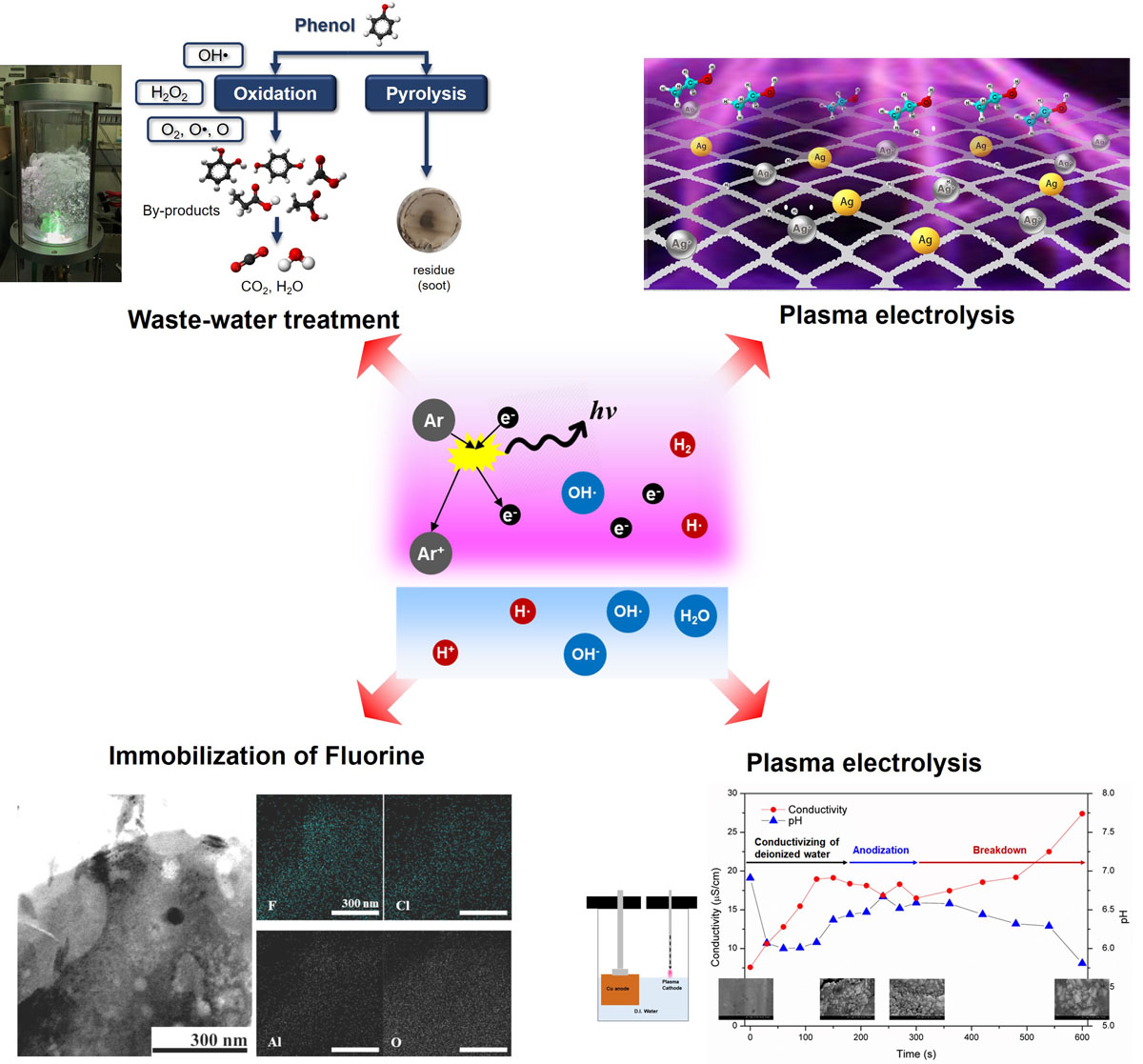

Atmospheric pressure plasma has been applied to induce a variety of unique reaction fields by supplying highly reactive species such as electrons, radicals, and ions. Among them, plasma reaction combined with water-based system has attracted intense attractions because plasma-water interaction generates various reactive species from dissociation of water molecule. Herein, applications of plasma-water interaction for fabrication of nanomaterials and treatment of waste water are introduced. Each application shows unique reaction system using various kind of plasmas and investigate the effect of plasma-water interaction. For fabrication of nanomaterials, plasma-assisted anodization and simultaneous reduction and immobilization of silver are described. Anodization of copper and zinc could be conducted using plasma in deionized water without addition of electrolyte. In this study, plasma-water interaction could increase electrical conductivity of deionized water by plasma electrolysis and trigger anodizing behavior. Meanwhile, silver nanoparticles were synthesized from reduction of silver nitrate with assist of plasma which provides reductive species. Especially, the reduction of silver could be accelerated by adding ethanol of which dissociation provides additional reductive species. When this process was conducted on the cellulose fiber, the reduced silver nanoparticles were simultaneously immobilized on the fiber. Treatment of waste water describes decomposition of phenol solution and immobilization of fluorine in fluorine-containing waste water. Decomposition of phenol aqueous solution was performed using in-liquid arc. Both oxidation and thermal decomposition were considered as the main decomposition mechanism. The oxidation occurred by hydroxyl radicals obtained from dissociation of water while the thermal decomposition was due to high enthalpy transfer from the plasma arc. The immobilization of fluorine was conducted to capture fluorine in waste water containing high concentration of HF. Alumina synthesized in situ by plasma could capture fluorine and significantly decrease the concentration of fluorine ion.

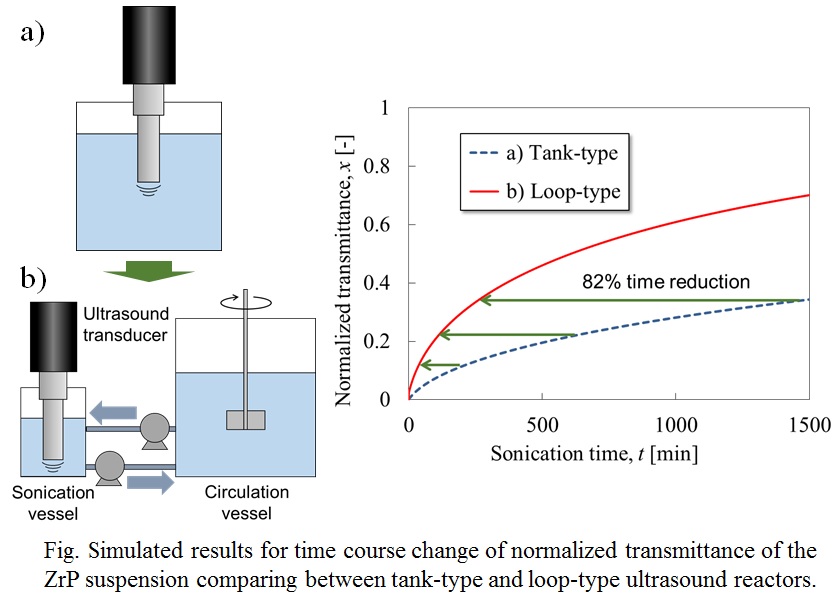

High aspect ratio nano-particles arising from the exfoliation or fragmentation of layered materials are widely used as fillers of polymers. Ultrasound irradiation is one of the potential methods to obtain the fillers rapidly and effectively. To keep up with the increasing demand of the filler production, ultrasound apparatus is expected to be developed to a large scale production process. However, ultrasound apparatus has been built only on an empirical basis since characteristic of the ultrasound and mechanism of layered compound fragmentation has not been revealed yet. In this study, the dependence of ultrasound irradiation conditions on fragmentation rate of the layered material, α-zirconium phosphate (α-ZrP), was investigated to construct the design methodology of the ultrasound process. Ultrasound generated from a horn mounted on a transducer with frequency of 20 kHz was irradiated to the α-ZrP aqueous suspension containing an intercalation agent. The fragmentation rate was evaluated by measuring the time course change of light transmittance of the suspension. The fragmentation rate was formulated with the proprietary developed fragmentation rate equation. The concentration of the α-ZrP and the ultrasound power input were varied and the fragmentation rate constants could be obtained by the linear fitting of the rate equation. It was found that the rate constant was linearly increased to the amount of ultrasound power input per unit weight of α-ZrP. Next, 4 types of sonication vessels having different volume were used to examine the vessel size effect. The smaller vessel used, the higher rate constant was obtained, and the rate constant was inversely proportional to the one-half power of volume. Eventually the fragmentation rate model could predict experimental results successfully, and the reactor model with the rate equation showed that a loop-type ultrasound reactor system with the smaller sonication vessel was promising for intensification of the ultrasound process.

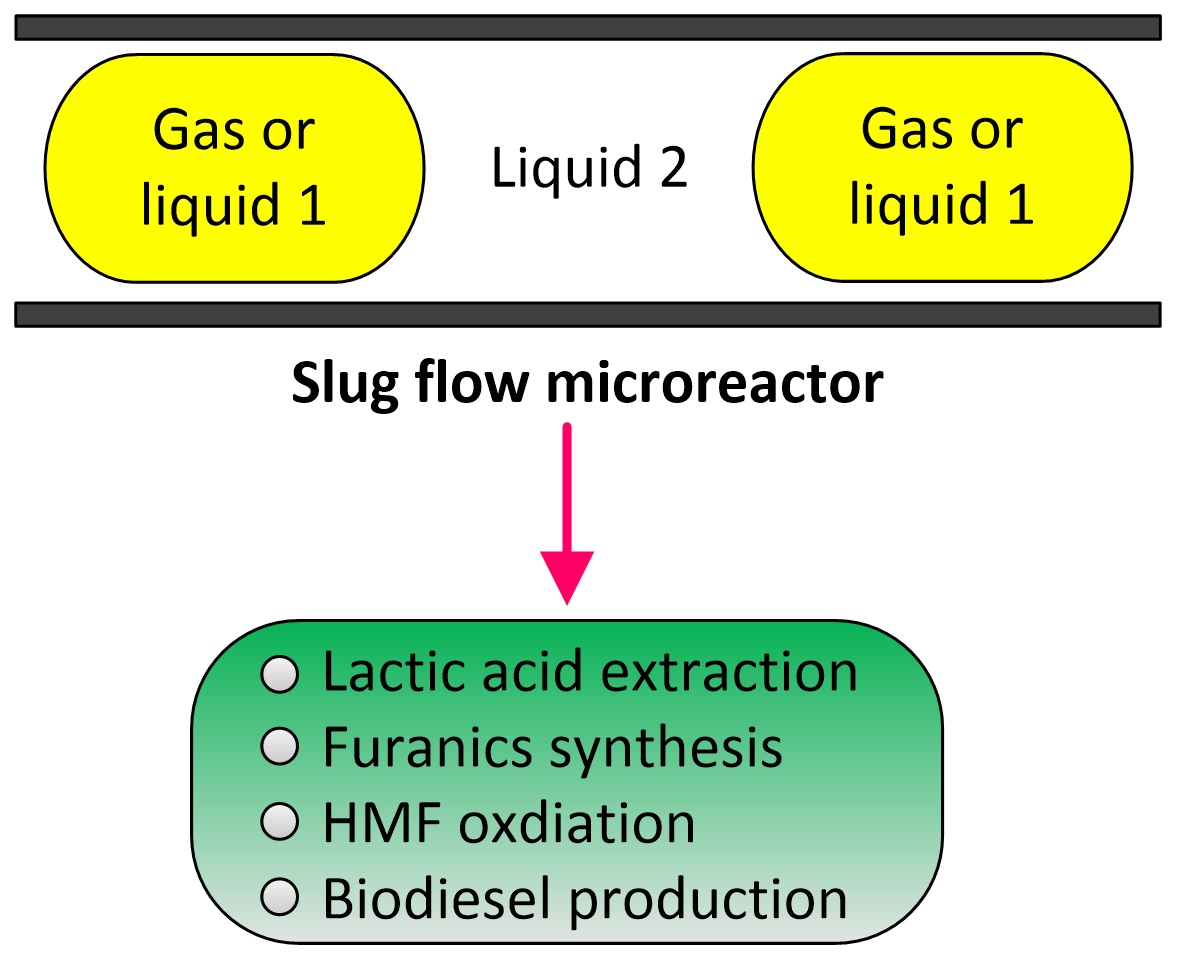

Microreactor technology as a promising tool of process intensification has received many research interests in the field of chemical and process engineering over recent decades. In this respect, the use of slug flow processing in microreactors represents an attractive alternative to carry out operations in biphasic systems (e.g., liquid-liquid extraction, gas-liquid/liquid-liquid reaction with or without the presence of homogeneous catalysts). The improved system performance can usually result from a precise manipulation of slug flow (e.g., uniform bubble/droplet dispersion, narrowed residence time distribution), and its superior mass transfer properties (e.g., high interfacial area, good mixing due to strong internal circulation). Up to now, a deep and fundamental understanding into mass transfer in slug flow microreactors is still limited, rendering the interpretation of the involved microreactor system somewhat empirical. When it comes to the emerging application areas, a number of opportunities exist for the use of slug flow microreactors within the context of green and sustainable chemistry, especially related to biomass conversion. In this presentation, our recent research highlights on mass transfer characterization in slug flow microreactors will be firstly summarized. The liquid-side mass transfer coefficient can well described based on the penetration theory, provided that the additional contribution of internal circulation within the droplet and slug under various operating conditions is properly considered. Then, the promising applications of slug flow microreactors in biobased chemical processes will be discussed. Typical examples include liquid-liquid reactive extraction of lactic acid, the synthesis of furanics (i.e. 5-hydroxymethylfurfural and furfural) from C5/C6 sugars in a biphasic system, the aerobic oxidation of 5-hydroxymethylfurfural to promising polymer building blocks (e.g., 2,5-diformylfuran), and enzymatic biodiesel synthesis. The microreactor operating principles, the slug flow mass transfer characteristics, the intensification potential as well as the (catalytic) chemistry insights will be addressed particularly.