In recent years, cyberattacks against plant control systems can certainly be a growing threat. Conventional plant control system was closed system. However, it has been connected to external networks such as MES, ERP, and maintenance network. This change enables the various way of cyberattacks.

The cyberattacks against plant control system can directly harm physical space and cause accidents and disasters affecting human life.When the plant control system is under the cyberattacks, on-site plant operators should handle the situation suitably. However, plant operators are usually not aware of cybersecurity for plant operations. They don't have enough experiences and knowledges of cyberattacks.

What can they do under the cyberattacks? They must maintain safe operation and prevent the cyberattacks. The simple and effective way to prevent the cyberattacks is to cut off the attack path by disconnecting network cables.

Then it's important to minimize the negative impacts on plant operations such as safety, productivity and so on. For this purpose, if zoning and conduit of the network has been done in advance, operators can make a decision which zone should be cut off under the situation considering the network monitoring and impacts on plant operations.

To make a suitable decision requires enough useful information for plant operators.

In this paper, we developed a support tool for plant operator to make a decision against cyberattacks by combining two important information.

One is the vulnerability information of the components of the plant control system such as OS, middleware and applications of each OPC server, HMI, and so on. It is based on CVSS (Common Vulnerability Scoring System.)

The other is network monitoring information in the plant control network.

The developed GUI shows the options of the points to cutoff the network and supports plant operators to make a suitable decision against the cyberattacks.

In this study, a new methodology was developed to enhance the performance of control system in chemical process. An artificial neural network (ANN) was used to develop a model of the control system. For this, the process model was initially developed using Aspen HYSYS, and operation data was generated based on various operation scenarios. Then, the generated data was implemented to ANN for training, and results were tested and analyzed. Subsequently, the developed ANN model was integrated with an optimization algorithm so that manipulated variables were optimized in real time to maximize the operation efficiency. The developed model predictive control (MPC) system was tested based on various operation scenarios, and the results showed higher performance of the control system against conventional control methods.

Acknowledgment:

This work was supported by a research project entitled “Development of Integrated Interactive Model for Subsea and Topside System to Evaluate the Process Design of Offshore Platform” funded by the Ministry of Trade, Republic of Korea (Project no. N10060099).

Human interventions are common and indispensable during process operations. However, even in this era of big data where large volumes of process measurements are regularly collected and monitored, very little is known about human operators and their cognitive state while operating the plant. This absence of measurements prevents a scientific evaluation of the contribution of operators to the overall system performance. In this paper, we will discuss the need for an informatics-based approach to study the operational behaviors of plant personnel. Next, using the control room operator as an example, we will identify various technologies such as eye tracking and electroencephalography that can offer insights into the operators' cognitive state and their decision-making processes. Finally, we will explore the various ways by which such studies could help enhance the operator's performance – including context-aware interfaces, decision-support systems, and training protocols.

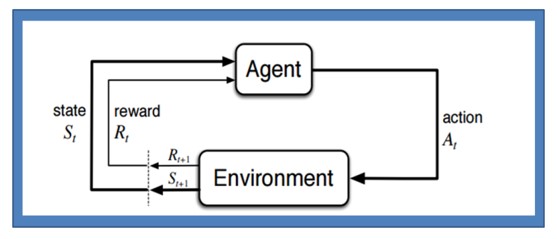

This paper provides a brief introduction to Reinforcement Learning (RL) technology, summarizes recent developments in this area, and discusses their potential implicationsfor the field of process systems engineering. This paper begins with a brief introduction to RL, a machine learning technology that allows an agent to learn, through trial and error, the best way to accomplish a task. We then highlight two new developments in RL that have led to the recent wave of applications and media interest. A comparison of the key features of RL vs. Model Predictive Control (MPC) and other traditional mathematical programming based methods is then presented in order to clarify their relative merits and shortcomings. This is followed by an assessment of areas that RL technology can potentially be used in process systems engineering applications. Particular focus is given on integrating planning and scheduling layers in multi-scale, multi-period, stochastic problems.