Gas hydrates are ice – like crystalline of natural gas and water. Several methods can be used to prevent hydrate formation such as solvent absorption, adsorption, and membrane process. This work studied modelling and optimization of natural gas dehydration using solvent absorption method. Triethylene glycol (TEG) was used as solvent to remove water from natural gas. Latin Hypercube sampling (LHS) was studied as sampling technique in term of its ability to represent the nonlinear model for optimization problem. The nonlinear model represents the relationship between the operating conditions and amount of produced dry natural gas. In the optimization, the total cost of the process was minimized. Both equipment and operating costs were considered in economic evaluation. The TEG absorption process was simulated using Aspen HYSYS version 8.8. The results show that LHS is able to accurately represent the nonlinear model between operating conditions and the total cost of the process for optimization problem. The optimal operating conditions of the process were obtained.

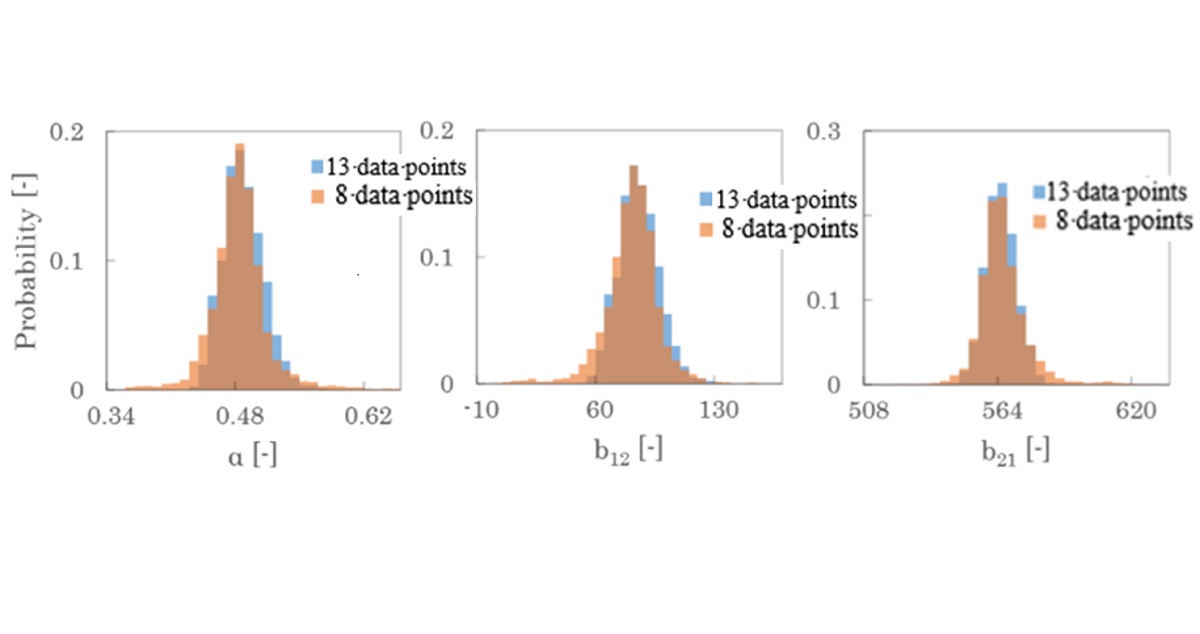

Model equations used in process design involve parameters, which can be estimated from experimental data. Estimating accuracy of model parameters is critical to ensure robustness of processes. The objective of this study is to quantify estimation accuracy using Bayesian inference techniques in parameter estimation. In this work, the Markov chain Monte Carlo (MCMC) method is used to obtain probability distribution. This algorithm repeats random sampling in parameter space and approximates the profile of posterior probability distributions by the density of sampled points. This method can handle complex nonlinear models. We demonstrate this method for estimating parameters in the Non-random two-liquid (NRTL) model for vapor-liquid equilibrium. The NRTL parameters are estimated by the MCMC method, and the influence of the number of experimental data on estimation accuracy is quantified. We compared two estimation cases, where 8 experimental data points and 13 experimental data points[1] are used, and the difference in the parameter accuracy is quantified. This estimation results for ethanol-water system are shown in Figure 1 for three parameters, a,b12, and b21 that describe intermolecular interactions in the NRTL model for the binary system. In addition, the proposed method is demonstrated for a multicomponent system that involve a larger number of components.

[1]Dortmund Data Bank Software & Separation Technology“VLE - Vapor Liquid Equilibria of Normal Boiling Substances”

http://www.ddbst.com/ddb-vle.html (2019.2.16)

The growth in global economy has made water a limited resource in both quantity and quality. Freshwater resources available for our use are less than 1 % of the total water on the Earth. Reverse osmosis (RO) desalination technology became popular over the last decade due to its potential to produce freshwater from seawater. However, energy consumption in RO plants remain high and emission of concentrated brine from the plant has an impact on the environment.

This study aims to analyse the energy efficiency of various RO based desalination processes. Firstly, single-stage RO with pressure exchanger (PX) is analysed. Minimum normalized specific energy consumption (NSEC) is reduced from 5.00×105 J/m3 to 2.05×105 J/m3 by adding PX with 0.95 efficiency. Secondly, a simulation on multi-stage RO with PX is carried out. It is found that two-stage RO reduces minimum NSEC by 5.4 % compared with single-staged operation and increase recovery by 13.6 %. Even though multi-stage design may require higher capital cost and operating cost, optimised-stage RO design has certain advantages.

In the on-going research, membrane distillation (MD) and pressure-retarded osmosis (PRO) will be combined with multi-stage RO process to improve the overall energy efficiency. MD is a thermally driven membrane process that produces pure water, and PRO is an osmotically driven membrane process with external pressure, which is lower than the osmotic pressure difference, applied on the higher salinity solution side. The use of these processes are limited to when one has low-cost heat source, e.g. waste heat, and inexpensive lower salinity solution, e.g. wastewater. Since MD is less concentration-sensitive, it is expected to further concentrate the brine output, and highly concentrated brine is assumed to support PRO to generate greater energy and reduce minimum NSEC of the total process.

Heat ingress from atmosphere to LNG inside a tank due to temperature difference causes continuous evaporation of LNG that leads to increase of pressure and temperature. Therefore, it is necessary to continuously estimate the change in pressure and temperature inside the tank, using accurate numerical model in real time operation. For this, a new methodology was developed in this work to estimate total amounts of boiled off gas (BOG) and its composition and physical properties more accurately than conventional method, based on various operation conditions.

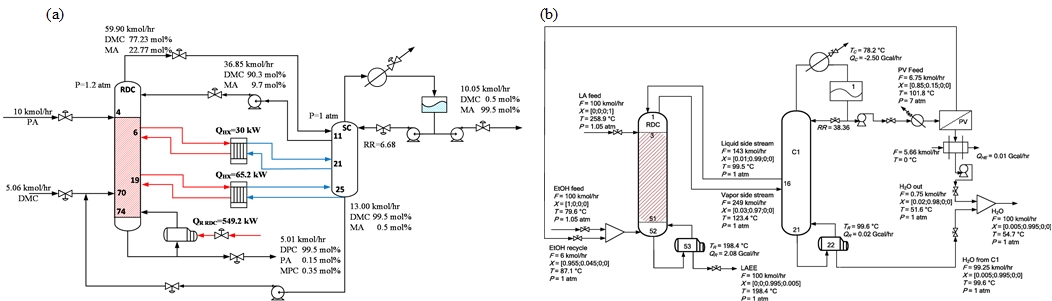

This work focuses on the efficient design with various heat integration methods and membrane arrangement for reactive distillation (RD) processes in order to enhance the energy saving. It is well-known that thermally-coupled, multi-effect, and external heat-integration approaches can reduce energy consumption in comparison with conventional distillation systems. Therefore, in this work, two processes will be discovered to demonstrate that hybrid configuration via various heat-integration and unit combination (such as pervaporation, PV) can provide further energy reduction compared to the conventional RD configuration. The first process is the diphenyl carbonate (DPC) production process that will be chosen to show a synergetic effect when thermally-coupling and external heat-integration arrangement are combined in the same reactive distillation sequence. The results show that in the DPC production process, the hybrid heat configuration can reduce energy consumption by 47% in comparison with the conventional RD configuration. On the other hand, another process is the ethyl levulinate (LAEE) production process that will be investigated to show a synergetic effect when thermal intensification is implemented in the hybrid RD-PV configuration in the LAEE production process. The hybrid heat-integrated configuration assisted with PV arrangement through excess ethanol (EtOH) design can save around 73% of energy consumption compared to the conventional LAEE RD configuration. Figure 1 shows the flowsheet of hybrid configurations for DPC and LAEE production processes, respectively. Finally, several control schemes of the DPC process would be investigated and tested the control performance based on this highly integrated configuration. Results show that the best control scheme has good disturbance rejection for throughput and feed composition disturbances.