Battery-assisted hydrogen production system can become one of the effective options to mitigate fossil resource consumption by utilizing variable renewable energy (VRE). In this study, the potential practicability of battery-assisted hydrogen production systems from photovoltaic (PV) power is examined on the basis of technoeconomic aspects and life cycle impacts. As an economically viable option, the conventional targets of levelized cost of hydrogen (LCOH) should be achievable by hydrogen production, e.g., less than 30 JPY/Nm3. Although the current technology readiness cannot always reach such levels, their developments based on technology roadmaps should be taken into account. As well as such technoeconomic aspects, life cycle impacts are also key performance indicators towards sustainable energy supply. For example, the life cycle greenhouse gas emission (LC-GHG) attributable to hydrogen production systems must be reduced in comparison with conventional energy supply. The abiotic resource depletion (ARD) originating in the hydrogen production should also become sustainable by reduction or circulation of irreplaceable resources. In this study, we conducted a case example on the analysis of battery-assisted hydrogen production The capacities of system components, i.e., PV, battery, and electrolyzer were defined as the design variables for minimizing LCOH, LC-GHG, and ARD. Through such quantitative analysis on hydrogen production, the conditions of battery-assisted hydrogen production required as applicable options towards sustainable energy technology options was discussed and specified.

Geopolymerization is an innovative technology that utilizes earthly-materials rich in silica and alumina to produce 3D polymeric structures called geopolymers. Sodium aluminosilicate monolith is a geopolymer used as concrete and can replace zeolite as adsorbent. In this study, compressive strength, density, porosity, and methylene blue adsorptive intensity of sodium aluminosilicate monolith produced from coal fly ash (CFA), ceramic tile waste (CTW), and spent bleaching earth (SBE) were evaluated. Using simple lattice mixture design, CFA-CTW-SBE blend with mass ratio of 55.95% CFA, 38.73% CTW, and 5.31% SBE, and an alkali solution containing 70% 8M NaOH and 30% sodium silicate, resulted to a maximum desirability of 12.4MPa compressive strength, 1310 kg/m3 density, 17.03% porosity, and 1.63% methylene blue adsorption intensity. The properties of the product conforms to the specifications of ASTM C90-14 for lightweight load-bearing concrete.

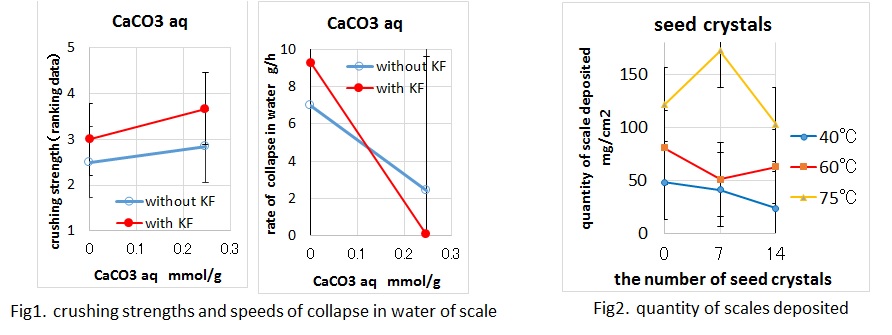

Gypsum scale in pipes has been a serious problem for a desulfurization scrubber. When there are many blocks of gypsum scale, the desulfurization efficiency decreases, and it is resulted in increase of SOx of the effluent gas. Because gypsum scale is solid and hard to collapse, it takes much time to remove the scale in a regular inspection. It is important to study why the scale is solid and hard to collapse. Therefore, a method to inhibit the formation of the scale was examined in this study. As a result of analysis, the composition of the scale was almost gypsum dehydrate(CaSO4·2H2O), 1-5 wt% calcium fluoride(CaF2), ND-1.5wt% calcium carbonate(CaCO3), and ND-0.2wt% calcium sulfite hemihydrate(CaSO3·1/2H2O). In other words, there was several percent of fluorine, and there was little calcium sulfite. Basic experiments to measure crushing strengths and rates of collapse in water were carried out. In these basic experiments, it was considered that fluorine ions and aqueous solution of calcium carbonate made the scale solid and hard to collapse (Fig 1). On the other hand, the formation of the gypsum scale and a behavior of seed crystals as a scale inhibitor were studied. As a result, when temperature was higher, the scale grew faster. However, the effect as the scale inhibitor of the seed crystals was limited (Fig 2).

Electric vehicles (EVs) has been pervasive in society to mitigate climate change in the world. A lithium-ion battery is mainly employed as an automotive battery because of a high voltage and a compact package. In view of the safety, it must be pay attention to fires and explosions of the lithium-ion battery due to vehicle fires. Therefore, investigation of combustion characteristics of materials for the battery case is important.

As materials for lithium-ion battery case, four kinds of sample plates making from flame-retardant plastics were prepared. First, standard combustion tests, UL 94 V tests, were performed. It found that the No. 15 sample was the best characteristic. Second, TG-DTA tests were performed to be clear the control factor of the combustion characteristics, and the amount of H2, CH4, CO2, and CO generation were determined. H2 generation of the No. 15 sample was the lowest. Finally, the ignition time and temperature for each sample was estimated from chemical compositions by elemental reaction simulation. In conclusion, the elemental reaction simulation using TG-DTA test results is available for evaluations of combustion characteristics.

Fiber reinforced plastic called FRP is used in various application such as fishing boats and wind generator blade etc. because of its light weight, high strength and resistance. However, it is generally difficult to recycle the waste FRP because of its high strength and resistance. As a new recycling method of the waste FRP, we proposed to make a porous water-permeable material by mixing binder with the waste FRP crushed and curing it. This material is expected the water permeable character, when it is used for paving roads, the drainage of rainwater will be effective in promoting tree growth and preventing urban floods. It is necessary to study the relationship between preparation conditions and performance focusing on the internal structure of the material. There were three processes to prepare the material. First, sieved waste FRP crushed to obtain aggregate with uniform particle size. Second, the aggregate and binder were mixed. Finally, the mixture was filled in a molding can and cured by heating and compressing. The material performances were evaluated permeable and compressive strength. They were determined by changing aggregate size, mass fraction of binder, and molding pressure. Permeability was measured by water permeability test using water head difference. Compressive strength was measured from stress-strain relationship obtained compressive test. Also, I measured an index of inner structure including porosity, tortuosity, specific surface area, and pore size for associating the relationship between preparation and performance theoretically. Porosity was measured by underwater weighing method. Others were measured by analysis of 3D image taken by X-ray computed tomography. It was found that the permeability was decreased with decreasing of the aggregate size, increasing of the mass fraction of binder and molding pressure. It is also found that there is a strong correlation between the permeability and porosity.