitable sites that satisfy those conditions in Japan. However, since Japan has the world's sixth largest Exclusive Economic Zone, development of offshore wind power generation is being expected.

Blades of onshore wind power generation are damaged by sand erosion. It is believed that rain erosion damage will be occurred on the blades of offshore wind power generations. Rrosion on the damage, using a water jet erosion method test apparatus, studies have been conducted about the erosion damage of metal material due to droplet impact. Fiber reinforced plastic is mainly used on blades of wind power generations. In many cases, for the improvement of erosion resistance, the resin coating layer has been performed on the blades of wind power generations.

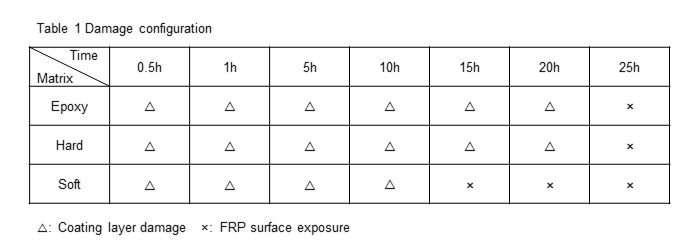

In this study, therefore, test pieces with resin coating layer were made and erosion resistance of resin coating layer was investigated by performing a rain erosion experiment. After the experiment, damaged surfaces were observed and erosion resistance of coating layer was discussed. The results obtained in this study are shown in Table 1. Erosion resistance of the test piece, which is combined with hard matrix and the hard coating layer, is higher than the test piece combined with soft matrix and the hard coating layer.

Accidents due to material degradation have occurred several times on FRP-made hydrochloric acid storage tanks. In order to prevent such accidents, we have developed a sensor that detects chemical degradation of polymeric materials using an optical fiber. This sensor has been modified to be installed at the nozzle attached on the tank for field application. In this study, problems were clarified that that occur when this sensor is applied to the actual plant, and after that, it was improved and field data was taken.

An amine cured epoxy resin including a pH indicator, such as BPB, shows discoloration when hydrochloric acid penetrates into the resin. The principle of detecting this color change by a spectroscope via an optical fiber was used for the sensor. This was loaded into a PVC blind flange and installed on a 35% hydrochloric acid storage tank in field chemical plants. By changing the embedding depth of the optical fiber, it is possible to return the time to detection, and at different depths. There was no problem in acquiring data at the time of installation, but even if it passed the water leak test, the leakage of the hydrochloric acid gas from the site where took out the optical fiber was found. To solve this problem, it was necessary to use a leakproof o-ring.

These days sewage system has many problems like high electric power consumption and aging of sewerage facilities. Development of new energy-saving wastewater treatment technology is an urgent issue for sewage works. New developed sewage treatment plant applied an “Energy Saving Wastewater Treatment Technology Using No-aeration System” method with hollow cylinder shape mineral-filled polyolefin carriers, this method a combined technology of a biological treatment and a filtration. The biological treatment uses carriers containing microorganisms and a trickling filter dissolving oxygen, and the filtration uses suspended carriers in the former and the after process. After one-year test operation, a slightly amount of degraded carriers would cause problem to the system. Thus it is necessary to analyze the degradation behavior and develop a lifetime evaluation method of these carriers inside this sewage treatment plant. In order to evaluate the performance of these carriers in this sewage environment, we conducted accelerated immersion tests under acid conditions using organic acid (acetic acid) or inorganic acid (sulfuric acid) with high concentrations and high temperature. After the samples reaching saturation, the mass change and FT-IR tests were used to analysis the changing during the degradation. The roughness of the sample surface was measured by contact angle test. Moreover, tensile tests of the cylinder shape samples and dumbbell shape samples were conducted to investigate the mechanical properties of these carriers under real sewage system condition and the ideal condition.