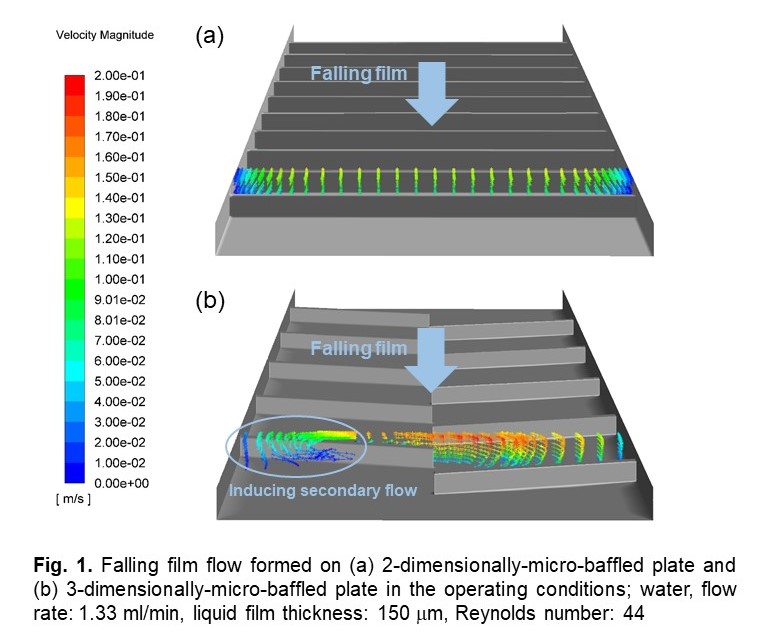

Recently falling film microreactors (FFMRs) are getting popularity for fast and exothermic gas-liquid reactions because of large specific surface area. Although FFMRs attain excellent mass transfer between phases, chemical reactions are often limited by diffusive mass transport in liquid phase. Therefore, this study aims to design novel reaction plates for promoting passive mixing and to derive the further potentials of FFMRs. First, micro-baffled plates with 2-dimensional structure are investigated numerically and experimentally in a systematic manner. The results indicate that the 2-dimensionally-structured baffles are not effective to enhance the overall mass transfer, although they can drastically change the wavy shape of gas-liquid interface and thicken the liquid film. A CFD model involving gas-liquid reaction is newly developed for the analysis of 2-dimensional wavy falling film. The CFD simulations show that gas absorption rate increases drastically in thin liquid film around the baffles while it decreases in the liquid film thickened between the baffles, and hence, the overall gas absorption rate slightly decreases compared to the standard plate without baffles. Subsequently, the micro-baffled plate with 3-dimensional structure is designed and examined. Fig. 1 shows the results of CFD simulations assuming that flat liquid film is formed on (a) 2-dimensionally-micro-baffled plate and (b) 3-dimensionally-micro-baffled plate. The vector plots in the figure show that the slantwise micro-baffled plate promotes secondary flow around the baffles, which is not observed on the 2-dimensionally-micro-baffled plate. This secondary flow is expected to enhance mass transfer. A CFD model being developed to resolve mass transfer across 3-dimensionally-wavy falling film will examine the effect of plate design and flowrate on gas absorption rate.

In a falling film microchannel, the interphase mass transfer strongly depends on the liquid-phase mass transfer behavior. The flow pattern of liquid film is predominantly laminar. And the liquid-side mass transfer relies heavily on molecular diffusion. Effectively improving the liquid film flow characteristics is the fundamental way to enhance the interphase mass transfer in falling film microchannels.

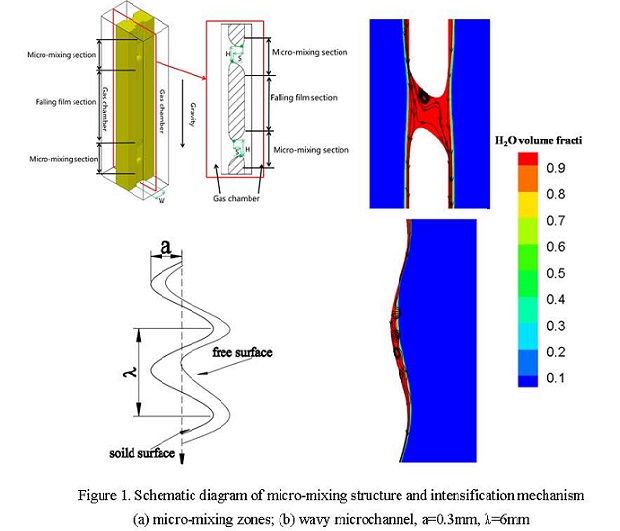

In this project, micro-mixing zones and wavy channel are configured respectively to improve the flow and mass transfer behavior of the liquid film in the falling film microchannel. The intensification mechanismes are systematically studied by experimental research and numerical simulation.

The results show that the fluid flow and mixing are improved by staggered flow mode in the double-side falling film microchannels with micro-mixing zones. Three flow patterns are observed inside the liquid film, including direct flow, cross flow, and vortex flow when the falling liquid film crosses the micro-mixing zones. Both cross flow and vortex flow intensify the surface renewal and turbulence of the liquid film, which is the fundamental reason for the enhancement of the liquid side mass transfer. The liquid side mass transfer coefficient of CO2 absorption into water is increased 7–14% by the configuration of micro-mixing zones. As the liquid flows on the falling film wavy microchannel, the liquid film resonates with the wavy microchannel wall. The surface fluctuation of liquid film can increase the gas-liquid interface area, and eddy might perturb the bottom of liquid film to enhance the mass transfer. Compared with flat microchannel, the falling film wavy microchannel increases the efficiency of CO2 absorption into water by 41%. The results suggest that falling film micorreactor with micro-mixing structrues can effectively enhance the interphase mass transfer behavior.

A large capacity micro-channel reactor called the Stacked Multi Channel Reactor (SMCR) was developed. SMCR enables having a larger capacity up to several tens liters by using a concept of numbering up of the channel than conventional micro-channel reactors and applying advantages of micro-channel reactor such as rapid heat and mass transfer to industrial chemical processes. Conventional micro-channel reactors have two dimensional structural junction such as Y-shaped and T-shaped for fluids mixing. These structures are not suitable to arrange numerous channels efficiently in an apparatus. Three dimensional structural junction for fluids mixing was adopted in SMCR. The SMCR consists of plates which have multi-channels on both sides and through-holes which connect the channels on both sides of the plate three dimensionally. This structure enables efficient arrangement of numerous channels on the plate and increasing the number of channels per unit volume of an apparatus by stacking the plates. In this work, the applications of SMCR to multi-stage continuous process, such as extraction, absorption and reaction, were investigated. Extraction experiments were carried out by using single channel equipment and SMCR bench scale equipment. The bench scale equipment consists of 3 SMCR and each SMCR has 24 channels with an inner radius of 1 mm. Total processing capacity of the bench scale equipment is approximately 0.6 liters and the processing flow rate could be on the order of several tens kilograms per hour. The bench scale equipment successfully reproduced the extraction performance of the single channel equipment. In this result, it was confirmed that SMCR can increase the throughput by numbering-up method maintaining performance in a single channel. Other applications on absorption and reaction process will be also presented on the day of presentation.

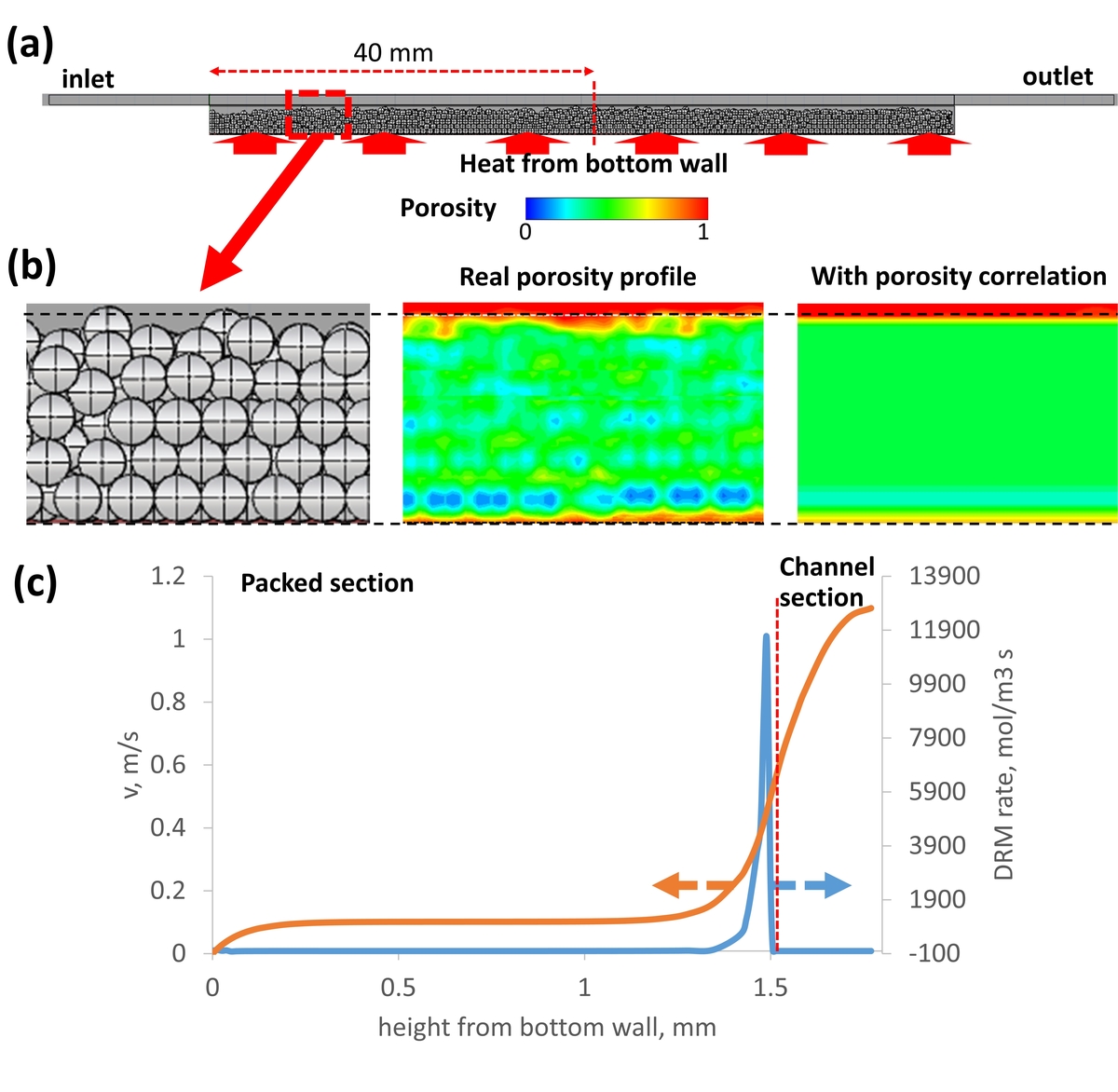

Recently, catalytic wall plate milireactor (CWPMR) has been proposed for process intensification of highly exo- and endothermic reaction by taking advantange of its high catalyst loading, scalability, and relatively low pressure loss. Although numerical study is indispensable to optimize device dimensions and operating conditions, neither of present options, namely the most accurate particle-resolved and inexpensive lumped continuum approaches, are able to achieve afforable computational cost and sufficient accuracy, respectively. In this study, computationally-inexpensive, detailed porosity profile-based continuum model has been developed and utilized to investigate different performance indices of CWPMR condcuting methane dry reforming. The new porosity profile model for CWPMR was developed by using DEM simulations. The examined range of packed layer thickness to particle size ratio (Np) was 1 to 5. The simulation results were compared to the experimental results for validation. The simulation results showed that mass and heat transport properties and their associated reaction performance were strongly influenced by the porosity profile. The highest reaction rates occured in the top region of packed layer where the momentum penetration was also observed, while the reaction rates were negligibly small in other regions as shown Figure 1. Such information can help to understand the interaction of reaction and transport phenomena in the CWPMR, as well as to improve the dimensions and design of the reactor.