In recent years, microfiltration is used in wastewater and drinking water treatments, and food and pharmaceutical industries. In the process of using microorganisms, the feed solution is a complex mixture comprising bacterial flocks and microbial metabolite. Therefore, it is essential to clarify the mechanism of flux decline behaviors in microfiltration of microorganism and its metabolite. The key objective of this study is to examine the effect of polysaccharide-protein interaction on membrane fouling caused by microbial metabolite since the microbial metabolite is composed mainly of polysaccharides and proteins. Microfiltration experiments were performed in a dead-end filtration mode using various types of solutions at pH of 4.5 and 6.5 under constant pressure condition. Sodium alginate (SA) with the molecular weight (MW) of 129 kDa was used as model polysaccharide, and lysozyme with the MW of 14.3 kDa, the isoelectric point (pI) of 11.0 and bovine serum albumin (BSA) with the MW of 67 kDa, the pI of 5.1 were used as model protein in this study. The flux decline behaviors were observed in the case of mixture of polysaccharide and protein, and in particular, the filtration rate of solution containing SA and BSA was influenced by the solution pH. The BSA molecule is negatively charged at pH 6.5 and positively charged at pH 4.5, while at both pH values, the lysozyme molecule has a net positive charge, and SA molecule has a negative charge. It is obvious that the effect of the surface charge of protein on the filtration resistance should be considered.

Algal bio-fuel as alternative to fossil fuel has been attracting lots of attention due to the global warming and depleting natural fuel resources. However, the cost of bio-fuel production is relatively high. Especially, harvesting and dewatering of microalgae suspension are reported to account for 20 - 30 % of the total cost, because suspended solid (SS) concentration of microalgae culture is low with 0.02 - 0.06 wt%. Therefore, efficient dewatering process is required. This study examined the performance of dewatering of microalgae suspension by cake filtration using filter cloth.

Two hundred milliliter of microalgae suspension with 0.02 wt%-SS was filtered at constant pressure (70 kPa) using filter cloths (24.4 cm2 of effective area) made from polypropylene, which have different pore size 0.8 - 14 μm. Average permeate flux was increased from 5.9 to 2600 L/(m2 h) with the increase in pore size, while SS rejection was decreased from 94 to 53 %. The filtration behavior was analyzed by existing filtration models. As a result, when filter cloths with smaller pore size than algal cell size (about 8 μm) were used, filtration mode was finally settled into cake filtration. On the other hand, for the filtration using filter cloth with 14 μm of pore size, filtration mode was not settled into cake filtration. Then, in order to conduct cake filtration using filter cloth with 14 μm of pore size for expecting high permeate flux, pre-concentrated suspension (0.1 wt%-SS) was filtered with the intention of forming a cake layer quickly by the deposition of many algal cells on the filter surface. Consequently, microalgae suspension was successfully concentrated up to 18 wt%-SS with 360 L/(m2 h) of average permeate flux and 99 % of SS rejection. These results suggest the potential of microalgae dewatering by cake filtration with high flux and rejection.

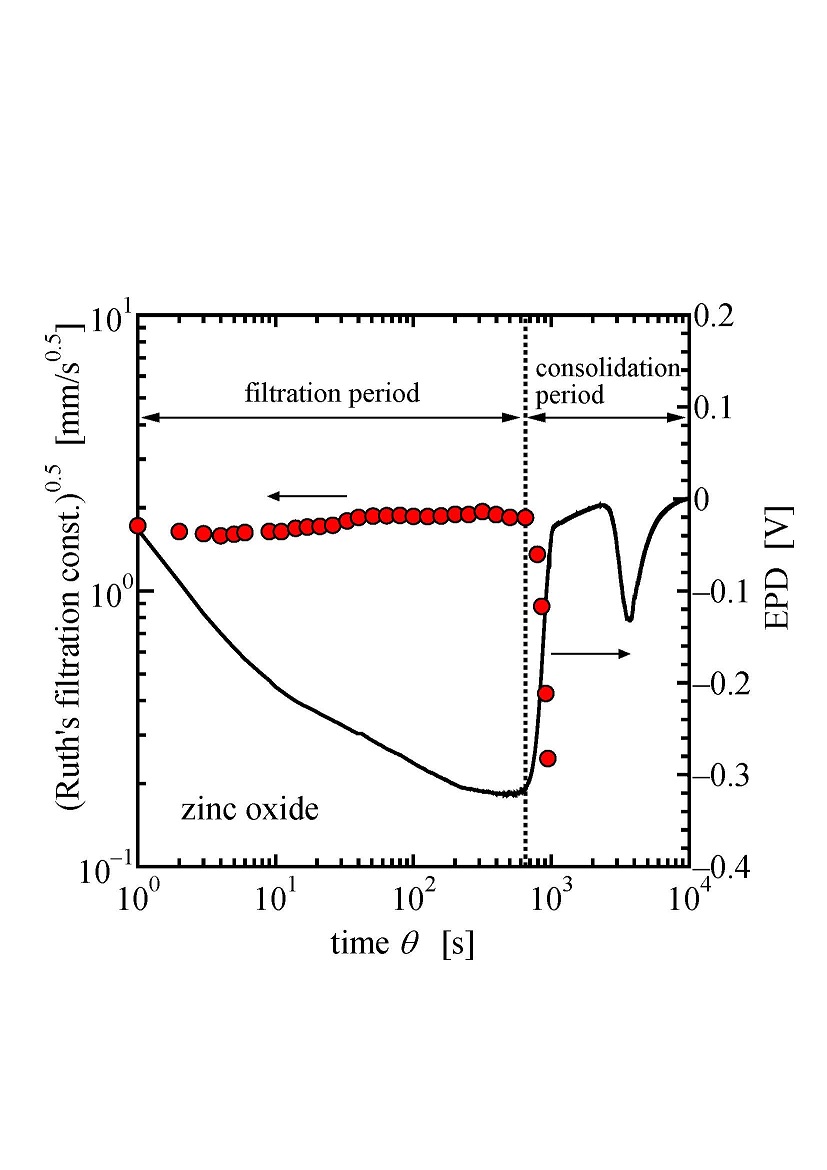

Expression is the separation of liquid from a solid/liquid system by compression due to the movement of the retaining walls of the filter chamber. In the expression of slurry material, the application of mechanical pressure to the retaining walls causes a sudden increase of hydraulic pressure uniformly throughout the slurry. Initially, the process of expression proceeds based on the principle of filtration, where the thickness of filter cake increases over time. Filtration terminates when the whole slurry forms a layer of filter cake, and the consolidation of the cake follows. Exact identification of the time when the chamber is filled with the cake is essential for an effective expression operation. The electrokinetic response of expressed material provides us with some information on the status of the filter chamber. In this work, we have measured the time course of electric potential difference (EPD) between the retaining walls to elucidate the electrokinetic aspects of mechanical dewatering. The experimental apparatus used in this study consists essentially of a piston press with a cylinder and a piston. Filter media are placed at the cylinder bottom and the very end of the piston. EPD between the filter media was monitored during the experiment. As can be seen from the figure, the absolute value of EPD increases with the progress of the filtration period, followed by the decrease during the consolidation period. It was observed that the time when the absolute value of EPD began to decline coincides with the time when the filtration period ended. We have derived a theoretical equation of streaming potential for a flow path of the expressed material and combined it with filtration and consolidation theories to calculate the theoretical time course of EPD of expressed material. It has been found that EPD reflects liquid pressure variation throughout the solid/liquid mixture.

The application of membrane filtration processes has been increased because of global shortage of water. Membrane fouling is considered as a major factor limiting the use of the membrane filtration process and is the irreversible alternation in the membrane caused by specific physical and chemical interactions between membrane and various components present in the process stream. The fouling configuration can be classified into three simple mechanisms: pore narrowing by adsorption, pore blocking/plugging and cake/gel layer formation. In many actual processes the species causing the dominant fouling effects is not always known because of the complexity of the feed stream. Identifying the foulant and understanding fouling phenomena are required for adopting countermeasures for the fouling. Electrostatic and hydrophobic interactions are recognized as the major interactions causing fouling. The zeta potential of the foulant or the membrane, that is, the electrical potential at the surface of shear between the solid and the liquid, can be useful for the prediction of the electrostatic interaction. Adsorption is a major cause of membrane fouling in microfiltration of macromolecule containing solutions. The change ratio of zeta potential by protein adsorption is directly proportional to the surface coverage regardless of pH. In pore blocking or cake formation caused by fine particles the location of pressure drop in the system depends on the fouling configuration. The zeta potential reflected the local pressure drop part, where the gap between particle and pore in pore blocking filtration and the gap between particles in cake filtration. These observations shows the zeta potential will useful for monitoring the fouling configuration during the filtration operation.

Traditional pharmaceuticals have been made from chemical processes. Today, a significant fraction of valuable pharmaceuticals, such as hormones, insulin, growth factors, interferon, enzymes, drug intermediates, etc. are replaced by biotechnology processes. One of the building blocks is to make protein out of recombinant processes where extracellular or intracellular protein can be “engineered” and secreted from host biological cells which have been inserted with vectors carrying human genes. The host cells, e.g. the mammalian cells, bacteria and yeast can secret high amounts of recombinant protein in a bioreactor or fermenter. For extracellular protein, the first step in harvesting protein is to separate the protein from the cells. On the other hand for intracellular protein, the bacteria cells have to be lysed first before releasing the protein in form of inclusion body, for which separation follows. Disk stack and tubular centrifuges operating between 4,000–15,000 times gravity are popular choices to make separation of cells, cell debris, and proteins from the broth. We will discuss the various scenarios of centrifugal separation of protein in clarification, separation, classification and purification by washing during protein harvest. This is an extremely important step that affects yield and downstream processes, e.g., purification by chromatography. We will also discuss testing, modelling and prediction of protein separation in protein harvesting. Further, new technologies on separation of flocculated bio-solids and other popular biotech separation processes by centrifugation will also be discussed.