This research presents a comparative life cycle assessment (LCA) of three photoluminescent types of organic light emitting diodes (OLED): fluorescent, phosphorescent, and thermally activated delayed fluorescent devices (TADF). OLED is garnering attention as a next generation display technology with high luminance, high resolution, and low power consumption. However, general OLED displays employ fluorescent materials with 25% luminous efficacy or phosphorescent materials with 100% theoretical luminous efficacy containing scarce metals such as iridium. Recent developments have discovered new materials exhibiting 100% luminous efficacy without scarce metal, called TADF materials. To analyze the environmental advantage of this new material development, we comparatively assessed lifecycle greenhouse gas emissions (GHG) of three types of OLED employing distinct materials: fluorescent, phosphorescent containing iridium, and TADF. The functional unit of this LCA is provision of one OLED television display. The system boundary considered raw material extraction to the use phase. The lifecycle inventory of fluorescent materials referred to past studies, and that of phosphorescent and TADF were constructed from patents and publications. Energy demand for the material synthesis and OLED fabrication was estimated from lab scale data to manufacturing scale using the authors' a scale up methodology. As a result, the GHG of the TADF and phosphorescent material synthesis were 4-60 times greater than that of the fluorescent material. The major GHG contributor in these materials were the solvent use. Additionally, there was little difference among the lifecycle GHG of OLED displays employing three materials. Because the amount of emissive materials in an OLED display is in the order of 1 mg, the high energy demand of TADF and phosphorescent materials contributed little to the overall GHG of one display. This study sorely analyzed GHG, but further analysis should consider material criticality, which TADF materials shows advantage over other materials.

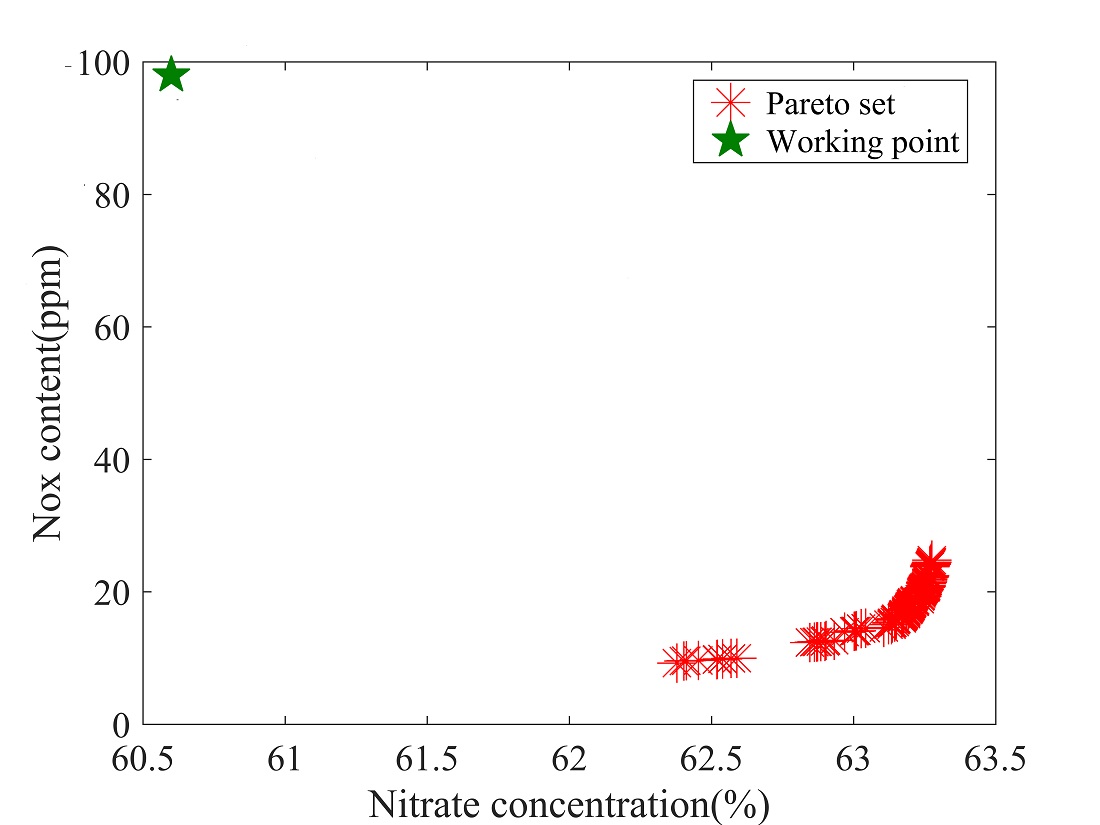

Absorption column is one of the key equipment for the production of nitric acid, which needs to facilitate both low emission of nitrogen oxides and high concentration of nitric acid product. Based on this, multi-objective optimization of the absorption operation through a framework integrating evolution algorithm and process simulation was conducted, with cooling water usage, reaction pressure, reactant feed & recovery position, mass flow of the middle reflux as key variables. Firstly, Radfrac module of Aspen Plus software was used to model the working process of absorption column, the predicted results of which are in good agreement with the real data collected from a local plant. Then, on the MATLAB platform, the interface program linking NSGA-II algorithm with Aspen Plus simulation was made. Hybrid coding was applied in the evolution algorithm, using real number and integer coding for different types of variables. Finally, simulation process with a population size of 100 and a terminating generation of 30, was performed. The calculation results show that the proposed method can be utilized to obtain a Pareto optimal solution set with uniform distribution. When the concentration of nitric acid is greater than 62.8%, the content of nitrogen oxides increases rapidly with the increase of concentration. Otherwise, the content of nitrogen oxides remains almost unchanged at about 10ppm. Compared with the actual operating condition, the concentration of NOx in the exhaust gas can be reduced by 70ppm while increasing acid concentration by 2%,and the industrial water consumption can be saved by 1200kg/h when adopting optimum settings.

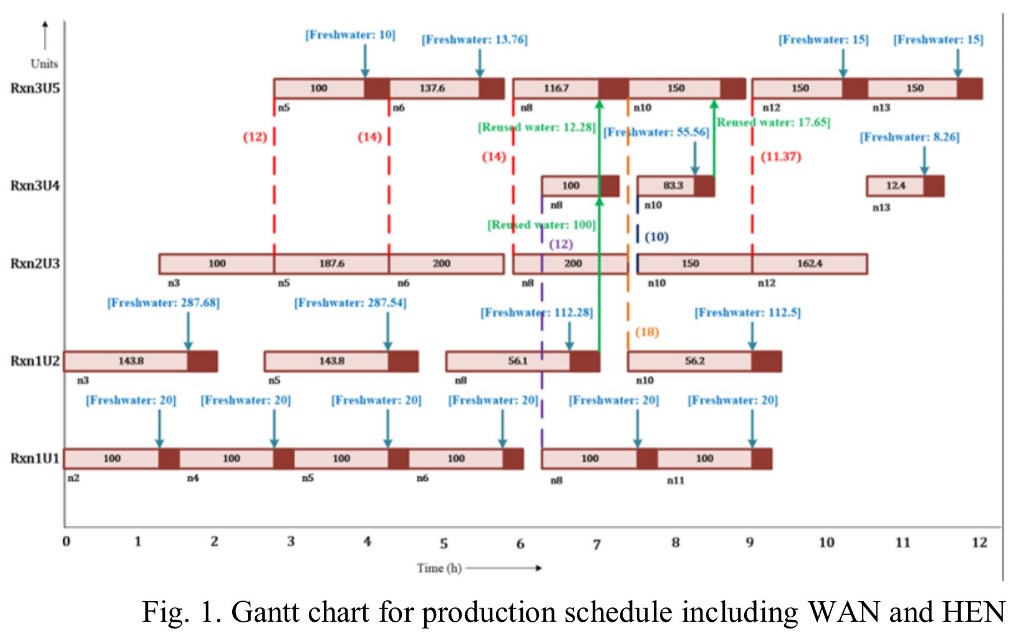

In batch plants, as process equipment are shared by different tasks to produce different products, they use freshwater for equipment cleaning. Also, some tasks require external utilities to meet heating and cooling demands. Now a days, due to stringent environment regulations and increasing cost of effluent treatment and energy, industries are motivated towards water and energy savings. The proposed mathematical formulation deals with wastewater minimization and minimum utility consumption along with the optimum production schedule. For production scheduling, a recent unit specific event based model of Vooradi and Shaik [1] has been adapted and water allocation network (WAN) has been accomplished by considering water reuse opportunities between washing units. Heat exchanger network (HEN) has been modeled by aligning the heat producing and heat consuming tasks in a common time of interval. The model is validated on a case study, from Seid & Majozi [2], comprises of five processing units. The reaction tasks occurring in units U1, U2 and U3 require cooling while tasks in units U4 and U5 require heating. The resulting Gantt chart is shown in Fig. 1 for the optimum production schedule including WAN and HEN. The objective value for total profit is $4809.76, which is comparable to the reported value from the literature.

References

[1] R. Vooradi; M.A. Shaik, Improved three-index unit-specific event-based model for short-term scheduling of batch plants. Comp. Chem. Eng., vol. 43, pp. 148-172, 2012.

[2] E. R. Seid; T. Majozi, Optimization of energy and water use in multipurpose batch plants using an improved mathematical formulation, Chem. Eng. Sci., vol. 111, pp. 335–349, 2014.

In many developing counties, processing manufacturing (i.e. chemical processing plant, manufacturing facilities, etc) plays an important role in contributing to the country's economic. With the cross-border trading, industrialists are further challenged with global monetary policies, government regulations, resources availability and environmental challenges. The United Nations has initiated the Sustainable Development Goal to encourage the industrialist moving forward to sustainable processing and manufacturing. Despite the Sustainable Development Goal initiatives are encouraging, the industrialists are facing challenges in achieving it. There is a lack of industry expert within the organisation to implement process improvement strategy effectively. The application of lean and green approach has shown positive result in many organisations (e.g. Toyota, Boeing, etc). The lean and green approach is able to reduce the non-value-added product from both operation and environmental perspective. However, the lack of experience personal has delayed the effect of lean and green approach. A systematic framework of lean and green approach should be developed to close the sustainability gap in the processing facility. By doing so, a lean and green index will be used as a benchmarking tool to allow the industrialist to monitor the progressive performance. By including the industry expert and practitioners' input in the framework, analytic network process method will be used together with an adaptive approach. The adaptive approach leverages on the back-propagation method that enables the framework evaluates continuous improvement with time step. The lean and green framework is expected to guide the industrialist for continuous improvement. An industry case study will be used to demonstrate the practicality of the lean and green framework.

Energy transition to renewable-based energy systems with adequate energy carriers such as hydrogen is needed for sustainability. The implementation effects such as greenhouse gas emission reduction largely depend on the specific characteristics in regions. The technologies would not always be implemented in the regions with preferable effects because socioeconomic drivers are needed for the diffusion of the technologies. The driving forces in regions are affected by the region-specific resources, such as financial and human resources in the local governments and firms. In terms of both implementation effects and socioeconomic drivers, the regional suitability for implementing technologies related to energy carriers should be explored for effective policy making and investment decision making. In this study, the regional suitability is explored from two analyses in Japan. Firstly, a region-specific analysis was performed to assess the implementation effects based on the simulation of energy systems. It quantitatively presented the influence of region-specific characteristics, such as energy demands sizes, energy use patterns, and existing structure of energy supply, on the environmental impacts of the technology implementation. Secondly, a factor-specific analysis was carried out by mapping regions based on three factors on implementation, i.e., environmental effects, socioeconomic driving forces, and potential scales. The analysis offers material for discussion on the regions which have preferable implementation effects and can proceed with implementation and on major drivers in the regions. Co-working process inside regions was further generated to explore suitable regions for technology implementation. Through the process, regional suitability, such as actor-network and actors' attitudes toward adopting new technologies and changing the regional systems, which cannot be assessed quantitatively, would be examined and grown. The analysis results can be also used in the co-working process to know prospective regions and actors, motivate actors, and share visions among actors.

Product designers generally prioritize functionality enhancement to meet design demands from the stakeholders in a product life cycle, which affects diverse aspects, e.g., the environment and our society. From an environmental perspective, functionality enhancement tends to cause additional environmental impacts. From a social perspective, the enhancement does not always satisfy the users' satisfaction. Ideally, the designers should be aware of such design consequences of functionality enhancement on the entire life cycle when designing products for sustainability. However, it is difficult for the designers to grasp the design consequences because the consequences are diverse. Therefore, a method is needed to grasp the effects of the functionality enhancement on various aspects in the product design stage.

This study aims to develop an activity model for multi-functional product design for sustainability based on a function-based assessment. To support product design for sustainability, we introduced function-based assessment methods to present the effects of the functionality enhancement on a specific aspect. The methods quantify the changes in the environmental impacts and consumer satisfaction caused by the functionality enhancement based on the linkage of product functions and design variables. To show the roles of our function-based assessment methods in the product design stage, we developed an activity model for supporting multi-functional product design for sustainability.

We performed several case studies, e.g., food packaging, and umbrella, to confirm the applicability of our methods. In the umbrella case, two designs were compared: redesign of the size from small to medium, and that from small to large. Both designs satisfied consumers at the same level, whereas the latter redesign had larger environmental impacts than the former redesign. The result determined the former design to be adopted from environmental and social perspectives. Case studies indicated that the function-based assessment methods could assist the designers in deciding for sustainability.