The organogel is expected to be useful in various fields such as cosmetics, pharmaceutical products and food industry. However there is still few research on lecithin organogel using edible oils.

In this study, for focusing on safety to the human health, we studied on a biocompatible organogel using soybean lecithin, water and edible oil as a gelling agent , polar substance and an oil phase respectively. The range of gel formation was clarified by changing the component. Also the dynamic viscoelasticity of the gel was measured using a rotary rheometer.

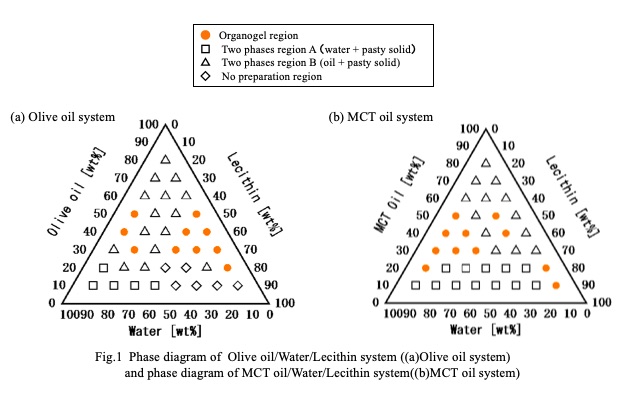

The product was classified into four regions: Organogel region, Two phases region A (water + pasty solid), Two phases region B (oil + pasty solid) and No preparation region. Fig. 1(a),(b) shows the triangular phase diagram in the case of olive oil and MCT(Medium Chain Triglyceride) oil used as the oil phases. The gel formation region was different depending on the type of edible oil. This was considered to be due to the difference in the fatty acid composition of the triglycerides.

Olive oil composed mainly long-chain fatty acids having 16 or 18 carbon atoms. It showed a wide gel region at water concentrations ranging from 10 wt% to 30 wt%. MCT oil composed medium-chain fatty acid having 8 or 10 carbon atoms. It showed a wide gel region at water concentrations ranging from 40 wt% to 70 wt%. In order to confirm the influence of fatty acid composition, the organogel was prepared using triglyceride consisting of a single fatty acid composition as the oil phase. It has been found that the gel region depends on the main component of the fatty acid constituting the edible oil and the carbon chain length.

Dried persimmon is a famous and traditional product in Japan. There exist various modified or unique manufacturing procedures depending on production regions; and different treatments during the drying process will influence its final properties and consumer acceptance.

In order to know the influence of two traditional treatments on the final properties of dried persimmon, the effects of kneading and brushing on the properties of dried persimmon were investigated. In this research, four types of dried persimmons were produced by a traditional drying method, which kneading and brushing were used. A secondary surface was formed during the drying process. Moisture and sugar content, color, thickness and texture of the secondary surface were measured; Sugar crystal on the surface was observed using scanning electron microscopy (SEM);X-ray computed tomography (X-ray CT) was applied to investigate the moisture distribution of the secondary surface. Kneading had a significant (p<0.05) influence on the properties (moisture, color, thickness and texture of the secondary surface) of the product; while, the effect of brushing was not obvious. According to the sugar analysis, brushing assisted the sugar crystalize on the surface as white powder. Kneading treatment promoted the drying process and influenced the properties of dried persimmon through influence its moisture evaporation. Brushing assisted sugar crystalize on the surface by creating tiny scars on the surface of dried persimmon. This information therefore given some fundamental knowledge for making high quality dried persimmon; it is possible to help us improve the quality of dried persimmon during drying process and provide some information for the following storage strategy.

Thermal protein denaturation (TPD) is considered to be the main factor of the physicochemical changes in kuruma prawn muscle during thermal treatment. TPD in prawn muscle originates the reduction in water holding capacity and myofibrillar shrinkage, which results in appearance and texture changes. In this study, prawn samples were heated at 50, 65, 75 and 85 °C for 3, 5, 10 and 20 min. Heat transfer, and moisture loss due to cooking were evaluated. The kinetics of thermal TPD was investigated by using DSC-dynamic method. Prawns were assumed to be hygroscopic porous medium and viscoelastic material. Modeling of moisture transfer was conducted using a model based on Darcy's law combined with structural mechanics model according to viscoelastic strain-stress in a 2D-axi-symmetric model. The internal pressure of element was assumed to be directly proportional to the volume of water and inversely proportional to the volume of the element. Simulation of heat transfer and TPD was also developed. An implicit finite element method was applied using FORTRAN program. Governing and boundary equations were solved numerically using Garlekin's finite element method.

Kinetic parameters, activation energies, and pre-exponential factors, and enthalpy values for predicting TPD were obtained. Shrinkage occurred in both longitudinal and radial directions, especially at the higher heating temperature. For heating processes at 75 °C and 85 °C, actin denaturation plays the most important role in volume shrinkage; moreover, the simulated moisture transfer and volume reduction showed a good fitness with the experimental values. With the prolonged heating process, internal pressure increased firstly, then decreased and tend to equilibrium finally. The moisture distribution and simulated internal pressure distributions showed that due to the slow water release, shrinkage was delayed, and promoted incremental change in the internal pressure; then the released water acts to reduce the internal pressure, which was closely related to the actin denaturation.

Methane with a potential of 25-CO2-equivalents on global warming is the second highest compound of greenhouse gases. The current level of global methane has hit a historic high over the past 800,000 years. Therefore, to mitigate methane emission is a critical task in this generation for preventing serious climate change. Methanotrophic bacteria in the soil as one of the global methane sinks have been a potential strategy for the removal of atmospheric methane as well as environmental remediations. However, methanotrophic reactions in the conventional process consumed high energy power due to the low solubility of methane in aqueous phases. In this study, we demonstrated a novelty gas-solid reaction system under a non-aerated condition for methane degradation by methanotrophic bacteria. Associating with the simple filtration technique and a freeze-thaw treatment, Methylococcus capsulatus (Bath), a representative of gamma-proteobacterial methanotrophs, showed a significant improvement in the immobilization efficiency from 47.8% to 87.0% for loading of 9.64 μg-DCW/mm2-support onto the glass fiber membrane. Through this novel method of cell immobilization, a real gas-solid reaction with high cell loading was achieved for rapid methane degradation. Notably, the rate of methane consumption showed the 7-fold enhancement in the gas-solid system comparing to the rate in the aerated aqueous phase reaction with stirring. Moreover, the catalytic efficiency in the developed gas-solid system is 8.3-fold higher than that in the gel-entrapment system when 2.80 μg-DCW/mm2-support and 42oC-reaction temperature were employed. It indicates that water barriers still dominate the resistance of mass transfer in the gel-entrapment system and limit the affinity between catalysts and gaseous substrates, which is not suitable for a gas-solid reaction. Therefore, the result in this study can facilitate to develop an effective bioprocess of the removal of atmospheric methane with low energy consumption.

Food powders are the most common format in the packaged food sector. Typical food powders are dairy or dairy-based powders, infant formula, instant coffee, cereal based powders, instant soup powders and powdered microorganisms such as probiotics.

Amongst others, the popularity of the powdered format is driven by its increased storage and shelf-life stability due to decreased moisture content as well as by advantages for transport, storage and handling due to decreased bulk weight and volume. Desired functional properties can be tailored by applying unit operations and combinations thereof including drying, micronization, encapsulation, agglomeration and coating. An overview and selected examples of recently applied approaches will be addressed in this presentation:

— Micronization of green coffee in oil and roasting of the micronized suspension for aroma protection1

— Drying of emulsions with ultra-high oil content for structuring of liquid oils2

— Structuring of amorphous, porous sucrose containing particles to enable sugar reduction3

— Mixing and drying to produce a powdered composition of bioavailable iron and stable probiotics for food fortification4

Furthermore, an outlook at emerging powdered food ingredients and products will be provided. More specifically, the technological challenges and opportunities of novel alternative protein sources (e.g. plant, insects or microbial sources) as well as of stable probiotics for liquid products will be enlightened.

References

1. Pouzot et al., WO 2016 102335 - Coffee compositions and uses thereof, 2016

2. Sarkar et al., Microstructure and long-term stability of spray dried emulsions with ultra-high oil content, Food Hydrocolloids 52, 2015

3. De Acutis et al., WO 2017/093309 - Amorphous porous particles for reducing sugar in food, 2017

4. Berrocal et al., WO 2018/087208 - Composition in powder form comprising iron and probiotic bacteria, 2018