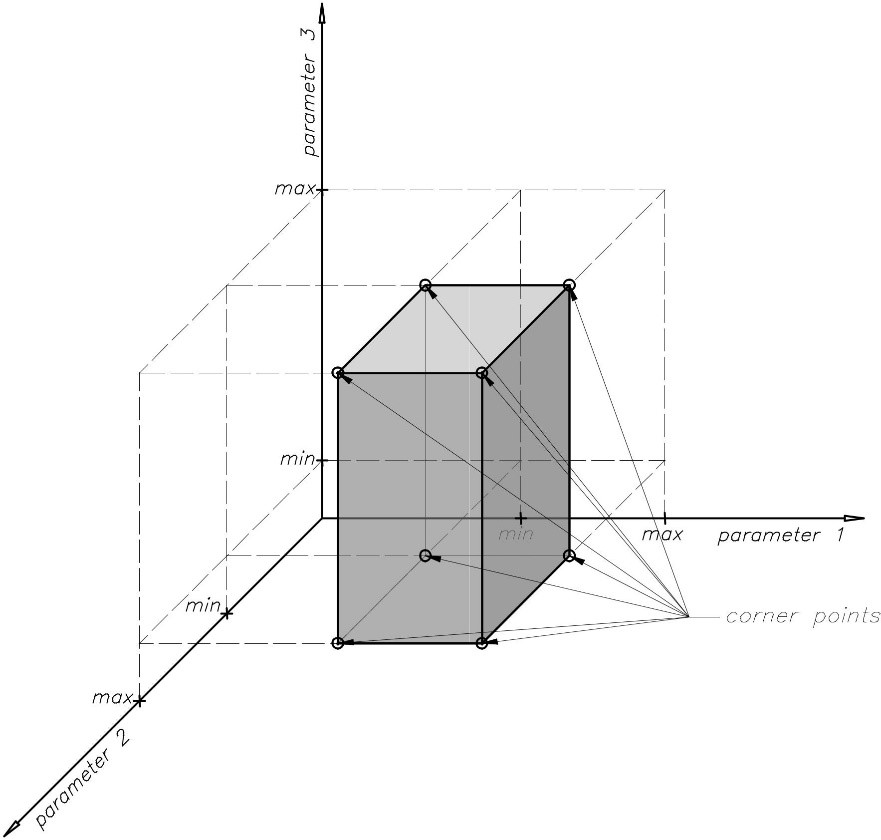

The United Nation 2030 Agenda for Sustainable Development has dedicated Goal 6 (Clean Water and Sanitation) for better water management, with 8 targets and 11 indicators identified for progress monitoring. Some of the common strategies to achieve better water management include the “4Rs” techniques – reduction of pollution at source, removal of contaminant from wastewater, reuse of wastewater, and recovery of by-products. Within the process system engineering community, some systematic techniques have been developed since the past 3 decades, aiming to design sustainable chemical processes. One of the most promising techniques is arguably process integration, with pinch analysis and mathematical programming tools developed specifically to handle water management issues. However, most developed techniques were meant for water network systems at steady state condition, i.e. without changes in process condition. This paper presents a new design methodology based on a recent developed corner point method, for the synthesis of flexible water networks system. In this case, the flowrate and purity of water sources and sinks may change periodically over time. Hence, the synthesised water network should be able to absorb the changes of sources and requirements of sinks. Literature example is used to illustrate the proposed methodology.

Monoclonal antibodies (mAbs) are an important fraction of the growing biopharmaceutical market. The rapidly expanding demand for mAbs is making it necessary to optimize the production processes to reduce manufacturing costs and time. Generally, production in continuous mode can improve process efficiency. Continuous manufacturing has been previously studied for individual process units in the upstream, e.g., perfusion cultivation, and downstream, e.g., chromatography separation using simulated moving bed. Integrated continuous production modes have been demonstrated experimentally, and stability in end-to-end operation have been presented. This work aims to explore the available design options and map favorable production modes at different production scales and sizes. The work also aims to explore the impacts of recent developments in cell design and advancement of cell tolerance on the process performance and resulting favorable operating modes.

Production data has been obtained from a pilot scale research facility for the production of mAbs from Chinese hamster ovary (CHO) cells. Different models for the large-scale cultivation and chromatography separation have been fitted against the production data, and the appropriate models were selected. After confirming the model performance using the production data, we performed economic process assessment. Different scenarios were considered regarding operation modes, i.e., batch or continuous, and equipment, i.e., single-use or multi-use, for the individual units as well as the end-to-end process.

The simulation results indicated that the favorable scenarios varied in the upstream and downstream depending on the production scale and the CHO cell performance. The superiority of the fully integrated continuous process has been seen regarding productivity. Sensitivity analysis revealed the relevance of the cell performance. This finding will open up a new research opportunity for PSE to tackle simultaneous design of cells, products, and processes.

It is very important to consider all the units and operating parameters of the individual units in the gas-oil-separation-plant (GOSP) optimization. However, the differences in the governing principle of these units make it extremely difficult to optimize the GOSP operation. Also in real operation, optimum parameters for the individual units are difficult to implement and establishing the optimum control condition for the individual unit will be difficult to achieve as all the units are interlinked to each other.

The current practice is to set the parameters determined at the design stage by simple laboratory test without accounting for the changes in temperature (fixed ambient temperature) and pressure on the crude oil properties as reservoir pressure. This results in loss of the quantity of the crude oil at the stock-tank causing a loss in the profitability of the plant.

The objective of this project is to develop a generic integrated framework for maximizing the oil recovery by optimizing the gas-oil-separation-plant (GOSP) parameters. A typical Saudi Aramco GOSP plant consists of multi-stage separators, heater-treater, and stabilization units along with the stock tank to mimic the oil train. Amongst the various parameters, only the controllable parameters such as pressure, and temperature were considered as optimization parameters to achieve the maximum oil recovery.

The GOSP plant model was developed using “Omegaland” software. To evaluate the effect of the various parameters many runs were initiated for generating the data. Based on the generated data a model was developed using artificial intelligence techniques. The model served as a tool for optimizing the controllable parameter to maximize the oil recovery which is the ultimate goal of the GOSP.

The generic integrated framework model serves as a guide to determine the optimum operating condition for maximizing the oil recovery resulting a significant monetary gain by improving GOSPs efficiency.

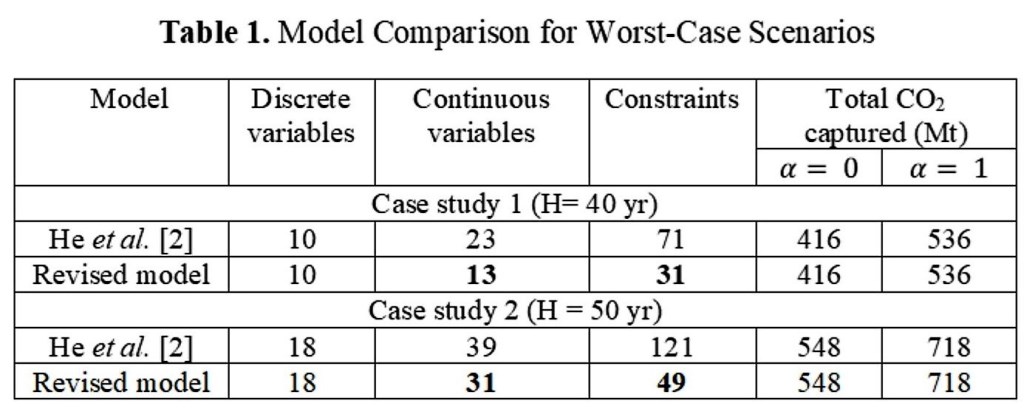

Carbon Capture and Storage (CCS) is one of the options for mitigating global warming by reducing carbon dioxide emissions, which involves source separation of CO2 from gaseous effluent streams, transportation of CO2 through suitable storage, and storing the same underground or geological reservoirs for a permanent period. Since CCS is a resource intensive process with multiple uncertainties, it must be modeled and validated under several circumstances for practical use. This study focuses on worst-case analysis based on continuous-time formulation for CCS systems under uncertainty. In the model, end time of operating life of CO2 sources, maximum storage capacity for different sinks, and compensatory power carbon footprint are considered as uncertain parameters. Recent work of Shaik and Kumar [1] has been extended to consider these uncertainties in the model. Two case studies are solved to validate the model over different time periods (40 yr and 50 yr). Similar to He et al. [2] the revised model [1] is also solved for different risk levels (α= 0 and α= 1) which demonstrates the modification and simplification of the model [1] compared to He et al. [2]. As shown in Table 1, the same optimal solutions are obtained compared to the literature for the minimum and maximum amounts of total CO2 captured. When compared to the worst-case solutions, the nominal solutions (without uncertainty) pertain to higher risk or perhaps infeasible zones.

References

[1] M. A. Shaik; A. Kumar, Simplified model for source–sink matching in carbon capture and storage systems, Ind. Eng. Chem. Res., vol. 57, no. 9, pp. 3441–3442, 2018.

[2] Y.-J. He; Y. Zhang; Z.-F. Ma; N. V. Sahinidis; R. R. Tan; D. C. Y. Foo, Optimal source–sink matching in carbon capture and storage systems under uncertainty, Ind. Eng. Chem. Res., vol. 53, no. 2, pp. 778–785, 2014.

The grand challenges facing human societies are all closely interconnected with the sustainable provision and consumption of energy, water and material resources for constantly growing and developing populations, as well as the subsequent processing and management of wastes and pollutions. In this work, a series of decision-support platforms are developed combining comprehensive database, agent-based simulation and resource technology network optimization, to deal with the challenges of energy, water, food, and waste systems through a nexus manner for a circular economy. As key components of smart city development strategies, the data-driven systematic tools and models can simulate different constraints and targets seamlessly with respect to environmental, economic and social costs and benefits in a bottom-up approach to inform infrastructure planning, investment and decision making for city regions globally.

From macro-level down to detailed systems, smart energy technologies, operational strategies and market design will be specially discussed. To tackle the increasing global energy demand the climate change problem, the integration of distributed resources, renewable energy, and negative emission technologies provides promising solutions for sustainable and resilient energy future. Compared with traditional design and operation of energy systems, the novel process that combines real-time prediction and optimization, model predictive control, demand-responsive scheme and other game-theoretic decentralized market strategies will improve energy systems performance from both the supply and demand side. The state-of-the-art modelling, machine learning, and blockchain technologies will be introduced and applied to the smart energy systems for overall economic and environmental benefits.