The polymer inclusion membranes (PIMs) composed by polymer and carrier without plasticizer have been used in this study. The extractant used in this study is containing in long alkyl chains and double bond. The great benefits of PIMs are to be used a small amount of extractant and less organic solvent and also are less leak of the extractant out of the membranes.

In the near future, it is expected that a large amount of wastes of used solar panels containing In(III), Ga(III) and Zn(II) is discharged. In this research, we were interested in alkyl-derivatives of sarcosine as an extractant to selectively separate In(III) and Ga(III) from Zn(II). Accordingly, a comparison of the metals(In(III), Ga(III) and Zn(II)) extraction was performed using four kind of extractants (two types of carboxylic acid and two types of sarcosine) and three polymers. Among them, We found the membrane containing poly(vinylidenefluoride-cohexafluoropropylene) (PVDF-HFP) as a polymer skeleton and N-oleoylsarcosine as a carrier. This membrane exhibited highly selective to In(III) and Ga(III) in hydrochloric acid solution. Finally we found that the PIM containing N-oleoyl sarcosine could perform the selectively separate In(III) and Ga(III) from Zn(II) from hydrochloric acid. In addition, we succeed in containing 60 % w/w N-oleoylsarcosine in the membrane.

We successfully developed a novel nanofiltration membrane that enables the separation of Mg2+ and Ca2+ from effluents in the electrodialysis process in salt productions. For that purpose, we first fabricated the polyamide layers using piperazine and trimesoyl chloride onto microfiltration membranes as supports, and then immobilized poly(2-methacryloyloxyethyl)trimethylaminium chloride) (polyMTMA) covalently on the surfaces and the pore walls of the polyamide layers by the plasma graft polymerization method. The polyMTMA grafted on the substrates made the membranes surface positively-charged, and at the same time reduced the pore sizes. Throughout the systematic nanofiltration experiments using various single salts with concentrations of 1.9 x 103 ppm, a membrane with a grafting amount of 0.24 mg cm-2 showed the following rejection performances that positively-charged nanofiltration membranes typically exhibit; the observed rejections (Robs) for NaCl, CaCl2, MgCl2, Na2SO4, CaSO4, MgSO4 were 0.20, 0.64, 0.65, 0.21, 0.35, 0.44, respectively. We also carried out Mg2+ separation tests from Na+-rich solutions by using aqueous solutions containing NaCl and MgCl2 with the ratios of 9:1, 14:1, and 19:1 as feed. The results indicated that around half of Mg2+ ions were retained with the permeation of more than 80% of Na+ ions.

Acknowledgement: Part of this study was financially supported by a grant from the Salt Science Research Foundation, Japan.

Oil/water separation has attracted more attention in both of academia and industry due to the increased amount of oily wastewater from the industrial process and frequent oil spill accidents, causing fatal damage to ecosystem and people's health. How to treat the oily wastewater has become a big challenge all over the world. In this work, an innovative aliphatic polyketone (PK) membrane surrounded by hydrophilic silica nanoparticles with hierarchical micro/nanoscale structure was developed by a APTES-assistance deposition process. With the APTES help to make the PK membrane positive charged, the negative charged silica was uniformed deposited on the membrane surface. The resultant silica-d-PK membrane displays superhydrophilicity, ultralow oil-adhesion underwater superoleophobicity, and distinctive self-cleaning ability, as well as excellent solvent resistance. More important, the membrane shows ultrafast and anti-oil-fouling separation performances for different oil-in-water emulsions. Therefore, it is very promising for large-scale applications.

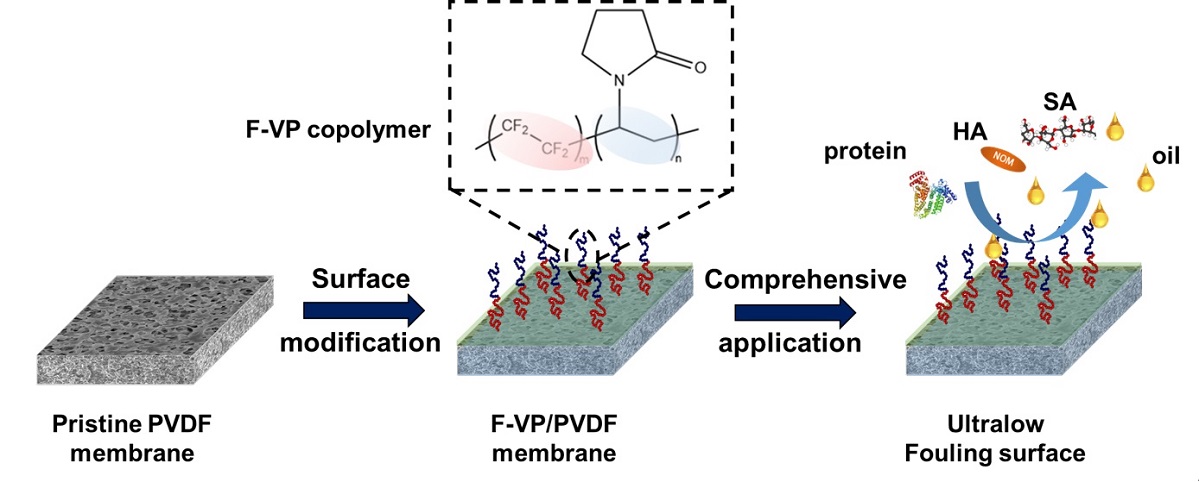

Fouling problem caused by oil and other pollutants is one of the most severe challenges for membranes used for the purification of comprehensive oil-in-water emulsions. Poly(tetraflouride-r-vinylpyrrolidone) (F-VP) with low-adhesive superleophobicity is a class of novel material for fouling-repellent membrane modification to achieve highly-efficient separation of complex oily wastewater. In this work, the construction an ultrathin F-VP layer with a controllable thickness of 2 μm supported by polyvinylidene difluoride (PVDF) substrate was achieved, via an extremely simple, scalable and one-step surface modification process. Benefiting from the ultrathin fouling-resistant skin layer, the resultant F-VP/PVDF membrane exhibited a superior comprehensive fouling-resistant and fouling releasing property, while maintained a highly mass-transfer efficiency without significant flux sacrificing. The intrinsically non-fouling nature of F-VP modification layer endowed the F-VP/PVDF membrane with superoleophobic property to various oils, superhydrophilic/under oil superhydrophilic properties, and excellent antifouling property for comprehensive oil-in-water emulsions. It is capable of efficiently separating the oil-in-water emulsions with a high water permeability of 4612 L m-1 h-1 bar-1, high emulsion permeability (10000 ppm soybean oil-in-water emulsion) of 461 L m-1 h-1 bar-1 with high rejection ratio of >99.9%, and an outstanding stable fouling-resistant and fouling-releasing property of ~93% flux recovery, over 5-time continuous cyclic tests. Overall, this work provides an insight into a facile preparation of advanced composite membrane with ultralow fouling-propensity property, which shows a great potential in treating practically challenging emulsified wastewater.

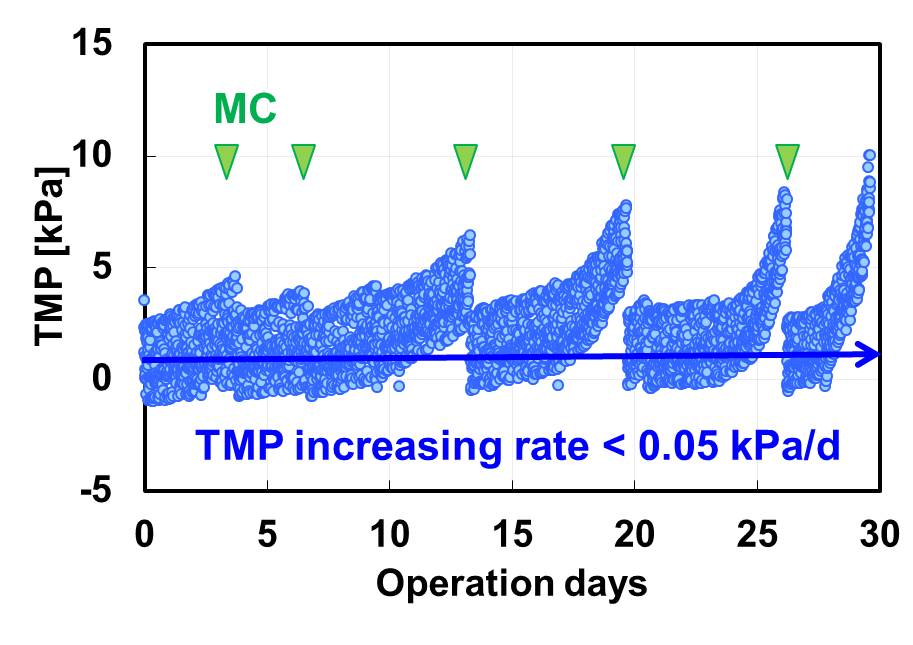

Membrane bioreactor (MBR) technology has many advantages from the views of high product water quality, small footprint and high possibility of treated water reuse. The critical challenges of MBR are membrane fouling and high energy consumption. Membrane air scouring is the main cause of high energy consumption in MBR. In fact, overall energy consumption can be reduced by operating at high flux or low air flow, on the other hand, serious membrane fouling will occur under high suction pressure. We investigated the fouling mechanism and main foulant type in high flux operation (42 LMH) comparing with low flux (25 LMH). The total amount of protein and polysaccharide clogged in the membrane at high flux operation was 2 times higher than that at low flux operation. Those clogging foulants in membrane pores were considered to be responsible for serious fouling at high flux operation. In order to mitigate those foulants, low concentration chemical cleaning, so-called maintenance cleaning (MC) was applied.

Additionally, we focused scouring efficiency to remove foulant from the membrane at low air flow operation. In order to increase scouring efficiency, new MBR structure that has 3 times higher scouring efficiency than the current MBR structure was developed. Scouring efficiency was improved by increase of the probability of contact of air and membrane in the new MBR.

A verification test using new membrane module at high flux and low air flow was conducted for a month with periodic MC every 3-7 days (Figure). The base membrane TMP (Trans Membrane Pressure) increasing rate was maintained at less than 0.05 kPa/d. The aeration energy consumption per product water was reduced 80% in high flux and low air flow operation.

Aromatics have numerous applications in the chemical and petrochemical industries (Odedairo and Al-Khattaf 2011). Transalkylation which includes transfer of alkyl group from one molecule to another is one of the prominent catalytic processes for the conversion of aromatics, especially for the production of industrially important products like xylenes, ethylbenzene, cumene, and cymene (Brown and Nelson 1953). The products of transalkylation reactions have commercial importance as they are derived from low-valued by-products like diethyl or diisopropyl benzenes, toluene, and benzene. An attempt was made to transalkylate low-valued toluene to industrially important product of great commercial value. A series of zeolite (LaB, CeB, and PrB) containing rare earth metals lanthanum (La), cerium (Ce), and praseodymium (Pr) were used for transalkylation reaction. The modified beta zeolites were characterized by EDS, XRD, BET, FTIR, and TPD. The effect of various process parameters like metal loading (2–10 wt%), catalyst loading (1.44–8.63 w/w%), temperature (448–573 K),reactant ratio 1–15, and space time (3.2–9.29 kg h/kmol)on the conversion of reactant and selectivity of product was studied. Catalytic performance of praseodymium-modified beta zeolite shows highest cumene conversion (86.4 wt%)and cymene selectivity (65.7 wt%) compared to other zeolites. The maximum cumene conversion and cymene selectivity were obtained at 523 K, toluene-to-cumene ratio of 9:1, and a space time of 9.29 kg h/kmol. Kinetic modelling of the reaction was done to estimate the reaction kinetic constants and adsorption constants. The activation energy of the transalkylation was found to be 61.44 kJ/mol.