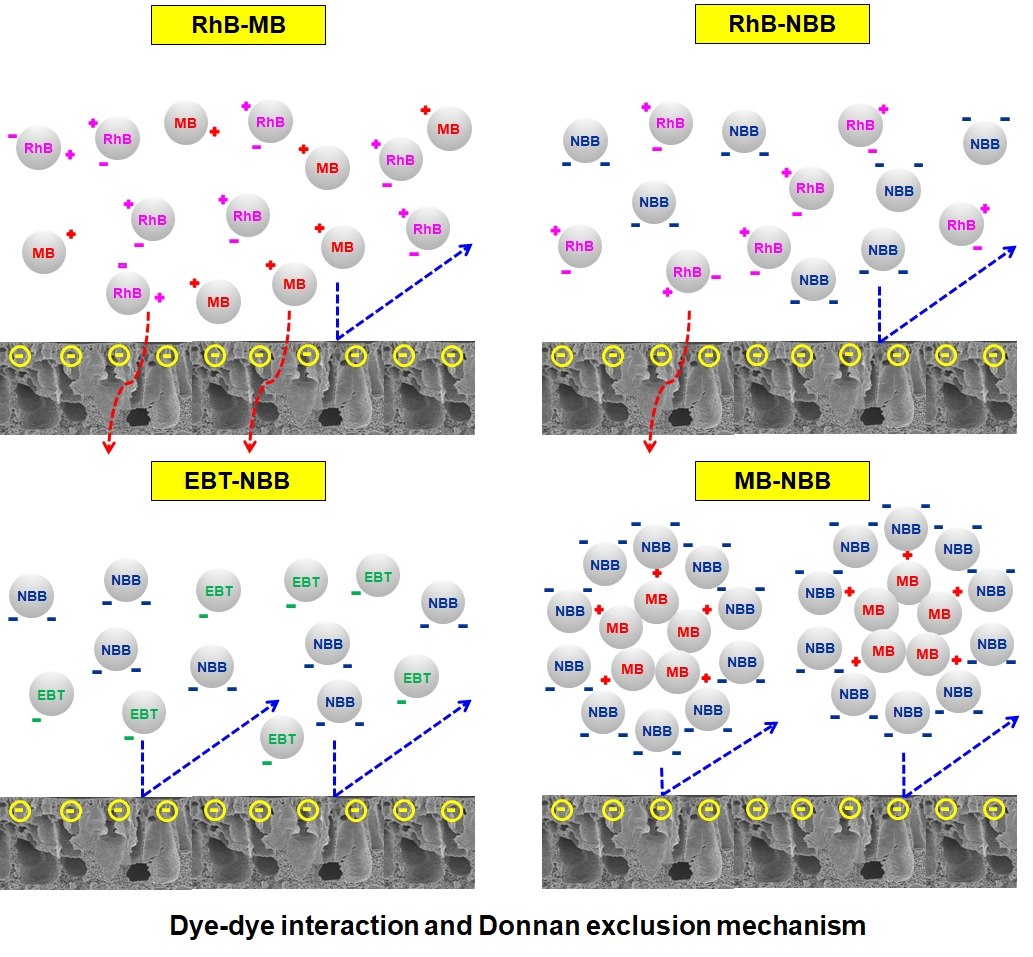

The objective of our research was to investigate the impact of dye-dye interaction on the separation performance of dual dye systems through an ultrafiltration (UF) membrane. Four representative charged dyes were chosen for single experiments, including rhodamine B (RhB) - a zwitterionic dye, methylene blue (MB) - a cationic dye, and eriochrome black T (EBT) and naphthol blue black (NBB) - anionic dyes. Four binary dye mixtures (RhB-MB, RhB-NBB, EBT-NBB and MB-NBB) were then studied in mixture experiments. A microporous poly(vinylidene fluoride) (PVDF) UF membrane was prepared via phase inversion method for the dye separation. The Donnan exclusion effect was proven as the predominant dye removal mechanism. The PVDF membrane surface was negatively charged in almost all experimental dye solutions (pH > 4.5). Therefore, zwitterionic RhB had nearly no rejection (1.1%), cationic MB exhibited low rejection (45.6%), whereas anionic EBT and NBB achieved high removal rates (83.5% and 89.1%, respectively). In dye mixtures, the mixed zwitterionic or same-charged dye solutions (RhB-MB, RhB-NBB and EBT-NBB) showed rejection efficiencies similar to their components' single dye solutions and filtrate permeance values in the range of the constituents' single dye solutions. On the contrary, in the case of the mixed opposite-charged dye solution (MB-NBB), intermolecular interaction induced the formation of micron-scale dye aggregates which provided stronger negative surface charge and were readily repulsed by the membrane. Hence, the MB-NBB mixture attained almost complete dye removal (98.0%) along with an enhanced permeation rate (111.1 L m-2 h-1 MPa-1). The excellent performance stability for all the dye feeds was demonstrated during three-cycle filtration tests. The separation mechanism proposed in this work can be applied to real dye wastewater systems of multi-components. The filtration performance may be predicted once the molecular interactions are known, and the surface zeta potentials of the solutes and membrane are identified.

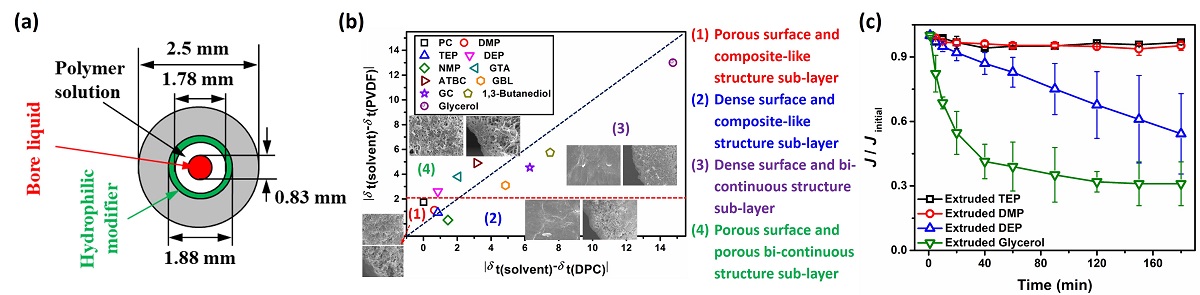

In this work, we demonstrated for the first time that by extruding solvents at the outermost layers of the extruded polymer solutions in the thermally induced liquid-liquid phase separation by using a triple orifice spinneret, both the surface and sub-layer structures of hollow fiber membranes were effectively tailored. Hence, four essential characteristics of the membranes, permeability, rejection, permeation stability and mechanical strength were balanced here simultaneously.

The ternary interactions among the extruded solvents, diluent and polymer played a substantial role in tailoring the surface pore size and permeation stability of TIPS-prepared membranes. At the interfaces between extruded solvents and polymer solutions, apart from the segregations of diluent or polymer that control the surface pores size, composite-like structure (spherules connected by the bicontinuous network) at the sub-layer substantially affected the membrane permeation stability. Regarding the importance of the ternary interaction in tailoring the surface pore size and the permeation stability of the prepared membrane in TIPS process, turn on a spotlight for selecting appropriate extruded solvents to obtain hollow fiber membranes with high water permeability, permeation stability, controlled pore size, and satisfying mechanical strength.

Jatiluhur dam is one of the biggest dams in Indonesia which serves water for various activities of millions of West Java population such as for fisheries, agricultures, recreations and also as a source of clean water and drinking water. The water comes from Citarum River which passing through different areas thus dissolves various impurities during their travel along the river body. One of the impurities that usually occur in surface water is natural organic matter (NOM) that extracted either from the soil or decaying of plants or animals contacted with the water body. NOM may harmful to human since during water treatment it will produce DBPs (Disinfection by Products) which are carcinogenic compounds.

This study is aimed to investigate the characteristics of NOM at Jatiluhur dam water and their removal efficiency using membrane. The water was obtained at 0.2 and 5 m depth and taken at two different seasons; rainy and dry season. Meanwhile, one commercial ultrafiltration membrane and two commercial nanofiltration membranes were investigated at various pressure and pH for NOM removal. The research found that the characteristics of NOM found on Jatiluhur dam were dominated by hydrophobic compounds either at rainy or dry season. The best permeability was obtained by using ultrafiltration membrane at pH 6 and 6 bar operated pressure. Whilst, higher rejection is obtained by nanofiltration membrane by around 73% of the NOM was rejected at pH 6 and 4 bar operated pressure.

Keywords: Membrane, NOM, Jatiluhur Dam, Drinking Water, Hydrophobicity

Energy conservation of distillation processes is still an important issue in process industries. Though the heat pump has been said to be a promising tool for energy saving, it has not been applied to many processes. One of the drawbacks that obstructs the installation is the high equipment cost of the custom-ordered compressor. In this paper, we propose to introduce a general-purpose heat pump system (G-HP) to the distillation processes. G-HP is superior to a custom-ordered heat pump in the cost and the maintainability, that is very important feature for the long term operation.

The G-HP proposed in this research uses water as the working fluid in the heat pump. The coefficient of performance (COP) decreases with the increase of the temperature difference between the heat source and the heat sink. Thus, it is preferable to select the heating and cooling stages that has small temperature difference. On the other hand, the efficiency of distillation is highest when the heat is supplied to the reboiler (highest temperature position) and removed from at the condenser (lowest temperature position). It means that the proper selection of the heating and cooling places is important.

In this study, by taking the simplicity of the process structure into account, the vapor to the condenser is selected as the heat source. The required compress ratio depends on the selection of the heat supply stage and affects COP. We executed the simulations of the cases having various VLE curves and product specifications, and derived the best location of the heating stage and the condition suitable for the introduction of G-HP. The effectiveness of the structures having double heat pumps that supplies heat to the middle of the column and the reboiler, and those having double feed streams is also discussed.

Since methanol is an attractive fuel and chemical for various applications, its demand will continue to increase in energy year. Most methanol is currently produced from fuel such as natural gas through steam reforming. A methanol–water mixture is produced from the carbon monoxide or carbon dioxide and hydrogen in the presence of a catalyst and distilled to acquire pure methanol.

Self-heat recuperation was recently developed as an energy-saving process design, in which overall-process internal energy caused by condition changes is recirculated within the process without the need for heat addition, leading to a reduction in the energy requirements of several chemical processes.

In this study, the feasibility of applying self-heat recuperation technology to the industrial methanol synthesis process which possesses both temperature and pressure changes, a reactor and separators was investigated from energy-saving and process design points of view, based on actual plant data. Based on simulation results, it was concluded that the use of self-heat recuperation technology is an attractive alternative for sustainable future development of the methanol synthesis process.

Mass transfer was both experimentally and theoretically investigated based on shell model for a packed distillation column equipped with wire-mesh structured packing. The experimental column consists of three packed beds stacked in series and total bed height is 5,320 mm. In order to observe local variation of HETP, thermocouples were embedded at an equal interval on the column centerline. Each thermocouple can be considered to measure the temperature of internal reflux liquid owing to its large heat capacity. Distillation test was conducted at normal pressure under total reflux condition with three kinds of binary systems. Local variation of HETP in each bed region was determined by comparing the observed temperatures with the calculated ones due to the process simulator package. After obtaining the corresponding overall HTU from the experimentally obtained HETP, the vapor-phase and liquid-phase film coefficients were calculated by solving a simultaneous equation deduced between two vertical locations. However since the stripping factor remains almost unchanged in the top and bottom regions, it was considerably difficult to obtain an appropriate simultaneous equation without approximation. On the other hand, it has been found that those film resistances can be easily determined by assuming that the tie-line and VLE equilibrium curve should have an orthogonal relation at an arbitrary theoretical stage.

As a result, this orthogonal model successfully gave comprehensive correlation of vapor-phase and liquid-phase HTUs with the corresponding F-factor and superficial liquid load.

Although this investigation is still in the process of analysis, the orthogonal model has a possibility to lead to further progress in distillation mass transfer from a view point of transport science.